Influence on surface performance of 2024-T3 aluminum alloy processed with oxidising paste

-

摘要:

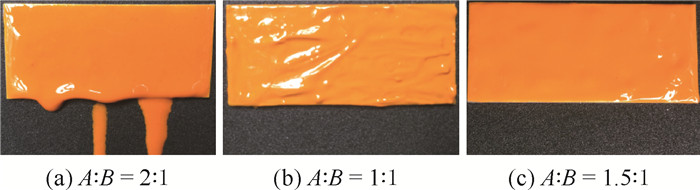

针对铝合金蒙皮表面涂层修复对基材局部现场氧化处理的需求,研究了膏状氧化材料的调制方法,并探讨了氧化膏在2024-T3铝合金表面的成膜性能。通过扫描电镜、能谱、体视显微镜、点滴、电化学、接触角测试以及拉伸剪切实验考察了氧化膜的形貌和组成、耐蚀性能及粘接性能。实验表明,室温下铝合金表面经氧化膏处理后可快速生成氧化膜,膜层具有一定的微观孔洞结构,主要包含Al、F、Cr、O等元素;膜层耐蚀性与阿洛丁氧化液处理效果相近,与未氧化试样相比腐蚀电压由-0.898 V升至-0.880 V,腐蚀电流密度由2.582×10-5 A/cm2降至3.334×10-7 A/cm2,阻抗值由1.556×103Ω/cm2增至1.347×105 Ω/cm2;表面自由能和粘附功分别由32.7 mJ/cm2和36.3 mJ提高到55.7 mJ/cm2和109.7 mJ,拉伸剪切强度由11.7 MPa提升为15.0 MPa,结果表明氧化膜的形貌和组成有助于获得更好的界面结合力并改善基材的粘接性能。

-

关键词:

- 氧化膏 /

- 2024-T3铝合金 /

- 氧化膜 /

- 耐蚀性能 /

- 粘接性能

Abstract:Oxidising paste was prepared for in-situ local oxidation treatment of coatings on aluminum alloy skin surface and its film-forming performance on 2024-T3 aluminum alloy was studied. Morphology and chemical composition, corrosion resistance, and adhesive performance of the oxidation film were investigated by SEM, EDS, stereomicroscope, drop test, electrochemistry test, contact angle and tension loading method. The results show that oxidation film can be obtained rapidly on aluminum alloy surface after treated by oxidising paste, and the film has microscopic pore structure, including Al, F, Cr, O, etc. Corrosion resistance of the film is similar to that gained by Alodine solution. Compared to the bare sample, corrosion potential increases from -0.898 V to -0.880 V, corrosion current density decreases from 2.582×10-5 A/cm2 to 3.334×10-7 A/cm2, and impedance improves from 1.556×103 Ω/cm2 to 1.347×105 Ω/cm2. Surface free energy and the work of adhesion rise from 32.7 mJ/cm2 and 36.3 mJ to 55.7 mJ/cm2 and 109.7 mJ, respectively. Strength properties of adhesive in shear is promoted from 11.7 MPa to 15.0 MPa. The results indicate that morphology and chemical composition of the oxidation film can enhance interface bonding strength and adhesive performance.

-

Key words:

- oxidising paste /

- 2024-T3 aluminum alloy /

- oxidation film /

- corrosion resistance /

- adhesive performance

-

表 1 氧化膏的成分

Table 1. Composition of oxidising paste

组分 三氧化铬 氟化氢铵 磷酸氢二胺 硼酸 调节剂A 调节剂B 质量分数/% 10~12 1~2 1~2 1 45~55 30~40 表 2 3种不同处理下试样的表面元素

Table 2. Surface elements of samples with three different treatments

处理方式 表面元素 未氧化 Al,Cu,Mg 氧化液 Al,Cu,Mg,O,F,Cr, 氧化膏 Al,Cu,Mg,O,F,Cr,P 表 3 Tafel曲线的电化学参数

Table 3. Electrochemical parameters of Tafel curves

处理方式 Ecorr/V(versus SCE) jcorr/(A·cm-2) η/% 未氧化 -0.898 2.582×10-5 氧化液 -0.904 3.491×10-7 98.6 氧化膏 -0.880 3.334×10-7 98.7 表 4 不同处理试样的电化学参数

Table 4. Electrochemical parameters of samples with different treatments

处理方式 Rs/(Ω·cm-2) Ccoat/(μF·cm-2) Rcoat/(Ω·cm-2) Cdl/(μF·cm-2) Rct/(Ω·cm-2) 未氧化 1.557 1.214×10-6 7.17 1.483×10-5 1.556×103 氧化液 1.544 7.420×10-7 11.71 3.879×10-6 6.103×104 氧化膏 1.947 6.619×10-7 6.936 4.557×10-6 1.347×105 表 5 试样的接触角、表面自由能及粘附功

Table 5. Water contact angel, surface free energy and work of adhesion of samples

处理方式 θ/(°) γ/(mJ·cm-2) WA/mJ 未氧化 83.7 32.7 36.3 氧化液 54.5 41.6 65.7 氧化膏 14.4 55.7 109.7 表 6 金属搭接的胶粘剂拉伸剪切强度

Table 6. Strength properties of adhesive in shear by tension loading(metal to metal)

处理方式 P/N B/mm L/mm τ/MPa 无氧化 3 500 25 12 11.7 氧化液 3 600 25 12.0 12.0 氧化膏 4 500 25 12 15.0 -

[1] 蔺国民, 孙秦, 李艳华, 等.隐身飞机综述[J].航空制造技术, 2005(9):73-76. http://www.cnki.com.cn/Article/CJFDTOTAL-HKGJ200509012.htmLIN G M, SUN Q, LI Y H, et al.Survey on stealth aircraft[J].Aeronautical Manufacturing Technology, 2005(9):73-76(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKGJ200509012.htm [2] 乔玉林, 臧艳, 易文斌.铝合金表面涂覆隐身吸波涂层脱落原因分析[J].装甲兵工程学院学报, 2009, 23(6):84-86. http://www.cnki.com.cn/Article/CJFDTOTAL-ZJBX200906022.htmQIAO Y L, ZANG Y, YI W B.Analysis on the causes of stealthy absorbing coatings peeling off aluminum alloyssurface[J].Journal of Academy of Armored Force Engineering, 2009, 23(6):84-86(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-ZJBX200906022.htm [3] 赵芯, 谢飞, 张帆, 等.浅析现代民用航空飞机蒙皮防腐蚀体系[J].全面腐蚀控制, 2014, 28(1):22-24. http://www.cnki.com.cn/Article/CJFDTOTAL-QMFK201401015.htmZHAO X, XIE F, ZHANG F, et al.Anti-corrosion system of modern civil aviation aircraft skin[J].Total Corrosion Control, 2014, 28(1):22-24(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-QMFK201401015.htm [4] 王新坤, 王东峰.飞机蒙皮局部腐蚀的原位快速修复工艺[J].电镀与涂饰, 2005, 24(4):34-35. http://www.cnki.com.cn/Article/CJFDTOTAL-DDTL200504011.htmWANG X K, WANG D F.In-situ rapid renovation process for local corrosion area of aircraft skin[J].Electroplating & Finishing, 2005, 24(4):34-35(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-DDTL200504011.htm [5] 汪定江, 陈名华, 葛文军, 等.钛合金表面氧化膜原位修复新工艺研究[J].新技术新工艺, 2012(3):48-50. http://www.cnki.com.cn/Article/CJFDTOTAL-XJXG201203019.htmWANG D J, CHEN M H, GE W J, et al.Research on the new in situ repair technology of titanium alloy surface oxide film[J].New Technology & New Process, 2012(3):48-50(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-XJXG201203019.htm [6] 曹慧明, 张世坤.航空铝合金结构表面的阿洛丁处理方法[J].航空维修与工程, 2012(1):54-55. http://www.cnki.com.cn/Article/CJFDTOTAL-KONG201201024.htmCAO H M, ZHANG S K.The alodine process on the surface of aviation aluminum alloy components[J].Aviation Maintenance & Engineering, 2012(1):54-55(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-KONG201201024.htm [7] ZHAO J, XIA L, SEHGAL A, et al.Effects of chromate and chromate conversion coatings on corrosion of aluminum alloy 2024-T3[J]. Surface & Coatings Technology, 2001, 140:5157. http://www.sciencedirect.com/science/article/pii/S0257897201010039 [8] KULINICH S A, AKHTAR A S, SUSAC D, et al.On the growth of conversion chromate coatings on 2024-Al alloy[J]. Applied Surface Science, 2007, 253:3144-3153. doi: 10.1016/j.apsusc.2006.07.004 [9] LIANG C S, LV Z F, ZHU Y L, et al.Protection of aluminium foil AA8021 by molybdate-based conversion coatings[J].Applied Surface Science, 2014, 288:497-502. doi: 10.1016/j.apsusc.2013.10.060 [10] HUA A Y, FANG W L, JUN D, et al.Preparation and properties of chrome-free colored Ti/Zr based conversion coating on aluminum alloy[J].Applied Surface Science, 2012, 258(16):5960-5964. doi: 10.1016/j.apsusc.2011.12.045 [11] MISHRA A K, BALASUBRAMANIAM R.Corrosion inhibition of aluminium by rare earth chlorides[J].Materals Chemistry and Physics, 2007, 103(2-3):385-393. doi: 10.1016/j.matchemphys.2007.02.079 [12] SANTA COLOMA P, IZAGIRRE U, BELAUSTEGI Y, et al.Chromium-free conversion coatings based on inorganic salts(Zr/Ti/Mn/Mo) for alumium alloys used in aircraft applications[J].Applied Surface Science, 2015, 345:24-35. doi: 10.1016/j.apsusc.2015.02.179 [13] 韩哲, 熊金平, 左禹.铝合金表面化学氧化工艺的研究进展[J].电镀与精饰, 2008, 30(11):14-17. doi: 10.3969/j.issn.1001-3849.2008.11.004HAN Z, XIONG J P, ZUO Y.Research development of chemical oxidation technologieson aluminium alloys[J].Plating and Finishing, 2008, 30(11):14-17(in Chinese). doi: 10.3969/j.issn.1001-3849.2008.11.004 [14] STARKE E A, STALEY J T.Application of modern aluminum alloys to aircraft[J].Progress in Aerospace Sciences, 1996, 32(2-3):131-172. doi: 10.1016/0376-0421(95)00004-6 [15] CHEN G S, GAO M, WEI R P.Microconstituent-induced pitting corrosion in aluminum alloy 2024-T3[J].Corrosion, 1996, 52(1):8-15. doi: 10.5006/1.3292099 [16] SZKLARSKA S P.Pitting corrosion of aluminum[J].Corrosion Science, 1999, 41(9):1743-1767. doi: 10.1016/S0010-938X(99)00012-8 [17] 张晓峰. 铝、镁合金氧化与粘接性能研究[D]. 北京: 北京化工大学, 2008: 5-6. http://cdmd.cnki.com.cn/Article/CDMD-10010-1014452162.htmZHANG X F.Studies on surface oxidation treatment of aluminum and magnesism alloys and its adhesive performence[D].Beijing:Beijing University of Chemical Technology, 2008:5-6(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10010-1014452162.htm [18] 中国第三机械工业部. 铝及铝合金化学氧化(磷酸-铬酸法)工艺: HB/Z5077-78[S]. 北京: 第三机械工业部, 1979: 97-99.Chinese Third Ministry of Machinery Industry.Chemical oxidation process of aluminum and aluminum alloys(phosphric-chromic acid method):HB/Z5077-78[S].Beijing:Chinese Third Ministry of Machinery Industry, 1979:97-99(in Chinese). [19] 中国第三机械工业部. 铝及铝合金化学氧化膜层质量检验: HB5060-77[S]. 北京: 第三机械工业部, 1978: 100-101.Chinese Third Ministry of Machinery Industry.Quality inspection of chemical oxidation films of aluminum and aluminum alloys:HB5060-77[S].Beijing:Chinese Third Ministry of Machinery Industry, 1978:100-101(in Chinese). [20] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 胶粘剂拉伸剪切强度的测定(刚性材料对刚性材料): GB/T 7124-2008[S]. 北京: 中国标准出版社, 2008.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Adhesives-Determination of tensile lap-shear strength of rigid-to-rigid bonded assemblies:GB/T 7124-2008[S].Beijing:Standards Press of China, 2008. [21] ZHANG X, SLOOF W G, HOVESTAD A, et al.Characterization of chromate conversion coatings on zinc using XPS and SKPFM[J].Surface Coating & Technology, 2015, 197(2-3):168-176. http://www.sciencedirect.com/science/article/pii/S0257897204008539 [22] CEREZO J, TAHERI P, VANDENDAEL I, et al.Influence of surface hydroxyls on the formation of Zr-based conversion coatings on AA6014 aluminum alloy[J].Surface Coating & Technology, 2014, 254:277-283. http://www.sciencedirect.com/science/article/pii/S0257897214005416 [23] LUNDER O, WALMSLEY J C, MACK P, et al.Formation and characterisation of a chromate conversion coating on AA6060 aluminium[J].Corrosion Science, 2015, 47(7):1604-1624. http://www.academia.edu/17084289/Formation_and_characterisation_of_a_chromate_conversion_coating_on_AA6060_aluminium [24] QI J T, HASHIMOTO T, WALTON J R, et al.Trivalent chromium conversion coating formation on aluminium[J].Surface Coating & Technology, 2015, 280:317-329. http://www.sciencedirect.com/science/article/pii/S0257897215302620 [25] GOLRU S S, ATTAR M M, RAMEZANZADEH B.Effects of surface treatment ofaluminium alloy 1050 on the adhesion and anticorrosion properties of theepoxy coating[J].Applied Surfce Science, 2015, 345:360-368. doi: 10.1016/j.apsusc.2015.03.148 -

下载:

下载: