Numerical simulation of shell-side gas flow of airborne hollow fiber membrane module

-

摘要:

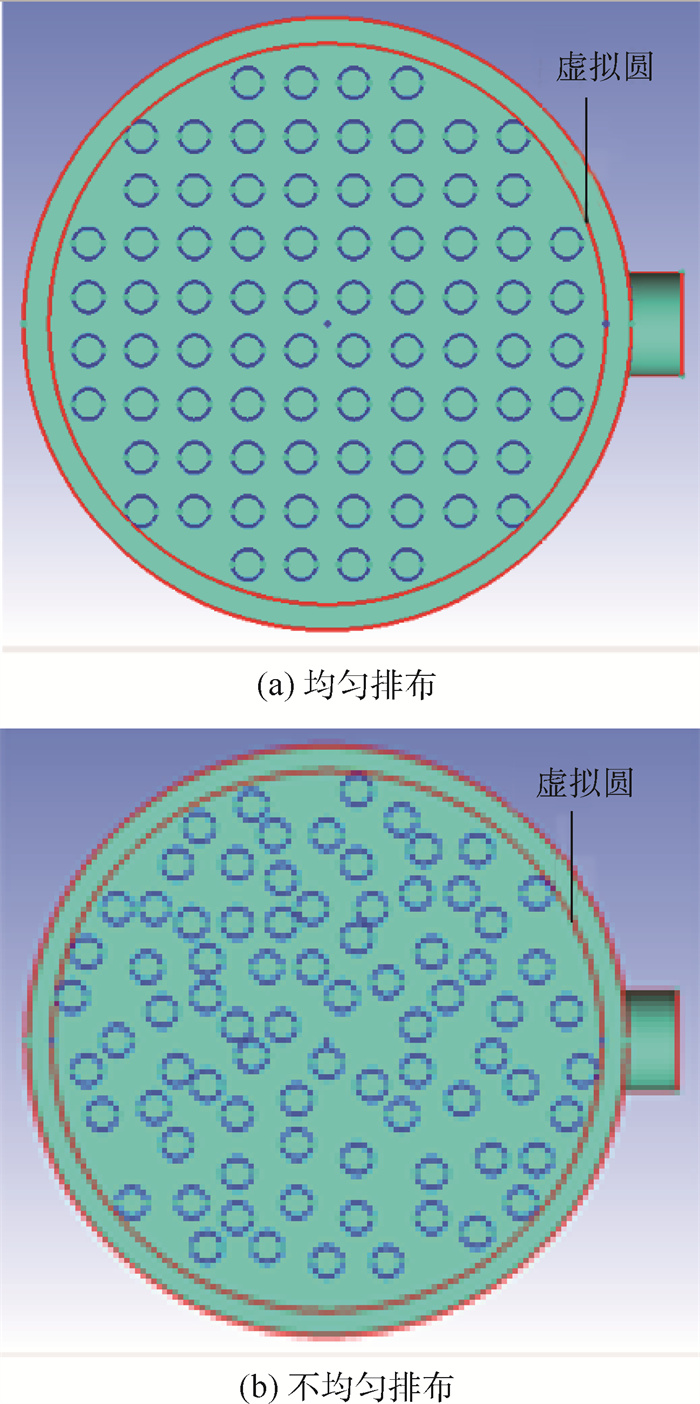

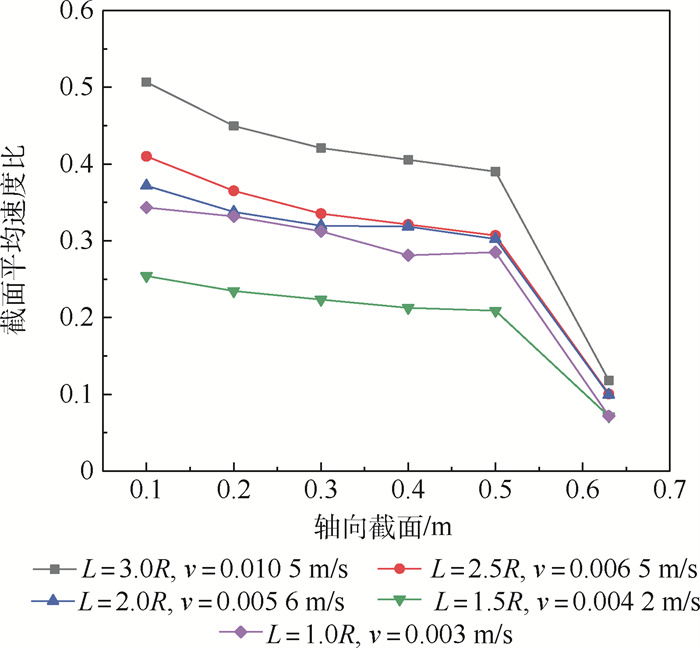

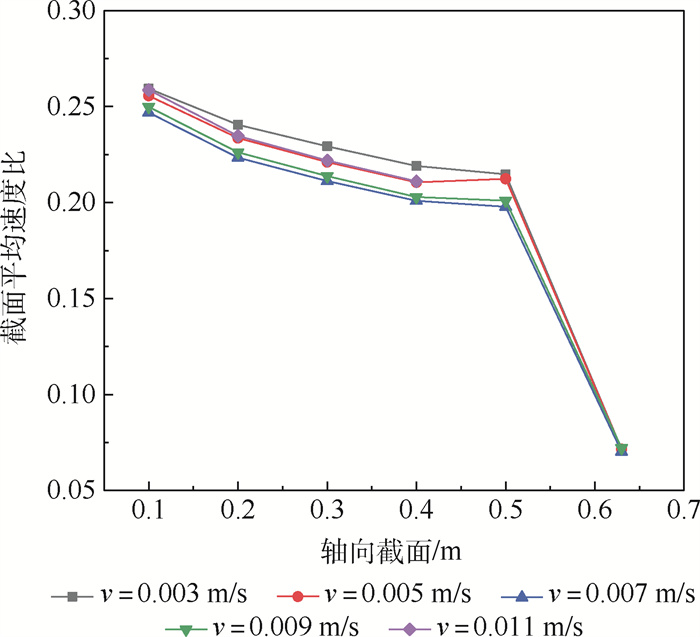

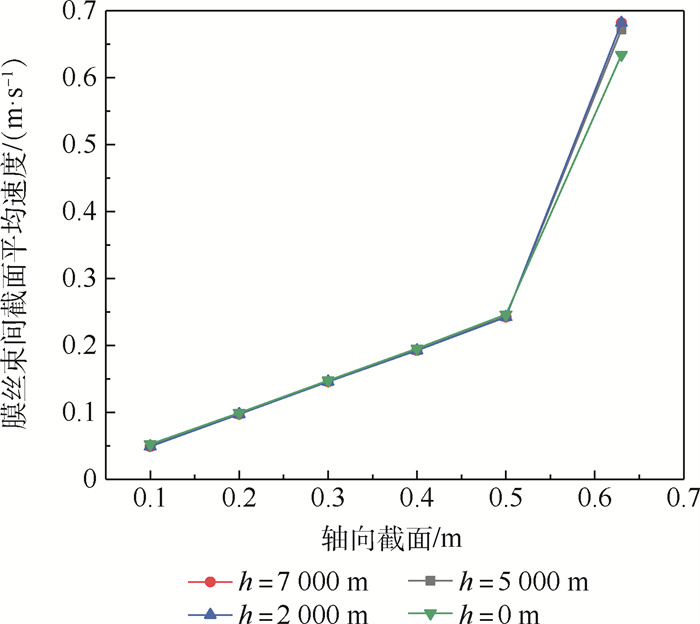

机载惰化用中空纤维膜组件具有分离效率高、安全稳定、结构紧凑等优点,是目前较为经济高效的飞机燃油箱惰化设备。采用计算流体力学(CFD)方法对某中空纤维膜组件壳程气体流动进行数值模拟,通过更改膜丝束间距、膜丝束入口速度、膜丝束流量、膜丝束排布方式及飞行高度,得到了不同工况下的组件轴向各截面的气体流动分布,并提出无量纲参数截面平均速度比来描述气体流动分布规律。仿真结果表明:在保持入口气体流动速度一定时,平均速度比值随着膜丝束间距的减小先减小后增大,在膜丝束间距为1.5倍膜丝半径时达到最小值, 在保持入口流量一定时,壳程气体流动有着相同的规律;在保持膜丝束填充数量不变时,均匀排布比不均匀排布的平均速度比值更小;保持膜丝束间距不变时,入口速度对平均速度比值影响不大;飞行高度对组件壳程气体分布的影响作用主要体现在膜组件内壁处。

Abstract:Hollow fiber membrane module used for airborne inerting has the advantages of high separation efficiency, security, stability and compact structure. It is a relatively economic and efficient equipment of aircraft fuel tank inerting. The computational fluid dynamics (CFD) method is used to simulation shell-side gas flow of hollow fiber membrane module. By changing the gap, entrance velocity, rate of flow, arrangement mode of membrane tow and flight height, the gas flow distribution of the axial sections of component under different working conditions is obtained. The dimensionless parameter sectional average velocity ratio is put forward to describe gas flow distribution rule. The simulation results show that sectional average velocity ratio decreases at first and then increases with the decrease of the gap when entrance velocity is constant, and reaches the minimum when the gap is 1.5 times of the radius of membrane tow, and shell-side gas flow has the same rule with constant rate of flow. When the gap is constant, sectional average velocity ratio of uniform distribution is lower than that of non-uniform distribution. With constant the gap, entrance velocity has little effect on sectional average velocity ratio. The effect of flight height on the shell-side gas flow of the module is mainly reflected from the inner wall of the membrane module.

-

Key words:

- hollow fiber membrane /

- numerical simulation /

- inerting system /

- air separation /

- shell side

-

-

[1] 李红宾, 石文英, 张海霞, 等. 中空纤维膜膜蒸馏过程研究进展[J]. 高分子材料科学与工程, 2020, 36(1): 175-182.LI H B, SHI W Y, ZHANG H X, et al. Progress on the processes of hollow fiber membrane distillation[J]. Polymer Materials Science & Engineering, 2020, 36(1): 175-182(in Chinese). [2] 朱加良, 孙奥博, 高志丰. 膜分离技术特点分析及应用[J]. 电站系统工程, 2020, 36(3): 73-74.ZHU J L, SUN A B, GAO Z F. Analysis and application of membrane separation technology[J]. Power System Engineering, 2020, 36(3): 73-74(in Chinese). [3] 卢吉. 机载空分装置及惰化系统的理论研究[D]. 南京: 南京航空航天大学, 2012.LU J. Theoretical study of onboard air separation unit and inerting system[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2012(in Chinese). [4] 王明波, 邵垒, 潘俊, 等. 耗氧型燃油箱惰化技术历史和现状[J]. 航空科学技术, 2016, 27(7): 1-7.WANG M B, SHAO L, PAN J, et al. History and current status of oxygen consumption based fuel tank inerting technology[J]. Aeronautical Science & Technology, 2016, 27(7): 1-7(in Chinese). [5] 汪明明, 冯诗愚, 蒋军昌, 等. 飞机燃油箱冲洗与洗涤惰化技术比较分析[J]. 南京航空航天大学学报, 2010, 42(5): 614-619.WANG M M, FENG S C, JIANG J C, et al. Comparative analysis of fuel washing and scrubbing in aircraft fuel tank[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2010, 42(5): 614-619(in Chinese). [6] AHMAD A L, LAU K K, BAKAR M Z A, et al. Integrated CFD simulation of concentration polarization in narrow membrane channel[J]. Computers & Chemical Engineering, 2005, 29(10): 2087-2095. [7] MARCOS B, MORESOLI C, SKOREPOVA J, et al. CFD modeling of a transient hollow fiber ultrafiltration system for protein concentration[J]. Journal of Membrane Science, 2009, 337(1/2): 136-144. [8] PARVAREH A, RAHIMI M, MADAENI S S, et al. Experimental and CFD study on the role of fluid flow pattern on membrane permeate flux[J]. Chinese Journal of Chemical Engineering, 2011, 19(1): 18-25. doi: 10.1016/S1004-9541(09)60171-3 [9] 卞锐, 许松林. 中空纤维式渗透汽化膜内流动的CFD模拟[J]. 现代化工, 2013, 33(10): 116-118.BIAN R, XU S L. CFD modeling of flow in hollow fiber pervaporation membrane[J]. Modern Chemical Industry, 2013, 33(10): 116-118(in Chinese). [10] ARDANEH M, ABOLHASANI M, ESMAEILI M. CFD modeling of two-stage H2 recovery process from ammonia purge stream by industrial hollow fiber membrane modules[J]. International Journal of Hydrogen Energy, 2019, 44(10): 4851-4867. [11] 杨毅, 王保国, 彭勇. 中空纤维膜组件壳程流动的数值模拟[J]. 化工学报, 2008, 59(8): 1979-1985.YANG Y, WANG B G, PENG Y. Numerical simulation of shell-side flow in hollow fiber membrane modules[J]. CIESC Journal, 2008, 59(8): 1979-1985(in Chinese). [12] BUETEHORN S, VOLMERING D, VOSSENKAUL K, et al. CFD simulation of single-and multi-phase flows through submerged membrane units with irregular fiber arrangement[J]. Journal of Membrane Science, 2011, 384(1/2): 184-197. [13] 吴云, 张楠, 张宏伟, 等. 膜曝气生物膜反应器内流场的CFD模拟及组件优化[J]. 化工学报, 2015, 66(1): 402-409.WU Y, ZHANG N, ZHANG H W, et al. CFD simulation of internal hydrodynamic characteristics and optimization of membrane module in membrane aerated biofilm reactor[J]. CIESC Journal, 2015, 66(1): 402-409(in Chinese). [14] COSTELLO M J, FANE A G, HOGAN P A, et al. The effect of shell side hydrodynamics on the performance of axial flow hollow fibre modules[J]. Journal of Membrane Science, 1993, 80(1): 1-11. [15] CAI J J, HAWBOLDT K, ABDI M A. Analysis of the effect of module design on gas absorption in cross flow hollow membrane contactors via computational fluid dynamics (CFD) analysis[J]. Journal of Membrane Science, 2016, 520: 415-424. [16] MA C Y, LIU Y B, LI F, et al. CFD simulations of fiber-fiber interaction in a hollow fiber membrane bundle: Fiber distance and position matters[J]. Separation and Purification Technology, 2019, 209: 707-713. -

下载:

下载: