-

摘要:

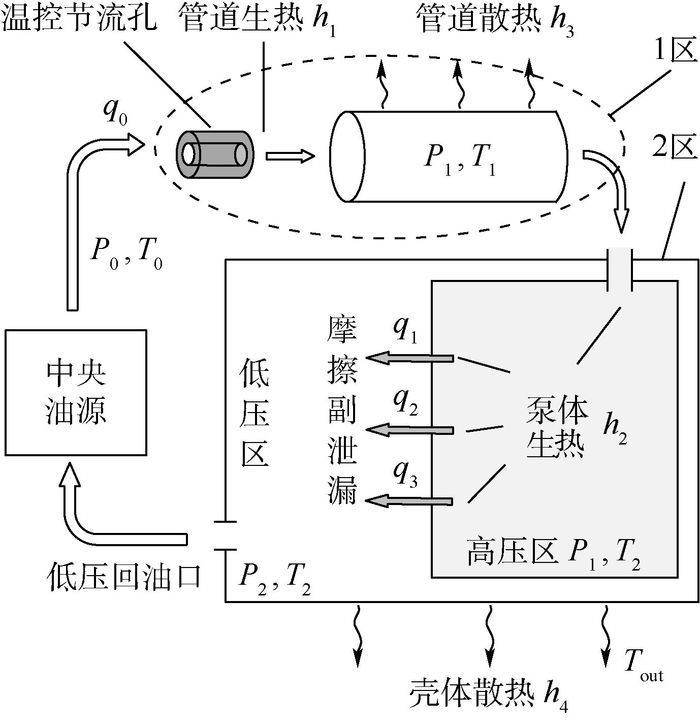

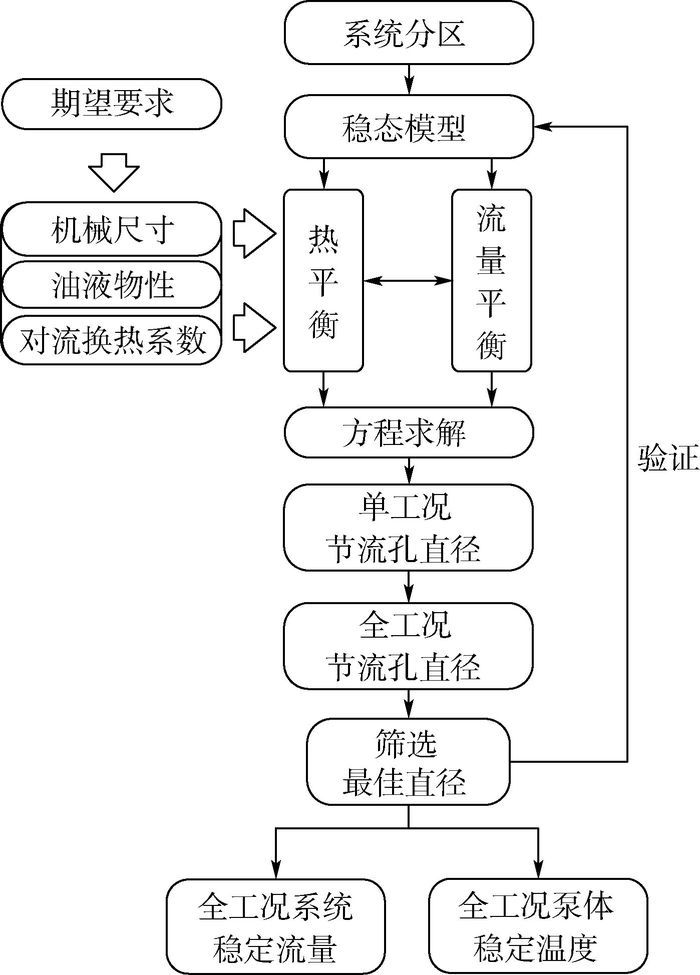

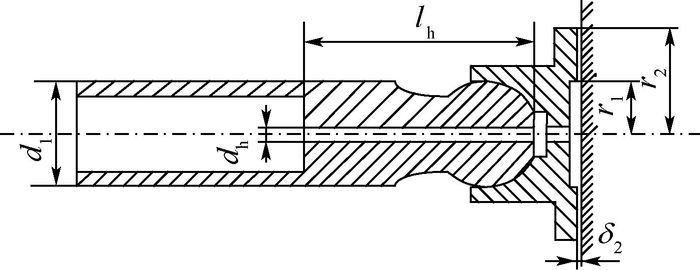

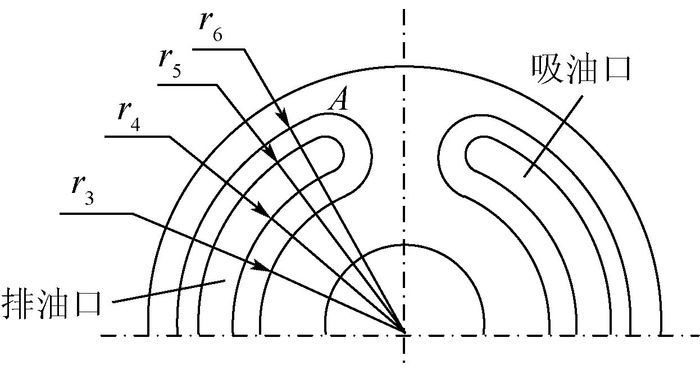

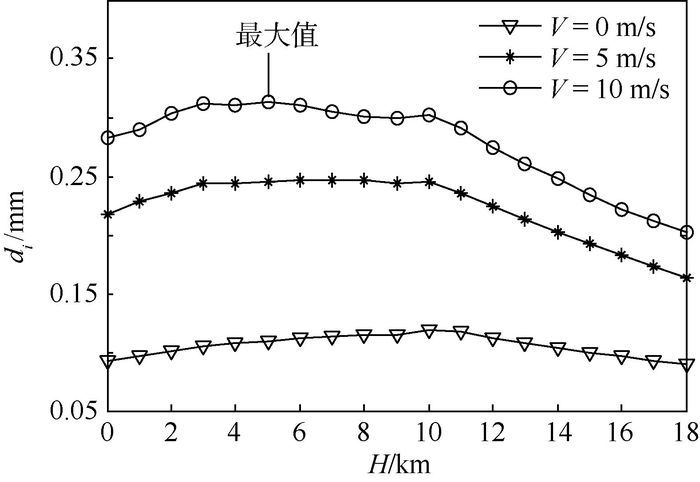

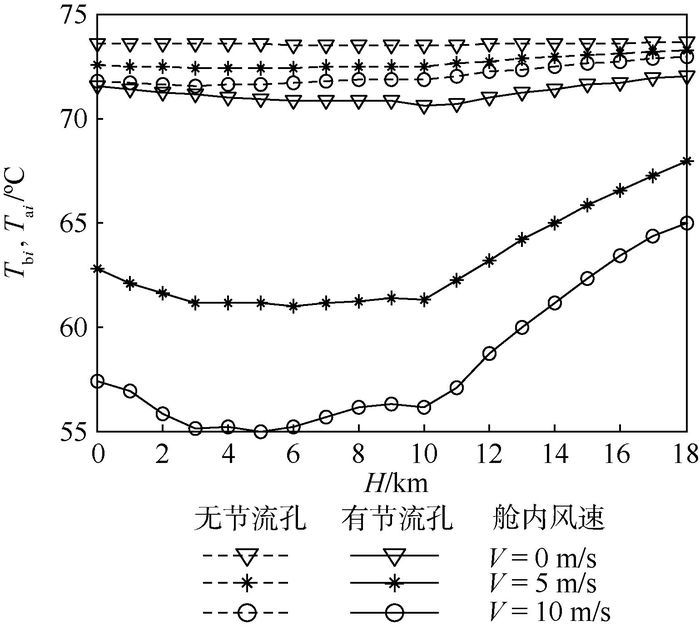

冲压空气涡轮(RAT)泵将涡轮输出的机械能转换为液压能用以操控飞机舵面,其快速起动是飞机安全的最后保证。长时间处于低温大气环境,液压油的高黏性阻碍了液压泵的快速起动,将飞机主液压系统的高压油液引入RAT泵是解决该问题的有效方法。本文以RAT泵为研究对象,探究RAT泵的最小温控节流孔计算方法。首先,阐述RAT泵待机状态下通过温控节流孔保温原理,提出温控节流孔的孔径计算方法;其次,建立RAT泵热力学模型,推导温控节流孔的孔径计算公式;然后,基于MATLAB平台搭建RAT泵温控系统热力学模型;最后,通过仿真计算,由仿真结果验证本文所提出的温控节流孔计算方法的正确性,且节能效果显著。

-

关键词:

- 冲压空气涡轮(RAT) /

- 航空液压泵 /

- 保温 /

- 热力学 /

- 节流孔

Abstract:Ram air turbine (RAT) pump, by transforming the mechanical energy into hydraulic energy, can be used to control the aircraft rudder in emergency situation. Its performance of rapid response is critical to ensure the aircraft's safety. Exposed to low-temperature atmosphere for long time, the high viscosity of hydraulic oil will hinder the rapid start of the hydraulic pump, and an effective method for this problem is to introduce the high-pressure oil into aircraft RAT pump from the main hydraulic system. Taking RAT pump as research object, this paper explores the calculation method of minimum temperature control orifice for the RAT pump. First, it explains the thermal insulation theory of the RAT pump which is equipped with temperature control orifice in standby mode and proposes an algorithm of the orifice. Second, it establishes RAT pump's thermodynamic model and deduces the calculation formula of the orifice's diameter. Next, it establishes temperature control system's thermodynamic model with MATLAB and calculates the results. Finally, it verifies the correctness of the algorithm through simulation calculation, and energy saving effect is remarkable.

-

Key words:

- ram air turbine (RAT) /

- aviation hydraulic pump /

- thermal insulation /

- thermodynamics /

- orifice

-

表 1 RAT泵系统参数

Table 1. System parameters of RAT pump

参数 参数设定 温控节流孔前油液压强P0/MPa 28 壳体油液压强P2/MPa 0.5 温控节流孔温度T0/℃ 60 壳体保温温度T2/℃ 55 机舱环境温度Tout 飞行高度H的函数 油液热容c/(J·(kg·℃)-1) 1 967.35 对流换热系数α 飞行高度H和舱内风速V的函数 -

[1] LI J, ZHANG X, YIN Y B.Dynamic temperature simulation of an accumulator in aircraft hydraulic systems[C]//2011 International Conference on Fluid Power and Mechatronics(FPM).Piscataway, NJ:IEEE Press, 2011:653-657. [2] STADLBAUER K, POLTSCHAK F, RAFETSEDER D, et al.A spice-based lumped parameter thermal model with geometrically distributed elements for electro-hydraulic actuators[C]//International Symposium on Power Electronics, Electrical Drives, Automation and Motion.Piscataway, NJ:IEEE Press, 2012:511-516. [3] LI C G, JIAO Z X.Calculation method for thermal-hydraulic system simulation[J].Journal of Heat Transfer, 2008, 130(8):084503. doi: 10.1115/1.2928006 [4] SCOTT T C, UPHOLD J.Thermal modeling of power steering system performance[J].SAE International Journal of Passenger Cars-Mechanical Systems, 2009, 1(1):1039-1044. [5] LANA E D, NEGRI V J D.A new evaluation method for hydraulic gear pump efficiency through temperature measurements:2006-01-3503 [R].SAE Technical Paper, 2006. [6] LI J, XU J L, ZHANG X, et al.An estimation method of the fluid temperature for commercial aircraft hydraulic systems[C]//2010 International Conference on Mechanic Automation and Control Engineering (MACE).Piscataway, NJ:IEEE Press, 2010:2962-2965. [7] 卢宁, 付永领, 孙新学.基于AMESim的双压力柱塞泵的数字建模与热分析[J].北京航空航天大学学报, 2006, 32(9):1054-1058.LU N, FU Y L, SUN X X.Digital modeling of double press axial piston pump and its thermal analysis basing on AMESim[J].Journal of Beijing University of Aeronautics and Astronautics, 2006, 32(9):1054-1058(in Chinese). [8] 韩孟虎, 曹克强, 胡良谋, 等.基于AMESim的柱塞泵热力学模型及仿真[J].机床与液压, 2012, 40(1):136-138. http://www.cnki.com.cn/Article/CJFDTOTAL-JCYY201201039.htmHAN M H, CAO K Q, HU L M, et al.Thermal model and simulation on hydraulic piston pump based on AMESim[J].Machine Tool & Hydraulic, 2012, 40(1):136-138(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JCYY201201039.htm [9] 李永林, 徐浩军, 曹克强, 等.航空柱塞泵全工况效率分析及热力学建模[J].北京航空航天大学学报, 2010, 36(12):1470-1472.LI Y L, XU H J, CAO K Q, et al.Efficiency analysis and thermal-hydraulic modeling of aerial piston pump at whole work condition[J].Journal of Beijing University of Aeronautics and Astronautics, 2010, 36(12):1470-1472(in Chinese). [10] LI C G, JIAO Z X.Thermal-hydraulic modeling and simulation of piston pump[J].Chinese Journal of Aeronautics, 2006, 19(4):354-358. doi: 10.1016/S1000-9361(11)60340-3 [11] OLEMS L.Investigations of the temperature behaviour of the piston cylinder assembly in axial piston pumps[J].International Journal of Fluid Power, 2000, 1(1):27-38. doi: 10.1080/14399776.2000.10781080 [12] WIECZOREK U, IVANTYSYNOVA M.Computer aided optimization of bearing and sealing gaps in hydrostatic machines-the simulation tool CASPAR[J].International Journal of Fluid Power, 2002, 3(1):7-20. doi: 10.1080/14399776.2002.10781124 [13] IVANTYSYNOVA M, HUANG C, JAPING A.Determination of gap surface temperature distribution in axial piston machines[C]//ASME 2006 International Mechanical Engineering Congress and Exposition.New York:ASME, 2006:85-93. [14] PELOSI M, IVANTYSYNOVA M.A novel fluid-structure interaction model for lubricating gaps of piston machines[C]//Proceedings of the 5th Fluid Structure Interaction Conference.Wessex:WIT Press, 2009:3-24. [15] PELOSI M, IVANTYSYNOVA M.Heat transfer and thermal elastic deformation analysis on the piston/cylinder interface of axial piston machines [J].Journal of Tribology, 2012, 134(4):1-15. [16] 王国志, 李玉辉, 吴文海, 等.变形对轴向柱塞泵柱塞副泄漏量的影响研究[J].机床与液压, 2011, 39(17):50-52. doi: 10.3969/j.issn.1001-3881.2011.17.015WANG G Z, LI Y H, WU W H, et al.Influence of deformation on leakage of piston and cylinder in axial piston pump[J].Machine Tool & Hydraulics, 2011, 39(17):50-52(in Chinese). doi: 10.3969/j.issn.1001-3881.2011.17.015 [17] 胡仁喜, 苑士华, 刘红宁, 等.高压高速条件下柱塞副泄漏流场分析[J].农业机械学报, 2009, 40(2):221-226. http://www.cnki.com.cn/Article/CJFDTOTAL-NYJX200904048.htmHU R X, YUAN S H, LIU H N, et al.Analysis on the leaking flow field of the piston sector considering the high press and high velocity[J].Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(2):221-226(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-NYJX200904048.htm [18] 徐兵, 张军辉, 杨华勇.基于虚拟样机的轴向柱塞泵柱塞副仿真分析[J].兰州理工大学学报, 2010, 36(3):31-37. http://www.cnki.com.cn/Article/CJFDTOTAL-GSGY201003007.htmXU B, ZHANG J H, YANG H Y.Simulative analysis of piston-cylinder pair of axial piston pump based on virtual prototype [J].Journal of Lanzhou University of Technology, 2010, 36(3):31-37(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-GSGY201003007.htm [19] 马吉恩. 轴向柱塞泵流量脉动及配流盘优化设计研究[D]. 杭州: 浙江大学, 2009.MA J E.Study on flow ripple and valve plate optimization of axial piston pump[D].Hangzhou:Zhejiang University, 2009(in Chinese). 期刊类型引用(4)

1. 周红华,黄辰,肖伟剑,陈向进,兰景权,许志刚,汪倍吉. 移动通信基站电磁辐射环境影响仿真预测与评价. 环境影响评价. 2020(03): 57-62 .  百度学术

百度学术2. 周红华,黄辰,肖伟剑,陈向进,兰景权,汪倍吉,许志刚. ±45°双极化通讯基站正向地面电磁辐射随角度变化的预测——通讯基站50m内电磁辐射环境超标范围3D准确仿真预测实验之二. 海峡科学. 2019(01): 8-13 .  百度学术

百度学术3. 吴雅琴,杨硕,师兰兰. 基于位置指纹与PDR融合的室内定位算法研究. 矿业科学学报. 2019(05): 448-454 .  百度学术

百度学术4. 周红华,黄辰,肖伟剑,兰景权,陈向进,许志刚,汪倍吉. 通讯基站50m内轴向发射电磁辐射预测——通讯基站50m内电磁辐射环境超标范围3D准确仿真预测实验之一. 海峡科学. 2018(11): 27-31 .  百度学术

百度学术其他类型引用(1)

-

下载:

下载:

百度学术

百度学术