-

摘要:

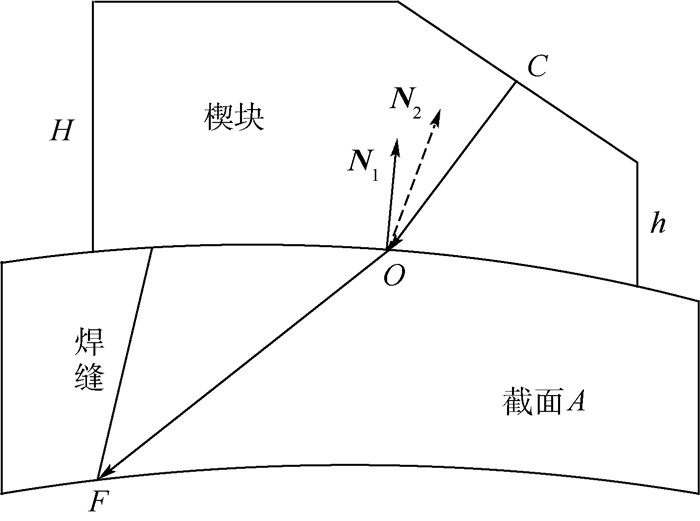

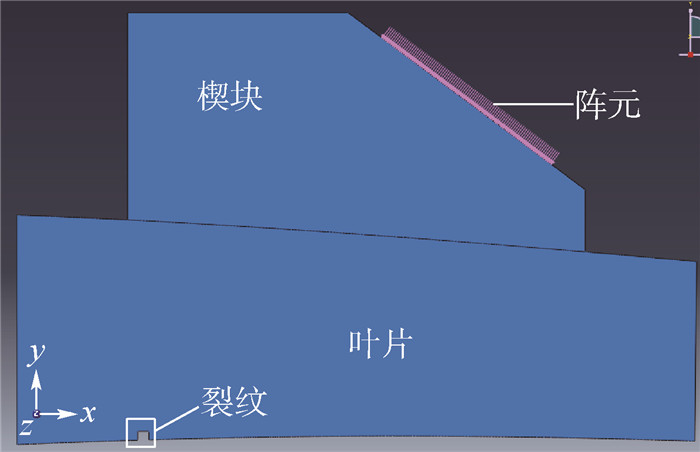

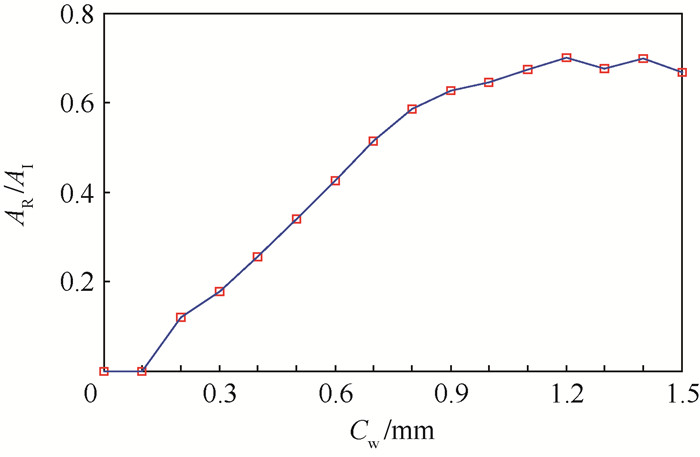

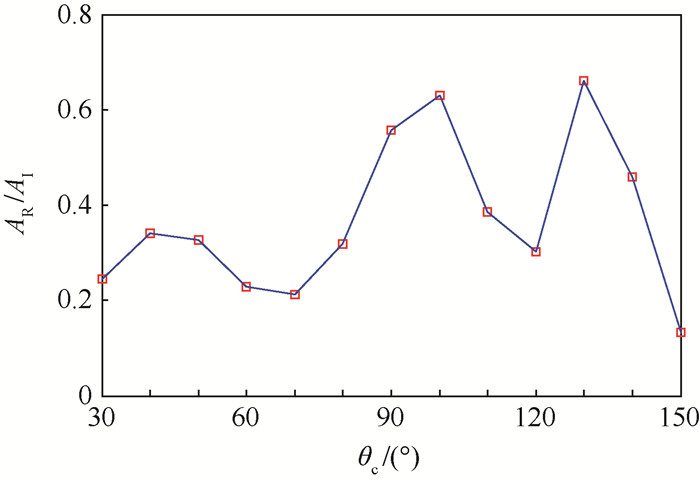

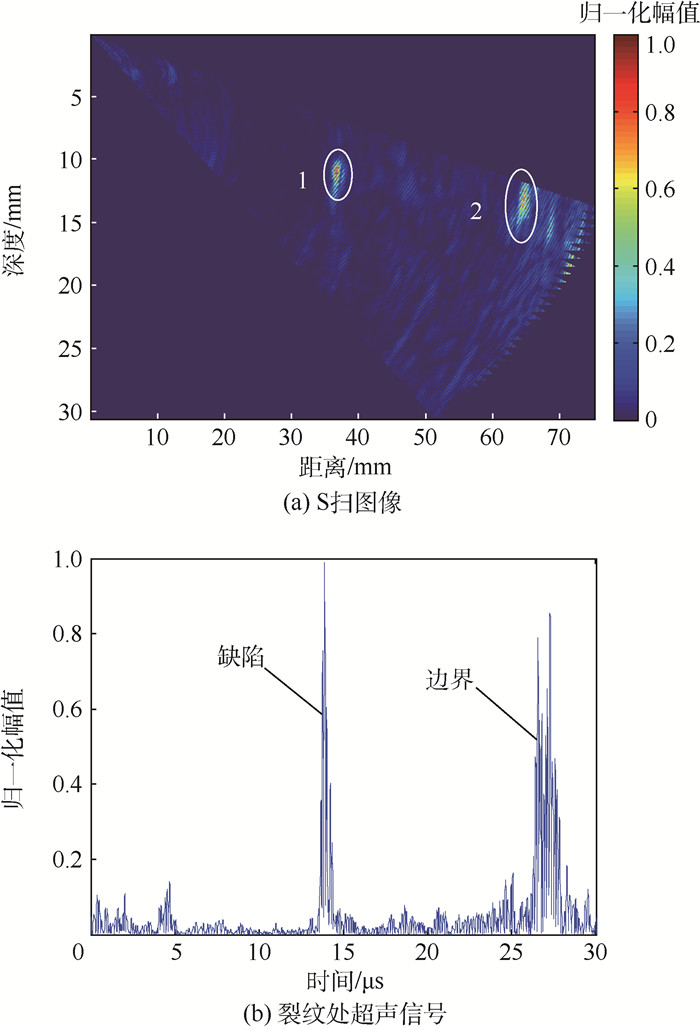

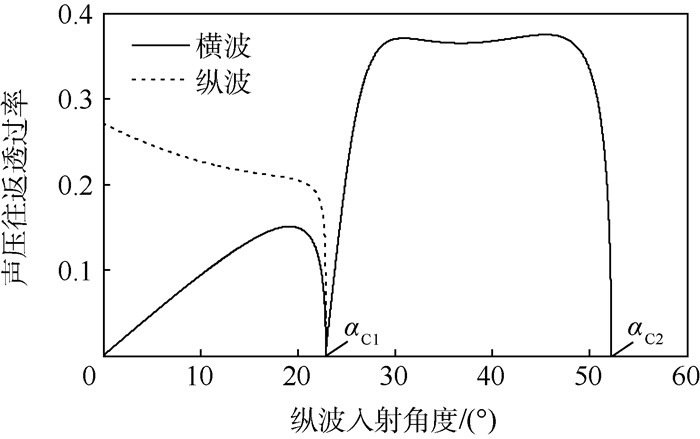

裂纹是线性摩擦焊整体叶盘结构制造过程中叶片焊缝区域常见的缺陷类型之一。由于叶片焊缝区域结构复杂且裂纹缺陷尺寸小,因此焊缝区域裂纹缺陷的检测难度大。为了满足新工艺的应用要求,研究了焊缝区域的相控阵超声全覆盖检测方法,建立了焊缝区域相控阵超声检测的有限元仿真模型,研究了裂纹特征参数和声束聚焦点位置对检测方案的影响,验证了检测方案的可行性与正确性。构建了机器人化的相控阵超声检测系统,模拟了声束在线性摩擦焊叶片试样中的传播过程,实现了对叶片中预制裂纹缺陷的识别。研究结果表明,设计的检测方案能够满足叶片快速检测的要求。

Abstract:Crack is a type of common defect in welding area of blade appearing in the process of blisk manufacture. Due to the complex structure of welding area in blade and the small size of crack defect, it is difficult to detect the welding crack. In order to satisfy the application requirement of this new process, a completely covered testing method, based on ultrasonic phased array inspection technique, to welding area was proposed. Finite element simulation models for phased array testing of welding area were built. The effects of crack parameters and ultrasonic beam focal position on the detection program were researched to testify the feasibility and validity of the detection program. A roboticized phased array ultrasonic testing system was established to simulate the propagation of ultrasonic beam in linear friction welding blade specimen and to achieve the recognition of prefabricated crack defects. The research results show that the proposed detection program can fulfill the requirement of rapid detection for linear friction welding blisk blade.

-

Key words:

- ultrasonic phased array detection /

- blade /

- linear friction welding /

- crack /

- finite element simulation

-

表 1 试验参数

Table 1. Test parameters

参数 数值 探头频率/MHz 5 阵元个数 32 孔径大小 32 聚焦深度/mm 10~20 扫查角度/(°) 40~70 增益/dB 60 激励电压/V 400 注:扫查方式为S扫。 -

[1] 刘杰, 郑宁, 徐朋飞, 等.整体叶盘结构叶片弹性变形规律及其对风扇气动性能的影响[J].科学技术与工程, 2014, 14(34):302-306. doi: 10.3969/j.issn.1671-1815.2014.34.058LIU J, ZHENG N, XU P F, et al.Blade flexibility deformation pattern of the blisk structure and it's influence on the aerodynamic performance of fan[J].Science Technology and Engineering, 2014, 14(34):302-306(in Chinese). doi: 10.3969/j.issn.1671-1815.2014.34.058 [2] YANG Y H, LIU D, LUO Z J.Microstructure homogeneity evaluation for TC11 blisk forging using loss function based on Taguchi method[J].Rare Metal Materials and Engineering, 2011, 401(4):565-570. [3] KLOCKE F, SCHMITT R, ZEIS M, et al.Technological and economical assessment of alternative process chains for blisk manufacture[J].Procedia CIRP, 2015, 35:67-72. doi: 10.1016/j.procir.2015.08.052 [4] RAVI-KUMAR B V R.A review on blisk technology[J].International Journal of Innovative Research in Science, Engineering and Technology, 2013, 2(5):1353-1358. [5] 张海燕, 张连锋.航空发动机整体叶盘制造技术国内外发展概述[J].航空制造技术, 2013(23):38-41. doi: 10.3969/j.issn.1671-833X.2013.23.002ZHANG H Y, ZHANG L F.Development overview of aeroengine integral blisk and its manufacturing technology at home and abroad[J].Aeronautical Manufacturing Technology, 2013(23):38-41(in Chinese). doi: 10.3969/j.issn.1671-833X.2013.23.002 [6] 朱瑞峰, 白钢, 苏利龙, 等.线性摩擦焊及其研究应用现状[J].热加工工艺, 2009, 38(9):100-103. http://www.cnki.com.cn/Article/CJFDTOTAL-SJGY200909034.htmZHU R F, BAI G, SU L L, et al.Research and application of linear friction welding[J].Hot Working Technology, 2009, 38(9):100-103(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-SJGY200909034.htm [7] 杨剑赟. 钛合金线性摩擦焊塑性流动对焊缝成形影响[D]. 南昌: 南昌航空大学, 2012: 25-30.YANG J Y.The influence of plastic flow on the weld formation of linear friction welding for titanium alloy[D].Nanchang:Nanchang Hangkong University, 2012:25-30(in Chinese). [8] Technical Committee of American Society for Testing and Materials.Standard reference radiographs of investment steel castings for aerospace applications:ASTM E192-2004[S].Philadelphia:ASTM, 2004:1-4. [9] 靳世久, 杨晓霞, 陈世利, 等.超声相控阵检测技术的发展及应用[J].电子测量与仪器学报, 2014, 28(9):925-934. http://www.cnki.com.cn/Article/CJFDTOTAL-DZIY201409001.htmJIN S J, YANG X X, CHEN S L, et al.Development and application of ultrasonic phased array inspection technology[J].Journal of Electronic Measurement and Instrumentation, 2014, 28(9):925-934(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-DZIY201409001.htm [10] KOMURA I, NAGAI S, KASHIWAYA H, et al.Improved ultrasonic testing by phased array technique and its application[J].Nuclear Engineering and Design, 1985, 87:185-191. doi: 10.1016/0029-5493(85)90107-4 [11] MACNAB A, CAMPBELL M J.Ultrasonic phased arrays for nondestructive testing[J].NDT International, 1987, 6(20):333-337. [12] 常文爽. 低压汽轮机叶轮轮缘裂纹的超声相控阵检测[D]. 天津: 天津大学, 2012: 25-36.CHANG W S.Ultrasonic phased array testing of cracks in low-pressure turbine disc rim[D].Tianjin:Tianjin University, 2012:25-36(in Chinese). [13] CHARLESWORTH C.Phased array ultrasonic inspection of low-pressure steam turbine rotors-curved axial entry fir tree roots[J].Insight, 2011, 2(53):37-44. [14] 郑辉, 林树青.超声检测[M].2版.北京:中国劳动社会保障出版社, 2008:36-43.ZHENG H, LIN S Q.Ultrasonic testing[M].2nd ed.Beijing:China Labour & Social Security Publishing House, 2008:36-43(in Chinese). [15] 李家伟, 陈积懋.无损检测手册[M].北京:机械工业出版社, 2002:157-163.LI J W, CHEN J M.Nondestructive testing manual[M].Beijing:China Machine Press, 2002:157-163(in Chinese). [16] 徐娜, 何方成, 周正干.基于动态孔径聚焦的L型构件相控阵超声检测[J].北京航空航天大学学报, 2015, 41(6):1000-1006.XU N, HE F C, ZHOU Z G.Ultrasonic phased array inspection of L-shaped components based on dynamic aperture focusing[J].Journal of Beijing University of Aeronautics and Astronautics, 2015, 41(6):1000-1006(in Chinese). -

下载:

下载: