-

摘要:

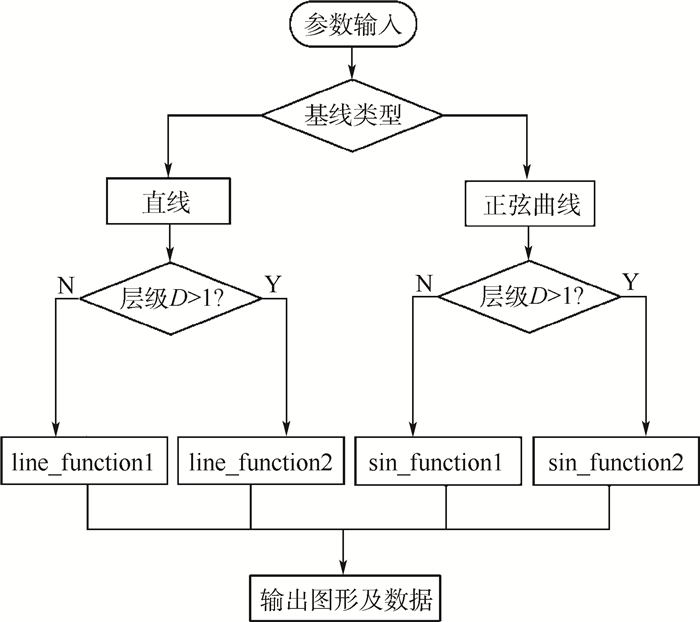

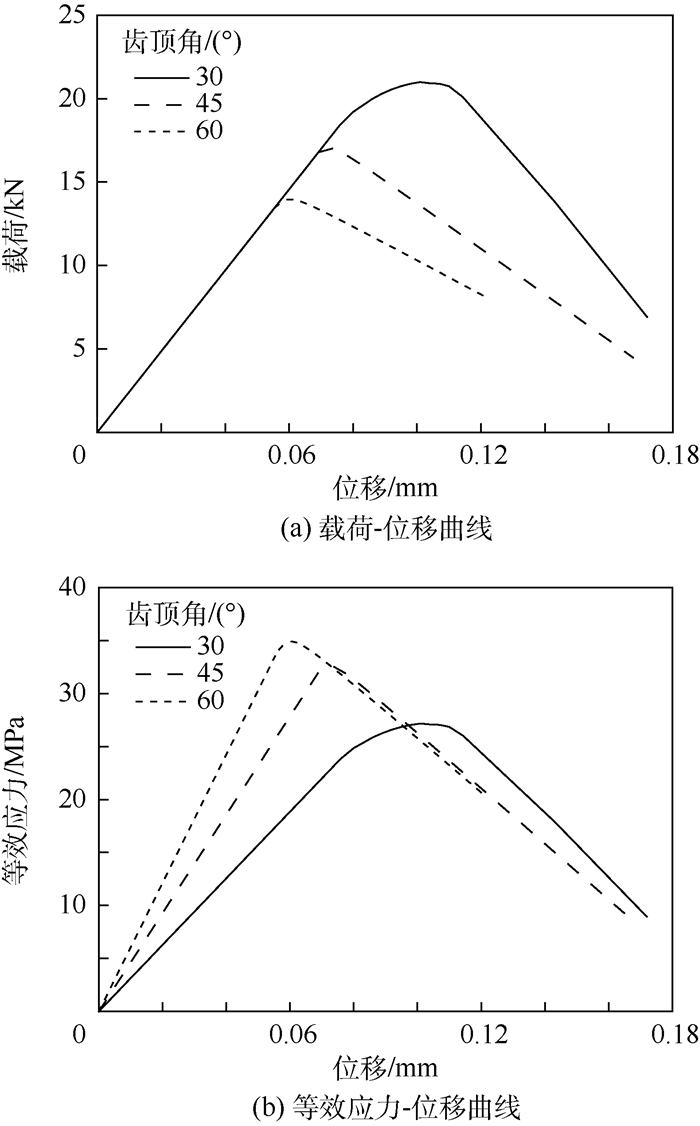

针对复合材料仿骨缝齿接结构模型表述复杂性问题,基于MATLAB与Python语言对有限元分析软件ABAQUS进行二次开发,提出了复合材料齿接结构的参数化构建方法。并以此为基础,初步研究了齿顶角、基线类型、层级与结构力学性能之间的关系。研究结果表明,在拉伸载荷作用下,具有小齿顶角度、复杂基线特性、高层级特性的齿接结构可以表现出更好的力学性能。通过本文工作,实现了齿接结构的参数化构建,初步揭示了齿接结构承载能力、损伤机理和几何形貌之间的关系。

Abstract:In this paper, we developed a parametric modeling framework for composite bionic suture joint structures through MATLAB and ABAQUS secondary development based on Python language. It shows the capability in describing the complicated suture joint geometry with different types of hierarchy and automatic generation of finite element mesh for mechanical modeling. Furthermore, interactions between geometric parameters (tooth angle, baseline type, and hierarchy) and structure performance are analyzed. The numerical results show that the bionic suture joint structure has better structural damage tolerance with the presence of a lower tooth angle, a sin curve baseline and a higher hierarchy. Through this work, parametric modeling of composite suture joint structure is realized, and the interaction among mechanical strength, damage mechanism and suture geometries is investigated, which provides meaningful guidelines for the design and optimization of novel high performance composite joint structures.

-

表 1 骨缝齿接结构关键参数

Table 1. Key parameters of suture joint structure

齿数 齿顶角/(°) 基线类型 层级 9 30 直线 1 9 45 直线 1 9 60 直线 1 15 45 直线 1 15 45 正弦曲线 1 5 45 直线 2 5 45 直线 3 表 2 骨缝齿接结构材料参数

Table 2. Material parameters of suture joint structure

材料参数 弹性模量/MPa 泊松比 数值 116 000 0.3 MPa 材料参数 Knn Kss Ktt 数值 491 000 264 500 264 500 注:Knn-法向刚度;Kss-1方向刚度;Ktt-2方向刚度。 表 4 内聚力界面失效应力

Table 4. Failure stress for cohesive interface

名义应力 法向 1方向 2方向 数值/MPa 55 30 30 -

[1] 赵美英.复合材料机械连接失效分析及强度影响因素研究[D].西安:西北工业大学, 2006:4-6.ZHAO M Y.Failure analysis of composite mechanically fastened joints and study of effects on failure strength[D].Xi'an:Northwestern Polytechnical University, 2006:4-6(in Chinese). [2] SAUNDERS W B, WORK D M.Shell morphology and suture complexity in upper carboniferous ammonoids[J].Paleobiology, 1996, 22(2):189-218. doi: 10.1017/S0094837300016171 [3] SONG J H, REICHERT S, KALLAI L, et al.Quantitative microstructural studies of the armor of the marine threespine stickleback (gasterosteus aculeatus)[J].Journal of Structural Biology, 2010, 171(3):318-331. doi: 10.1016/j.jsb.2010.04.009 [4] JASLOW C R, BIEWENER A A.Strain patterns in the horncores, cranial bones and sutures of goats (capra hircus) during impact loading[J].Journal of Zoology, 1995, 235(2):193-210. [5] LI Y, ORTIZ C, BOYCE M C.Stiffness and strength of suture joints in nature[J].Physical Review E Statistical Nonlinear & Soft Matter Physics, 2011, 84(6Pt1):2184-2188. [6] HARTWIG C W.Fractal analysis of sagittal suture morphology[J].Journal of Morphology, 1991, 210(3):289-298. doi: 10.1002/(ISSN)1097-4687 [7] JASLOW C R.Mechanical properties of cranial sutures[J].Journal of Biomechanics, 1990, 23(4):313-321. doi: 10.1016/0021-9290(90)90059-C [8] MEHRAN M, NEIL C, PAUL O, et al.Assessment of the role of sutures in a lizard skull:A computer modelling study[J].Proceedings Biological Sciences, 2009, 276(1654):39-46. doi: 10.1098/rspb.2008.0863 [9] DE BLASIO VITTORIO F.The role of suture complexity in diminishing strain and stress in ammonoid phragmocones[J].Lethaia, 2007, 41(1):15-24. [10] GAO H J.Application of fracture mechanics concepts to hierarchical biomechanics of bone and bone-like materials[J].International Journal of Fracture, 2006, 138(1-4):101-137. doi: 10.1007/s10704-006-7156-4 [11] JASINOSKI S C, REDDY B D, LOUW K K, et al.Mechanics of cranial sutures using the finite element method[J].Journal of Biomechanics, 2010, 43(16):3104-3111. doi: 10.1016/j.jbiomech.2010.08.007 [12] ORTIZ C, BOYCE M C.Materials science-Bioinspired structural materials[J].Science, 2008, 319(5866):1053-1054. doi: 10.1126/science.1154295 [13] LI Y, ORTIZ C, BOYCE M C.Bioinspired, mechanical, deterministic fractal model for hierarchical suture joints[J].Physical Review E Statistical Nonlinear & Soft Matter Physics, 2012, 85(3):922-938. [14] LI Y, ORTIZ C, BOYCE M C.A generalized mechanical model for suture interfaces of arbitrary geometry[J].Journal of Mechanics Physics of Solids, 2013, 61(4):1144-1167. doi: 10.1016/j.jmps.2012.10.004 [15] 曹金凤.Python语言在Abaqus中的应用[M].北京:机械工业出版社, 2011:2-3.CAO J F.The application of Python language in Abaqus[M].Beijing:China Machine Press, 2011:2-3(in Chinese). [16] BENZEGGAGH M L, KENANE M.Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus[J].Composites Science & Technology, 1996, 56(4):439-449. -

下载:

下载: