Wind tunnel test of gust alleviation active control for flying wing configuration aircraft

-

摘要:

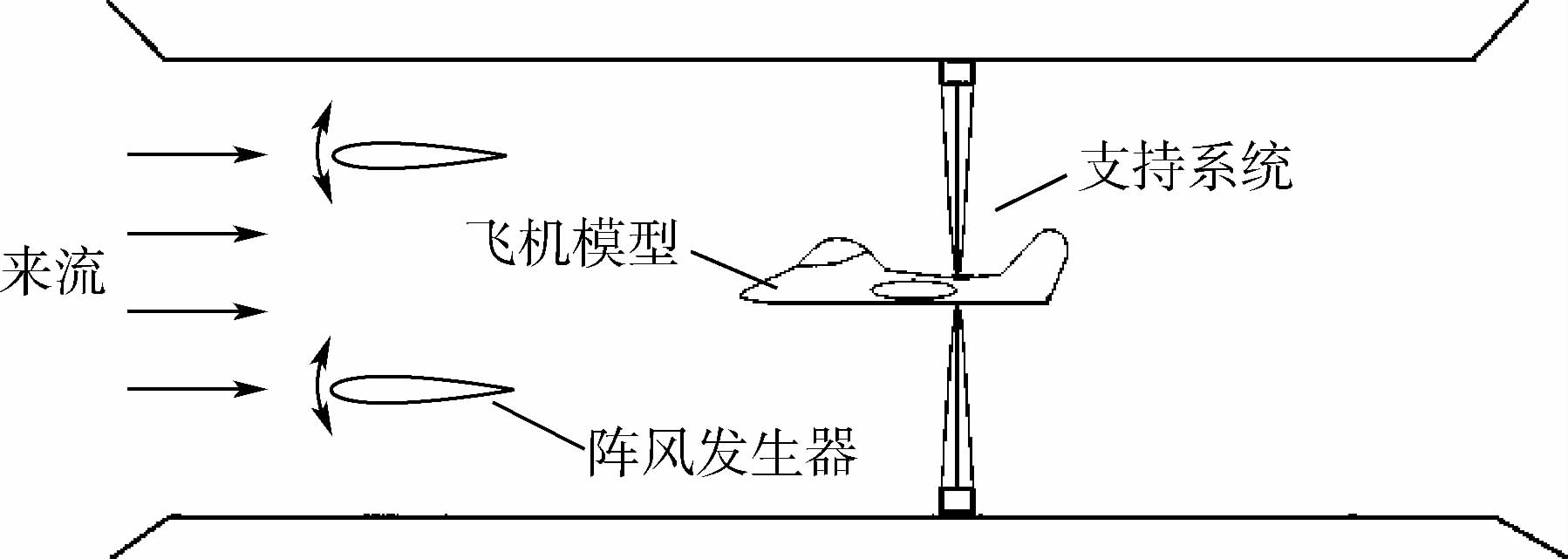

飞翼布局飞机具有优越的隐身和气动特性,但由于布局原因无法配置常规控制面,因此常规布局飞机的阵风减缓控制方法不再适用。针对大展弦比飞翼布局飞机,设计了风洞模型、具有沉浮和俯仰2个方向自由度的支持系统以及能够产生连续正弦阵风的阵风发生器,采用经典控制律理论设计了能够同时减缓翼尖过载和翼根弯矩的3组控制方案,开展了阵风减缓主动控制风洞试验,对开、闭环试验数据进行了分析。试验数据表明,和正常式布局飞机不同,阵风引起的飞翼布局飞机的翼尖过载和翼根弯矩在俯仰模态对应的频率处有一个很大的峰值,而在一弯频率附近峰值比较小;对于不同控制面组合,阵风减缓效果不一样;对于飞翼布局飞机,选用合适的控制面组合可以有效减缓阵风载荷和阵风响应。

Abstract:Flying wing configuration aircraft is advantageous on the characteristics of stealth and aerodynamics, but due to lack of conventional elevator and rudder, gust alleviation control method for the aircraft with conventional configuration is not suitable anymore. For the flying wing configuration aircraft with large aspect ratio, a wind tunnel model, support system with two degrees of freedom of plunging and pitching, and gust generator which is capable of generating continuous sine gust are designed. Three control schemes that can simultaneously reduce wing tip acceleration and wing root bending moment are designed using classical control law theory. Wind tunnel test of gust alleviation active control is conducted and the open and closed loop test data are analyzed. Test data show that the wing tip acceleration and the wing root bending moment due to gust of flying wing aircraft have a large peak at the frequency of pitch mode, while the peak at the frequency of first bending mode is relatively small; for different combinations of control surface, the effects of gust alleviation are different; for flying wing configuration aircraft, selecting the appropriate combination of control surfaces can effectively reduce the gust load and gust response.

-

Key words:

- aeroservoelastic /

- flying wing configuration /

- gust alleviation /

- active control /

- wind tunnel test

-

表 1 模型几何参数

Table 1. Model geometric parameters

项目 参数 翼展/m 0.8 根部弦长/m 0.6 梢部弦长/m 0.2 前缘后掠角/(°) 20 机身后缘前掠角/(°) 57.4 机翼后缘后掠角/(°) 20 翼型 NACA0015 表 2 模态分析

Table 2. Modal analysis

模态阶数 模态描述 频率/Hz 1 沉浮 0 2 俯仰 0 3 一弯 2.56 4 面内一弯 6.88 5 二弯 8.16 6 一扭 27.57 表 3 不同控制方案控制回路组成

Table 3. Contol loop composition of differentcontrol schemes

控制方案 TE1回路 TE3回路 TE4回路 LE回路 1 √ × √ √ 2 √ × √ × 3 √ √ × √ 表 4 3种控制方案在不同频率下的翼尖过载减缓效果

Table 4. Wing tip overload alleviation effect of threecontrol schemes at different frequency

频率/Hz 减缓效果/% 控制方案1 控制方案2 控制方案3 1.2 9.2 46.5 25.6 1.5 10.2 -0.2 35.0 1.8 -10.5 -0.1 19.0 表 5 3种控制方案在不同频率下的翼根弯矩减缓效果

Table 5. Wing root bending moment alleviation effectof three control schemes at different frequency

频率/Hz 减缓效果/% 控制方案1 控制方案2 控制方案3 1.2 4.5 34.6 3.4 1.5 -2.7 -18.4 23.8 1.8 -48.3 -40.0 -11.7 表 6 3种控制方案在不同风速下的翼尖过载减缓效果

Table 6. Wing tip overload alleviation effect of three control schemes at different wind speed

风速/(m·s-1) 减缓效果/% 控制方案1 控制方案2 控制方案3 18 9.2 46.5 25.6 20 25.5 -6.5 56.1 22 55.2 -56.7 59.2 表 7 3种控制方案在不同风速下的翼根弯矩减缓效果

Table 7. Wing root bending moment alleviation effectof three control schemes at different wind speed

风速/(m·s-1) 减缓效果/% 控制方案1 控制方案2 控制方案3 18 4.5 34.6 3.4 20 9.7 -30.0 47.2 22 41.4 -104.5 41.7 -

[1] 金长江, 肖业伦.大气扰动中的飞行原理[M].北京:国防工业出版社,1992:5-7.JIN C J,XIAO Y L.Flight principle in atmosphere turbulence[M].Beijing:National Defence Industry Press,1992:5-7(in Chinese). [2] MCKENZIE J R.B-52 control configured vehicles ride control analysis and flight test:AIAA-1973-782[R].Reston:AIAA, 1973. [3] DISNEY T E.C-5A active load alleviation system[J]. Journal of Spacecraft and Rockets,1977,14(2):81-86. doi: 10.2514/3.57164 [4] WINTHER B A, SHIRLEY W A,HEIMBAUGH R M. Wind-tunnel investigation of active control technology applied to a DC-10 deribative:AIAA-1980-0771[R].Reston:AIAA,1980. [5] KARPEL M,MOULIN B,FELDGUN V.Active alleviation of gust loads using special control surfaces:AIAA-2006-1833[R]. Reston:AIAA,2006. [6] ERIC V, ANTHONY S. Structural modal control and gust load alleviation for a sensor craft concept:AIAA-2005-1946[R]. Reston:AIAA,2005. [7] SCOTT R C, TRAVIS K.Aeroservoelastic testing of a sidewall mounted freeflying wind-tunnel model:AIAA-2008-7186[R]. Reston:AIAA,2008. [8] ERIC R. Aeroservoelastic design and test validation of the joined wing sensorcraft:AIAA-2008-7189[R].Reston:AIAA, 2008. [9] ERIC R, MARK C,BRADLEY S. Joined wing sensorcraft aeroserelastic wind tunnel test program:AIAA-2011-1956[R]. Reston:AIAA,2011. [10] 陈磊,吴志刚,杨超,等.多控制面机翼阵风减缓主动控制与风洞试验验证[J].航空学报,2009,30(12):2250-2256. http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB200912003.htmCHEN L,WU Z G,YANG C,et al.Active control and wind tunnel test verification of multi-contol surfaces wing for gust alleviation[J].Acta Aeronautica et Astronautica Sinica,2009,30(12):2250-2256(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB200912003.htm [11] 陈磊,吴志刚,杨超,等.弹性机翼阵风响应和载荷减缓与风洞试验验证[J].工程力学,2011(6):212-218. http://www.cnki.com.cn/Article/CJFDTOTAL-GCLX201106033.htmCHEN L, WU Z G,YANG C,et al.Gust response,load alleviation and wind-tunnel experiment verification of elastic wing[J].Engineering Mechanics,2011(6):212-218(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-GCLX201106033.htm [12] 吴志刚,陈磊,杨超,等.弹性飞机阵风响应建模与减缓方案设计[J].中国科学:科学技术,2011,41(3):394-402. http://www.cnki.com.cn/Article/CJFDTOTAL-JEXK201103016.htmWU Z G,CHEN L,YANG C,et al.Gust response modeling and alleviation scheme design for an elastic aircraft[J].Science China Technological Sciences, 2011,41(3):394-402(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JEXK201103016.htm [13] 刘伏虎, 马晓平,张子健.飞翼布局无人机阵风减缓主动控制研究[J].机械科学与技术,2015,34(10):1631-1635. http://www.cnki.com.cn/Article/CJFDTOTAL-JXKX201510030.htmLIU F H,MA X P,ZHANG Z J.Active control of gust alleviation for glying wing configuration UAV[J].Mechanical Science and Technology for Aerospace Engineering,2015,34(10):1631-1635(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JXKX201510030.htm [14] WANG L B, SHEN L,CHEN L, et al.Design and analysis of a wind tunnel test model system for gust alleviation of aeroelastic aircraft:AIAA-2012-1469[R].Reston:AIAA,2012. [15] 楚龙飞, 刘晓燕,吴志刚.阵风减缓模型风洞试验的阵风发生器设计与应用[C]//第十一届全国空气弹性学术交流会会议论文集.北京:中国力学学会,2009:187-192.CHU L F, LIU X Y,WU Z G.Design and application of gust generator for gust alleviation wind-tunnel test[C]//The eleventh National Conference on Air Elasticity.Beijing:The Chinese Society of Theoretical and Applied Mechanics,2009:187-192(in Chinese). -

下载:

下载: