Finite element analysis of flow field and temperature field of electro-hydraulic pump by Fluent

-

摘要:

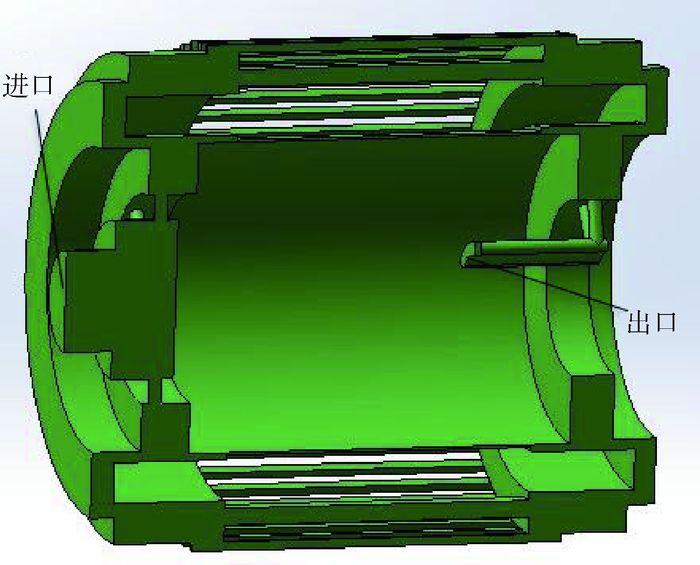

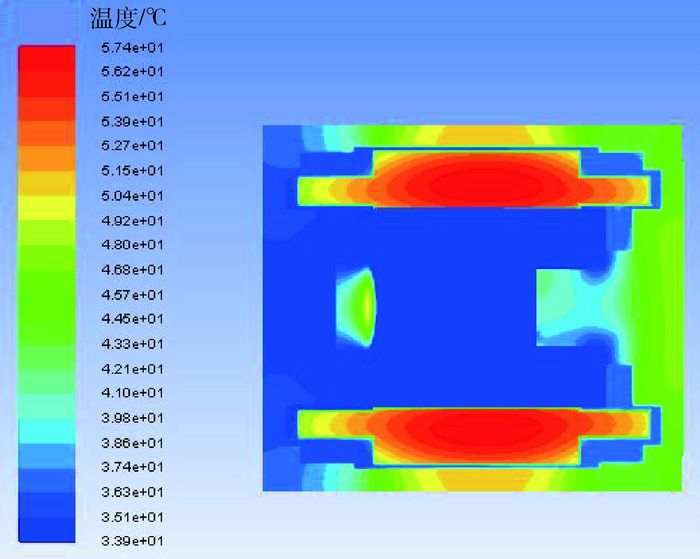

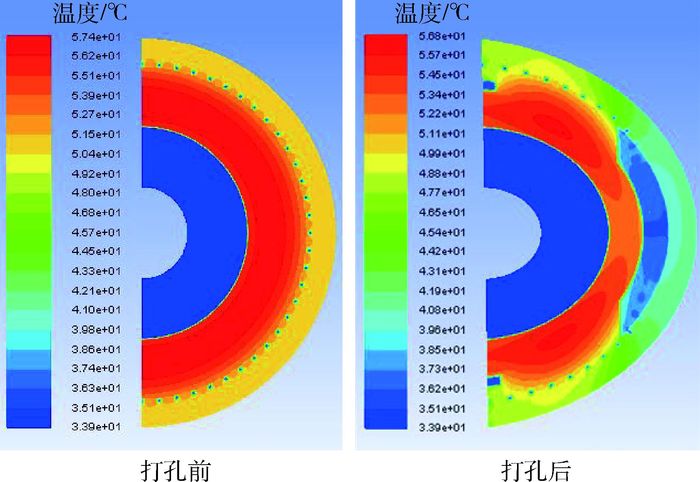

介绍三相异步电机-轴向柱塞式电液泵(EHP)的集成结构与工作原理,计算电液泵机械损耗,在Ansoft软件中建立电液泵电机模型,仿真分析电液泵的电磁损耗,并在此基础上建立有限元耦合模型,借助Fluent软件仿真分析液压油在壳体内腔的流动与温度分布状态,以及关键零部件的温度分布。有限元分析结果表明,液压油可以在流道内充分流动,并且额定工作状态下,当进口液压油温度为35℃时,电机定子最高温度不超过58℃,转子最高温度不超过40℃,散热效果好于传统电动机-泵组。针对定子内部温度较高的现象,研究了定子四周打4个直径10 mm的通孔后的温度分布情况,并与打孔前进行了对比,结果表明,打孔后电机定子最高温度降低了0.6℃,局部区域温度降低超过3℃,散热效果改善明显。

Abstract:The integrated structure and working principle of three phase induction motor-axial piston electro-hydraulic pump (EHP) were introduced. The mechanical losses were calculated. A model of EHP was established in Ansoft software, and then the electromagnetic losses were analyzed. Finite element coupling model was established. The flow and temperature distribution of hydraulic oil as well as the temperature field distribution of the key parts were analyzed by Fluent software. The analysis results depict that hydraulic oil can fully flow in internal flow road. The maximum temperature of stator is not more than 58℃, and the maximum temperature of rotor is not more than 40℃ under rated condition when the inlet oil temperature is 35℃. Cooling effect is better than motor-pump sets. The results also show that stator oil hole can obviously improve cooling effect. The maximum temperature of stator is reduced by 0.6℃, and local region temperature is reduced by more than 3℃ when four oil holes with a diameter of 10 mm are made.

-

Key words:

- electro-hydraulic pump (EHP) /

- flow field /

- temperature field /

- finite element /

- loss

-

表 1 电机主要参数

Table 1. Main parameters of motor

参数 数值 定子外径/mm 290 定子内径/mm 187 转子内径/mm 90 铁芯长度/mm 190 气隙长度/mm 0.6 极对数 2 输出功率/kW 22 表 2 电磁损耗参数

Table 2. Electromagnetic loss parameters

W 损耗类型 数值 定子铜耗 892.93 定子铁耗 432.04 转子铝耗 482.53 摩擦损耗 293.65 杂散损耗 110.00 表 3 柱塞泵主要参数

Table 3. Main parameters of piston pump

参数 数值 Z 9 dz/mm 14.2 μ/(Pa·s) 0.04 Rf/mm 50 Δp/MPa 28 R/mm 92.9 β/(°) 20 ω/(rad·s-1) 1 460 fc1 0.1 fc2 0.1 fc3 0.08 fb 0.002 注:dz—柱塞直径;Rf—分度圆直径。 表 4 机械损耗

Table 4. Mechanical losses

W 损耗类型 数值 黏性摩擦损耗 配流副 335.34 柱塞副 300.84 滑靴副 17.67 滑动摩擦损耗 配流副 46.48 柱塞副 2.10 滑靴副 38.30 滑靴球绞 21.06 油隙摩擦损耗 1 491.60 轴承摩擦损耗 5.73 表 5 材料属性

Table 5. Material property

材料 密度/

(kg·m-3)比热容/

(J·kg-1·

K-1)热导率/

(W·m-1·

K-1)运动黏度/

(Pa·s)46#液压油 872 1 800 0.13 0.04 硅钢片 7 850 502.4 58.2 铸铝 2 719 871 202.4 碳钢 8 030 502.48 16.27 表 6 热源参数

Table 6. Heat source parameters

参数 体热源 面热源 定子产热率/

(W·m-3)转子产热率/

(W·m-3)转子轴承面产热率/

(W·m-2)斜盘面产热率/

(W·m-2)配流盘面产热率/

(W·m-2)数值 169 445.80 281 531.60 64.85 11 134.87 67 630.48 -

[1] 付永领, 安高成, 李祝锋.电液泵发展现状与关键技术综述[J].机床与液压, 2012, 40(1):143-149. http://www.cnki.com.cn/Article/CJFDTOTAL-JCYY201201041.htmFU Y L, AN G C, LI Z F.Review of the state of the art and core techniques of edropump[J].Machine Tool and Hydraulics, 2012, 40(1):143-149(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JCYY201201041.htm [2] LESLIE M C, ROBERT C H.Integrated electric motor driven in line hydraulic pump:USA, 5708311[P].1998-01-13. [3] ALLAN A V.Integrated motor pump combination:USA, 4850812[P].1989-07-25. [4] KAZUNORI K, MASAAKI S, MASAHITO H.Fluid pressure generating device:USA, 5591013[P].1997-01-07. [5] FRANZ A, GUNTHER N.Motor driven pump unit:US2004/0136847A1[P].2004-07-15. [6] GERD H, FRANZ A.Motor-pump unit:US7381036B2[P].2008-06-03. [7] 冀宏, 丁大力, 王峥嵘, 等.液压电机泵内置孔板离心泵的流场解析与优化[J].机械工程学报, 2009, 45(6):199-205. http://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200906032.htmJI H, DING D L, WANG Z R, et al.Flow analysis and optimization of port-plate centrifugal pump in electric motor pump[J].Journal of Mechanical Engineering, 2009, 45(6):199-205(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200906032.htm [8] 张大杰, 高殿荣, 王有杰, 等.基于ANSYS的轴向柱塞液压电机泵电磁场数值计算与分析[J].机械工程学报, 2008, 44(12):69-74. http://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200812013.htmZHANG D J, GAO D R, WANG Y J, et al.Numerical calculation and analysis of electro-magnetic-field of axial piston hydraulic motor pump based on ANSYS[J].Chinese Journal of Mechanical Engineering, 2008, 44(12):69-74(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200812013.htm [9] 冀宏, 孙磊, 王峥嵘, 等.液压电机泵中浸油电机的负载效应[J].兰州理工大学学报, 2009, 35(4):52-56. http://www.cnki.com.cn/Article/CJFDTOTAL-GSGY200904012.htmJI H, SUN L, WANG Z R, et al.The load effect of oil immersed motor in hydraulic motor pump[J].Journal of Lanzhou University of Technology, 2009, 35(4):52-56(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-GSGY200904012.htm [10] 黄志新.ANSYS Workbench 14.0超级学习手册[M].北京:人民邮电出版社, 2013:472-473.HUANG Z X.ANSYS Workbench 14.0 super learning handbook[M].Beijing:Posts and Telecom Press, 2013:472-473(in Chinese). [11] 魏永田, 孟大伟.电机内热交换[M].北京:机械工业出版社, 1998:1-10.WEI Y T, MENG D W.Heat exchange in motors[M].Beijing:China Machine Press, 1998:1-10(in Chinese). [12] 赵博.Ansoft 12在工程电磁场中的应用[M].北京:中国水利水电出版社, 2010:377-380.ZHAO B.Application of Ansoft 12 in engineering electromagnetic field[M].Beijing:China Water and Power Press, 2010:377-380(in Chinese). [13] 张斌. 轴向柱塞泵的虚拟样机及油膜压力特性研究[D]. 杭州: 浙江大学, 2009: 80-83.ZHANG B.Study on virtual prototype and pressure characteristics of oil film for axial piston pump[D].Hangzhou:Zhejiang University, 2009:80-83(in Chinese). [14] 许耀铭.油膜理论和液压泵和马达的摩擦副设计[M].北京:机械工业出版社, 1987:140.XU Y M.Film theory and friction design of hydraulic pumps and motors[M].Beijing:China Machine Press, 1987:140(in Chinese). [15] 付永领, 李祝锋, 祁晓野, 等.轴向柱塞式电液泵能量转化效率研究[J].机械工程学报, 2014, 50(14):204-212. http://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201414033.htmFU Y L, LI Z F, QI X Y, et al.Research on the energy conversion efficiency of axial piston electro-hydraulic pump[J].Journal of Mechanical Engineering, 2014, 50(14):204-212(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201414033.htm -

下载:

下载: