Optimization method of multi-echelon system equipment configuration under unsteady state and multi-constraint

-

摘要:

针对非稳态及多约束下多层级系统器材配置问题进行了研究。首先,以索马里护航器材利用率非常低为研究背景,给出了基地和中心仓库备件需求率求解方法;其次,运用边际效应法、拉格朗日乘子法求出了3个约束条件的因子值;再次,按是否进行串件拼修或横向供应2种情况,建立了多层级系统器材配置的4个方案;最后,通过案例对比分析了4个方案,可为决策者制定编队平时和战时器材配置方案提供有效的参考依据。

Abstract:Some related questions in system equipment configuration under unsteady state and multi-constraint are discussed. First, taking the very low utilization rate of escort equipment in the waters off Somalia as study background, the paper presents the solution to base and central warehouse spare parts demand rate. Second, the factors of three constraints are calculated by using the edge effect method and Lagrange multiplier method. Then, four projects of multi-echelon system equipment configuration are built according to whether considering the cannibalization or lateral transshipment policy. Finally, the results of four projects are comparatively analyzed, and numerical projects show that an indicative reference can be provided for decision-makers to make up warship formation equipment configuration projects in peace and war time.

-

Key words:

- spare parts /

- warship formation /

- lateral transshipments /

- cannibalization /

- multi-constraint

-

表 1 舰艇编队备件携带方案

Table 1. Warship formation spare parts carrying project

备件携带方案 是否串件拼修 是否横向供应 1 N N 2 N Y 3 Y N 4 Y Y 表 2 备件保障参数信息

Table 2. Information of spare parts support parameters

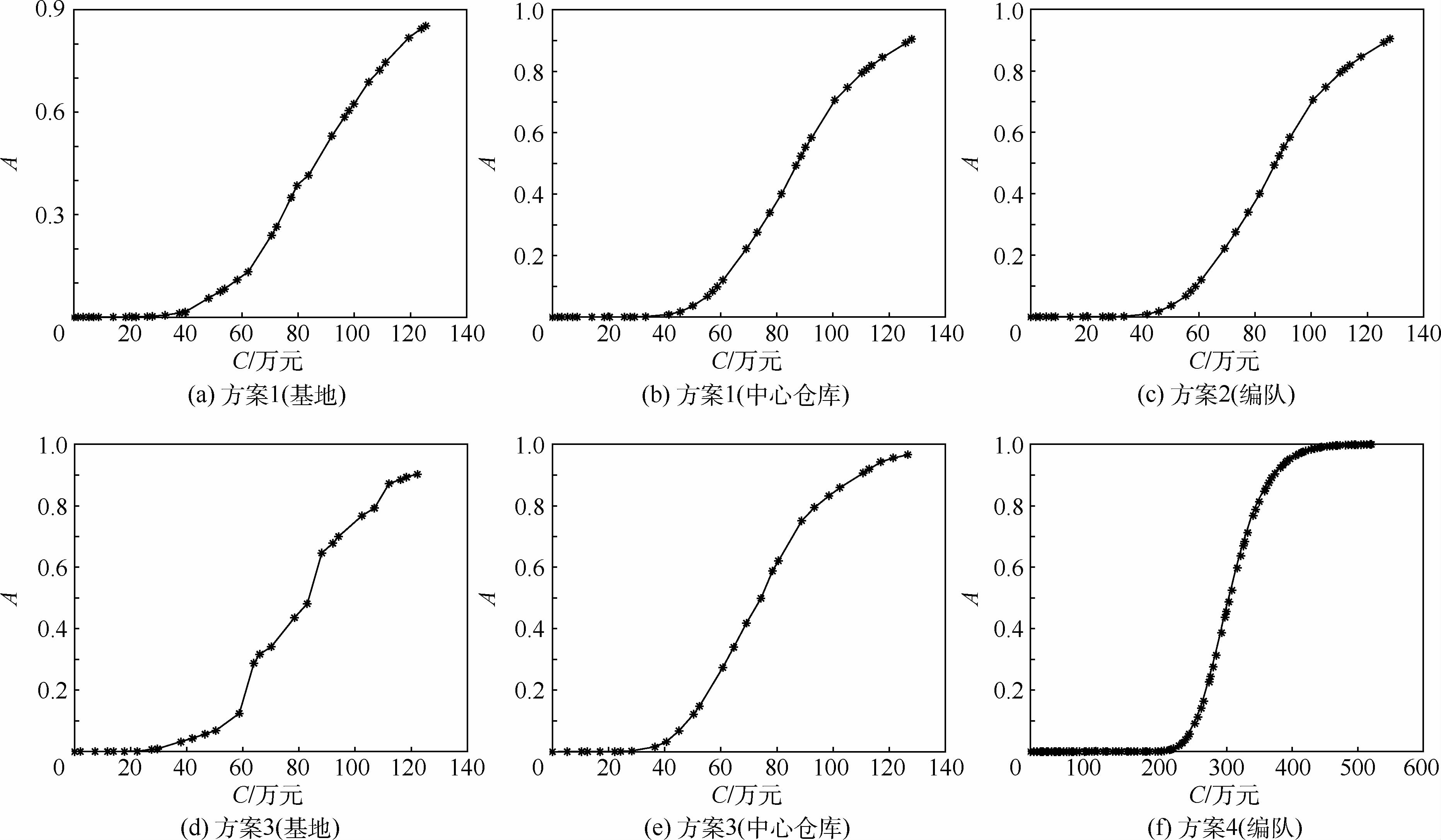

备件 Z MTBF/h C/万元 M/kg V/m3 r1 r2 r3 Tw LRU1 1 998 5.2 28.7 1.8 0.8 0.8 0.8 0.5 LRU2 1 1 617 4.1 12.3 2.1 0.7 0.7 0.7 0.4 LRU3 1 1 053 3.9 6.5 0.9 0.9 0.9 0.9 0.7 LRU4 1 552 8.3 3.7 1.9 0.8 0.8 0.8 0.7 LRU5 1 1 001 2.1 4.2 4.1 0.9 0.9 0.9 0.6 LRU6 1 1 775 4.5 13.6 1.3 0.8 0.8 0.8 0.8 SRU11 1 2 234 1.6 1.9 0.6 0 0 0 0.5 SRU12 1 997 1.8 3.1 0.5 0 0 0 0.5 表 3 费用约束下的4个方案可用度

Table 3. Availability of four projects under cost constraint

方案 保障站点 指标 可用度

A/%站点 编队 C/万元 M/kg V/m3 C/万元 M/kg V/m3 A/% C/万元 M/kg V/m3 1 基地 130 314 54.0 85.24 125.5 289.6 54.8 86.56 504.5 1 176.6 220.2 中心仓库 132 360 55.5 90.43 128.0 307.8 55.8 2 编队 522 1 302 217.5 99.29 516.3 1 205.7 221.2 99.29 516.3 1 205.7 221.2 3 基地 130 314 54.0 90.22 122.2 314.4 57.6 91.82 493.2 1 304.3 229.0 中心仓库 132 360 55.5 96.62 126.6 361.1 56.2 4 编队 522 1 302 217.5 99.94 521.1 1 315.5 232.0 99.94 521.1 1 315.5 232.0 表 4 多约束下的4个方案可用度

Table 4. Availability of four projects under multi-constraint

方案 保障站点 指标 可用度

A/%站点 编队 C/万元 M/kg V/ m3 C/万元 M/kg V/m3 A/% C/万元 M/kg V/m3 1 基地 130 314 54.0 52.62 125.2 288.5 51.2 62.35 505.6 1 181.4 207.4 中心仓库 132 360 55.5 91.54 130.0 315.9 53.8 2 编队 522 1 302 217.5 99.23 515.8 1 201.5 217.1 99.23 515.8 1 201.5 217.1 3 基地 130 314 54.0 59.82 111.0 275.0 50.8 68.76 451.4 1 157.4 206.8 中心仓库 132 360 55.5 95.57 121.4 332.4 54.4 4 编队 522 1 302 217.5 99.85 497.8 1 223.8 216.8 99.85 497.8 1 223.8 216.8 -

[1] SHERBROOKE C C.METRIC:A multi-echelon technique for recoverable item control[J].Operations Research,1968,16(1):122-141. doi: 10.1287/opre.16.1.122 [2] SHERBROOKE C C.Optimal inventory modeling of systems:Multi-echelon techniques[M].Amsterdam:Springer Science & Business Media,2006. [3] LEVNER E,PERLMAN Y,CHENG T C E,et al.A network approach to modeling the multi-echelon spare-part inventory system with backorders and interval-valued demand[J].International Journal of Production Economics,2011,132(1):43-51. doi: 10.1016/j.ijpe.2011.03.004 [4] SAMOUEI P,KHEIRKHAH A S,FATTAHI P.A network approach modeling of multi-echelon spare-part inventory system with backorders and quantity discount[J].Annals of Operations Research,2015,226(1):551-563. doi: 10.1007/s10479-014-1718-z [5] COSTANTINO F,DI GRAVIO G,TRONCI M.Multi-echelon,multi-indenture spare parts inventory control subject to system availability and budget constraints[J].Reliability Engineering & System Safety,2013,119:95-101. [6] TOPAN E,BAYINDIR Z P.Multi-item two-echelon spare parts inventory control problem with batch ordering in the central warehouse under compound Poisson demand[J].Journal of the Operational Research Society,2012,63(8):1143-1152. doi: 10.1057/jors.2011.125 [7] WONG H,VAN HOUTUM G J,CATTRYSSE D,et al.Multi-item spare parts systems with lateral transshipments and waiting time constraints[J].European Journal of Operational Research,2006,171(3):1071-1093. doi: 10.1016/j.ejor.2005.01.018 [8] WONG H,KRANENBURG B,VAN HOUTUM G J,et al.Efficient heuristics for two-echelon spare parts inventory systems with an aggregate mean waiting time constraint per local warehouse[J].OR Spectrum,2007,29(4):699-722. doi: 10.1007/s00291-007-0077-4 [9] WONG H,VAN HOUTUM G J,CATTRYSSE D,et al.Simple,efficient heuristics for multi-item multi-location spare parts systems with lateral transshipments and waiting time constraints[J].Journal of the Operational Research Society,2005,56(12):1419-1430. doi: 10.1057/palgrave.jors.2601952 [10] TOPAN E,BAYINDIR Z P,TAN T.An exact solution procedure for multi-item two-echelon spare parts inventory control problem with batch ordering in the central warehouse[J].Operations Research Letters,2010,38(5):454-461. doi: 10.1016/j.orl.2010.05.006 [11] WONG H,CATTRYSSE D,VAN OUDHEUSDEN D.Inventory pooling of repairable spare parts with non-zero lateral transshipment time and delayed lateral transshipments[J].European Journal of Operational Research,2005,165(1):207-218. doi: 10.1016/j.ejor.2003.09.031 [12] TIACCI L,SAETTA S.Reducing the mean supply delay of spare parts using lateral transshipments policies[J].International Journal of Production Economics,2011,133(1):182-191. doi: 10.1016/j.ijpe.2010.03.020 [13] PATERSON C,KIESMVLLER G,TEUNTER R,et al.Inventory models with lateral transshipments:A review[J].European Journal of Operational Research,2011,210(2):125-136. doi: 10.1016/j.ejor.2010.05.048 [14] FISHER W W.Markov process modelling of a maintenance system with spares,repair,cannibalization and manpower constraints[J].Mathematical and Computer Modelling,1990,13(7):119-125. doi: 10.1016/0895-7177(90)90134-9 [15] EYNAN A.The multi-location inventory centralization problem with first-come,first-served allocation[J].European Journal of Operational Research,1999,114(1):38-49. doi: 10.1016/S0377-2217(98)00036-8 [16] 蔡芝明,金家善,李广波.多约束下随船备件配置优化方法[J].系统工程理论与实践,2015,35(6):1561-1566. http://www.cnki.com.cn/Article/CJFDTOTAL-XTLL201506021.htmCAI Z M,JIN J S,LI G B.Warship spare parts allotment optimization method under multi-constraints[J].Systems Engineering-Theory & Practice,2015,35(6):1561-1566(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-XTLL201506021.htm [17] 刘任洋,李庆民,李华.基于横向转运策略的可修件三级库存优化模型[J].航空学报,2014,35(12):3341-3349. http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201412017.htmLIU R Y,LI Q M,LI H.Optimal model of three-echelon inventory for repairable spare parts with lateral transshipments strategy[J].Acta Aeronautica et Astronatica Sinica,2014,35(12):3341-3349(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201412017.htm [18] LI Y Y.The big data:Check the smart ship time[EB/OL].Beijing:Economic Daily News,2014(2014-10-20)[2016-01-04].http://www.ce.cn/xwzx/gnsz/gdxw/201410/20/t20141020_3730494.shtml. -

下载:

下载: