Detection of skin desoldering defect in Ti-alloy honeycomb using linear frequency modulated infrared imaging

-

摘要:

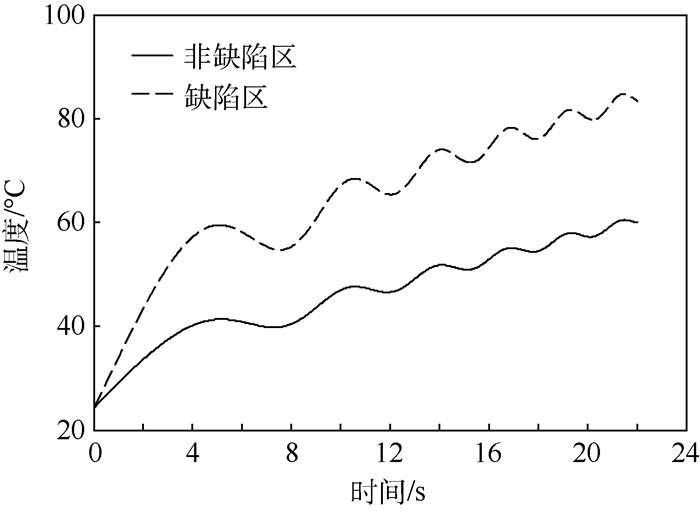

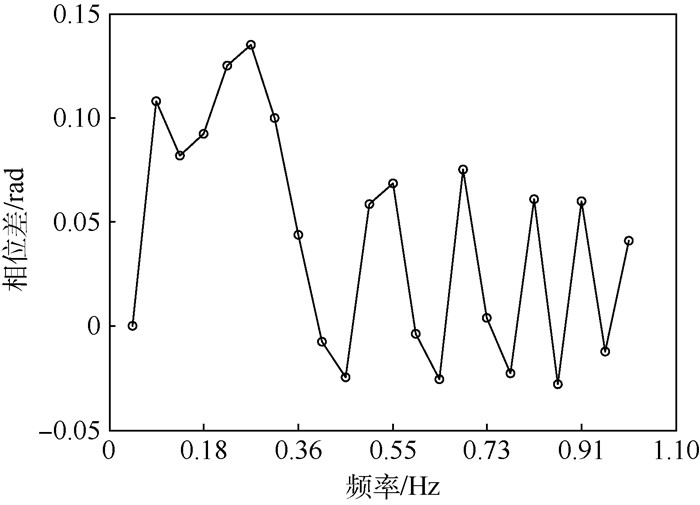

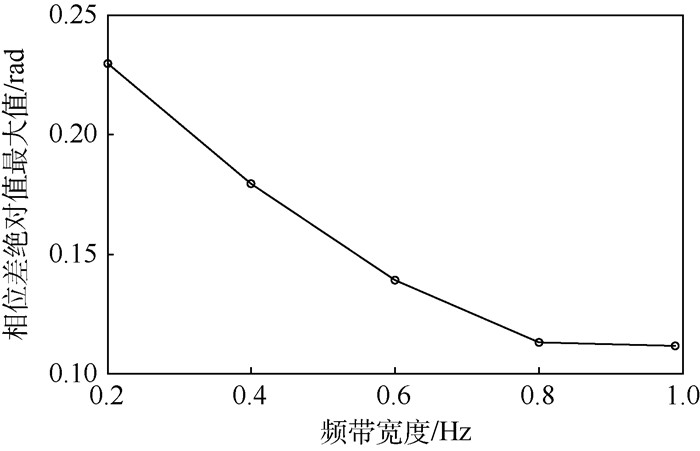

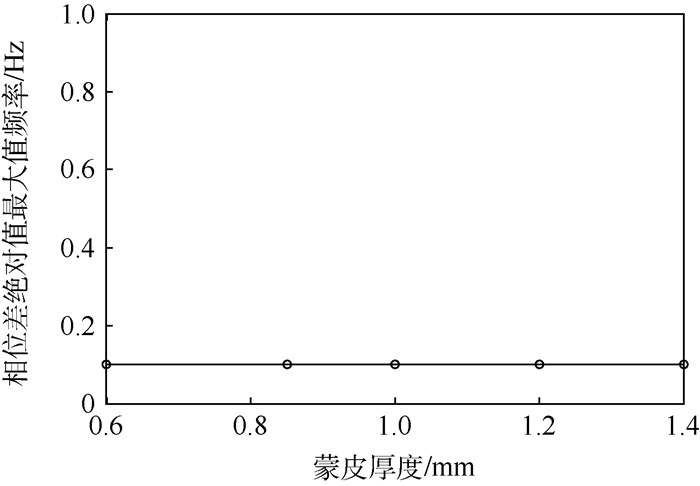

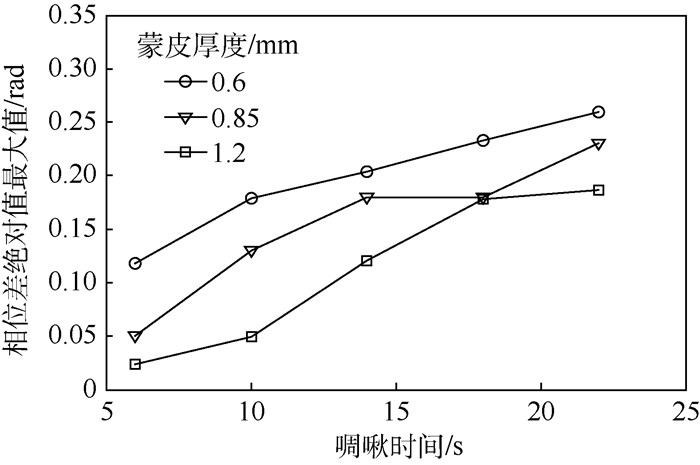

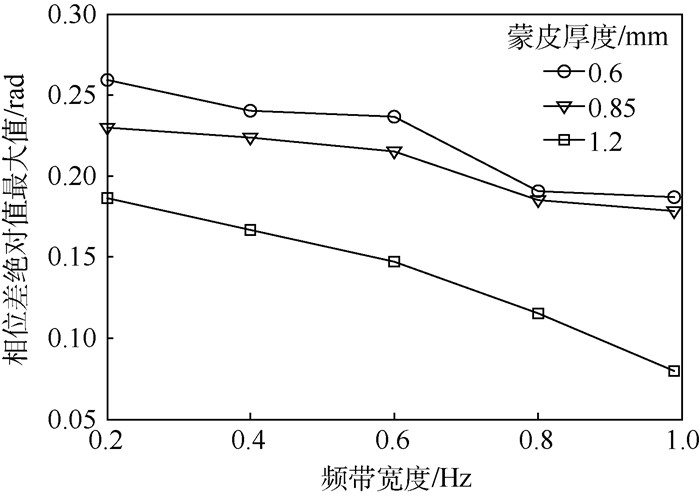

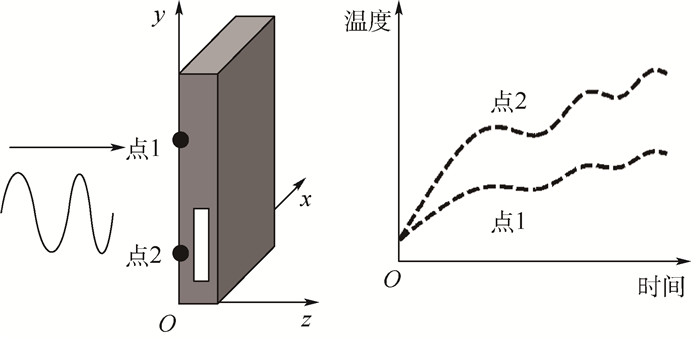

变蒙皮厚度的钛合金蜂窝在航空航天领域有着广泛的应用,蒙皮脱焊是钛合金蜂窝结构最常见的缺陷类型之一。传统锁相红外检测由于调制频率单一,不能对变蒙皮厚度的蒙皮脱焊实现一次性检测,检测效率低。针对这一问题,研究了线性调频激励红外检测以及激励参数选择方法。使用ANSYS建立了钛合金蜂窝有限元仿真模型,通过相关算法计算了对应脱焊区域和正常区域的相位差,分析了频带范围、啁啾时间对相位差绝对值最大值的影响以及蒙皮厚度与相位差绝对值最大值所在频率成分的关系。利用线性调频激励对预制脱焊缺陷的蜂窝试样进行了实验研究,获得了不同频带范围和不同啁啾时间下的相位图。实验结果表明,采用频带范围为0.01~0.21 Hz,啁啾时间为22 s的线性调频信号可以对蒙皮厚度为0.6~1.2 mm的钛合金蜂窝实现一次性检测,为钛合金蜂窝结构的实际检测提供了工艺指导。

Abstract:Ti-alloy honeycomb with variable skin thickness has been widely used in the aerospace field. Skin desoldering is one of the most common defects of Ti-alloy honeycomb sandwich. Because of single frequency, traditional lock-in thermography cannot defect desoldering under skin with a variety of thicknesses in one time and has low detection efficiency. To solve this problem, linear frequency modulated infrared imaging and excitation parameter selection method were studied. The finite element simulation model of Ti-alloy honeycomb was established by using ANSYS. Phase difference between desoldering region and normal region was calculated through correlation algorithm and the relationship between freqnency bandwidth, chirp time, skin thickness and maximum of phase difference absolute value was analyzed. Honeycomb sample with prefabricated desoldering defects was experimentally studied using linear frequency modulated exciting. Phase diagrams with different frequency bandwidth and different chirp time are obtained. The results show that one-time detection of Ti-alloy honeycomb with skin thickness 0.6-1.2 mm can be realized using linear frequency modulated signal with the frequency range 0.01-0.21 Hz and chirp time 22 s. These results provide a technical guidance for the practical detection of Ti-alloy honeycomb sandwich structure.

-

表 1 材料的热学性能参数

Table 1. Parameters of thermal properties of material

材料 热导率/

(W·(m·℃)-1)密度/

(kg·m-3)比热容/

(J·(kg·℃) -1)钛合金 7 4450 678 空气 0.026 1.161 1007 表 2 边界与初始条件参数

Table 2. Parameters of boundary and initial conditions

参数 换热系数/

(W·(m·℃)-1)热流强度/

(W·m-2)环境温度/

℃数值 12.5 200 24 表 3 仿真变化参数

Table 3. Simulation change parameters

参数 数值 啁啾时间/s 6,10,12,14,16,18 蒙皮厚度/mm 0.6,0.85,1.0,1.2,1.4,2.0 频带宽度/Hz 0.2,0.4,0.6,0.8,0.99 -

[1] HUANG X, RICHARDS N L.Activated diffusion brazing technology for manufacture of titanium honeycomb structures-A statistical study[J].Welding Journal, 2004, 83(3):73-81. [2] 静永娟, 李晓红, 岳喜山.TC1钛合金蜂窝夹层结构的钎焊工艺研究与分析[J].航空制造技术, 2012(13):137-139. doi: 10.3969/j.issn.1671-833X.2012.13.029JING Y J, LI X H, YUE X S.Research and analysis of processing parameter for brazing honeycomb sandwich construction in titanium alloy[J].Aeronautical Manufacturing Technology, 2012(13):137-139(in Chinese). doi: 10.3969/j.issn.1671-833X.2012.13.029 [3] 苏小丽. 钛合金蜂窝芯制造技术研究[D]. 南京: 南京航空航天大学, 2014.SU X L.Research on the manufacturing technology of titanium alloy honeycomb cores[D].Nanjing:Nanjing University of Aeronautics and Astronautics, 2014(in Chinese). [4] 杨海波, 江少华, 赵志远, 等.钛合金蜂窝整体机身壁板技术应用研究[J].航空制造技术, 2013(16):126-128. doi: 10.3969/j.issn.1671-833X.2013.16.029YANG H B, JIANG S H, ZHAO Z Y, et al.Engineering application research of titanium honeycomb integral fuselage panel technology[J].Aeronautical Manufacturing Technology, 2013(16):126-128(in Chinese). doi: 10.3969/j.issn.1671-833X.2013.16.029 [5] 谢凯文, 杜丽婷, 张斌, 等.钎焊蜂窝夹层结构的超声检测技术研究[J].无损探伤, 2014, 38(4):24-26. http://www.cnki.com.cn/Article/CJFDTOTAL-WSTS201404009.htmXIE K W, DU L T, ZHANG B, et al.Research on the inspection of defects in Ti-alloy honeycomb sandwich using ultrasonic testing[J].NDT, 2014, 38(4):24-26(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-WSTS201404009.htm [6] 刚铁, 石端虎, 袁媛.射线检测钛合金激光焊件微小缺陷分布特征[J].光电子·激光, 2006, 17(11):1372-1376. doi: 10.3321/j.issn:1005-0086.2006.11.022GANG T, SHI D H, YUAN Y.Distribution feature of tiny flaw in laser welding parts of titanium alloy using X-ray detection[J].Journal of Optoelectronics·Laser, 2006, 17(11):1372-1376(in Chinese). doi: 10.3321/j.issn:1005-0086.2006.11.022 [7] 赵林博, 徐珊珊, 雷鹍, 等.无损检测新技术在钛合金SPF/DB结构检测中的应用研究[J].新技术新工艺, 2012(3):77-79. http://www.cnki.com.cn/Article/CJFDTOTAL-XJXG201203031.htmZHAO L B, XU S S, LEI K, et al.A study on application of infrared detection testing for SPF/DB of titanium alloy[J].New Technology & New Process, 2012(3):77-79(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-XJXG201203031.htm [8] GHALI V S, MULAVEESALA R.Frequency modulated thermal wave imaging techniques for non-destructive testing[J].Progress in Electromagnetics Research Monitoring, 2010, 52(9):475-480. [9] MULAVEESALA R, TULI S.Theory of frequency modulated thermal wave imaging for nondestructive subsurface defect detection[J].Applied Physics Letters, 2006, 89(19):191913. doi: 10.1063/1.2382738 [10] MALDAGUE X P V.Theory and practice of infrared technology for nondestructive testing[M].New York:Wiley, 2001:307. [11] LIU J, YANG W, DAI J.Research on thermal wave processing of lock-in thermography based on analyzing image sequences for NDT[J].Infrared Physics & Technology, 2010, 53(5):348-357. [12] 刘俊岩, 刘勋, 王扬.线性调频激励的红外热波成像检测技术[J].红外与激光工程, 2012, 41(6):1416-1422. http://www.cnki.com.cn/Article/CJFDTOTAL-HWYJ201206005.htmLIU J Y, LIU X, WANG Y.Technology of linear frequency modulation infrared thermal-wave imaging for nondestructive testing[J].Infrared and Laser Engineering, 2012, 41(6):1416-1422(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HWYJ201206005.htm [13] GONG J, LIU J, QIN L, et al.Investigation of carbon fiber reinforced polymer (CFRP) sheet with subsurface defects inspection using thermal-wave radar imaging (TWRI) based on the multi-transform technique[J].Ndt & E International, 2013, 62(2):130-136. [14] VÁZQUEZ P, THOMACHOT-SCHNEIDER C, MOUHOUBI K, et al.Infrared thermography monitoring of the NaCl crystallisation process[J].Infrared Physics & Technology, 2015, 71:198-207. [15] SARDOT T, MCDONALD A G, SMITH G.Characterization of a cardboard recycling facility's mixed plastic waste for beneficial use[J].Waste & Biomass Valorization, 2013, 4(1):161-171. doi: 10.1007/s12649-012-9111-0 [16] 周正干, 贺鹏飞, 赵翰学, 等.钛合金蜂窝结构蒙皮脱焊缺陷锁相红外检测[J].北京航空航天大学学报, 2016, 42(9):1795-1802.ZHOU Z G, HE P F, ZHAO H X, et al.Detection of desoldering defect in Ti-alloy honeycomb sandwich using lock-in infrared thermography[J].Journal of Beijing University of Aeronautics and Astronautics, 2016, 42(9):1795-1802(in Chinese). -

下载:

下载: