-

摘要:

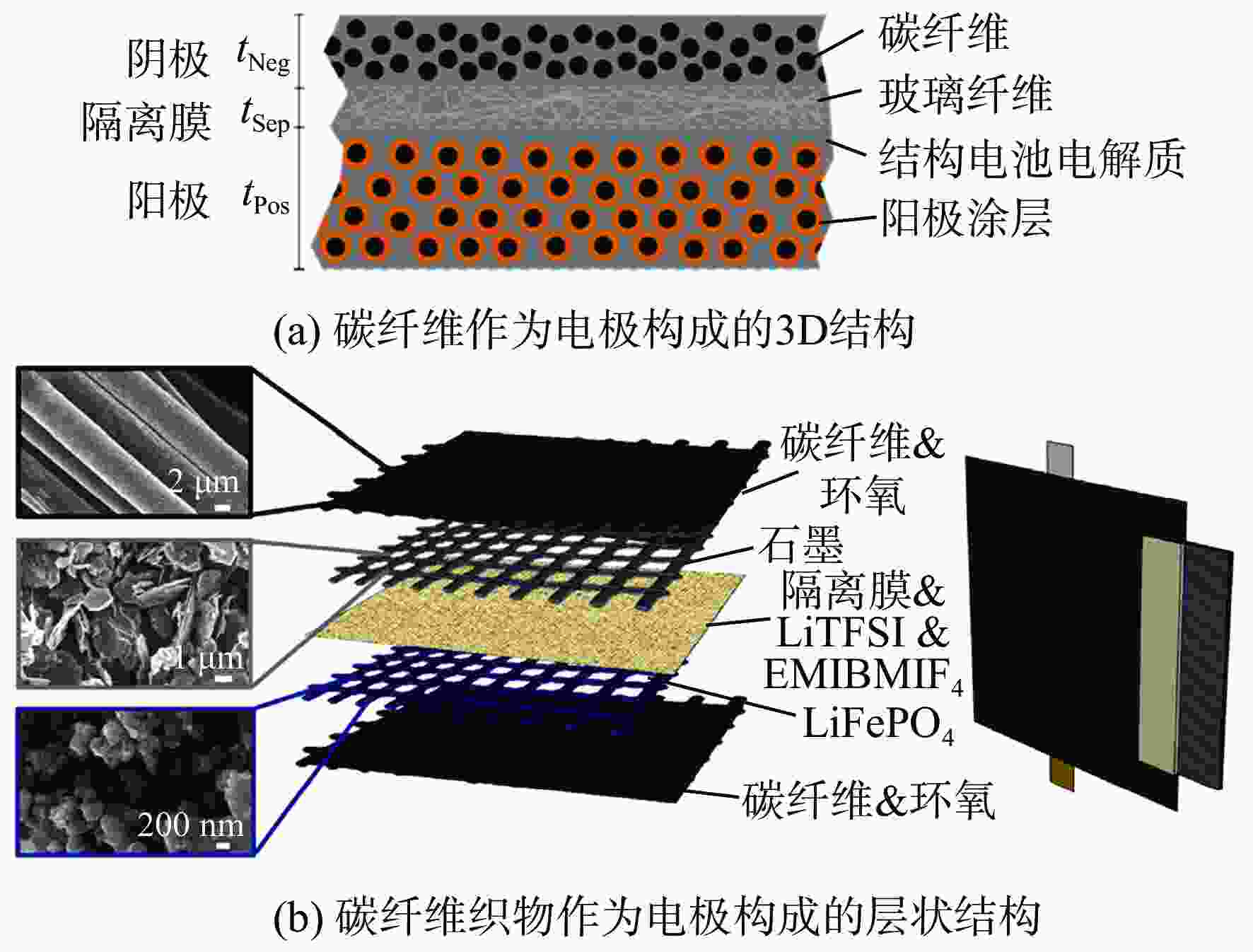

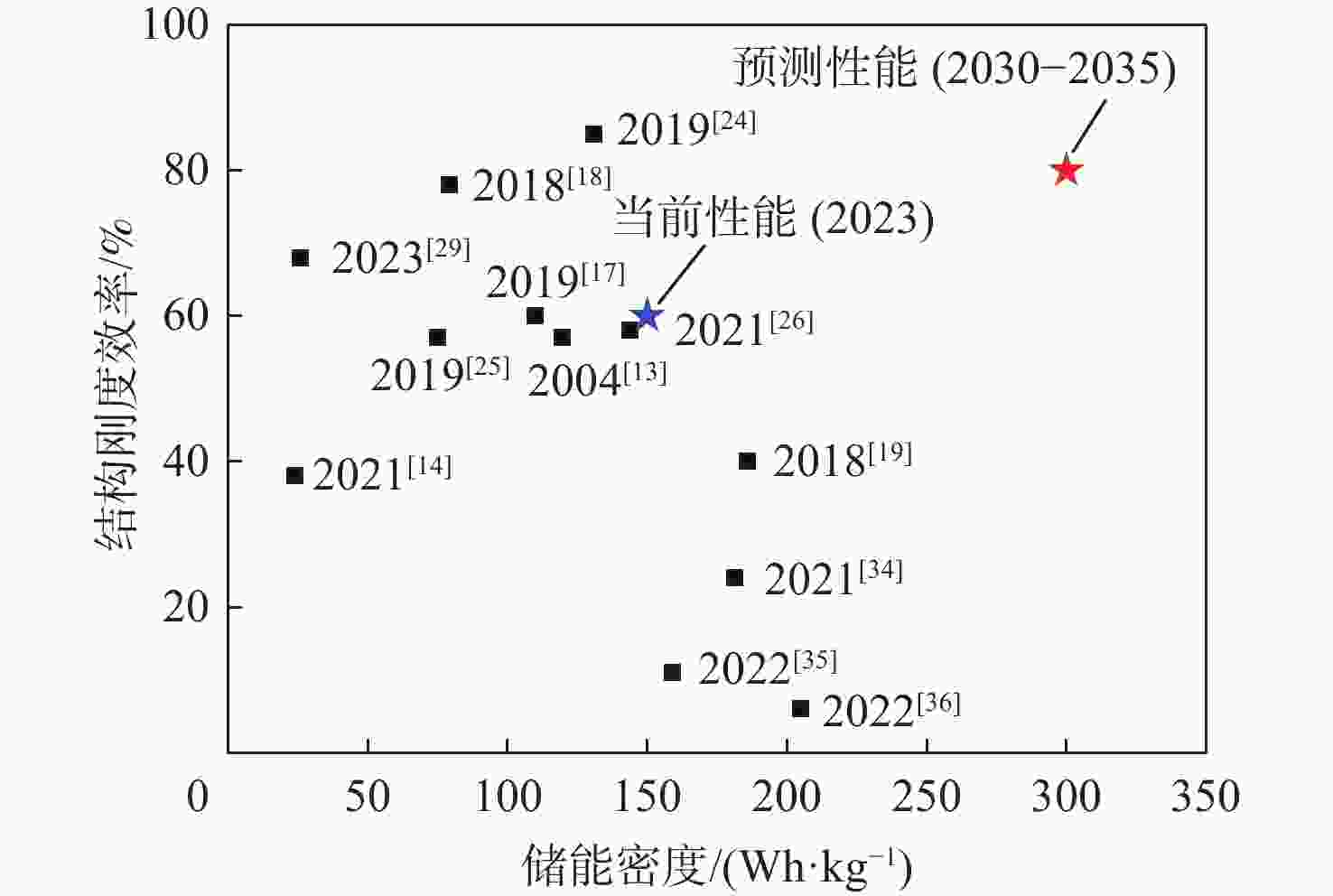

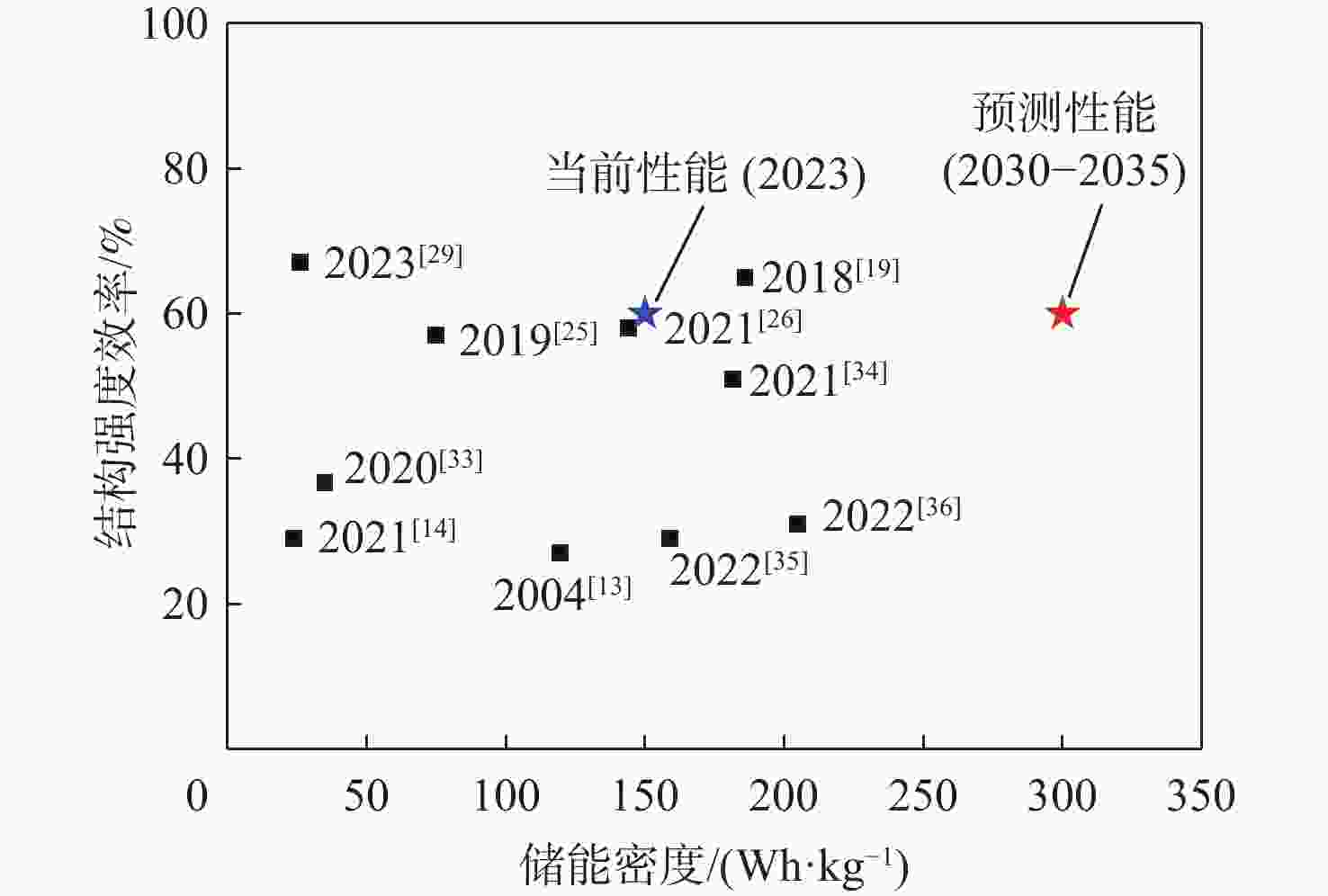

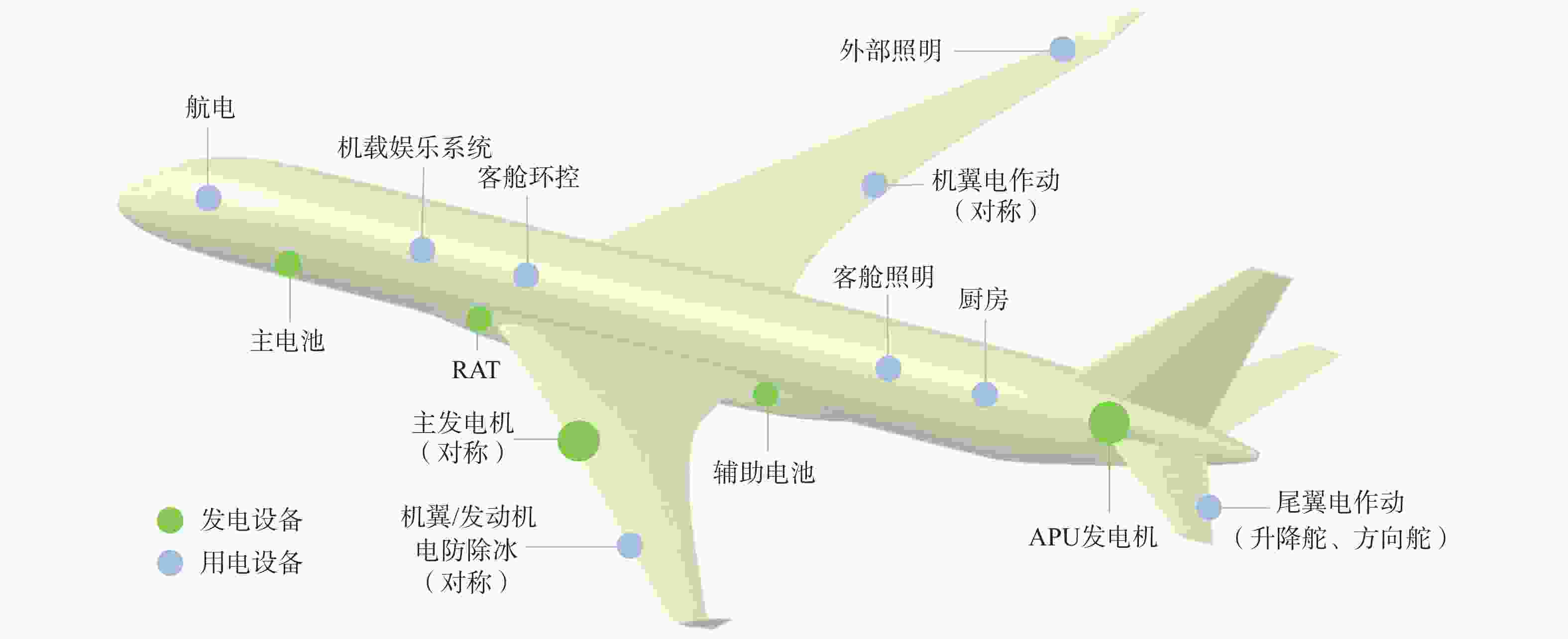

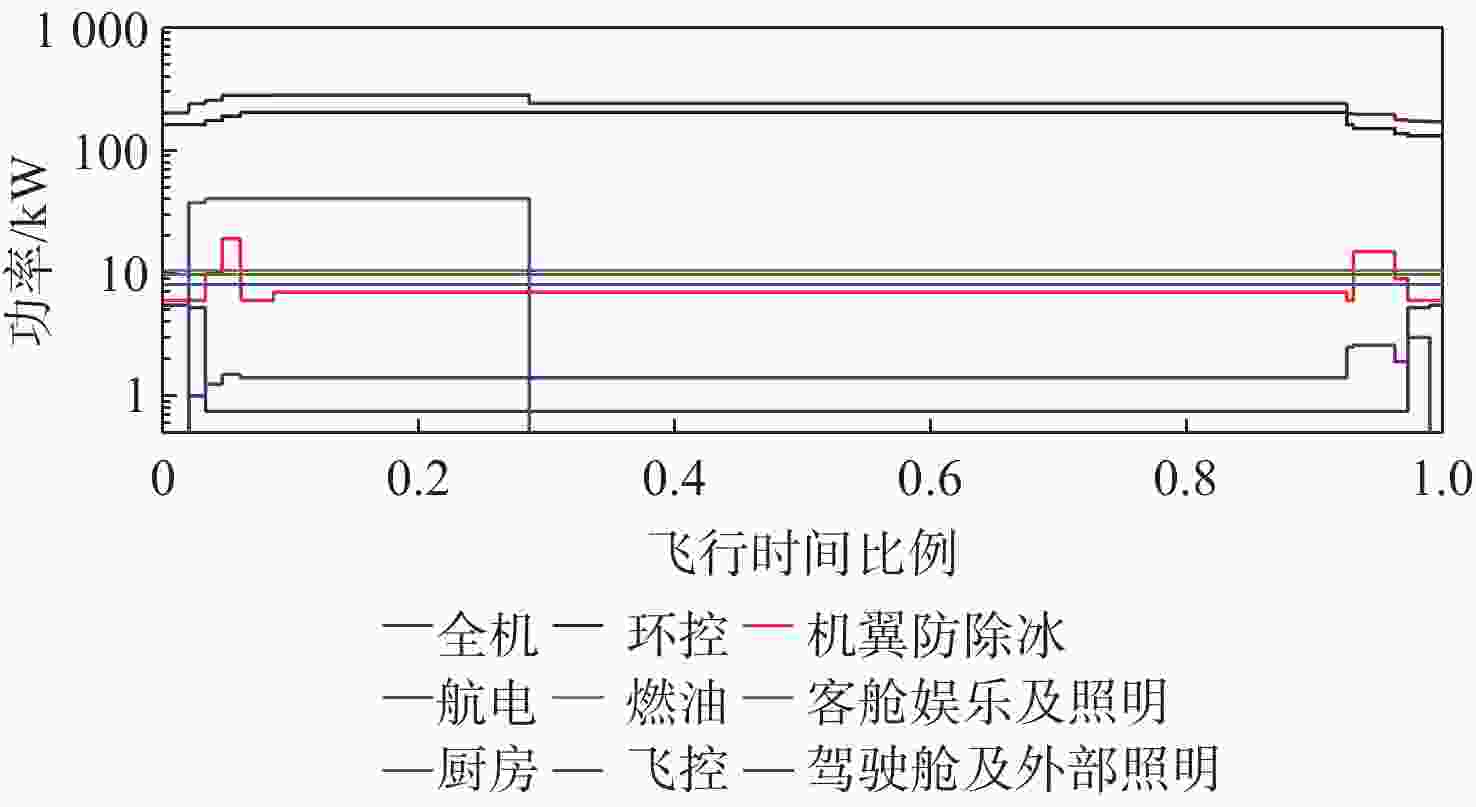

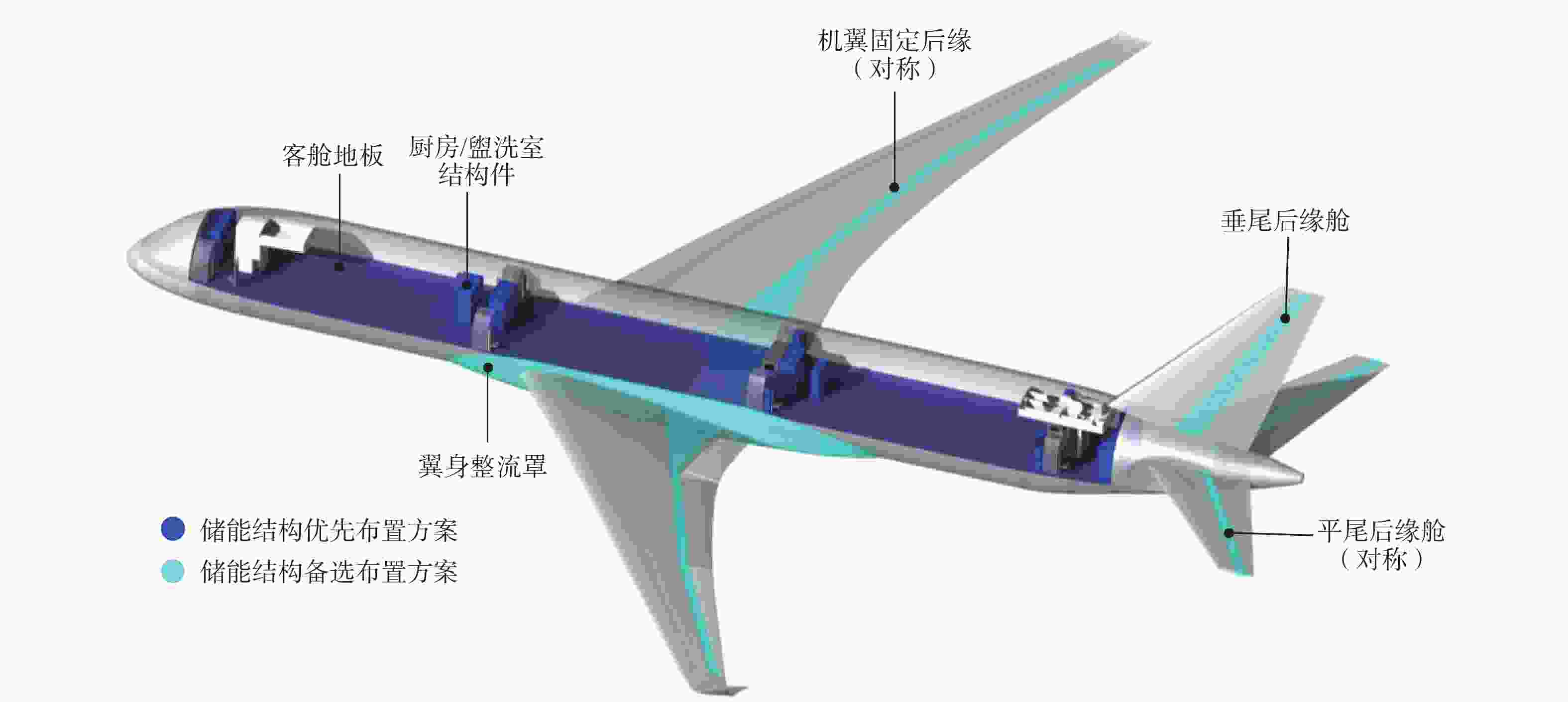

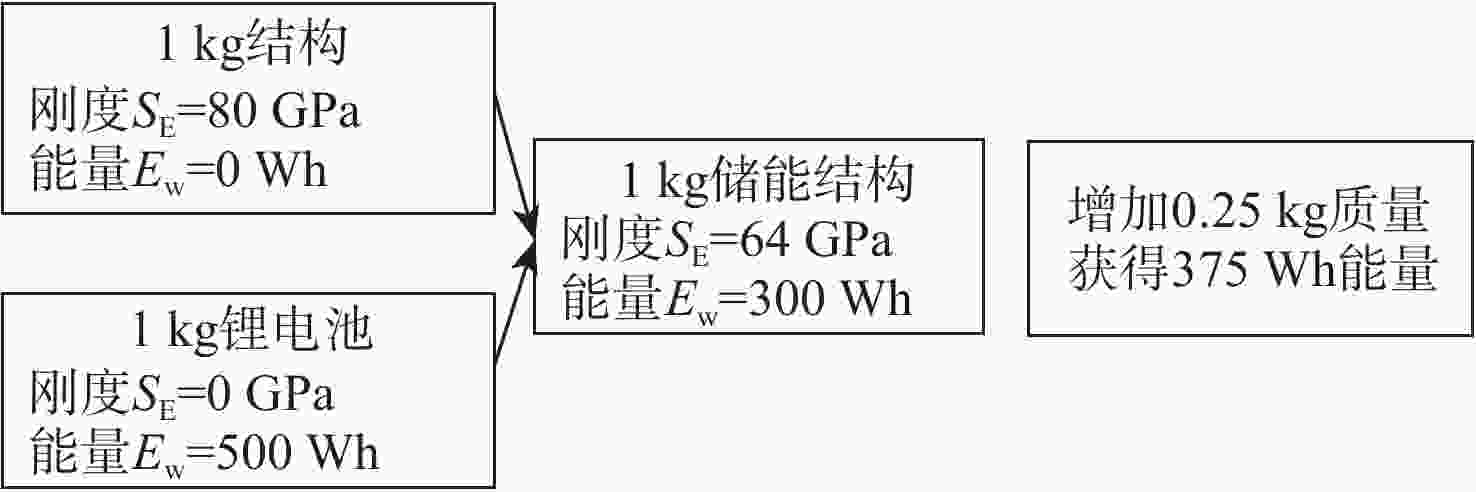

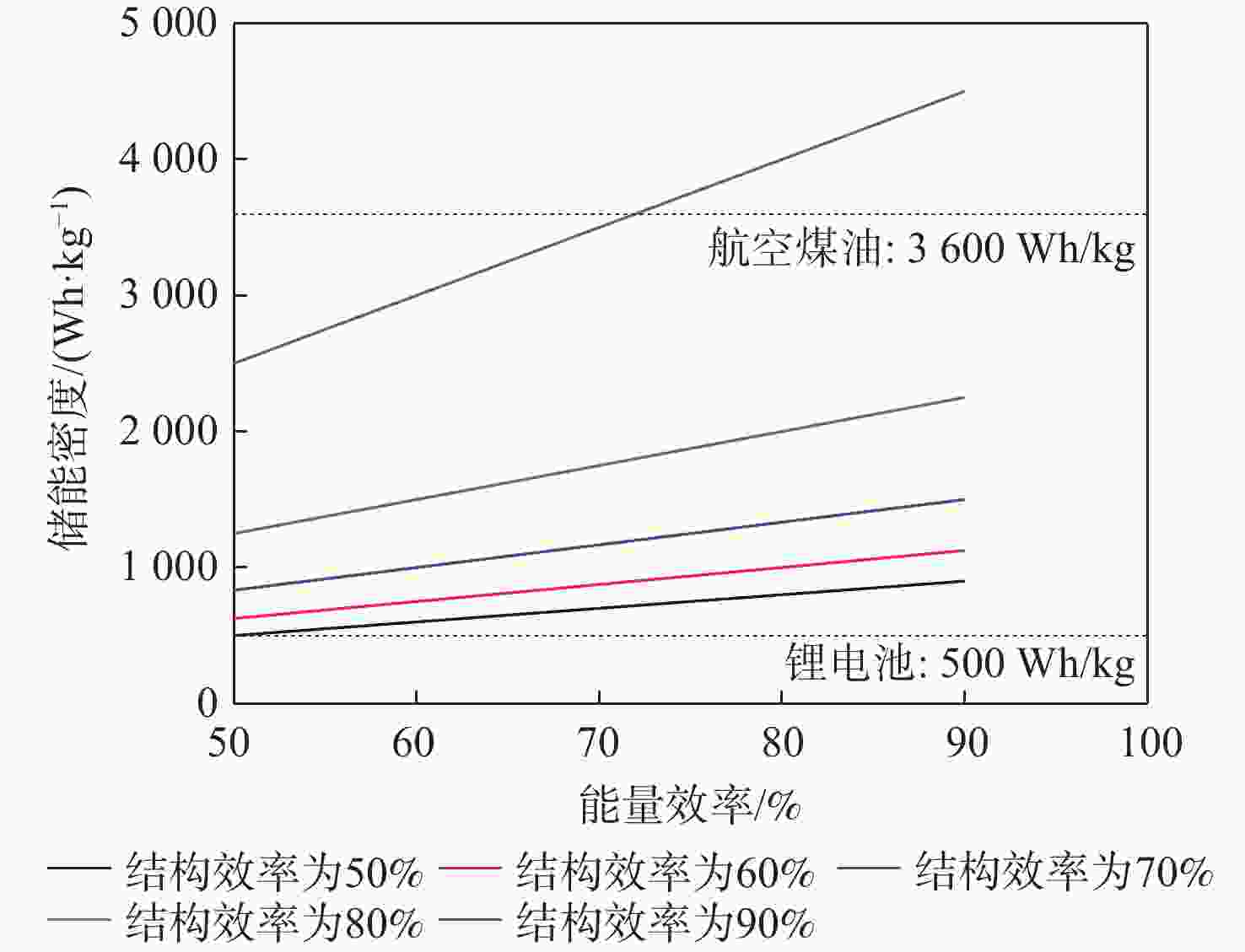

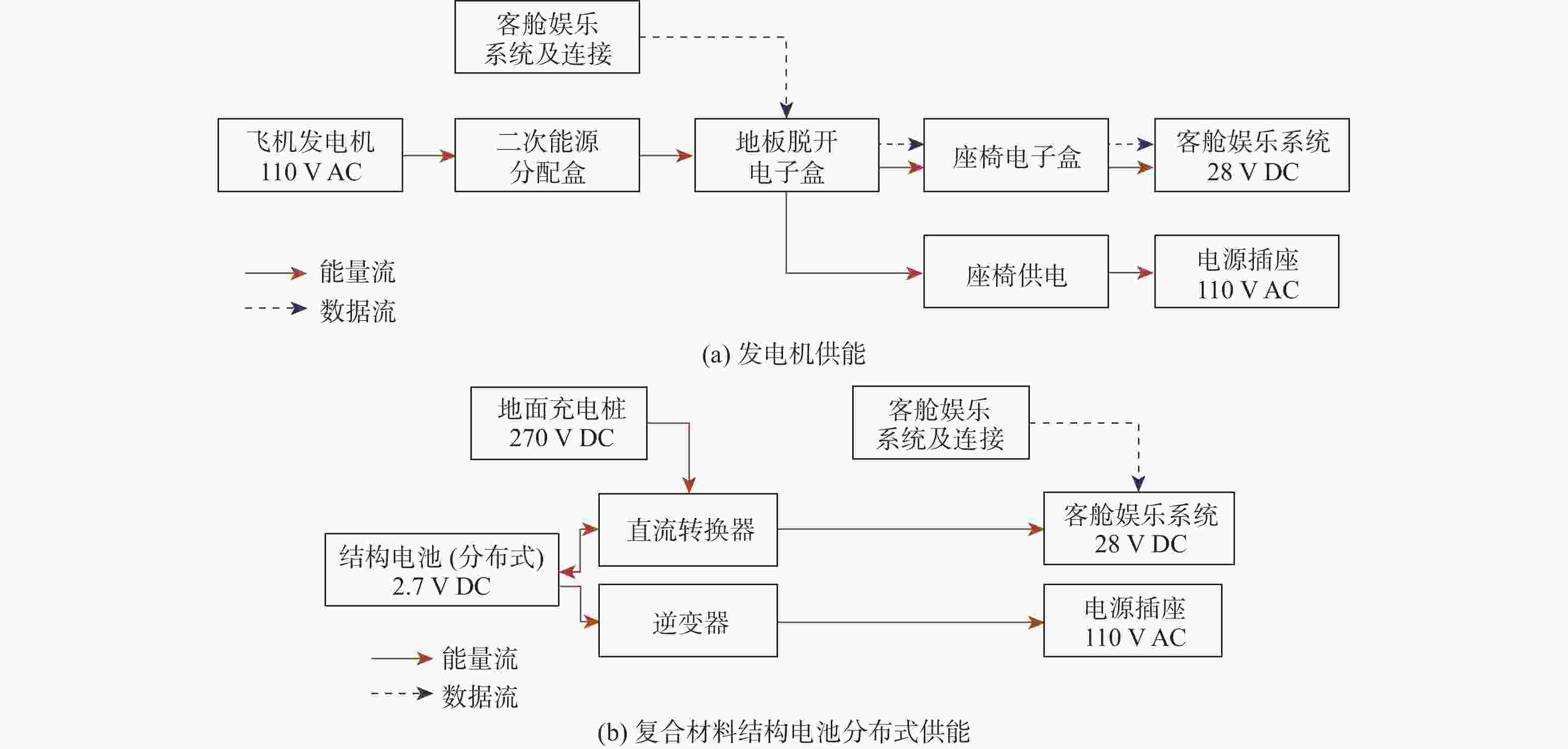

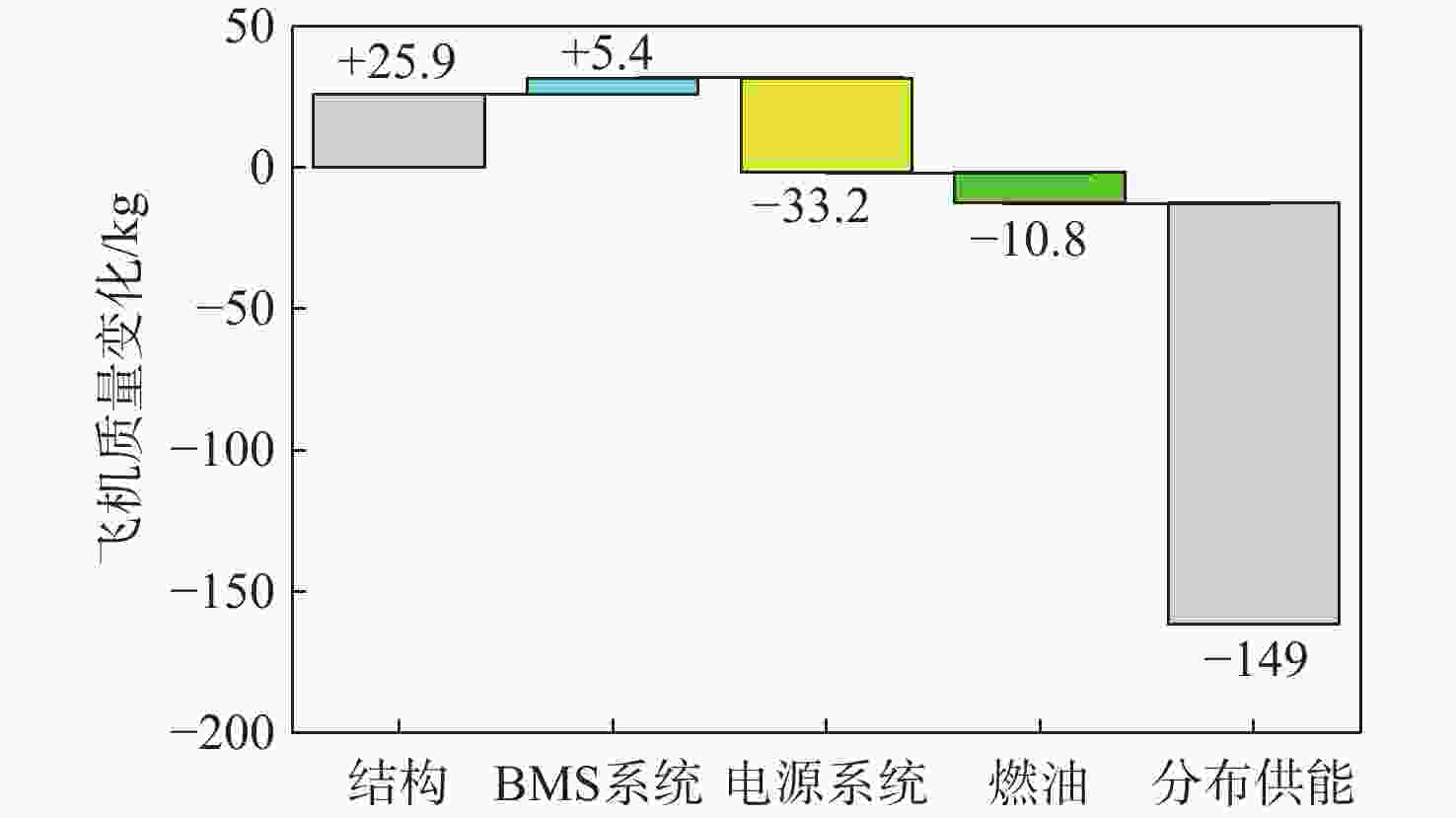

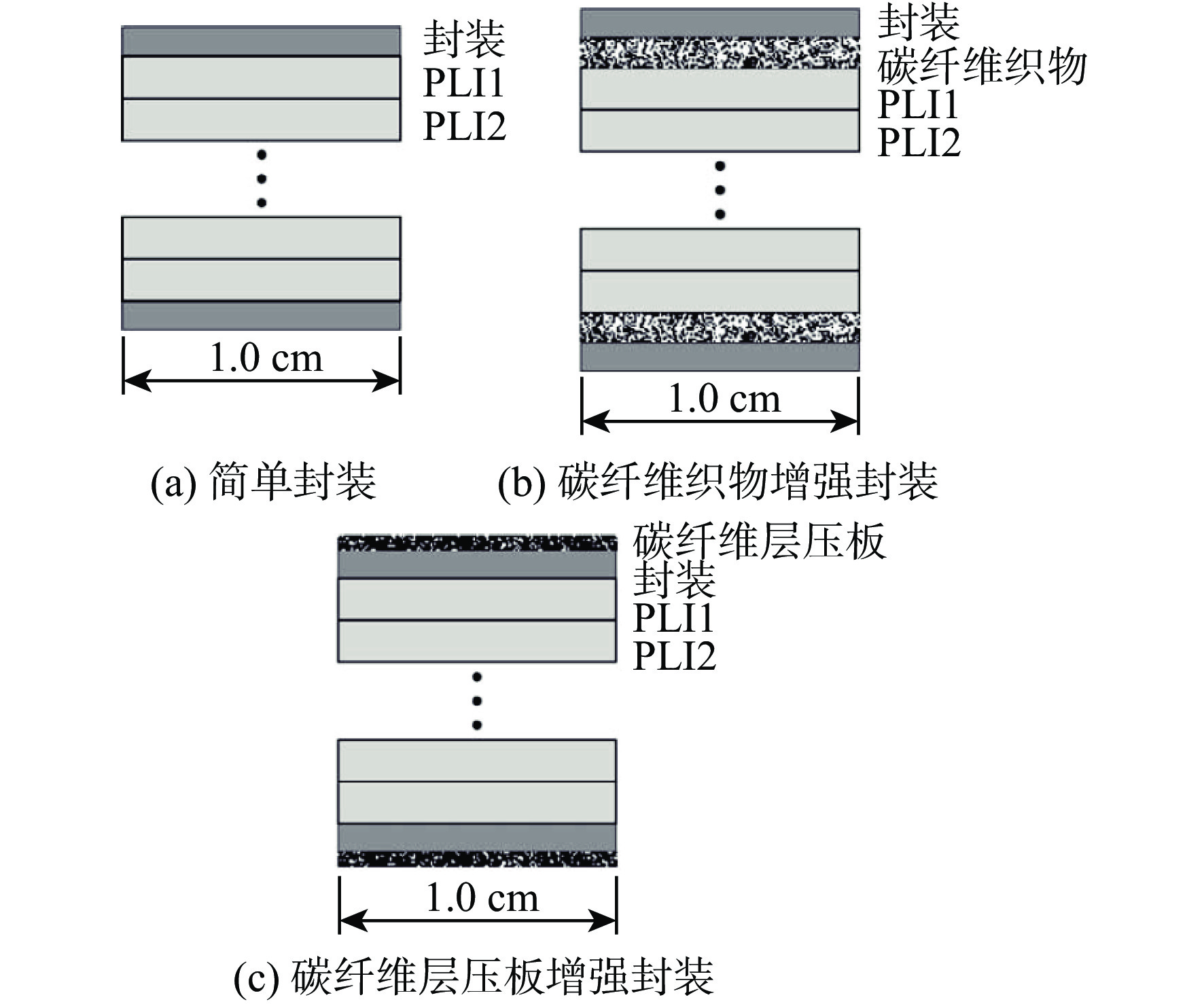

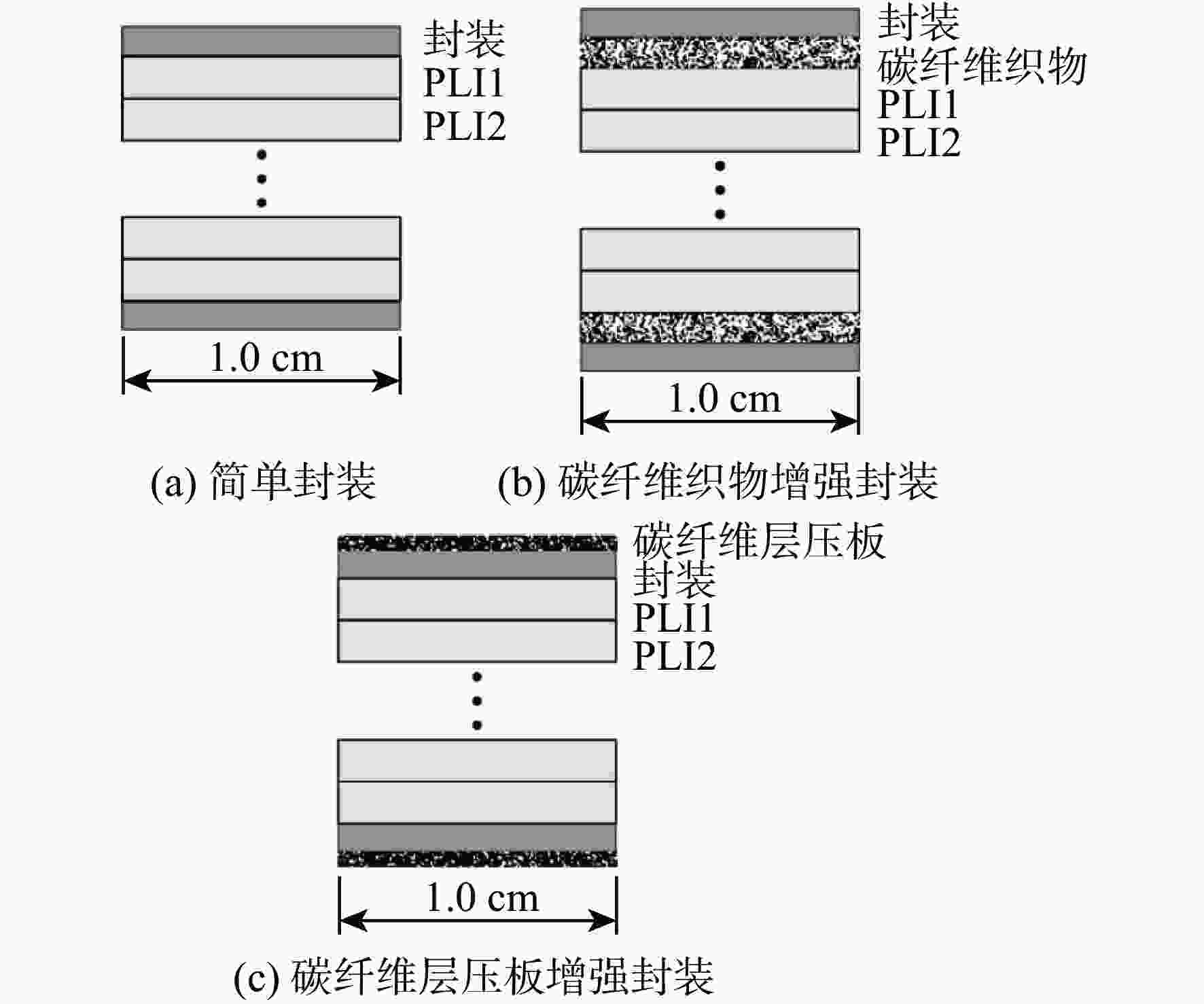

复合材料结构电池能够使传统复合材料结构在满足承载功能的同时,具备电存储性能,是实现民用飞机结构功能一体化的途径之一。复合材料结构电池的研究现状及性能指标表明,其结构刚度效率和结构强度效率约为60%,储能效率约为50%。复合材料结构电池可优先用于向飞机厨房系统和客舱娱乐系统供电,待技术进一步提升后可用于向客舱环控系统、机翼电防除冰等系统供电;复合材料结构电池布置首选客舱地板、厨房和盥洗室结构件,其次可选择翼身整流罩、机翼/尾翼后缘舱等结构。对于复合材料结构电池应用于民用飞机结构的有利条件和不利因素进行了综合对比分析,典型应用场景下复合材料结构电池可实现结构减重和燃油节约的效益,同时也会带来制造成本、检查维护成本、地面充电/基础设施建设成本的增加。复合材料结构电池应用于民用飞机也对客舱防火技术和电池热管理技术带来了新的挑战。

Abstract:The composite structural battery enables the traditional composite structure not only to meet load-bearing requirements, but also to provide an electrical storage capability, which is one feasible way to realize the integration of structure and function in civil aircraft. In this paper, the research status and performance of composite structural batteries are reviewed. The structural stiffness efficiency and structural strength efficiency of the composite structure battery are about 60% respectively, and the energy storage efficiency is about 50%. The aircraft galley system and in-flight entertainment system can be powered primarily by the composite structure battery. As technology advances, it can also power the cabin environmental control system, wing electric anti-icing, and other systems. The first choice for structural battery application is the cabin floor, galley/lavatory structure, followed by wing-body fairing, wing/tail trailing edge and other structures. The advantages and disadvantages of composite structure batteries applied to civil aircraft structures are analyzed comprehensively. In typical application scenarios, composite structure batteries can achieve structural weight reduction and fuel saving benefits, but also bring an increase in manufacturing costs, inspection and maintenance costs, and ground electrical charging/infrastructure construction costs. Battery thermal management and cabin fire safety technologies face additional difficulties as a result of the use of composite structure batteries in passenger aircraft.

-

表 1 复合材料结构电池性能预测

Table 1. Performance prediction of composite material structure battery

类型 参数 当前值 预测值 常规电池 储能密度/(Wh·kg−1) 300 500 常规复材层板 等效刚度/GPa 80 80 压缩许用应力/MPa 300 300 复合材料

结构电池储能效率$ {\varOmega _{E_{\mathrm{w}}}} $/% 50 60 结构刚度效率$ {\varOmega _{S_{\mathrm{E}}}} $/% 60 80 结构强度效率$ {\varOmega _{S_{\text{σ}} }} $/% 60 60 储能密度/(Wh·kg−1) 150 300 刚度/GPa 48 64 压缩许用应力/MPa 180 180 注:常规复材层板指T800级碳纤维层板,按典型铺层比例40/50/10计算等效刚度;压缩许用应力通常由冲击后压缩、开孔压缩等性能决定;当前值表示2023年的数值,预测值表示2023—2033年的数值。 表 2 复合材料结构电池潜在应用部位分析

Table 2. Analysis of potential application position of composite structure battery

结构部位 可用空间 外形复杂度 服役温度[55-56] 外部威胁 检修维护 防火要求 总分 机翼前缘 1 1 1(考虑防除冰加温,约−55~100 ℃) 1(鸟撞、冰雹) 3 3 10 机翼后缘 3 4 2(约−55~80 ℃) 3(作动器漏液) 5 3 20 尾翼前缘 2 1 2(约−55~80 ℃) 1(鸟撞、冰雹) 4 3 13 尾翼后缘 3 4 2(约−55~80 ℃) 3(作动器漏液) 5 3 20 翼身整流罩 5 3 1(考虑空调组件,约−55~100 ℃) 3(跑道碎石、液体腐蚀) 4 3 19 厨房/盥洗室结构件 3 5 5(约20~50 ℃) 3(厨房/盥洗室液体腐蚀) 4 1 21 客舱侧板/天花板 3 2 5(约20~50 ℃) 4(颠簸撞击) 2 1 17 行李架 1 1 5(约20~50 ℃) 4(颠簸撞击) 3 1 15 客舱地板 5 5 5(约20~50 ℃) 4(行李掉落) 3 1 23 货舱地板 3 5 5(约5~35 ℃) 1(货物撞击、液体腐蚀) 2 1 17 注:分数范围为1~5,5表示非常适用,1表示较不适用。 -

[1] 吴光辉. 民用飞机先进技术展望[J]. 网信军民融合, 2021(7): 5-7.WU G H. Prospect of advanced technology of civil aircraft[J]. Civil-Military Integration on Cyberspace, 2021(7): 5-7(in Chinese). [2] MARINO M, SABATINI R. Advanced lightweight aircraft design configurations for green operations[C]//Proceedings of the Practical Responses to Climate Change. Melbourne: Engineers Australia, 2014: 1-9. [3] GILANI M, KORPE D S. Airline weight reduction to minimize direct operating cost[C]//Proceedings of the 4th International Aviation Management Conference. Ankara: INTAVIC, 2019: 1-11. [4] FERREIRA A D B L, NÓVOA P R O, MARQUES A T. Multifunctional material systems: a state-of-the-art review[J]. Composite Structures, 2016, 151: 3-35. doi: 10.1016/j.compstruct.2016.01.028 [5] 丁颖慧, 祁国成, 张博明. 结构储电碳纤维复合材料研究进展[J]. 复合材料学报, 2021, 38(1): 16-24.DING Y H, QI G C, ZHANG B M. Recent progress in carbon fiber reinforced composites for electricity storage[J]. Acta Materiae Compositae Sinica, 2021, 38(1): 16-24(in Chinese). [6] ASP L E, GREENHALGH E S. Structural power composites[J]. Composites Science and Technology, 2014, 101: 41-61. doi: 10.1016/j.compscitech.2014.06.020 [7] KÜHNELT H, BEUTL A, JIANG Q X, et al. Structural batteries for aeronautic applications[C]//Proceedings of the Transport Transitions: Advancing Sustainable and Inclusive Mobility. Berlin: Springer, 2025: 254-260. [8] ASP L E, JOHANSSON M, LINDBERGH G, et al. Structural battery composites: a review[J]. Functional Composites and Structures, 2019, 1(4): 042001. doi: 10.1088/2631-6331/ab5571 [9] DANZI F, SALGADO R M, OLIVEIRA J E, et al. Structural batteries: a review[J]. Molecules, 2021, 26(8): 2203. doi: 10.3390/molecules26082203 [10] JIN T W, SINGER G, LIANG K Y, et al. Structural batteries: advances, challenges and perspectives[J]. Materials Today, 2023, 62: 151-167. doi: 10.1016/j.mattod.2022.12.001 [11] 顾涧潇. 结构/储能一体化复合材料研究进展综述[J]. 冶金与材料, 2020, 12(3): 59-63.GU J X. Review on research progress of structure/energy storage integrated composites[J]. Metallurgy and Materials, 2020, 12(3): 59-63(in Chinese). [12] 张峻滔, 王亚震, 李晖, 等. 碳纤维复合材料结构锂离子电池研究综述[J]. 复合材料学报, 2023, 40(3): 1263-1273.ZHANG J T, WANG Y Z, LI H, et al. Study review on structure lithium-ion batteries of carbon fiber reinforced composites[J]. Acta Materiae Compositae Sinica, 2023, 40(3): 1263-1273(in Chinese). [13] THOMAS J P, QIDWAI M A. Mechanical design and performance of composite multifunctional materials[J]. Acta Materialia, 2004, 52(8): 2155-2164. doi: 10.1016/j.actamat.2004.01.007 [14] ASP L E, BOUTON K, CARLSTEDT D, et al. A structural battery and its multifunctional performance[J]. Advanced Energy and Sustainability Research, 2021, 2(3): 2000093. doi: 10.1002/aesr.202000093 [15] CARLSTEDT D, ASP L E. Performance analysis framework for structural battery composites in electric vehicles[J]. Composites Part B: Engineering, 2020, 186: 107822. doi: 10.1016/j.compositesb.2020.107822 [16] TU V, ASP L E, SHIRSHOVA N, et al. Performance of bicontinuous structural electrolytes[J]. Multifunctional Materials, 2020, 3(2): 025001. doi: 10.1088/2399-7532/ab8d9b [17] JOHANNISSON W, ZENKERT D, LINDBERGH G. Model of a structural battery and its potential for system level mass savings[J]. Multifunctional Materials, 2019, 2(3): 035002. doi: 10.1088/2399-7532/ab3bdd [18] CARLSTEDT D, JOHANNISSON W, ZENKERT D, et al. Conceptual design framework for laminated structural battery composites[C]//Proceedings of the 18th European Conference on Composite Materials. Athens: Applied Mechanics Laboratory, 2018: 1-8. [19] JOHANNISSON W, IHRNER N, ZENKERT D, et al. Multifunctional performance of a carbon fiber UD lamina electrode for structural batteries[J]. Composites Science and Technology, 2018, 168: 81-87. doi: 10.1016/j.compscitech.2018.08.044 [20] ISHFAQ A, NGUYEN S N, GREENHALGH E S, et al. Multifunctional design, feasibility and requirements for structural power composites in future electric air taxis[J]. Journal of Composite Materials, 2023, 57(4): 817-827. doi: 10.1177/00219983221132621 [21] VALKOVA M, NGUYEN S, SENOKOS E, et al. Current collector design strategies: the route to realising scale-up of structural power composites[J]. Composites Science and Technology, 2023, 236: 109978. doi: 10.1016/j.compscitech.2023.109978 [22] GREENHALGH E S, ANKERSEN J, ASP L E, et al. Mechanical, electrical and microstructural characterisation of multifunctional structural power composites[J]. Journal of Composite Materials, 2015, 49(15): 1823-1834. doi: 10.1177/0021998314554125 [23] LEE C H, GREENHALGH E S, SHAFFER M S P, et al. Optimized microstructures for multifunctional structural electrolytes[J]. Multifunctional Materials, 2019, 2(4): 045001. doi: 10.1088/2399-7532/ab47ed [24] LADPLI P, NARDARI R, KOPSAFTOPOULOS F, et al. Multifunctional energy storage composite structures with embedded lithium-ion batteries[J]. Journal of Power Sources, 2019, 414: 517-529. doi: 10.1016/j.jpowsour.2018.12.051 [25] MUKHOPADHYAY V, OLSON E D, OZOROSKI T. Structural analysis of a test flight vehicle with multi-functional energy storage[C]//Proceedings of the AIAA Scitech Forum. Reston: AIAA, 2019. [26] NGUYEN S N, MILLEREUX A, POUYAT A, et al. Conceptual multifunctional design, feasibility and requirements for structural power in aircraft cabins[J]. Journal of Aircraft, 2021, 58(3): 677-687. doi: 10.2514/1.C036205 [27] 王朝阳, 杨向涛, 徐祥博, 等. 结构储能碳纤维复合材料设计及其在无人机上的应用[J]. 航空制造技术, 2020, 63(18): 84-90.WANG C Y, YANG X T, XU X B, et al. Structural energy storage carbon fiber composite design and application in drone[J]. Aeronautical Manufacturing Technology, 2020, 63(18): 84-90(in Chinese). [28] 杨向涛, 王朝阳, 张金纳, 等. 超薄碳纤维复合材料结构电池制备及其性能评价[J]. 复合材料科学与工程, 2021(7): 39-47.YANG X T, WANG C Y, ZHANG J N, et al. Preparation and performance evaluation of ultra-thin carbon fiber composite structure battery[J]. Composites Science and Engineering, 2021(7): 39-47(in Chinese). [29] ZHANG J T, WANG Y Z, LIANG X, et al. Experimental evaluation of energy efficiency and structural efficiency of ultra-thin carbon fiber composite structural battery tube[J]. Journal of Solid State Electrochemistry, 2023, 27(10): 2751-2760. doi: 10.1007/s10008-023-05576-w [30] 祁国成. 基于垂直微通道结构电解质的碳纤维复合材料结构电池设计与多功能特性[C]//北京力学会第二十九届学术年会论文集. 北京: 北京交通大学, 2023: 58-59.QI G C. Design and multifunctional characteristics of carbon fiber composite structure battery based on vertical microchannel structure electrolyte[C]//Proceedings of the 29th Annual Conference of Beijing Institute of Mechanics. Beijing: Beijing Jiaotong University, 2023: 58-59(in Chinese). [31] QI G C, CUI Q, ZHANG B M, et al. A carbon fiber lamina electrode based on macroporous epoxy with vertical ion channels for structural battery composites[J]. Composite Structures, 2023, 304: 116425. doi: 10.1016/j.compstruct.2022.116425 [32] YADAV A, DE B, SINGH S K, et al. Facile development strategy of a single carbon-fiber-based all-solid-state flexible lithium-ion battery for wearable electronics[J]. ACS Applied Materials & Interfaces, 2019, 11(8): 7974-7980. [33] MOYER K, MENG C Z, MARSHALL B, et al. Carbon fiber reinforced structural lithium-ion battery composite: multifunctional power integration for CubeSats[J]. Energy Storage Materials, 2020, 24: 676-681. doi: 10.1016/j.ensm.2019.08.003 [34] CHEN J Y, ZHOU Y, ISLAM M S, et al. Carbon fiber reinforced Zn-MnO2 structural composite batteries[J]. Composites Science and Technology, 2021, 209: 108787. doi: 10.1016/j.compscitech.2021.108787 [35] LIU X, HAN Q G, WANG J H, et al. Tree root-inspired structural electrolyte for laminated carbon fiber reinforced composites with high energy density and mechanically-robust properties[J]. Chemical Engineering Journal, 2022, 449: 137828. doi: 10.1016/j.cej.2022.137828 [36] LIU X, LI H M, WANG J H, et al. Achieving mechanically sturdy properties and high energy density for Zn-ion structural batteries based on carbon-fiber-reinforced composites[J]. Composites Science and Technology, 2022, 218: 109156. doi: 10.1016/j.compscitech.2021.109156 [37] DOMINKO R, FICHTNER M, OTUSZEWSKI T, et al. Battery 2030+ inventing the sustainable batteries of the future[EB/OL]. (2020-04-02)[2023-10-16]. https://www.isc.fraunhofer.de/en/press-and-media/press-releases/battery2030-inventing-the-sustainable-batteries-of-the-future.html. [38] MA J, LI Y, GRUNDISH N S, et al. The 2021 battery technology roadmap[J]. Journal of Physics D: Applied Physics, 2021, 54(18): 183001. doi: 10.1088/1361-6463/abd353 [39] MANFREDY MARQUINA L, LA TORRE RIVEROS L, JAUJA CCANA V, et al. Recent studies on polymer electrolytes containing ionic liquids and their applications in lithium-ion batteries[J]. Journal of Electroanalytical Chemistry, 2023, 948: 117819. doi: 10.1016/j.jelechem.2023.117819 [40] CHOI J, ZABIHI O, VARLEY R, et al. Multiple hydrogen bond channel structural electrolyte for an enhanced carbon fiber composite battery[J]. ACS Applied Energy Materials, 2022, 5(2): 2054-2066. doi: 10.1021/acsaem.1c03354 [41] HUANG F, SINGER G, ZHOU Y, et al. Creating ionic pathways in solid-state polymer electrolyte by using PVA-coated carbon nanofibers[J]. Composites Science and Technology, 2021, 207: 108710. doi: 10.1016/j.compscitech.2021.108710 [42] HUANG F, ZHOU Y, SHA Z, et al. Surface functionalization of electrodes and synthesis of dual-phase solid electrolytes for structural supercapacitors[J]. ACS Applied Materials & Interfaces, 2022, 14(27): 30857-30871. [43] MISHRA A, MEHTA A, BASU S, et al. Electrode materials for lithium-ion batteries[J]. Materials Science for Energy Technologies, 2018, 1(2): 182-187. doi: 10.1016/j.mset.2018.08.001 [44] REHNLUND D, WANG Z H, NYHOLM L. Lithium-diffusion induced capacity losses in lithium-based batteries[J]. Advanced Materials, 2022, 34(19): 2108827. doi: 10.1002/adma.202108827 [45] LIM G J H, CHAN K K, SUTRISNOH N A A, et al. Design of structural batteries: carbon fibers and alternative form factors[J]. Materials Today Sustainability, 2022, 20: 100252. doi: 10.1016/j.mtsust.2022.100252 [46] 王亚震, 张峻滔, 李晖, 等. 超薄镀镍碳纤维管状结构电池的制备及性能研究[J]. 复合材料科学与工程, 2023(5): 12-18.WANG Y Z, ZHANG J T, LI H, et al. Preparation and performance study on ultra-thin nickel-plated carbon fiber tubular structure battery[J]. Composites Science and Engineering, 2023(5): 12-18(in Chinese). [47] 李世超, 张正, 巴文兰, 等. 超薄预浸料对碳纤维/环氧树脂复合材料导电性能的影响[J]. 复合材料学报, 2020, 37(3): 539-545.LI S C, ZHANG Z, BA W L, et al. Effect of ultra-thin prepreg on conductive properties of carbon fiber/epoxy composites[J]. Acta Materiae Compositae Sinica, 2020, 37(3): 539-545(in Chinese). [48] 张卓然, 许彦武, 姚一鸣, 等. 多电飞机电力系统及其关键技术[J]. 南京航空航天大学学报, 2022, 54(5): 969-984.ZHANG Z R, XU Y W, YAO Y M, et al. Electric power system and key technologies of more electric aircraft[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2022, 54(5): 969-984(in Chinese). [49] LAMPL T S, MUSCHKORGEL S, HORNUNG M. Parameterized flight mission for secondary power requirement estimations of commercial transport aircraft[C]//Proceedings of the 17th AIAA Aviation Technology, Integration, and Operations Conference. Reston: AIAA, 2017. [50] WANG P. Civil aircraft electrical power system safety assessment, chapter 5-preliminary system safety assessment[M]. Oxford: Butterworth-Heinemann, 2017: 101-156. [51] SILVA E L S E, DE OLIVEIRA MORAES A, CAICCIA F R D A S. Smart cabin design concept for regional aircraft: technologies, applications & architecture[J]. Journal of Aerospace Technology and Management, 2023, 15: e2023. doi: 10.1590/jatm.v15.1310 [52] 杜善义, 关志东. 我国大型客机先进复合材料技术应对策略思考[J]. 复合材料学报, 2008, 25(1): 1-10.DU S Y, GUAN Z D. Strategic considerations for development of advanced composite technology for large commercial aircraft in China[J]. Acta Materiae Compositae Sinica, 2008, 25(1): 1-10(in Chinese). [53] FRANCO-URQUIZA E A, DOLLINGER A, TORRES-ARELLANO M, et al. Innovation in aircraft cabin interior panels part I: technical assessment on replacing the honeycomb with structural foams and evaluation of optimal curing of prepreg fiberglass[J]. Polymers, 2021, 13(19): 3207. doi: 10.3390/polym13193207 [54] SMTC. Reducing the weight of aircraft interiors[J]. Reinforced Plastics, 2014, 58(4): 36-37. doi: 10.1016/S0034-3617(14)70180-8 [55] WALESON J E A. Thermal loads of horizontal tail plane structure[C]//Proceedings of the CMH-17 meeting. Montreal: CMH, 2015: 1-14. [56] 蔡宇宏, 蒋彦龙, 蔡玉飞, 等. 民机客舱热载荷的数值计算[J]. 世界科技研究与发展, 2010, 32(6): 794-797.CAI Y H, JIANG Y L, CAI Y F, et al. Numerical calculation of heat load for civil-aircraft cabin[J]. World Sci-Tech R&D, 2010, 32(6): 794-797(in Chinese). [57] GREENHALGN E S, ASP L, ZENKERT D, et al. SORCERER structural power composites for future civil aircraft[C]//Proceedings of the Clean Sky 2 Special Session–AIAA Science & Technology Forum. Reston: AIAA, 2021. [58] NASA. Visions of the future: hybrid electric aircraft propulsion[EB/OL]. (2016-07-28)[2023-10-20]. https://ntrs.nasa.gov/api/citations/20170002633/downloads/20170002633.pdf. [59] CARVALHO M L, TEMPORELLI A, GIRARDI P. Life cycle assessment of stationary storage systems within the Italian electric network[J]. Energies, 2021, 14(8): 2047. doi: 10.3390/en14082047 [60] MADONNA V, GIANGRANDE P, GALEA M. Electrical power generation in aircraft: review, challenges, and opportunities[J]. IEEE Transactions on Transportation Electrification, 2018, 4(3): 646-659. doi: 10.1109/TTE.2018.2834142 [61] 罗云烽, 王高鹏, 程文礼, 等. 复合材料快速成型技术研究综述[J]. 纤维复合材料, 2023, 40(2): 96-102.LUO Y F, WANG G P, CHENG W L, et al. Review on rapid prototyping technology of composite materials[J]. Fiber Composites, 2023, 40(2): 96-102(in Chinese). [62] 刘亚男, 刘晨晓, 朱明浩, 等. 模压成型CF/PEKK与自动铺丝CF/PEEK热塑性复合材料对比研究[J]. 航空制造技术, 2021, 64(11): 50-57.LIU Y N, LIU C X, ZHU M H, et al. Comparative study between CF/PEKK thermoplastic composite by hot-press molding and CF/PEEK composite using automated fiber placement process[J]. Aeronautical Manufacturing Technology, 2021, 64(11): 50-57(in Chinese). [63] CARLSON, T. Multifunctional composite materials design, manufacture and experimental characterization[D]. Sweden: Luleå University of Technology, 2013: 22-30. [64] HERMANSSON F, EDGREN F, XU J, et al. Climate impact and energy use of structural battery composites in electrical vehicles: a comparative prospective life cycle assessment[J]. The International Journal of Life Cycle Assessment, 2023, 28(10): 1366-1381. doi: 10.1007/s11367-023-02202-9 [65] 郭博智, 王敏芹, 吴昊. 民用飞机维修性工程[M]. 北京: 航空工业出版社, 2018: 21-74.GUO B Z, WANG M Q, WU H. Civil aircraft maintainability engineering[M]. Beijing: Aviation Industry Press, 2018: 21-74(in Chinese). [66] 魏静, 顾铮, 蒋绍新. 民用飞机客舱设施与维修[M]. 西安: 西北工业大学出版社, 2016: 119-150.WEI J, GU Z, JIANG S X. Civil aircraft cabin facilities and maintenance[M]. Xi’an: Northwestern Polytechnical University Press, 2016: 119-150(in Chinese). [67] WILLIAMS C. A350 MPD analysis and maintenance planning[J]. Aircraft Commerce, 2018, 115: 36-44. [68] WILLIAMS C. 787 MPD analysis & check planning[J]. Aircraft Commerce, 2016, 106: 43-56. [69] 梁剑武. 浅谈波音787飞机锂电池电瓶检测间隔[J]. 航空维修与工程, 2020(7): 105-106.LIANG J W. Discussion on test interval of lithium battery for B787 aircraft[J]. Aviation Maintenance & Engineering, 2020(7): 105-106(in Chinese). [70] 魏娟. 民用飞机蓄电池选型浅析[J]. 科技视界, 2015(25): 98-99.WEI J. Analysis for battery category selection of civil aircraft[J]. Science & Technology Vision, 2015(25): 98-99(in Chinese). [71] 中国民用航空局. 运输类飞机适航标准: CCAR-25-R4[S]. 北京: 中国民用航空局, 2016.Civil Aviation Administration of China. Airworthiness standards for transport aircraft: CCAR-25-R4[S]. Beijing: Aviation Administration of China, 2016(in Chinese). [72] Federal Aviation Administration. Composite aircraft structure: AC 20-107B[S]. Washton, D. C.: Department of Transportation Federal Aviation Administration, 2009: 1-37. [73] CHISHOLM S A, RUFIN A C, CHAPMAN B D, et al. Forty years of structural durability and damage tolerance at boeing commercial airplanes[J]. Boeing Technical Journal, 2016: 1-24. [74] WU M H, HAN S H, LIU S M, et al. Fire-safe polymer electrolyte strategies for lithium batteries[J]. Energy Storage Materials, 2024, 66: 103174. doi: 10.1016/j.ensm.2024.103174 [75] Federal Aviation Administration. Airborne equipment environmental conditions and test procedures: RTCA DO-160G[S]. Washington, D. C.: RTCA, Inc. , 2010. [76] NTSB. Auxiliary power unit battery fire japan airlines boeing 787-8, ja829J: NTSB/AIR-14/01 PB2014-108867[R]. Boston: National Transportation Safety Board, 2013: 1-110. [77] Federal Aviation Administration. Guidelines for development of civil aircraft and systems: ARP 4754B[S]. Warrendale: SAE International, 2023. [78] Federal Aviation Administration. Guidelines and methods for conducting the safety assessment process on civil airborne system and equipment: ARP 4761A[S]. Warrendale: SAE International, 2023. -

下载:

下载: