Stiffness analysis of a flexible lever magnifying mechanism based on transfer matrix method

-

摘要:

刚度是影响柔性微动机构动态性能和定位精度的重要指标。将工程中的传递矩阵概念引入到刚度分析中,首先根据结构特点将柔性微动机构模块化并将各子单元视为柔性体,全面考虑其轴向、剪切和弯曲等变形,求解各子单元柔性体的传递矩阵,然后通过传递矩阵将各子单元组合,最后根据力平衡建立柔性微动机构输入力和输出位移之间的关系模型。研究结果表明,传递矩阵法由于考虑了各单元的多维度真实变形,因此保证了结果的高精度。同时分析过程不需要求解刚柔单元变形协调方程,而且避免了微动机构全局坐标系的转换,减少了分析计算量。最后应用该方法建立了一种柔性杠杆放大微动机构的刚度模型,与有限元分析结果的对比误差小于6.4%,有效提高了分析精度,为参数设计提供了重要理论依据。

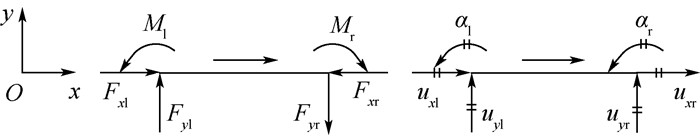

Abstract:Stiffness is an important performance index for the dynamic performance and positioning precision of compliant micromanipulator. Concept of transfer matrix in engineering was applied to the stiffness analysis here. First, according to its structure characteristics, the compliant micromanipulator was modularized and each unit was treated as flexible body. Taking axial, shear and bending deformation into consideration, we solved transfer matrix of the subunit. Then each unit was assembled through the transfer matrix. Finally, relational model between input force and output displacement of compliant micromanipulator was established according to the force balance. The research result indicates that because multi-dimensional real deformation of each unit was taken into consideration, high-precision result was guaranteed. At the same time, the deformation compatibility equations between flexible and rigid units did not need to be solved during the analysis, and conversion of compliant micromanipulator global coordinate system was avoided. The analysis and computation time was also reduced. A kind of flexible lever magnifying mechanism stiffness model was established with this method. The error is less than 6.4% compared with the result of finite element analysis. The accuracy of analysis is improved effectively, and important theoretical basis is provided for parameter design.

-

表 1 有限元法与传递矩阵法刚度对比

Table 1. Comparison of stiffness between finite element method and transfer matrix method

l5/mm 刚度/(MN·m-1) 误差/% 有限元法 传递矩阵法 50.5 10.931 9 11.618 2 6.278 28 60.5 11.326 9 12.034 7 6.248 46 70.5 12.008 9 12.768 9 6.329 08 80.5 12.903 9 13.273 1 6.348 12 -

[1] 于靖军, 郝广波, 陈贵敏, 等.柔性机构及其应用研究进展[J].机械工程学报, 2015, 51(13):53-68. http://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201513006.htmYU J J, HAO G B, CHEN G M, et al.State-of-art of compliant mechanisms and their applications[J].Journal of Mechanical Engineering, 2015, 51(13):53-68(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201513006.htm [2] 宫金良, 裴童, 张彦斐.面向高精度放大比的微动机构设计与实现[J].北京理工大学学报, 2015, 35(7):691-696. http://www.cnki.com.cn/Article/CJFDTOTAL-BJLG201507007.htmGONG J L, PEI T, ZHANG Y F.Parameter design method of micro-motion mechanism targeting for precise displacement amplification ratio[J].Transactions of Beijing Institute of Technology, 2015, 35(7):691-696(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-BJLG201507007.htm [3] 赵荣丽, 陈新, 李克天.双柔性平行六连杆微动平台结构的设计及测试[J].光学精密工程, 2015, 23(10):2860-2869. http://www.cnki.com.cn/Article/CJFDTOTAL-GXJM201510017.htmZHAO R L, CHEN X, LI K T.Design and experiments of micro motion platform based on a pair of flexible parallel six-bar linkages[J].Optics and Precision Engineering, 2015, 23(10):2860-2869(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-GXJM201510017.htm [4] HAO G B, KONG X W.A novel large-range XY compliant parallel manipulator with enhanced out-of-plane stiffness[J].Journal of Mechanical Design, 2012, 134(6):061009. doi: 10.1115/1.4006653 [5] SARAJILIC E, YAMAHATA C, CORDERO M, et al.Three-phase electrostatic rotary stepper micromotor with a flexural pivot bearing[J].Journal of Microelectromechanical System, 2012, 19(2):338-349. https://www.researchgate.net/publication/224116279_Three-Phase_Electrostatic_Rotary_Stepper_Micromotor_With_a_Flexural_Pivot_Bearing [6] 陈兴林, 刘川, 刘杨, 等.精密运动平台宏微控制系统的设计[J].中南大学学报 (自然科学版), 2013, 44(6):2318-2323. http://www.cnki.com.cn/Article/CJFDTOTAL-ZDHJ201506002.htmCHEN X L, LIU C, LIU Y, et al.Dual-stage actuator control system design for precision motion platform[J]. Journal of Central South University (Science and Technology), 2013, 44(6):2318-2323(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-ZDHJ201506002.htm [7] 胡俊峰, 徐贵阳, 郝亚州.一种新型空间微操作平台的设计和性能[J].机械设计与研究, 2014, 30(1):42-46. http://www.cnki.com.cn/Article/CJFDTOTAL-JSYY201401017.htmHU J F, XU G Y, HAO Y Z.Design and characteristics of a novel spatial micro-manipulation stage[J].Machine Design and Research, 2014, 30(1):42-46(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JSYY201401017.htm [8] YU J J, HU Y D, BI S S, et al.Kinematics feature analysis of a 3 DOF in-parallel compliant mechanism for micro manipulation[J].Chinese Journal of Mechanical Engineering, 2004, 17(1):127-131. doi: 10.3901/CJME.2004.01.127 [9] YU Y Q, FENG Z L, XU Q P.A pseudo-rigid-body 2R model of flexural beam in compliant mechanisms[J].Mechanism and Machine Theory, 2012, 55(9):19-33. http://www.sciencedirect.com/science/article/pii/S0094114X12000948 [10] 邱丽芳, 霍明磊, 李威.六杆柔顺机构的伪刚体模型[J].北京科技大学学报, 2013, 35(5):682-686. http://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201305020.htmQIU L F, HUO M L, LI W.Pseudo-rigid-body model of a six-bar full-compliant mechanism[J].Journal of University of Science and Technology Beijing, 2013, 35(5):682-686(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201305020.htm [11] 李茜, 余跃庆, 常星.基于2R伪刚体模型的柔顺机构动力学建模及特性分析[J].机械工程学报, 2012, 48(13):40-48. http://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201213008.htmLI Q, YU Y Q, CHANG X.Dynamic modeling and analysis of compliant mechanisms based on 2R pseudo-rigid-body model[J].Journal of Mechanical Engineering, 2012, 48(13):40-48(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201213008.htm [12] 于靖军, 毕树生, 宗光华.空间全柔性机构位置分析的刚度矩阵法[J].北京航空航天大学学报, 2002, 28(3):323-326. http://bhxb.buaa.edu.cn/CN/abstract/abstract10852.shtmlYU J J, BI S S, ZONG G H.Stiffness matrix method for displacement analysis of fully spatial compliant mechanisms[J].Journal of Beijing University of Aeronautics and Astronautics, 2002, 28(3):323-326(in Chinese). http://bhxb.buaa.edu.cn/CN/abstract/abstract10852.shtml [13] 艾青林, 黄伟锋, 张洪涛, 等.并联机器人刚度与静力学研究现状与进展[J].力学进展, 2012, 42(5):583-592. doi: 10.6052/1000-0992-11-073AI Q L, HUANG W F, ZHANG H T.Review of stiffness and statics analysis of parallel robot[J]. Advances in Mechanics, 2012, 42(5):583-592(in Chinese). doi: 10.6052/1000-0992-11-073 [14] HOWELL L L, MIDHA A.A method for the design of compliant mechanisms with small-length flexural pivots[J].Transactions of the ASME, Journal of Mechanical Design, 1994, 116(1):280-290. doi: 10.1115/1.2919359 [15] 李青宁.变截面杆元传递矩阵法[J].西安建筑科技大学学报, 2001, 33(1):18-23. http://www.cnki.com.cn/Article/CJFDTOTAL-XAJZ200101004.htmLI Q N.The transfer matrix method of bar elements with variable cross-section[J].Journal of Xi'an University of Architecture & Technology, 2001, 33(1):18-23(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-XAJZ200101004.htm [16] 杨春辉.平行板型柔性移动副的刚度计算及分析[J].现代制造工程, 2013(12):30-33. doi: 10.3969/j.issn.1671-3133.2013.12.008YANG C H.The stiffness design calculation and analysis of parallel plate flexible prismatic pair[J].Modern Manufacturing Engineering, 2013(12):30-33(in Chinese). doi: 10.3969/j.issn.1671-3133.2013.12.008 [17] 吴鹰飞, 周兆英.柔性铰链的设计计算[J].工程力学, 2002, 19(6):136-140. http://www.cnki.com.cn/Article/CJFDTOTAL-GCLX200206026.htmWU Y F, ZHOU Z Y.Design of flexure hinges[J]. Engineering Mechanics, 2002, 19(6):136-140(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-GCLX200206026.htm -

下载:

下载: