Effect of inverse load on critical heat flux of steam-water two-phase flow in a tube

-

摘要:

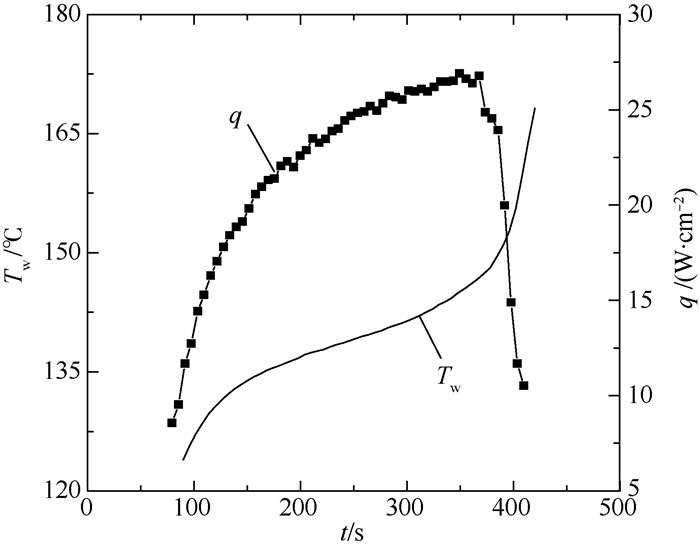

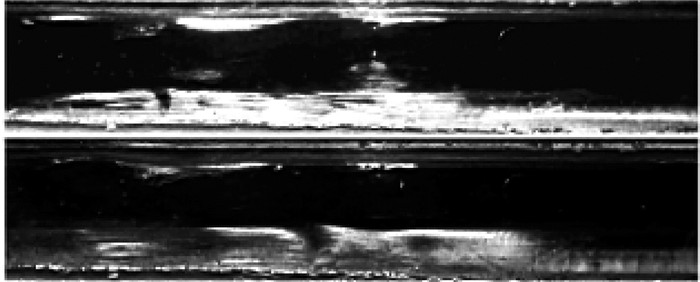

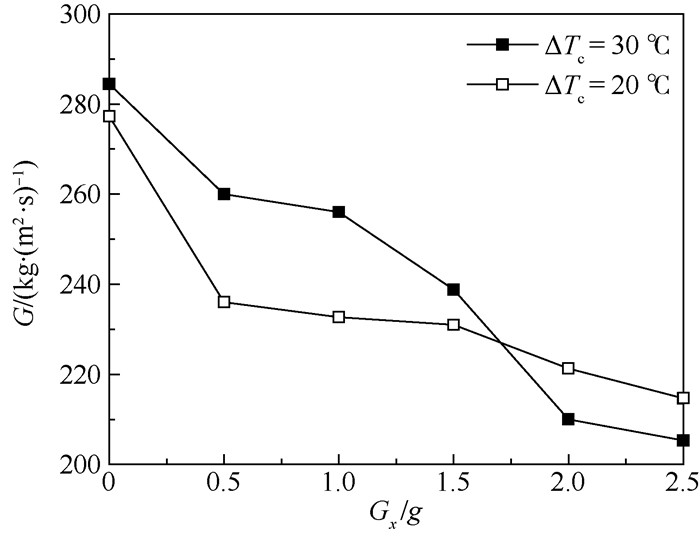

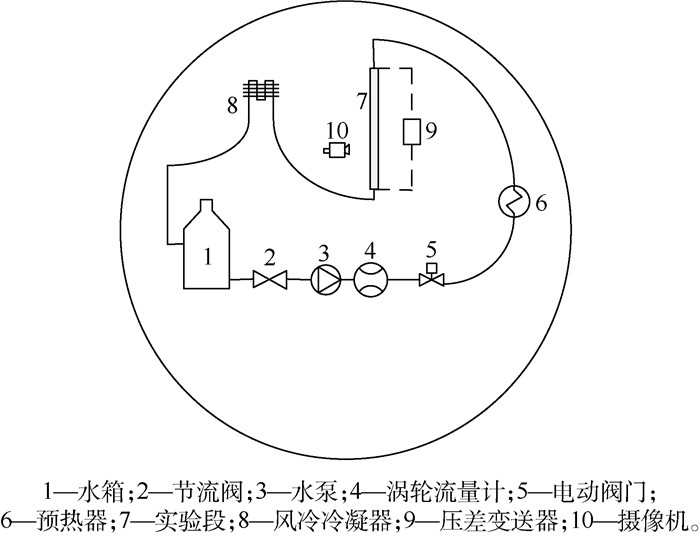

利用旋转平台对逆载作用下矩形通道内汽水两相流临界换热进行了实验研究。通过改变逆载大小、入口流体过冷度、流体质量流速等参数,获得了静止和逆载作用2种状态下矩形管道内汽水两相流临界换热实验数据。实验结果表明,质量流速随着加热时间的增长而减小,进出口压差则反之;临界状态下,质量流速随着逆载、过冷度的增大而减小;进出口压差随着逆载、质量流速的增大而增大,随着过冷度的增大而减小;临界热流密度值随着逆载、质量流速、入口过冷度的增大而增大;其中逆载对临界热流密度的影响最为显著,在逆载从0

g ~2.5g 变换范围内,临界热流密度可提高50%。Abstract:An experimental investigation using a rotating platform was performed to obtain the critical heat transfer performance of steam-water two-phase flow in a rectangle tube under inverse load. By changing the parameters such as magnitude of inverse load, inlet subcooling and mass flow rate, the critical flow and heat transfer data of steam-water two-phase flow boiling under static and inverse load were obtained. The results show that mass flow rate decreases with continuous heating, but the variation of fluid pressure difference in the test section is opposite. At critical state, mass flow rate decreases with increasing inverse load and/or inlet subcooling. Fluid pressure difference increases with increasing inverse load and mass flow rate, and decreases with increasing inlet subcooling. The critical heat flux increases with increasing inverse load, mass flow rate and inlet subcooling. Inverse load greatly impacts critical heat flux. Within its changing range from 0

g to 2.5g , the critical heat flux could be increased by 50%.-

Key words:

- rectangle channel /

- two-phase flow /

- critical heat flux /

- inverse load /

- experimental research

-

表 1 不同逆载下的加速度值

Table 1. Acceleration values under different inverse loads

逆载/g 向心加速度/(m·s-2) 哥氏加速度/(m·s-2) 0 0 0 0.5 4.9 2.0 1.0 9.8 2.5 1.5 14.7 3.9 2.0 19.6 4.1 2.5 24.5 4.6 表 2 主要测量仪器及参数误差

Table 2. Main measuring instruments and parameter errors

测量仪器 量程 精度 参数误差/% 涡轮流量计 0~0.25 m3/h 1.0% 1.1 压力传感器 0~1 MPa 0.5% 0.51 Pt100热电阻 -200~420 ℃ ±0.1 ℃ 0.32 -

[1] DENG D, WAN W, TANG Y, et al.Experimental investigations on flow performance of reentrant and rectangular micro-channels-A comparative study[J].International Journal of Heat and Mass Transfer, 2015, 82:435-446. doi: 10.1016/j.ijheatmasstransfer.2014.11.074 [2] 盛程, 周涛, 琚忠云, 等.矩形通道临界热流密度计算模型的实验评价[J].核动力工程, 2014, 35(1):52-55. http://www.cnki.com.cn/Article/CJFDTOTAL-HDLG201401013.htmCHENG C, ZHOU T, JU Z Y, et al.Experimental evaluation of critical heat flux calculation models of rectangular channel[J].Nuclear Power Engineering, 2014, 35(1):52-55(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HDLG201401013.htm [3] 罗小平, 唐杨.矩形微槽道饱和沸腾临界热流密度特性[J].低温与超导, 2010, 38(6):66-70. http://www.cnki.com.cn/Article/CJFDTOTAL-DWYC201006017.htmLUO X P, TANG Y.Properties of saturated flow boiling critical heat flux through rectangular micro-channel[J].Low Temperature and Superconductivity, 2010, 38(6):66-70(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-DWYC201006017.htm [4] 刘振华, 杨荣华, 秋雨豪.倾斜管内自然对流沸腾临界热流密度的研究[J].航空动力学报, 2004, 19(3):342-345. http://www.cnki.com.cn/Article/CJFDTOTAL-HKDI200403011.htmLIU Z H, YANG R H, QIU Y H, et al.Critical heat flux during natural convection boiling in inclined tubes[J].Journal of Aerospace Power, 2004, 19(3):342-345(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKDI200403011.htm [5] KONISHI C, MUDAWAR I, HASAN M M.Investigation of the influence of orientation on critical heat flux for flow boiling with two-phase inlet[J].International Journal of Heat and Mass Transfer, 2013, 61(6):176-190. [6] ZHANG H, MUDAWAR I, HASAN M M.Experimental and theoretical study of orientation effects on flow boiling CHF[J].International Journal of Heat and Mass Transfer, 2002, 45(22):4463-4477. doi: 10.1016/S0017-9310(02)00152-7 [7] TIBIRICA C B, SZCZUKIEWICZ S, RIBATSKI G, et al.Critical heat flux of R134a and R245fa inside small-diameter tubes[J].Heat Transfer Engineering, 2013, 34(3):492-499. doi: 10.1080/01457632.2012.722457?src=recsys&journalCode=uhte20 [8] 潘杰, 杨冬, 肖荣鸽, 等.低干度流动沸腾临界热流密度预测模型[J].核动力工程, 2013, 34(4):58-63. http://www.cnki.com.cn/Article/CJFDTOTAL-HDLG201304013.htmPAN J, YANG D, XIAO R G, et al.Critical heat flux prediction model for flow boiling of low quality flow boiling[J].Nuclear Power Engineering, 2013, 34(4):58-63(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HDLG201304013.htm [9] 刘腾, 钱吉裕, 孔祥举, 等.低干度两相流工质在矩形流道冷板内的换热特性实验研究[J].西安交通大学学报, 2015, 49(1):59-64. doi: 10.7652/xjtuxb201501010LIU T, QIAN J Y, KONG X J, et al.Experimental study on the heat transfer performance of the low quality two-phase working medium in cool plat evaporation with rectangular channels[J].Journal of Xi'an Jiaotong University, 2015, 49(1):59-64(in Chinese). doi: 10.7652/xjtuxb201501010 [10] 郭亚军, 徐应坤, 毕勤成, 等.竖直方管内两相流动临界热流密度的实验研究[J].西安建筑科技大学学报, 2013, 45(1):126-129. http://www.cnki.com.cn/Article/CJFDTOTAL-XAJZ201301021.htmGUO Y J, XU Y K, BI Q C, et al.Experimental study on critical heat flux of two-phase flow in a vertical square tube[J].Journal of Xi'an University of Architecture and Technology, 2013, 45(1):126-129(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-XAJZ201301021.htm [11] 卢冬华, 黄彦平, 白雪松.高流速下窄矩形通道内临界热流密度试验研究[J].核动力工程, 2004, 25(2):118-122. http://www.cnki.com.cn/Article/CJFDTOTAL-HDLG200402005.htmLU D H, HUANG Y P, BAI X S.Experimental investigation on the critical heat flux of rectangular channel with narrow gap under high mass velocity[J].Nuclear Power Engineering, 2004, 25(2):118-122(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HDLG200402005.htm [12] 李卓, 俞坚, 夏国栋, 等.水平矩形小通道内气-液两相流摩擦压降的研究[J].工程热物理学报, 2006, 27(增刊1):185-188. http://www.cnki.com.cn/Article/CJFDTOTAL-GCRB2006S1049.htmLI Z, YU J, XIA G D, et al.Frictional pressure drop of gas-liquid two-phase flow in small horizontal rectangular channels[J].Journal of Engineering Thermophysics, 2006, 27(Suppl.1):185-188(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-GCRB2006S1049.htm [13] TRAN T N, CHYU M C, WAMBSGANSS M.W.Two-phase pressure drop of refrigerants during flow boiling in small channels:An experimental investigation and correlation development[J].International Journal of Multiphase Flow, 2000, 26(11):1739-1754. doi: 10.1016/S0301-9322(99)00119-6 [14] 庞凤阁, 高璞珍, 王兆祥, 等.摇摆对常压水临界热流密度 (CHF) 影响实验研究[J].核科学与工程, 1997, 17(4):367-372. http://www.cnki.com.cn/Article/CJFDTOTAL-HKXY704.011.htmPANG F G, GAO P Z, WANG Z X, et al.Experimental study on the influence of rolling movement on the critical heat flux (CHF) of atmospheric water[J].Chinese Journal of Nuclear Science and Engineering, 1997, 17(4):367-372(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKXY704.011.htm [15] MA Y, CHUNG J N.An experimental study of critical heat flux in microgravity forced-convection boiling[J].International Journal of Multiphase Flow, 2001, 27(10):1753-1767. doi: 10.1016/S0301-9322(01)00031-3 [16] 姚秋萍, 宋保银, 赵枚.动载对管内汽水两相流流阻、空隙率和传热的影响[J].北京航空航天大学学报, 2010, 36(1):43-47.YAO Q P, SONG B Y, ZHAO M.Effects of dynamic load on flow resistance, void fraction and heat transfer of steam-water two-phase flow in pipes[J].Journal of Beijing University of Aeronautics and Astronautics, 2010, 36(1):43-47(in Chinese). [17] 李冈, 宋保银, 张钊, 等.侧载对矩形通道内水流动特性影响的实验研究[J].制冷与空调, 2015, 29(3):237-242. http://www.cnki.com.cn/Article/CJFDTOTAL-ZLKT201503001.htmLI G, SONG B Y, ZHANG Z, et al.Experimental study of the effect of side load on flow characteristics of water flow in a rectangular channel[J].Refrigeration and Air Conditioning, 2015, 29(3):237-242(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-ZLKT201503001.htm [18] 李冈, 宋保银, 张钊, 等.侧载及加热方位对槽道内临界热流密度影响[J].航空动力学报, 2016, 31(1):203-210. http://www.cnki.com.cn/Article/CJFDTOTAL-HKDI201601027.htmLI G, SONG B Y, ZHANG Z, et al.Influences of side load and heating orientation on critical heat flux in a rectangular groove[J].Journal of Aerospace Power, 2016, 31(1):203-210(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKDI201601027.htm -

下载:

下载: