Effect of seawater wet-dry cycles on mechanical performance of RC beams with initial damage

-

摘要:

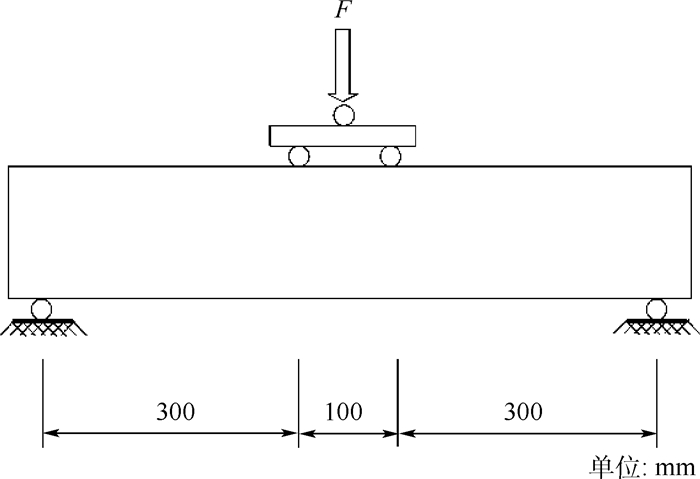

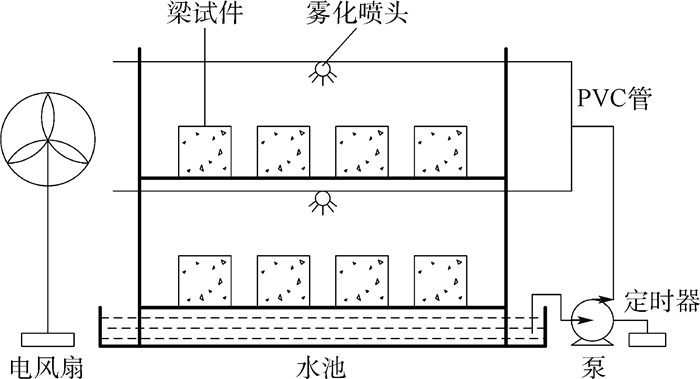

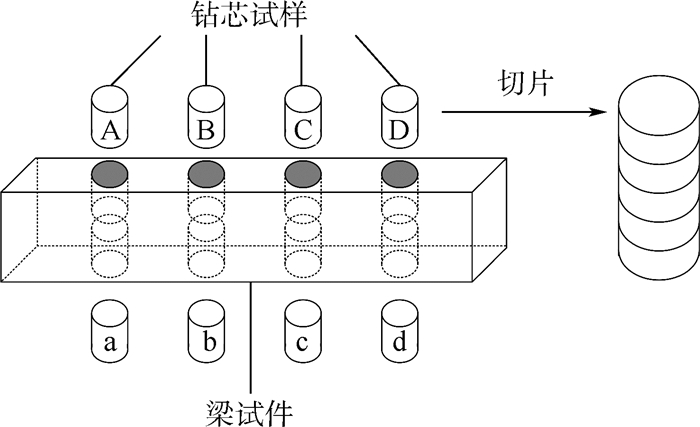

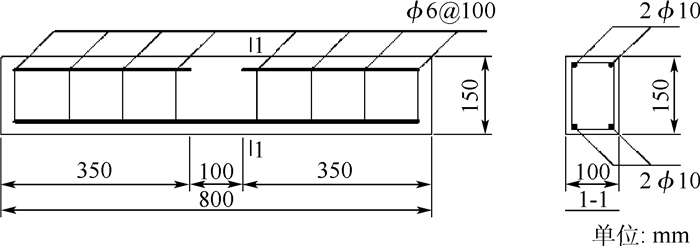

沿海环境下的钢筋混凝土(RC)结构处于荷载作用和环境作用同时存在的工作状态且在正常条件下会出现不同程度的荷载损伤。为了在实验室内模拟其工作状态,对RC梁试件施加幅值分别为0.3

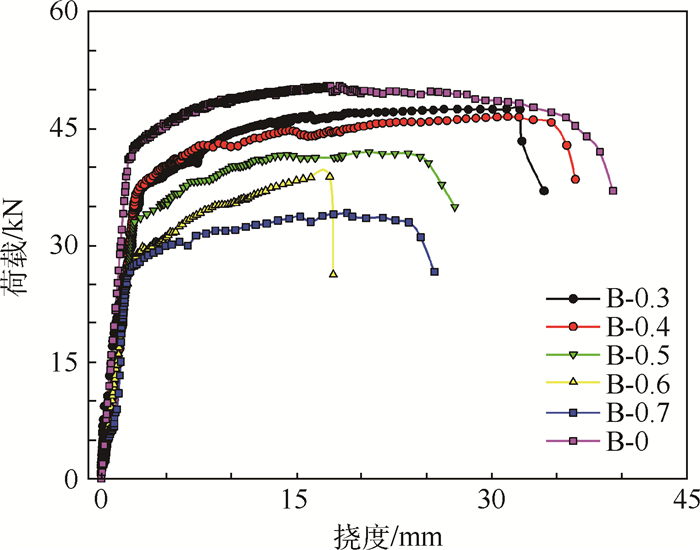

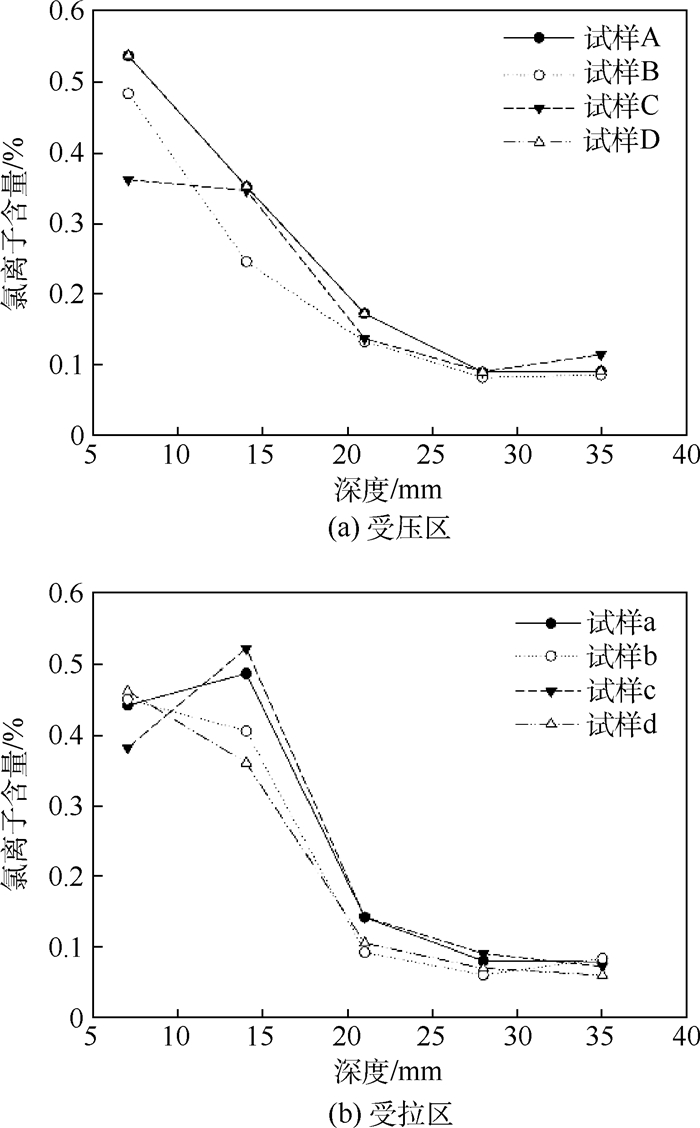

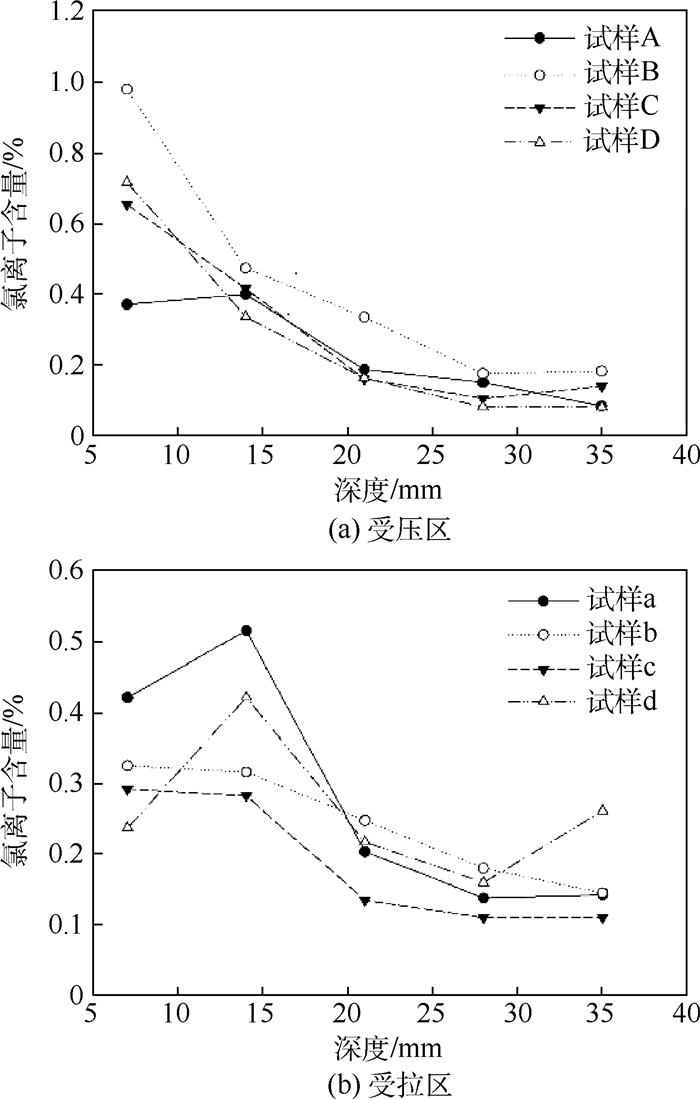

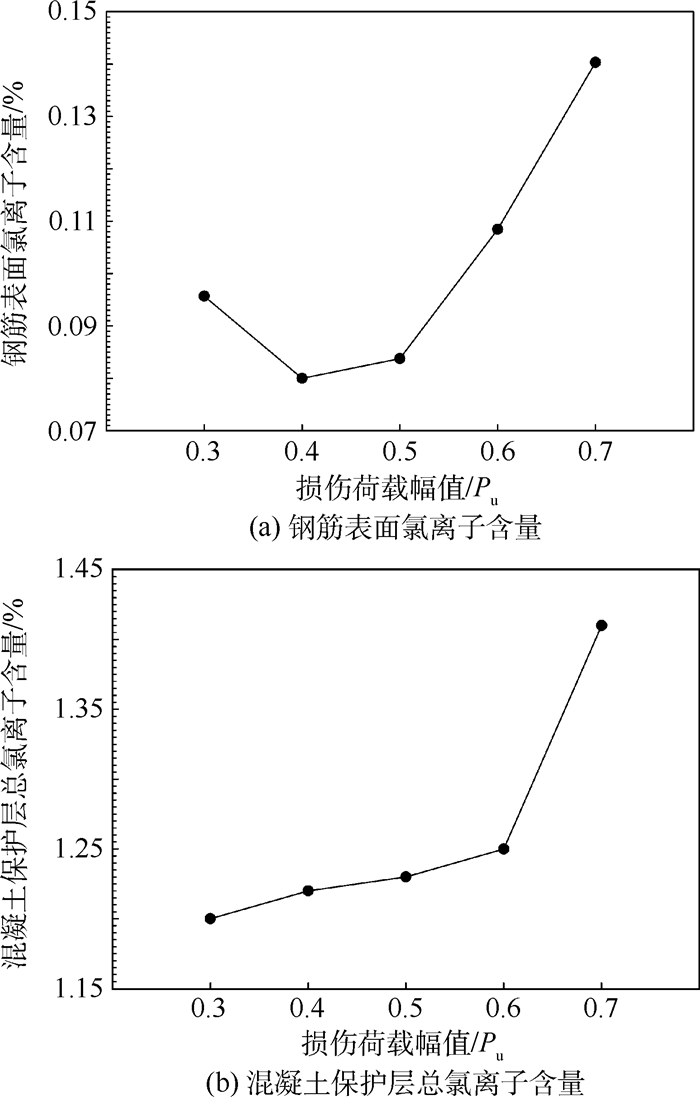

P u、0.4P u、0.5P u、0.6P u和0.7P u(P u为单调加载梁的极限荷载)的初始荷载造成不同程度的损伤,经历120次海水干湿循环作用后,进行单调加载试验测试剩余力学性能,并对梁试件钻芯取样测试不同位置及深度处混凝土的氯离子含量。试验结果表明,不同程度初始损伤RC梁经历120次海水干湿循环后,其屈服荷载、极限荷载和延性均随初始荷载幅值的增加而降低;与无损伤梁试件相比,当初始损伤荷载为0.4P u时,梁试件的屈服荷载和极限荷载降幅分别为10.4%和7.9%,随着初始荷载增大,屈服荷载和极限荷载快速下降,当初始损伤荷载为0.7P u时,屈服荷载和极限荷载降幅分别达33.7%和32.4%。氯离子含量测试结果表明,梁试件混凝土受拉区氯离子含量均大于受压区氯离子含量;当初始损伤荷载小于0.5P u时,受拉钢筋表面混凝土的氯离子含量差别不大且小于0.1%,当初始损伤荷载为0.7P u时, 钢筋表面氯离子含量最大达到0.14%。可见,初始荷载损伤与海水干湿循环综合作用对RC梁力学性能及耐久性劣化影响显著。-

关键词:

- 初始损伤 /

- 钢筋混凝土(RC)梁 /

- 海水干湿循环 /

- 耐久性 /

- 氯离子含量

Abstract:The working condition of reinforced concrete (RC) structures in coastal chloride environment combined load effects and environmental effects and there would be a different degree of damage due to load effects in normal conditions. In order to simulated that working condition in laboratory, different loads of 0.3

P u, 0.4P u, 0.5P u, 0.6P u and 0.7P u (P u is the ultimate load of beam under monotonic loading) were applied on RC beam specimens to induce varying degrees of damage. Subsequently, beam specimens were placed in an automatic sprinkler device to simulate seawater wet-dry cycles. After 120 wet-dry cycles, monotonic loading test and chloride concentration test were conducted on RC beams. The test results show that the yield load, ultimate load and ductility of specimens decrease with the increase of initial damage load amplitude. When the initial load is 0.4P u, the decrease of yield load and ultimate load is 10.4% and 7.9% respectively, compared with control group. With the damage increasing, the yield load and ultimate load decrease constantly. When the initial load is 0.7P u, a great degeneration of mechanical performance occurs and the decrease of yield load and ultimate load is 33.7% and 32.4% respectively. The results of chloride concentration test show that the chloride ion content of concrete in tension area is higher than that in compression area. When the initial load is below 0.5P u, the chloride ion content in steel position is below 0.1% and has no significant changes. When the initial load is 0.7P u, the chloride ion content increases significantly and the maximum value is up to 0.14%. Thus, the initial damage combined with seawater wet-dry cycles has a great impact on degradation of mechanical performance and durability of RC beams. -

表 1 梁试件初始损伤加载幅值和试验环境

Table 1. Beam specimen initial damage load amplitude and test environment

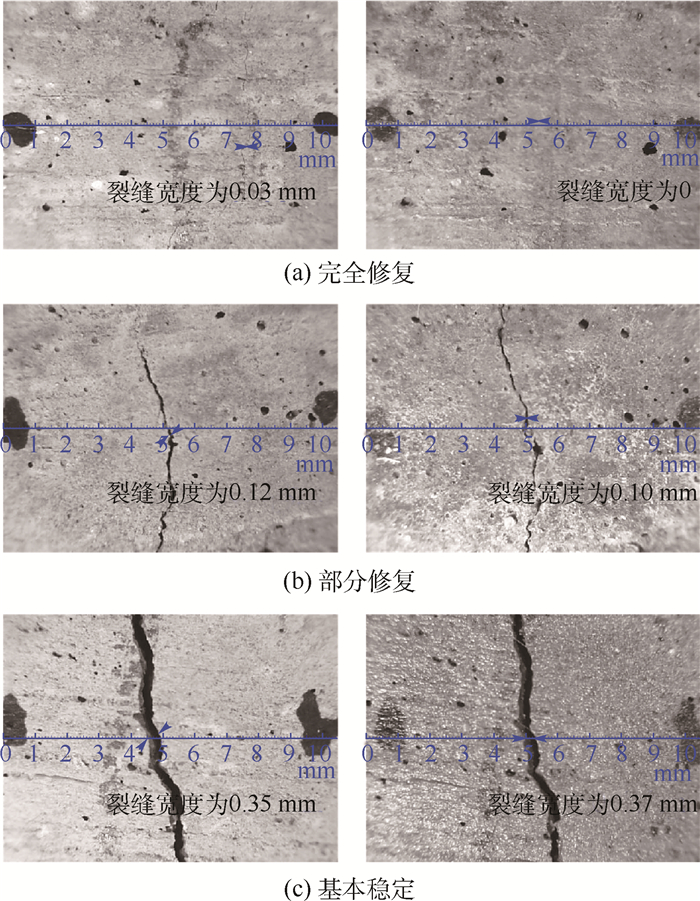

编号 荷载幅值 试验环境 B-0 0 干湿循环 B-0.3 0.3 Pu 干湿循环 B-0.4 0.4 Pu 干湿循环 B-0.5 0.5 Pu 干湿循环 B-0.6 0.6 Pu 干湿循环 B-0.7 0.7 Pu 干湿循环 B-Ref 0 标准养护 表 2 干湿循环前后梁试件裂缝宽度变化统计

Table 2. Variation statistics of crack width of beam specimen before and after wet-dry cycles

编号 最大裂缝宽度/mm 干湿循环前裂缝宽度/mm 总测点数量 干湿循环后裂缝变化测点数量 完全愈合 部分愈合 基本稳定 B-0.3 0.08 < 0.1 7 5 2 0 0.1~0.2 0 0 0 0 ≥0.2 0 0 0 0 B-0.4 0.19 < 0.1 15 9 4 2 0.1~0.2 15 2 3 10 ≥0.2 0 0 0 0 B-0.5 0.34 < 0.1 15 12 2 1 0.1~0.2 17 1 4 12 ≥0.2 4 0 0 4 B-0.6 0.63 < 0.1 26 15 6 5 0.1~0.2 20 2 3 15 ≥0.2 8 0 0 8 B-0.7 1.16 < 0.1 22 15 5 2 0.1~0.2 14 0 1 13 ≥0.2 9 0 0 9 表 3 梁试件单调加载试验结果

Table 3. Testing results of beam specimen under monotonic loading

编号 Py/kN δy/mm Pm/kN δm/mm δu/mm δu/δy B-0 41.09 2.06 50.50 17.37 37.82 18.4 B-0.3 38.05 2.85 47.48 26.31 33.11 11.6 B-0.4 36.81 2.75 46.51 31.23 36.25 13.2 B-0.5 33.03 2.56 41.99 20.56 26.89 10.5 B-0.6 27.32 2.27 38.79 17.54 17.81 7.8 B-0.7 27.25 2.33 34.14 18.86 25.02 10.7 表 4 梁试件屈服荷载和极限荷载降幅

Table 4. Decreasing amplitude of yield load and ultimate load of specimens

编号 ΔPy/% ΔPm/% Δμ/% B-0.3 7.4 6.0 37.0 B-0.4 10.4 7.9 28.3 B-0.5 19.6 16.9 42.9 B-0.6 33.5 23.2 57.6 B-0.7 33.7 32.4 41.8 表 5 梁试件抗弯刚度变化和降幅

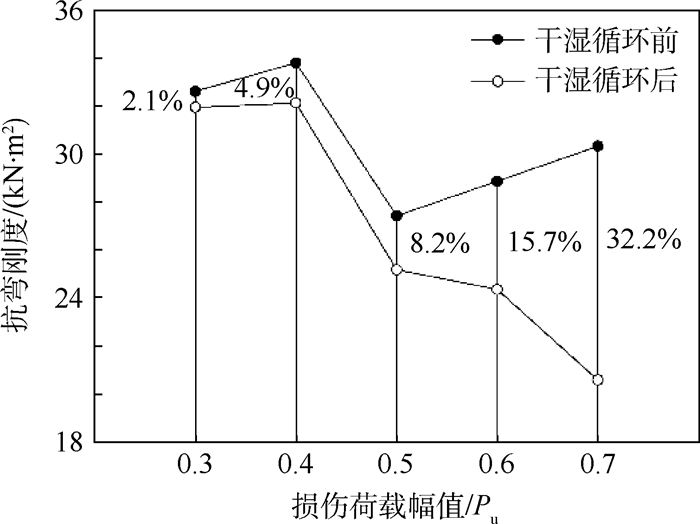

Table 5. Variation of bending rigidity of specimens and decreasing amplitude

编号 干湿循环前抗弯刚度/(kN·m2) 干湿循环后抗弯刚度/(kN·m2) 降幅/% B-0.3 32.63 31.96 2.1 B-0.4 33.82 32.14 4.9 B-0.5 27.43 25.18 8.2 B-0.6 28.88 24.36 15.7 B-0.7 30.34 20.58 32.2 B-0 41.03 表 6 氯离子含量分布函数的参数拟合结果

Table 6. Fitting results of parameters of chloride ion content distribution function

编号 裂缝区 非裂缝区

Cs/% D/(mm2·d-1) Cs/% D/(mm2·d-1) B-0.3 2.05 2.10 1.75 1.65 1.17 B-0.4 2.09 1.62 1.49 1.67 1.40 B-0.5 3.65 1.31 1.84 2.19 1.98 B-0.6 2.84 1.61 1.37 2.23 2.07 B-0.7 3.16 1.39 1.25 2.59 2.53 -

[1] ALDEA C M, SHAH S P, KARR A.Permeability of cracked concrete[J].Materials and Structures, 1999, 32(5):370-376. doi: 10.1007/BF02479629 [2] DJERBI A, BONNET S, KHELIDJ A, et al.Influence of traversing crack on chloride diffusion into concrete[J].Cement and Concrete Research, 2008, 38(6):877-883. doi: 10.1016/j.cemconres.2007.10.007 [3] JANG S Y, KIM B S, OH B H.Effect of crack width on chloride diffusion coefficients of concrete by steady-state migration tests[J].Cement and Concrete Research, 2011, 41(1):9-19. doi: 10.1016/j.cemconres.2010.08.018 [4] SAHMARAN M. Effect of flexure induced transverse crack and self-healing on chloride diffusivity of reinforced mortar[J].Journal of Materials Science, 2007, 42(22): 9131-9136. doi: 10.1007/s10853-007-1932-z [5] BENTZ D P, GARBOCZI E J, LU Y, et al.Modeling of the influence of transverse cracking on chloride penetration into concrete[J].Cement and Concrete Composites, 2013, 38(2):65-74. [6] RODRIGUEZ O, HOOTON R.Influence of cracks on chloride ingress into concrete[J].ACI Materials Journal, 2003, 100(2): 120-126. [7] LI C Q.Initiation of chloride-induced reinforcement corrosion in concrete structural members-prediction[J].ACI Structural Journal, 2002, 99(2):133-141. [8] LI C Q.Initiation of chloride-induced reinforcement corrosion in concrete structural members-experimentation[J].ACI Structural Journal, 2001, 98(4):502-510. [9] WIN P P, WATANABE M, MACHIDA A.Penetration profile of chloride ion in cracked reinforced concrete[J].Cement and Concrete Research, 2004, 34(7):1073-1079. doi: 10.1016/j.cemconres.2003.11.020 [10] 陆春华, 金伟良, 延永东.氯盐干湿环境下受弯横向裂缝对钢筋混凝土耐久性影响[J].海洋工程, 2012, 30(1):131-136. http://www.cnki.com.cn/Article/CJFDTOTAL-HYGC201201018.htmLU C H, JIN W L, YAN Y D.Influence of transverse cracks on durability of RC member under chloridedry and wet cycles[J].The Ocean Engineering, 2012, 30(1):131-136(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HYGC201201018.htm [11] 刁波, 孙洋.混合侵蚀与冻融交替作用下持载钢筋混凝土偏压构件试验[J].建筑结构学报, 2009(增刊2):298-303. http://www.cnki.com.cn/Article/CJFDTOTAL-JZJB2009S2051.htmDIAO B, SUN Y.Experiments of reinforced concrete columns with eccentric compressive persistent loading under alternative actions of a mixed aggressive solution and freeze-thaw cycles[J].Journal of Building Structures, 2009(S2):298-303(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JZJB2009S2051.htm [12] 沈孛, 叶英华, 刁波, 等.海水干湿循环对带裂缝钢筋混凝土柱力学性能及氯离子含量的影响[J].建筑结构学报, 2014(增刊1):69-74. http://www.cnki.com.cn/Article/CJFDTOTAL-JZJB2014S1010.htmSHEN B, YE Y H, DIAO B, et al.Effects of seawater wet-dry cycles on performance and chloride content of RC columns with different initial cracks[J].Journal of Building Structures, 2014(S1):69-74(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JZJB2014S1010.htm [13] 耿娇, 刁波, 陈圣刚.冻融与侵蚀作用下引气混凝土劣化微观机理[J].北京航空航天大学学报, 2013, 39(10):1392-1396.GENG J, DIAO B, CHEN S G.Degradation mechanism of air-entrained concrete under alternative actions of freeze-thaw cycles and seawater immersion[J].Journal of Beijing University of Aeronautics and Astronautics, 2013, 39(10):1392-1396(in Chinese). [14] 中国钢铁工业协会. 金属材料拉伸试验第1部分: 室温试验方法: GB/T228. 1—2010[S]. 北京: 中国国家标准化管理委员会, 2010.China Iron and Steel Association.Metallic materials—Tensile testing—Part 1: Method of test at room temperature:GB/T228.1—2010[S].Beijing:Standardization Administration of the People's Republic of China, 2010(in Chinese). [15] 中国建筑科学研究院. 普通混凝土力学性能试验方法标准: GB/T50081—2002[S]. 北京: 中国建筑工业出版社, 2003.China Academy of Building Research.Standard for test method of mechanical properties on ordinary concrete:GB/T50081—2002[S].Beijing: China Architecture & Building Press, 2003(in Chinese). [16] 中国建筑科学研究院. 混凝土中氯离子含量检测技术规程: JGJ/T322—2013[S]. 北京: 中国建筑工业出版社, 2013.China Academy of Building Research.Technical specification for test of chloride ion content in concrete:JGJ/T322—2013[S].Beijing: China Architecture & Building Press, 2013(in Chinese). [17] 中国建筑科学研究院. 钢筋混凝土结构设计规范: GB50010—2010[S]. 北京: 中国建筑工业出版社, 2010.China Academy of Building Research.Code for design of concrete structures:GB50010—2010[S].Beijing: China Architecture & Building Press, 2010(in Chinese). [18] 吴庆, 袁迎曙.锈蚀钢筋力学性能退化规律试验研究[J].土木工程学报, 2008, 41(12):42-47. doi: 10.3321/j.issn:1000-131X.2008.12.007WU Q, YUAN Y S.Experimental study on the deterioration of mechanical properties of corroded steel bars[J].China Civil Engineering Journal, 2008, 41(12):42-47(in Chinese). doi: 10.3321/j.issn:1000-131X.2008.12.007 -

下载:

下载: