Corner building method and algorithm of automatic programing for aircraft structural parts

-

摘要:

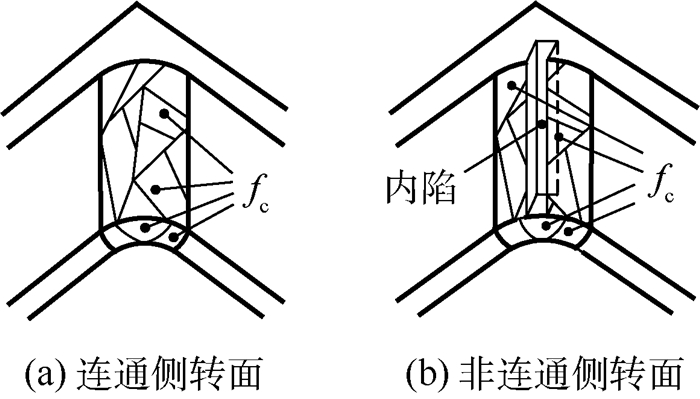

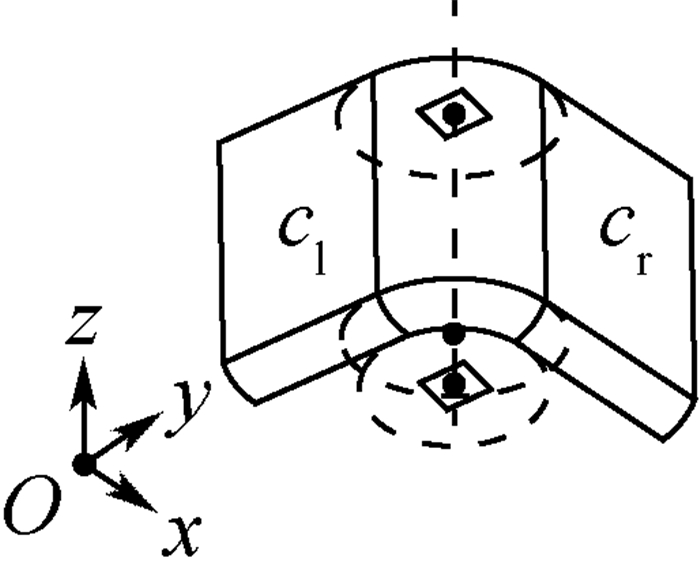

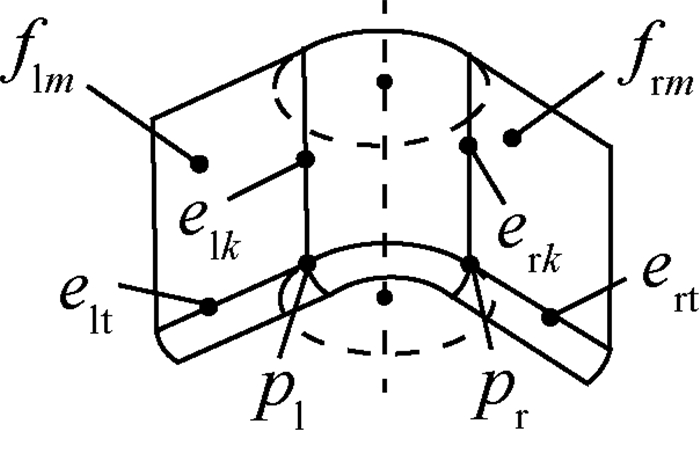

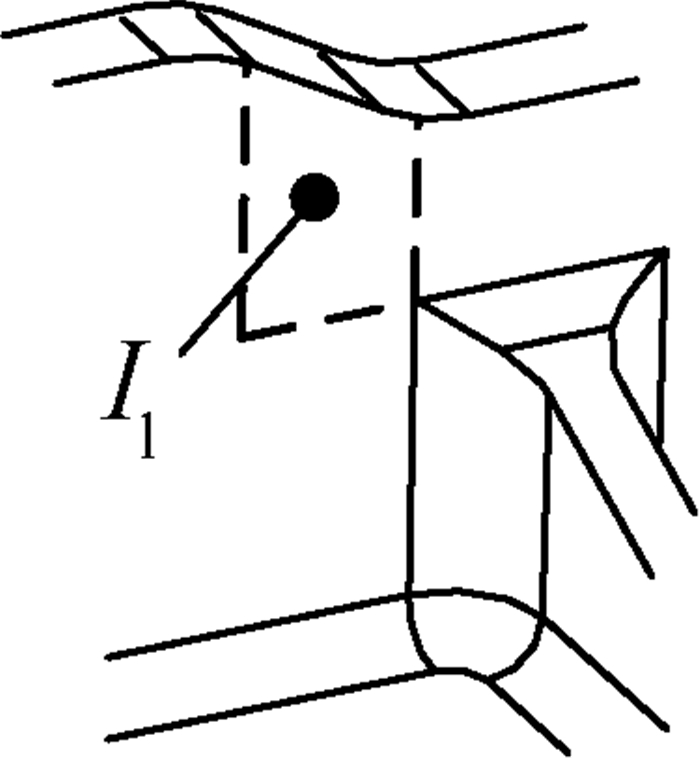

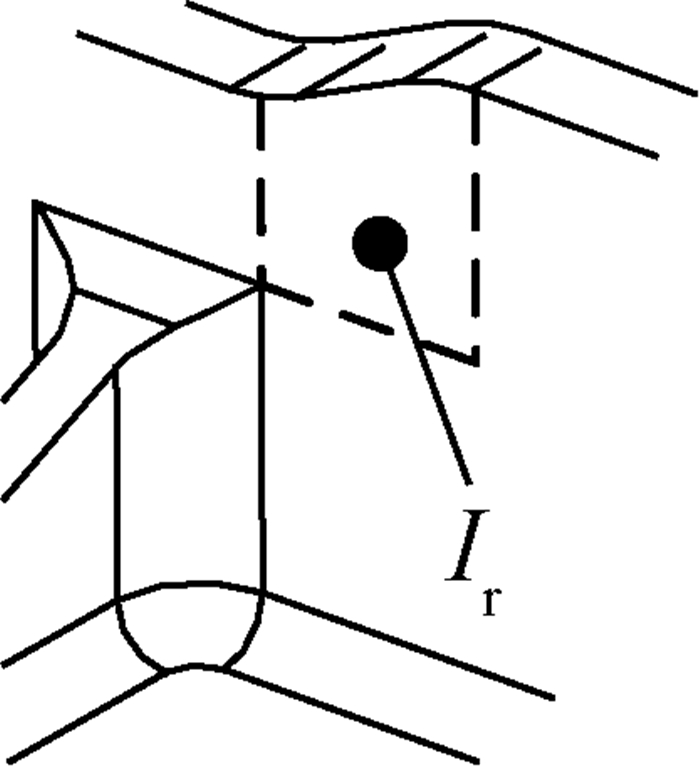

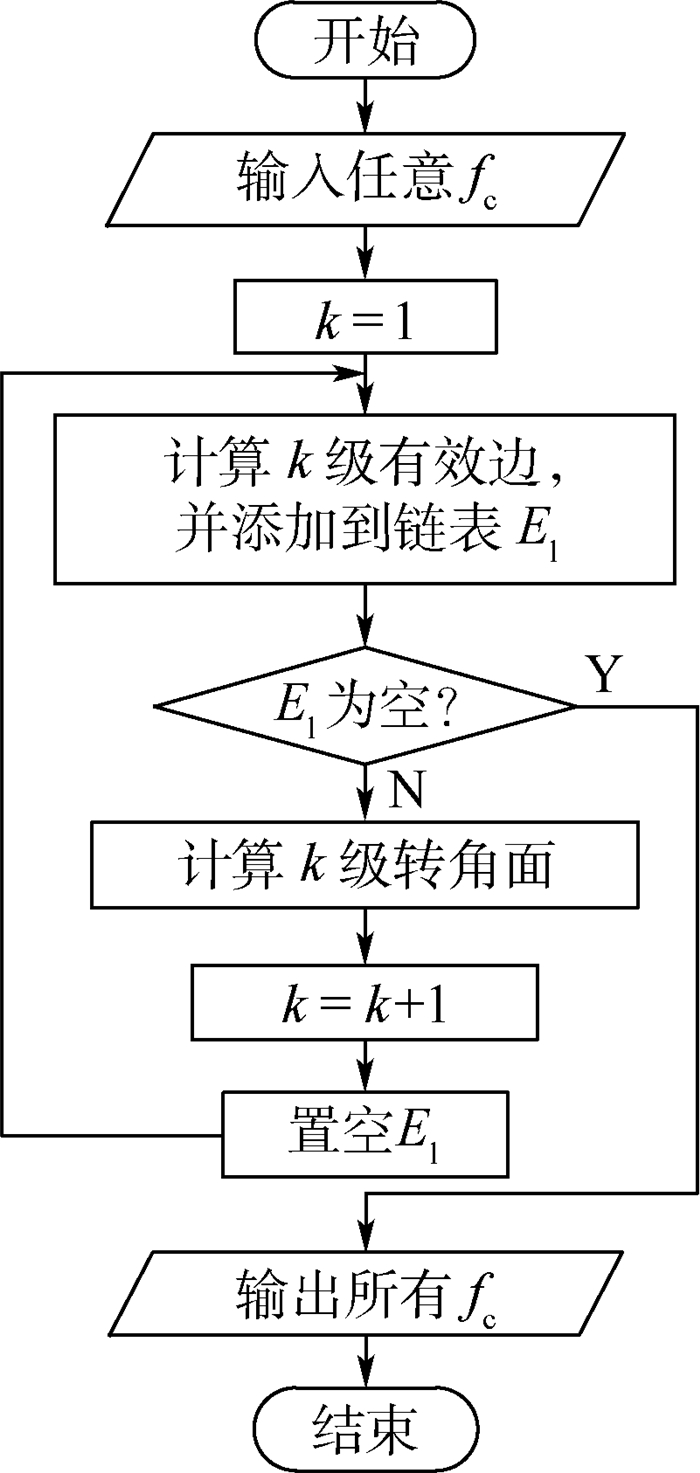

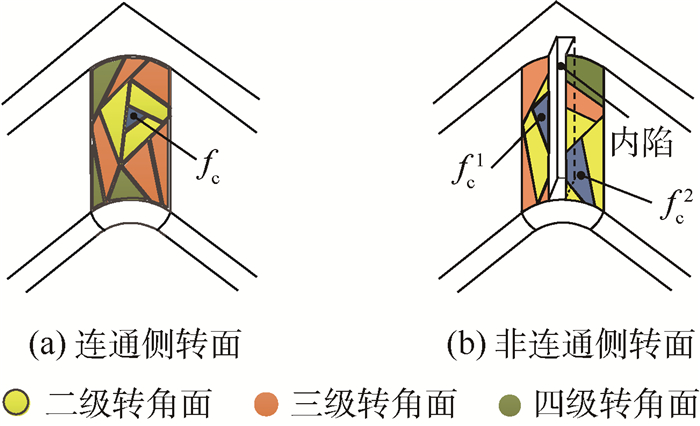

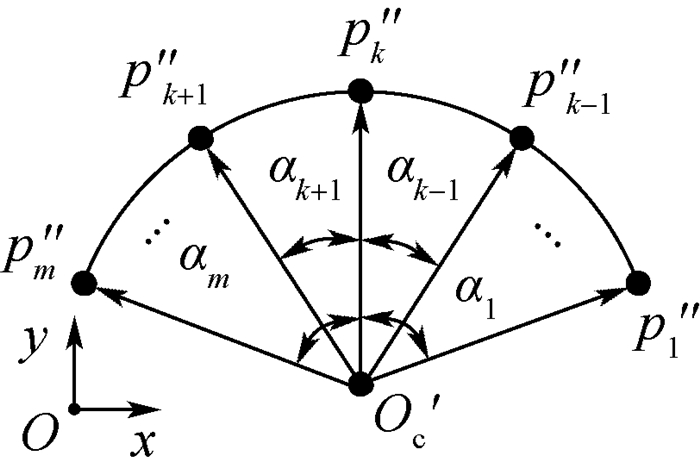

针对飞机结构件转角数控(NC)加工编程效率低、工作量大、质量不稳定等问题,提出一种基于转角面的自动扩展技术,并结合工艺知识建立加工模型,为实现转角数控加工自动编程技术奠定了基础。首先定义了转角、转角面、转角加工模型及转角加工干涉域等概念;然后给出了自动扩展、侧转面与切元计算、干涉域构建等技术,实现转角加工模型的构建;最后,基于以上研究开发了转角数控加工自动编程系统,并初步应用于某型号飞机结构件的生产,应用结果表明,该技术显著提高了转角数控加工编程的效率和质量,降低了编程工作量。

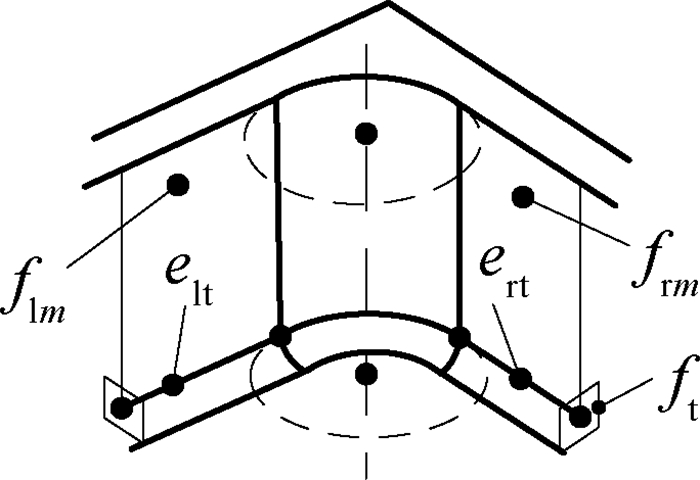

Abstract:Aimed at the problems of inefficiency, heavy work and unstable quality in corner numerical control (NC) programing for aircraft structural parts, a new auto-extended method based on rounded corner face was put forward. Combined with process knowledge, the processing model of corner is set up, which is the key issue of automatic NC programming. First, some new terms were introduced, such as corner, rounded corner face, processing model of corner and interference region of corner machining. Next, in order to set up a model of corner processing, some methods were proposed which include auto-extended technology, side surface of revolution and cutting element computation methods, and interference region building approach. Based on the above research, an automatic NC programing system of corner was developed, which had been successfully applied in a large aviation manufacturing enterprise. The preliminary application shows that the method is valid for increasing efficiency and quality of corner NC programing, which leads to programing workload reduction.

-

表 1 转角特征计算正确率

Table 1. Calculation accuracy of corner feature

类型 tc 正确率/% 连通侧转面 0 98.5 1 98.2 -1 98.2 2 97.5 非连通侧转面 0 97.2 1 96.5 -1 96.5 2 95.1 表 2 转角加工数控编程工作量及耗时对比

Table 2. Workload and time-consumption of corner machining numerical control programing

类型 tc 平均交互次数 平均耗时/s 效率/% 手工 自动 手工 自动 ηt ηw 连通侧转面 0 40 1 120 1 99.2 97.5 1 60 1 180 1 99.4 98.3 -1 60 1 180 1 99.4 98.3 2 70 1 240 1 99.6 98.6 非连通侧转面 0 40 3 120 2 98.3 92.5 1 60 3 180 2 98.9 95.0 -1 60 3 180 2 98.9 95.0 2 70 3 240 2 99.2 95.7 -

[1] CHEN S L, ZHENG G L, ZHOU M, et al.Process-scheme-driven automatic construction of NC machining cell for aircraft structural parts[J].Chinese Journal of Aeronautics, 2013, 26(5):1324-1335. doi: 10.1016/j.cja.2013.07.035 [2] 施建飞, 李迎光, 刘旭, 等.基于属性边点图的飞机结构件筋特征识别方法[J].计算机集成制造系统, 2014, 20(3):521-529. http://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ201403009.htmSHI J F, LI Y G, LIU X, et al.Rib feature recognition method for aircraft structural parts based on vertex attributed adjacency graph[J].Computer Integrated Manufacturing Systems, 2014, 20(3):521-529(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ201403009.htm [3] 高鑫, 李迎光, 张臣, 等.飞机结构件内型转角一体加工刀轨生成方法[J].航空学报, 2014, 35(9):2660-2671. http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201409030.htmGAO X, LI Y G, ZHANG C, et al.An integrated machining tool path generation method for corner and profile of aircraft structural parts[J].Acta Aeronautica et Astronautica Sinica, 2014, 35(9):2660-2671(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201409030.htm [4] TOLOUEI-RAD G M, PAYEGANEH G.A hybrid approach to automatic generation of NC programs[J].Journal of Achievements in Materials and Manufacturing Engineering, 2005, 14(1-2):83-89. [5] HAN J H, PRATT M, REGLI W C.Manufacturing feature recognition from solid models:A status report[J].IEEE Transactions on Robotics, 2000, 16(6):782-796. doi: 10.1109/70.897789 [6] HENDERSON M R, ANDERSON D C.Computer recognition and extraction of form features:ACAD/CAM link[J].Computers in Industry, 1984, 5(4):329-339. doi: 10.1016/0166-3615(84)90056-3 [7] JOSHI S, CHANG T C.Graph-based heuristics for recognition of machined features from a 3D solid model[J].Computer-Aided Design, 1988, 20(2):58-66. doi: 10.1016/0010-4485(88)90050-4 [8] 刘雪梅, 张树生, 崔卫卫, 等.逆向工程中基于属性邻接图的加工特征识别[J].计算机集成制造系统, 2008, 14(6):1162-1167. http://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ200806018.htmLIU X M, ZHANG S S, CUI W W, et al.Machined features recognition based on attributed adjacency graph in reverse engineering[J].Computer Integrated Manufacturing Systems, 2008, 14(6):1162-1167(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ200806018.htm [9] VANDENBRANDE J H, REQUICHA A A G.Spatial reasoning for the automatic recognition of machinable features in solid models[J].IEEE Transactions on Transacitions on Pattern Analysis & Machine Intelligence, 1993, 15(12):1269-1285. [10] TSENG Y J, JOSHI S B.Recognition of interacting rotational and prismatic machining features from 3D mill-turn parts[J].International Journal of Production Research, 1998, 36(11):3147-3165. doi: 10.1080/002075498192346 [11] WOO T C.Feature extraction by volume decomposition[C]//Proceedings CAD/CAM Technology in Mechanical Engineering.Cambridge:MIT, 1982:76-94. [12] SAKURAI H, DAVE P.Volume decomposition and feature recognition, Part Ⅱ:Curved objects[J].Computer-Aided Design, 1996, 28(6-7):519-537. doi: 10.1016/0010-4485(95)00067-4 [13] SHEEN B T, YOU C F.Machining feature recognition and tool-path generation for 3-axis CNC milling[J].Computer-Aided Design, 2006, 38(6):553-562. doi: 10.1016/j.cad.2005.05.003 [14] YU F F, DU B, REN W, et al.Slicing recognition of aircraft integral panel generalized pocket[J].Chinese Journal of Aeronautics, 2008, 21(6):585-592. doi: 10.1016/S1000-9361(08)60178-8 [15] ZHOU G, LI Y, LIU C, et al.A feature-based automatic broken surfaces fitting method for complex aircraft skin parts[J].International Journal of Advanced Manufacturing Technology, 2015, 84(5-8):1001-1011. [16] WANG C C L, ELBER G.Multi-dimensional dynamic programming in ruled surface fitting[J].Computer-Aided Design, 2014, 51(6):39-49. [17] 任朴林, 周来水, 安鲁陵, 等.基于散乱数据截面线的曲面重构算法研究[J].机械设计与制造工程, 2003, 32(3):82-85. http://www.cnki.com.cn/Article/CJFDTOTAL-JSYZ200606020.htmREN P L, ZHOU L S, AN L L, et al.A surface reconstruction algorithm based on planar contours of discrete data[J].Machine Design and Manufacturing Engineering, 2003, 32(3):82-85(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JSYZ200606020.htm 期刊类型引用(5)

1. 景凤,郭婧娟. 基于BIM的高铁工程量清单EBS\WBS研究. 铁道标准设计. 2020(02): 68-74 .  百度学术

百度学术2. 周泽鑫,孙志强,徐冰,洪扬. 空间光学遥感器真空热试验工装模块化设计. 北京航空航天大学学报. 2019(08): 1544-1551 .  本站查看

本站查看3. 张秋雁,张俊玮,丛中笑,宋锡强,曾招辉,王忠义. 符合智能制造硬件要求的积木式单相智能电能表设计研究. 自动化与仪器仪表. 2018(06): 37-40 .  百度学术

百度学术4. 田启华,梅月媛,杜义贤,周祥曼. 基于聚类分析的大容量耦合设计任务规划的研究. 中国机械工程. 2018(05): 544-551 .  百度学术

百度学术5. 刘航,何铭鑫,聂仕麟. 基于模块化技术的复杂产品融合设计方案研究——以斯特林发动机为例. 管理工程师. 2017(06): 28-31 .  百度学术

百度学术其他类型引用(11)

-

下载:

下载:

百度学术

百度学术