-

摘要:

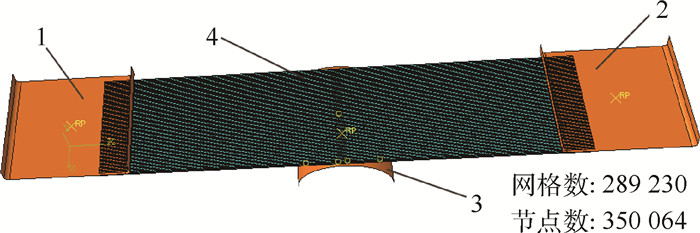

预载荷下板料激光弯曲成形是一种较新的板料弯曲成形方法,本文对其工艺参数进行了分析研究。使用软件ABAQUS建立了预载荷下板料激光弯曲成形的有限元模型,并进行了试验验证,在此模型的基础上,采用均匀设计法进行了变工艺参数仿真试验设计,利用仿真试验结果建立了各工艺参数与变形量间的回归模型,并进一步分析了工艺参数对变形量的影响及其内在原因。研究表明,各工艺参数中扫描速度对变形量的影响最大,而激光功率的影响最小;光斑直径与扫描速度间存在对变形量有高度显著影响的负交互作用;变形量随预载荷增大近似呈指数上升,随激光功率的增大近似呈线性增大,随光斑直径的增大近似呈线性下降,随扫描速度的增大呈现先减小后增大的趋势。

Abstract:Laser bending of preloaded metal plate is a relatively new bending method and its process parameters are researched in this paper. A finite element model of the forming process was established based on software ABAQUS, and its reliability was verified by test. Then, finite element simulations using different process parameter values were done by uniform design. On the basis of the simulation results, a regression model of relationship between the process parameters and deformation amount was developed. Further, influences of the process parameters on the deformation amount and the internal reasons of these influences were analyzed. It is shown that among the parameters the scanning speed has the greatest influence on the deformation amount while the laser power has the minimal influence. The negative interaction of the laser spot diameter and scanning speed affects the deformation amount significantly. The deformation amount increases almost exponentially with the increase of preload amount, increases linearly with the increase of laser power, and decreases almost linearly with the increase of laser spot diameter. Moreover, it decreases at first and increases later with the increase of scanning speed.

-

Key words:

- preload /

- laser bending /

- process parameters /

- finite element method /

- uniform design /

- regression analysis

-

表 1 试验方案和结果

Table 1. Test scheme and results

试验号 F/N P/W Φ/mm V/(mm·s-1) H/mm 1 830 1 200 5.5 30 2.61 2 830 1 500 4.5 25 3.49 3 874 1 200 6.5 15 3.85 4 874 1 500 5.0 10 6.02 5 918 1 100 4.0 35 4.17 6 918 1 400 6.0 25 2.94 7 962 1 100 4.5 20 4.82 8 962 1 400 6.5 10 6.82 9 1 006 1 000 5.5 35 4.67 10 1 006 1 300 4.0 30 5.53 11 1 050 1 000 6.0 20 5.85 12 1 050 1 300 5.0 15 7.48 表 2 各回归系数的t值

Table 2. t values of regression coefficients

回归系数 X1 X4 X12 X22 X42 X3X4 t值 -5.33 -9.47 6.04 2.25 10.30 -7.76 -

[1] 陈光南, 王秀凤, 罗耕星, 等. 压弯激光复合成形方法: 200710062910.2[P].2008-03-12.CHEN G N, WANG X F, LUO G X, et al.A forming methodology including bending and laser heating:200710062910.2[P].2008-03-12(in Chinese). [2] YIBAS B S, AKHTAR S, SHUJA S Z.Laser forming and welding processes[M].Heidelberg:Springer International Publishing, 2013:1-4. [3] GUAN Y J, SUN S, ZHAO G Q, et al.Finite element modeling of laser bending of pre-loaded sheet metals[J].Journal of Materials Processing Technology, 2003, 142(2):400-407. doi: 10.1016/S0924-0136(03)00603-4 [4] XU L, LI W D, WAN M, et al.Laser bending process of preloaded sheet metal[C]//Proceedings of the 4th International Conference on New Forming Technology.Glasgow:EDP Sciences, 2015, 4:1-7. [5] 彭青, 陈光南, 吴臣武, 等.整体壁板激光辅助预应力成形[J].航空学报, 2009, 30(8):1544-1548. http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB200908030.htmPENG Q, CHEN G N, WU C W, et al.Laser-assisted pre-stress forming for integral panels[J].Acta Aeronautica et Astronautica Sinica, 2009, 30(8):1544-1548(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB200908030.htm [6] WANG X F, LIU D X, LI W D, et al.Study of laser bending of a preloaded titanium alloy sheet[J].Manufacturing Review, 2014, 1:1-6. doi: 10.1051/mfreview/2013001 [7] VOLLERTSEN F, KOMEL I, KALS R.Laser bending of steel foils for micro parts by the buckling mechanism-A model[J].Modelling & Simulation in Materials Science & Engineering, 1995, 3(1):107-119. https://www.researchgate.net/publication/231027175_The_laser_bending_of_steel_foils_for_microparts_by_the_buckling_mechanism-a_model [8] LIU J, SUN S, GUAN Y J.Numerical investigation on the laser bending of stainless steel foil with pre-stresses[J].Journal of Materials Processing Technology, 2009, 209(3):1580-1587. doi: 10.1016/j.jmatprotec.2008.04.006 [9] YAO Z Q, SHEN H, SHI Y J.Numerical study on laser forming of metal plates with pre-loads[J].Computational Materials Science, 2007, 40(1):27-32. doi: 10.1016/j.commatsci.2006.10.024 [10] ROOHI A H, GOLLO M H, NAEINI H M.External force-assisted laser forming process for gaining high bending angles[J].Journal of Manufacturing Processes, 2012, 14(3):269-276. doi: 10.1016/j.jmapro.2012.07.004 [11] 彭青, 陈光南, 王明星, 等.工艺参数对激光辅助预应力成形效率的影响[J].中国激光, 2011, 38(10):73-77. http://www.cnki.com.cn/Article/CJFDTOTAL-JJZZ201110014.htmPENG Q, CHEN G N, WANG M X, et al.Finite element modeling of laser bending of pre-loaded sheet metals[J].Chinese Journal of Lasers, 2011, 38(10):73-77(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JJZZ201110014.htm [12] 彭青, 陈光南, 王秀凤.激光辅助预应力成形的相似性问题[J].中国激光, 2009, 36(5):1261-1266. http://www.cnki.com.cn/Article/CJFDTOTAL-JJZZ200905048.htmPENG Q, CHEN G N, WANG X F.Similarity criterion of laser-assisted pre-stress forming[J].Chinese Journal of Lasers, 2009, 36(5):1261-1266(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JJZZ200905048.htm [13] National Technical Information Service.Metallic materials properties development and standardization-01:DOT/FAA/AR-MMPDS-01[S].Washington, D.C.:Department of Transportation, 2003:166-181. [14] XI Y, ZHAN H Y, RASHID R A, et al.Numerical modeling of laser assisted machining of a beta titanium alloy[J].Computational Materials Science, 2014, 92(5):149-156. https://www.researchgate.net/publication/263164190_Numerical_modeling_of_laser_assisted_machining_of_a_beta_titanium_alloy [15] 方开泰.均匀设计与均匀设计表[M].北京:科学出版社, 1994:14-18.FANG K T.Uniform design and uniform design tables[M].Beijing:Science Press, 1994:14-18(in Chinese). [16] 唐启义.DPS数据处理系统[M].北京:科学出版社, 2013:474-477.TANG Q Y.DPS data processing system[M].Beijing:Science Press, 2013:474-477(in Chinese). [17] 王黎明.应用回归分析[M].上海:复旦大学出版社, 2008:64-65.WANG L M.Applied regression analysis[M].Shanghai:Fudan University Press, 2008:64-65(in Chinese). -

下载:

下载: