-

摘要:

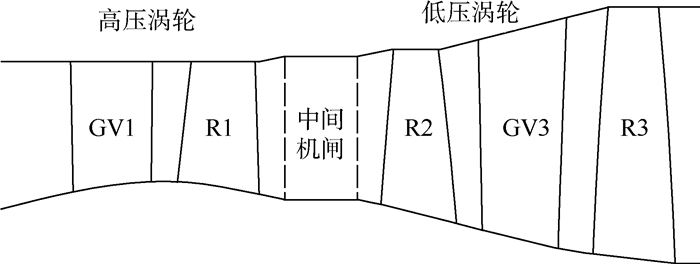

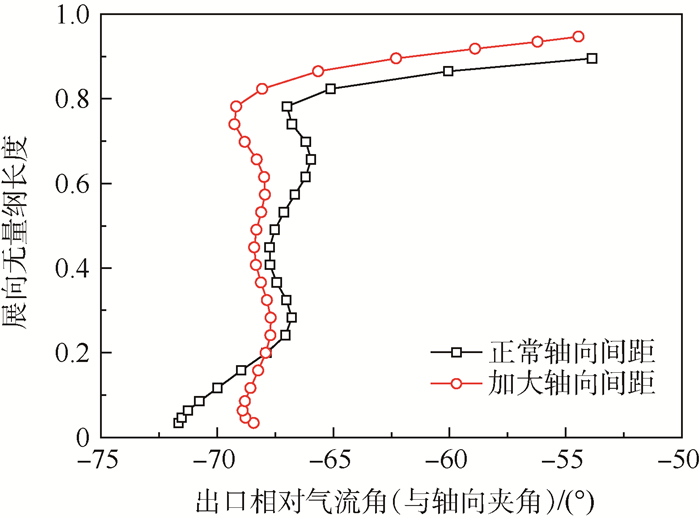

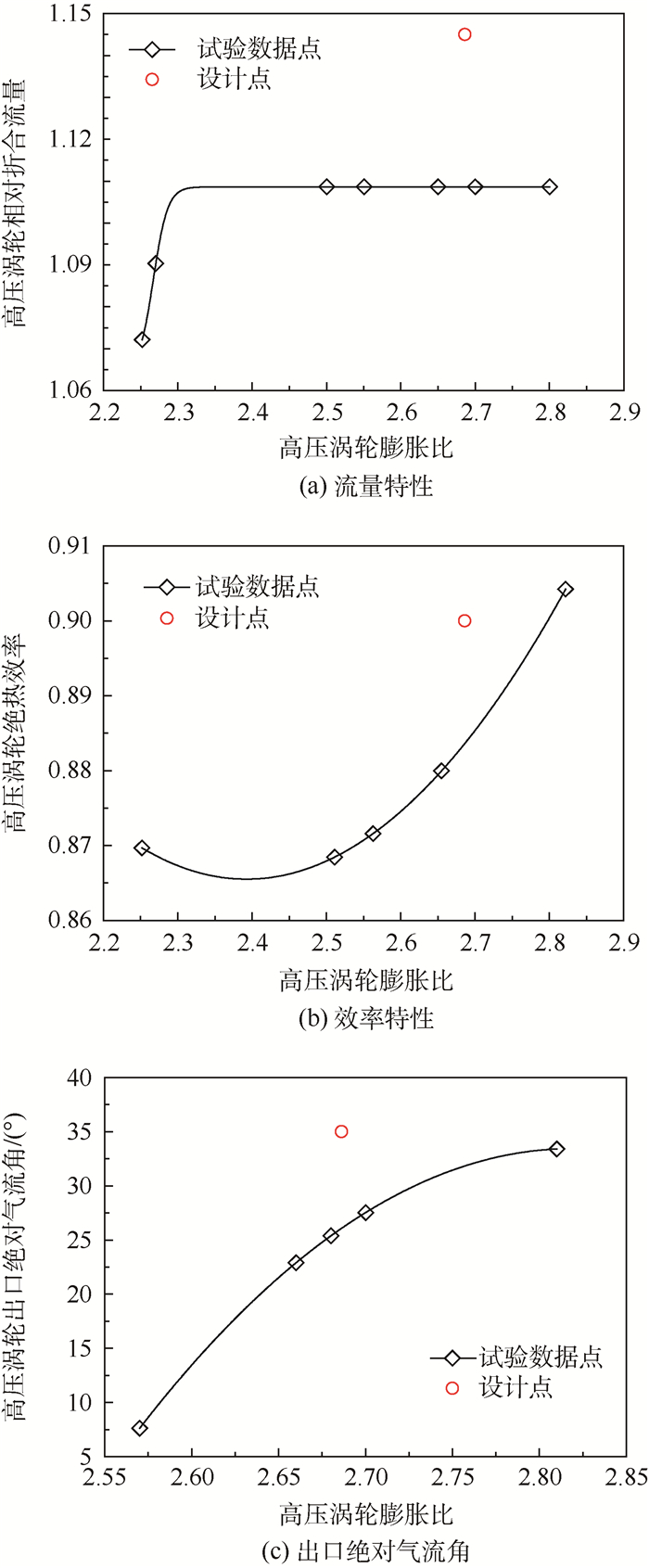

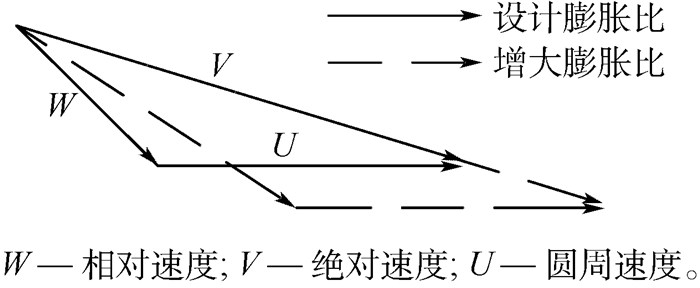

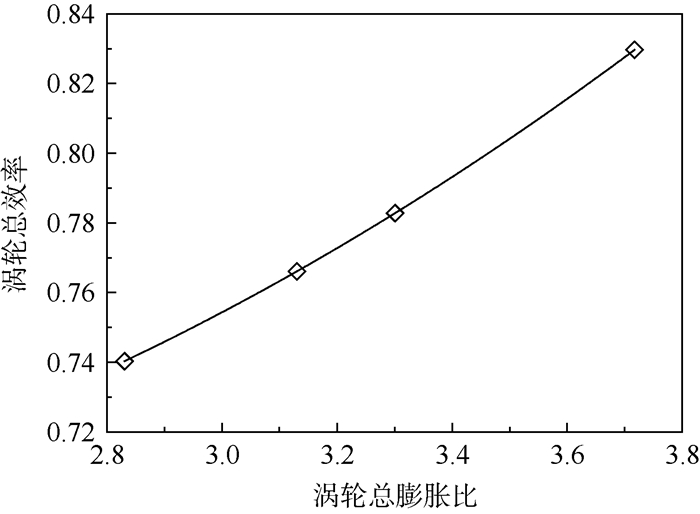

无导叶对转涡轮是高性能发动机的关键技术之一。本文采用试验方法对1+ 3/2级对转涡轮进行了气动性能研究。本试验分为3个阶段,第1阶段为单独高压涡轮(HPT)试验,第2阶段为加大HPT和低压涡轮(LPT)间轴向间距联合试验,第3阶段为HPT和LPT间正常轴向间距联合试验。在正常轴向间距HPT和LPT试验中,LPT状态的确定通过利用单独HPT试验获得的效率与压比特性反推获得。试验表明,HPT喉道面积减小,而LPT喉道面积增大,这导致在总膨胀比一定情况下,HPT膨胀比增大,LPT膨胀比下降,同时LPT的存在对HPT特性影响不大。在总膨胀比分配中,HPT膨胀比变化很小,而LPT膨胀比变化范围较宽。涡轮级总效率由HPT决定,LPT轮一般相对较低,加大HPT和LPT间轴向间距对LPT性能影响很小。

Abstract:Vaneless contra-rotating turbine is one of the key technologies of the high performance engine. Experimental research was conducted to investigate aerodynamic performance of 1+3/2 contra-rotating turbine. The experiment was tested over three phases:first the alone high pressure turbine (HPT) experiment, second the HPT and low pressure turbine (LPT) with axial gap enlarging between them, and finally HPT and LPT with normal axial gap. In the normal gap experiment, the condition of LPT was confirmed by HPT performance curve by converse calculation. Research shows that LPT has little effect on HPT performance; HPT throat decreases while LPT throat increases, which leads to HPT expansion ratio increasing at the constant total expansion ratio. HPT expansion ratio changes very little during the total expansion ratio varying; however LPT expansion ratio changes greatly. The turbine efficiency is mainly determined by HPT, and the LPT is generally relative low. Enlarging axial gap between HPT and LPT has little influence on LPT performance.

-

表 1 原型涡轮设计参数

Table 1. Design parameters of original turbine

参数 数值 高压涡轮 低压涡轮 折合转速/(r·min-1·

352.3 274.5 折合流量/(kg·s-1·

1.23 3.49 折合功/(J·K-1) 245.5 180.9 总对总绝热效率 0.90 0.89 膨胀比 2.686 2 2.088 8 -

[1] 方昌德.美国航空推进系统关键技术[J].燃气涡轮试验与研究, 2001, 14(3):1-6. http://www.cnki.com.cn/Article/CJFDTOTAL-RQWL200103000.htmFANG C D.Key technologies of American aviation propulsion systems[J].Gas Turbine Experiment and Research, 2001, 14(3):1-6(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-RQWL200103000.htm [2] KAUSER F B.An overview of gas turbine propulsion technology:AIAA-1994-2828[R].Reston:AIAA, 1994. [3] MACLIN H, KRAUSE F.Propulsion technology for future commercial aircraft:AIAA-2003-2544[R].Reston:AIAA, 2003. [4] 蔡睿贤.对转涡轮基本分析[J].航空学报, 1992, 13(1):57-63. http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB199201011.htmCAI R X.Basic analysis of counter-rotating turbines[J].Acta Aeronautica et Astronautica Sinica, 1992, 13(1):57-63(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB199201011.htm [5] 蔡睿贤.有关对转涡轮基本设计与应用的进一步思考[J].航空动力学报, 2001, 16(3):193-198. http://www.cnki.com.cn/Article/CJFDTOTAL-HKDI200103000.htmCAI R X.Consideration on the basic design and application of counter-rotating turbines[J].Journal of Aerospace Power, 2001, 16(3):193-198(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKDI200103000.htm [6] 季路成.1+3/2对转涡轮基本分析[C]//中国工程热物理学会热机气动力学学术会议.北京:中国工程热物理学会, 2006:476-484.JI L C.Basic analysis on 1+3/2 counter-rotating turbines[C]//Proceedings of Engineering Thermophysics.Beijng:Chinese Society of Engineering Thermophysics, 2006:476-484(in Chinese). [7] 季路成.1+3/2与1+1/2对转涡轮对比分析[J].工程热物理学报, 2007, 28(增刊1):113-116.JI L C.Basic analysis on 1+3/2 and 1+1/2 counter-rotating turbines[J].Journal of Engineering Thermophysics, 2007, 28(Suppl.1):113-116(in Chinese). [8] 季路成.对转涡轮研究的回顾与展望[J].航空发动机, 2006, 32(4):49-53. http://www.cnki.com.cn/Article/CJFDTOTAL-HKFJ200604017.htmJI L C.Review and prospect on research of counter-rotating turbine[J] Aeroengine, 2006, 32(4):49-53(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKFJ200604017.htm [9] 季路成, 邵卫卫, 王宝臣.一种对转涡轮性能基本分析[J].推进技术, 2008, 29(1):62-66. http://www.cnki.com.cn/Article/CJFDTOTAL-TJJS200801014.htmJI L C, SHAO W W, WANG B C. Basic analysis of a counter-rotating turbine[J].Journal of Propulsion Tecnology, 2008, 29(1):62-66(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-TJJS200801014.htm [10] 陈云, 胡松岩, 王雷.1+3/2无导叶对转涡轮设计特点分析[J].航空发动机, 2011, 37(4):20-23.CHEN Y, HU S Y, WANG L.Analysis of design characteristics for 1+3/2 vaneless counter-rotating turbine[J].Aeroengine, 2011, 37(4):20-23(in Chinese). [11] GUENETTE G.Turbine aerodynamic performance measurements in short duration facilities:AIAA-1989-2690[R].Reston:AIAA, 1989. [12] ATKINS N R, MILLER R J, AINSWORTH R W.Aerodynamic performance measurements in a transient turbine test facility[C]//The 16th Symposium on Measuring Techniques in Transonic and Supersonic Flow in Cascades and Turbomachines.Oxford:Oxford University, 2005:1-12. [13] KEOGH R C, GUENETTE G R, SOMMER T P.Aerodynamic performance measurements of a fully-scaled turbine in a short duration facility[C]//ASME Turbo Expo 2000:Power for Land, Sea, and Air.New York:ASME, 2000:1-12. [14] HALDEMAN C J.Uncertainty analysis of turbine aerodynamic performance measurementsin short duration test facilities:AIAA-1991-2131[R].Reston:AIAA, 1991. [15] 唐菲, 陈党慧, 秦立森, 等.1+1/2对转涡轮短周期试验台性能测试[J].工程热物理学报, 2006, 27(6):944-946.TANG F, CHEN D H, QIN L S, et al.1+1/2 counter-rotating turbine performance measurement of short-duration facility[J].Journal of Engineering Thermophysics, 2006, 27(6):944-946(in Chinese). [16] 刘思永, 王屏, 卢聪明, 等.超跨音对转涡轮试验台[J].航空动力学报, 2002, 17(4):404-406. http://www.cnki.com.cn/Article/CJFDTOTAL-HKDI200204003.htmLIU S Y, WANG P, LU C M, et al.Contra-rotating turbine test rig with transonic-supersonic profiles[J].Journal of Aerospace Power, 2002, 17(4):404-406(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKDI200204003.htm [17] KEITH B D, BASU D K, STEVENS C.Aerodynamic test results of controlled pressure ratio engine (COPE) dual spool air turbine rotating rig[C]//ASME, Turbo Expo 2000:Power for Land, Sea, and Air.New York:ASME, 2000:1-10. [18] NGO V H, MILLAR D A J.Design and performance prediction of axial flow turbines:ME-73-3[R].Ottawa:Carleton University, 1973:27-28. -

下载:

下载: