Performance optimization for 150 kV inverter power supply and its electron beam source characteristics

-

摘要:

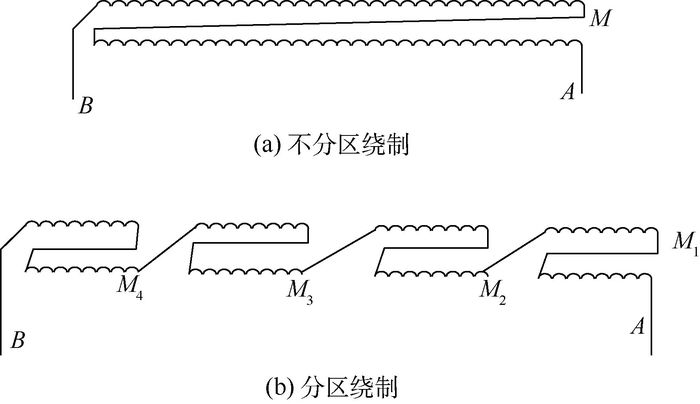

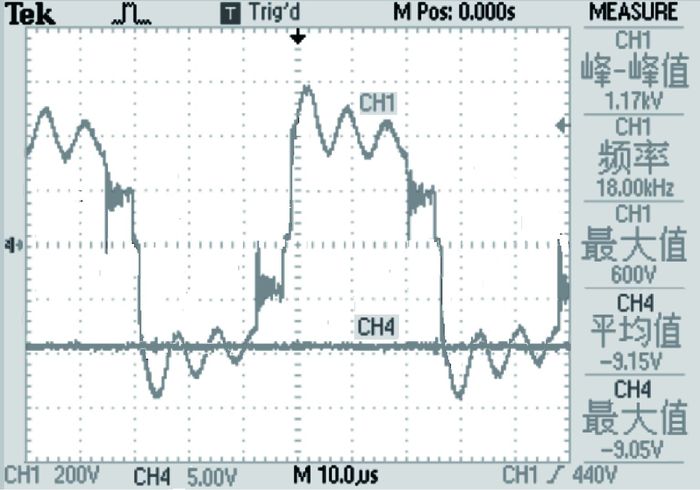

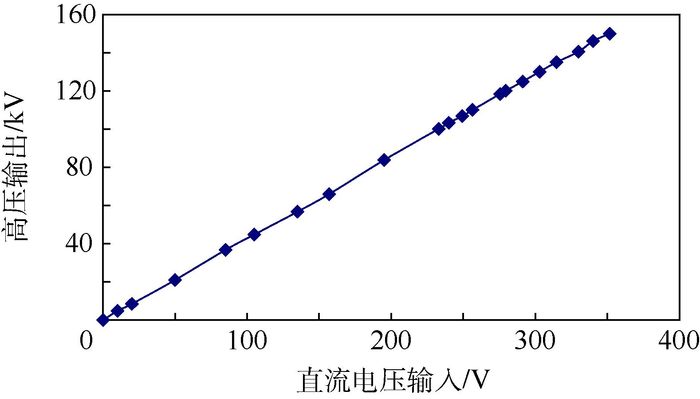

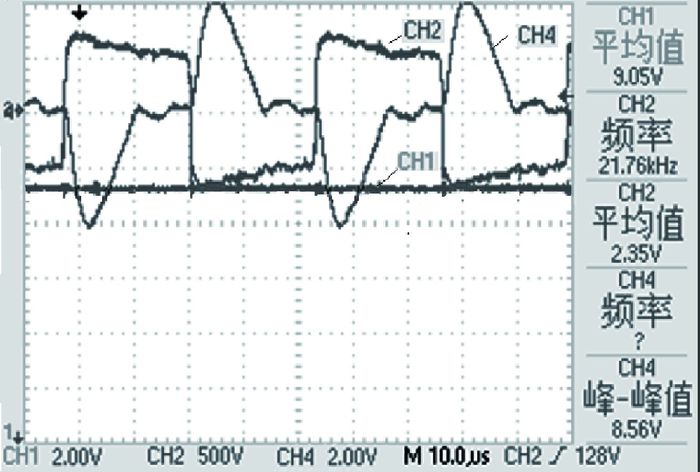

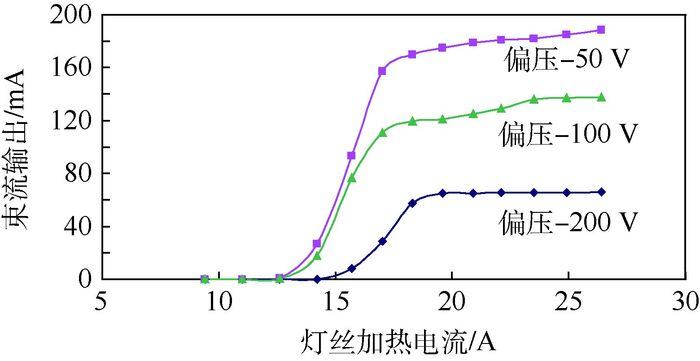

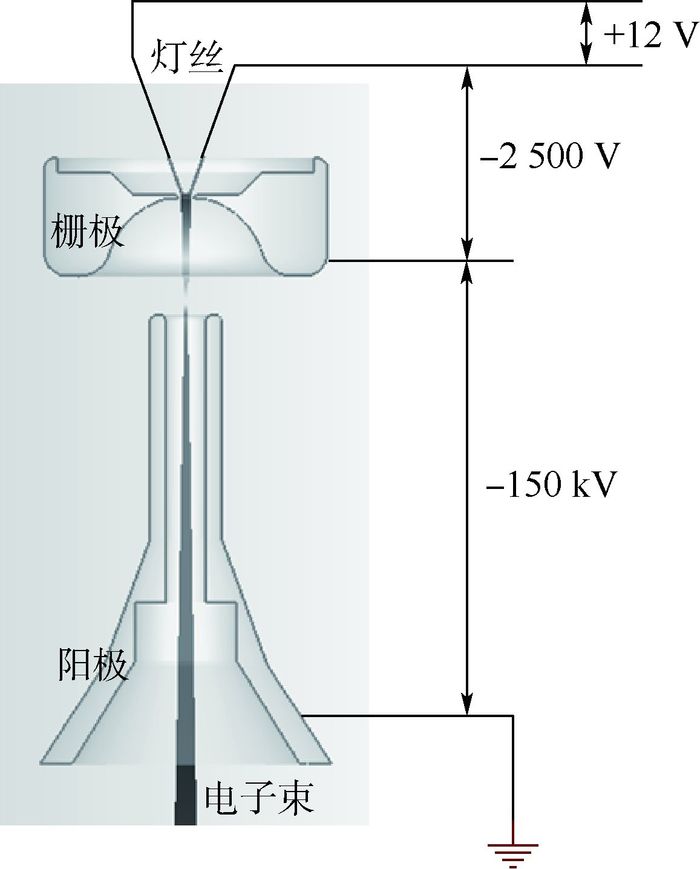

为了进一步提高电子束流发生系统工作的可靠性和稳定性,提高电子束加工质量,采用AC-DC-AC-DC-AC-DC的拓扑电路、新型功率变压器、高压脉冲检测技术、优化的束流反馈控制与灯丝加热电流闭环反馈控制技术等,分别优化了高压加速电源、偏压电源与灯丝加热电源。将所研制逆变电源与150 kV/30 kW电子枪、真空系统等组成了一套电子束流发生系统,测试了该电子束流发生系统输出的高压、最大束流以及灯丝加热电流、偏压变化对束流输出的影响。试验结果表明:经过优化的逆变电源高压输出达到-150 kV,高压输出线性度较好,最大束流达到200 mA;高压、灯丝加热电流给定时,随着偏压降低,束流输出逐渐增大;高压、偏压给定时,随着灯丝加热电流增大,束流输出存在死区、线性增大区和恒流区。

Abstract:In order to enhance the stability and reliability of electron beam source system and improve the machining quality of electron beam, the topology circuit of AC-DC-AC-DC-AC-DC, new power transformer, high voltage pulse detection technology, optimized feedback control technology of electron beam and closed-loop control technology of filament current are introduced to optimize high voltage power source, bias voltage power source and filament power source. The inverter power supply, 150 kV/30 kW EB gun, vacuum system and others control system were integrated to establish a set of electron beam system. The high voltage, maximal electron beam output, and the influence of bias voltage and filament current on beam output are tested. The results of a series of tests show that the high voltage output of the inverter power supply has a fine linearity, and the maximum beam output is up to 200 mA at the high voltage output up to-150 kV. At given high voltage and current of filament, the electron beam will increase with the decrease of bias voltage. When the high voltage and bias voltage are given changeless, the electron beam output experiences non-beam phase, linear increasable phase and steady changeless phase with the increase of filament current.

-

Key words:

- inverter power supply /

- high voltage /

- electron beam /

- bias voltage /

- filament heating current

-

-

[1] 李晓延, 武传松, 李午申.中国加工制造领域学科发展研究[J].机械工程学报, 2012, 48(6):19-31.LI X Y, WU C S, LI W S.Study on the progress of welding science and technology in China[J].Journal of Mechanical Engineering, 2012, 48(6):19-31(in Chinese). [2] HO C Y.Fusion zone during focused electron-beam welding[J].Journal of Materials Processing Technology, 2005, 167(2-3):265-272. doi: 10.1016/j.jmatprotec.2005.05.025 [3] 李晓红, 毛唯, 熊华平.先进航空材料和复杂构件的加工技术[J].航空材料学报, 2006, 26(3):276-282.LI X H, MAO W, XIONG H P.Welding technologies of advanced aeronautical materials and complex-shaped structural components[J].Journal of Aeronautical Materials, 2006, 26(3):276-282(in Chinese). [4] 闫晓峰.真空电子束焊在我国航空机载设备上的应用及发展趋势[J].航空制造技术, 2005(9):90-102. http://www.cnki.com.cn/Article/CJFDTOTAL-HKGJ200509017.htmYAN X F.Application and development trend of vacuum EB welding in airborne equipment in China[J].Aeronautical Manufacturing Technology, 2005(9):90-102(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKGJ200509017.htm [5] 毛智勇.电子束加工技术在大飞机中的应用分析[J].航空制造技术, 2009(2):92-94.MAO Z Y.Application of electron beam welding technology in large aircraft[J].Aeronautical Manufacturing Technology, 2009(2):92-94(in Chinese). [6] 樊兆宝, 安绍孔, 王英健, 等.真空电子束焊接技术及其在空空导弹弹体加工中的应用[J].航空制造技术, 2010(16):53-56. doi: 10.3969/j.issn.1671-833X.2010.16.007FAN Z B, AN S K, WANG Y J, et al.Technology of vacuum electron beam welding and its application in manufacturing of air-to-air missile's body[J].Aeronautical Manufacturing Technology, 2010(16):53-56(in Chinese). doi: 10.3969/j.issn.1671-833X.2010.16.007 [7] 张伟, 杜慧聪, 齐铂金, 等.150 kV/30 kW逆变式电子束焊接高压电源设计[J].北京航空航天大学学报, 2014, 40(11):1531-1536.ZHANG W, DU H C, QI B J, et al.150 kV/30 kW inverter for electron beam welding power supply design[J].Journal of Beijing University of Aeronautics and Astronautics, 2014, 40(11):1531-1536(in Chinese). [8] 杜秉初, 汪健如.电子光学[M].北京:清华大学出版社, 2002.DU B C, WANG J R.Electron optics[M].Beijing:Tsinghua University Press, 2002(in Chinese). [9] DUPAK J, VLCEK I, ZOBAC M.Electron gun for computer-controlled welding of small components[J].Vacuum, 2001, 62(2-3):159-164. doi: 10.1016/S0042-207X(00)00435-8 [10] 张仁毅, 陈昌渔, 王昌长.高电压试验技术[M].北京:清华大学出版社, 2012.ZHANG R Y, CHEN C Y, WANG C C.High-voltage testing technology[M].Beijing:Tsinghua University Press, 2012(in Chinese). [11] 王亚君, 周岐.PWM型倍压电路压降的计算[J].辽宁工业大学学报(自然科学版), 2008, 28(5):299-301. http://www.cnki.com.cn/Article/CJFDTOTAL-LNGX200805008.htmWANG Y J, ZHOU Q.Calculation of output voltage from voltage multiplying circuit of PWM[J].Journal of Liaoning University of Technology(Natural Science Edition), 2008, 28(5):299-301(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-LNGX200805008.htm [12] 许海鹰, 杨波, 左从进, 等. 一种高压逆变功率变压器及其制作方法: ZL201410253182. 3[P]. 2014-06-09.XU H Y, YANG B, ZUO C J, et al.A type of high voltage inverter power transformer and manufacture method:ZL201410253182.3[P].2014-06-09(in Chinese). [13] 范霁康, 齐铂金, 刘方军, 等.新型电子束焊机高压电源的设计与实现[J].北京航空航天大学学报, 2017, 43(2):293-300.FAN J K, QI B J, LIU F J, et al. Design and implementation off a novel high-voltage power supply in electron beam welding machine[J].Journal of Beijing University of Aeronautics and Astronautics, 2017, 43(2):293-300(in Chinese). [14] IQBAL M, RAFIQ M, BHATTI S A, et al. The electron beam gun with thermionic hairpin-like cathode for welding and surface modifications[J].Vacuum, 2004, 77(1):19-26. doi: 10.1016/j.vacuum.2004.07.066 [15] HORACEK M, DUPAK J. Temperature controlled cathode heating in electron beam welding machine[J]. Vacuum, 2001, 62(2-3):165-169. doi: 10.1016/S0042-207X(01)00273-1 -

下载:

下载: