-

摘要:

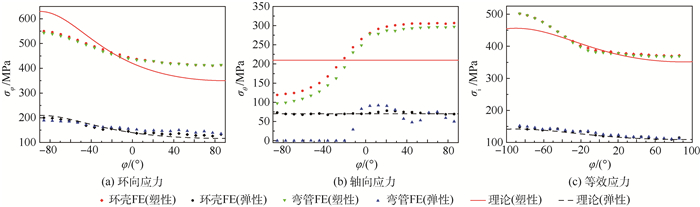

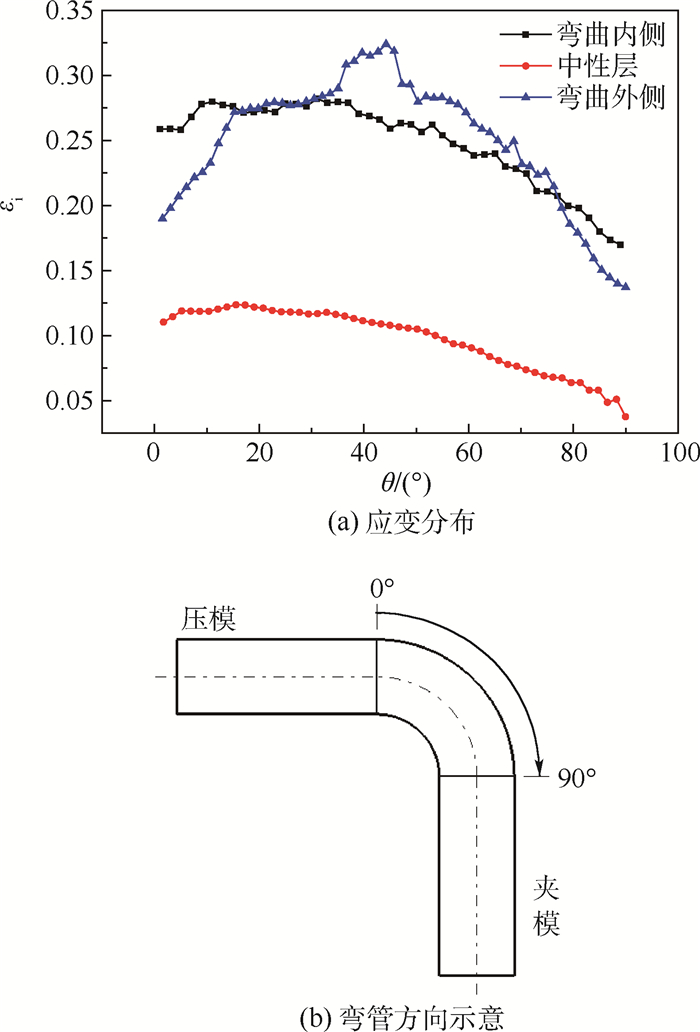

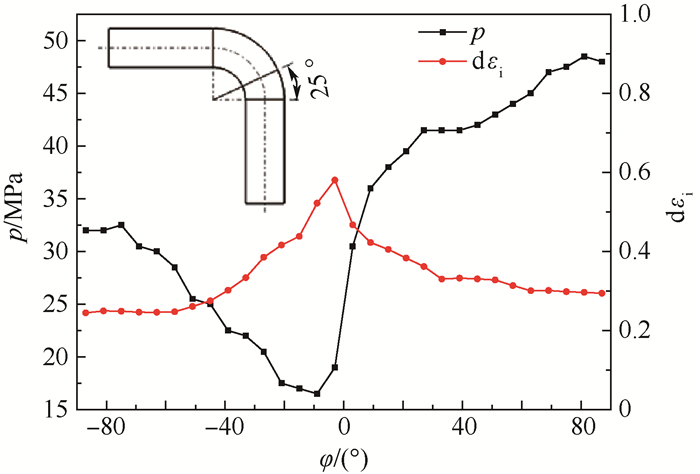

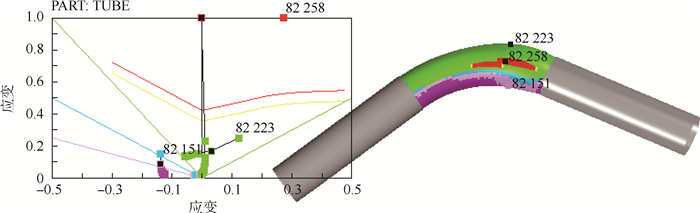

随着制造业轻量化的发展趋势,复杂弯曲异形充液成形管件的应用日益广泛。为了更好地研究弯曲异形复杂管件在充液成形过程中的变形规律,进行可靠的工艺设计。本文通过结合薄膜理论和塑性变形理论对弯曲管件在自由胀形状态下的应力应变进行了理论解析,并通过有限元(FE)分析对理论计算模型进行了验证。FE分析结果与理论模型基本吻合。同时分析了管材在绕弯过程的硬化行为,并探索了在不同的弯曲硬化状态下弯曲管材在自由胀形过程下的破裂位置的规律,并且用实验进行了验证,实验结果与FE分析结果吻合。

Abstract:As the development of lightweight design in manufacture industry, the application of thin-walled bent hollow tubes with various sections is expanding widely. In order to study the deformation behavior of bent tubes during hydroforming process and have a reliable process design, a theoretical model of free-expansion bent tubes based on membrane theory and plastic theory was put forward, and the model was verified by finite element (FE) analysis. The FE analysis results show good agreement with the theoretical model. The stresses distribution and deformation behavior were revealed. Finally, the work-hardening behavior during rotary draw bending was analyzed, and meanwhile, the fracture site of pre-bent tubes with different work-hardening states during free-expansion process was explored. The experimental results show good agreement with the FE analysis results.

-

Key words:

- hydroforming /

- bending /

- deformation behavior /

- work-hardening /

- fracture

-

-

[1] ZENG Y S, LI Z Q.Experimental research on the tube push-bending process[J]. Journal of Material Processing Technology, 2002, 122(2-3):237-240. doi: 10.1016/S0924-0136(02)00027-4 [2] 苑世剑.现代液压成形技术[M].北京:国防工业出版社, 2009:8-9.YUAN S J.Modern hydroforming technology[M]. Beijing: National Defence Industry Press, 2009:8-9(in Chinese). [3] KEELER S P, BACKOFEN W A.Plastic instability and fracture in sheets stretched over rigid punches[J]. ASM Transactions Quarterly, 1963, 56:25-48. [4] GOODWIN G M.Application of strain analysis to sheet metal forming in the press shop:680093[R]. Warrendale, PA:SAE, 1968. [5] MUAMMER K, TAYLAN A.Prediction of forming limits and parameters in the tube hydroforming process[J]. International Journal of Machine Tools & Manufacture, 2002, 42(1):123-138. [6] KIM S W, SONG W J, KANG B S, et al.Analytical and number approach to prediction of forming limit in tube hydroforming[J]. International Journal of Mechanical Sciences, 2005, 47(7):1023-1037. doi: 10.1016/j.ijmecsci.2005.02.011 [7] HWANG Y M, LIN Y K, CHUANG H C.Forming limit diagrams of tubular materials by bulge test[J]. Journal of Material Processing Technology, 2009, 209(11):5024-5034. doi: 10.1016/j.jmatprotec.2009.01.026 [8] CHEN X F, LI S H, YU Z Q, et al.Study on experimental approaches of forming limit curve for tube hydroforming[J]. International Journal of Advanced Manufacturing Technology, 2012, 61(1):87-100. [9] LANG L H, CAI G S, LIU K N, et al.Investigation on the effect of through thickness normal stress on forming limit at elevated temperature by using modified M-K model[J]. International Journal of Material Forming, 2015, 8(2):211-228. doi: 10.1007/s12289-014-1161-3 [10] 崔晓磊, 王小松, 林艳丽, 等.管材流体压力成形三维成形极限图[J].塑性工程学报, 2014, 21(5):1-5. http://www.cnki.com.cn/Article/CJFDTOTAL-SXGC201405001.htmCUI X L, WANG X S, LIN Y L, et al.Three-dimension forming limit diagram for fluid pressure forming of tubes[J]. Journal of Plasticity Engineering, 2014, 21(5):1-5(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-SXGC201405001.htm [11] 杨希英, 郎利辉, 刘康宁, 等.基于修正M-K模型的铝合金板材成形极限图预测[J].北京航空航天大学学报, 2015, 41(4):675-679.YANG X Y, LANG L H, LIU K N, et al.Prediction of forming limit diagram of AA7075-O aluminum alloy sheet based on modified M-K model[J]. Journal of Beijing University of Aeronautics and Astronautics, 2015, 41(4):675-679(in Chinese). [12] GRAF A, HOSFORD W.Calculations of forming limit diagrams for changing strain paths[J]. Metallurgical Transactions A, 1993, 24:2503-2512. doi: 10.1007/BF02646529 [13] KLEEMOLA H J, PELKKIKANGAS M T.Effect of predeformation and strain path on the forming limits of steel copper and brass[J]. Sheet Metal Industries, 1977, 63:591-599. [14] STOUGHTON T B.A general forming limit criterion for sheet metal forming[J]. International Journal of Mechanical Sciences, 1999, 42(1):1-27. [15] YOSHIDA K, KUWABARA T.Effect of strain hardening behavior on forming limit stresses of steel tube subjected to nonproportional loading paths[J]. International Journal of Plasticity, 2007, 23(7):1260-1284. doi: 10.1016/j.ijplas.2006.11.008 [16] SINGH H.Computer simulation of tubular hydroforming[J]. Tube & Pipe Journal, 2000, 11:8-13. -

下载:

下载: