Performance simulation of a 76 km simulated high-altitude test system for liquid attitude-control engines

-

摘要:

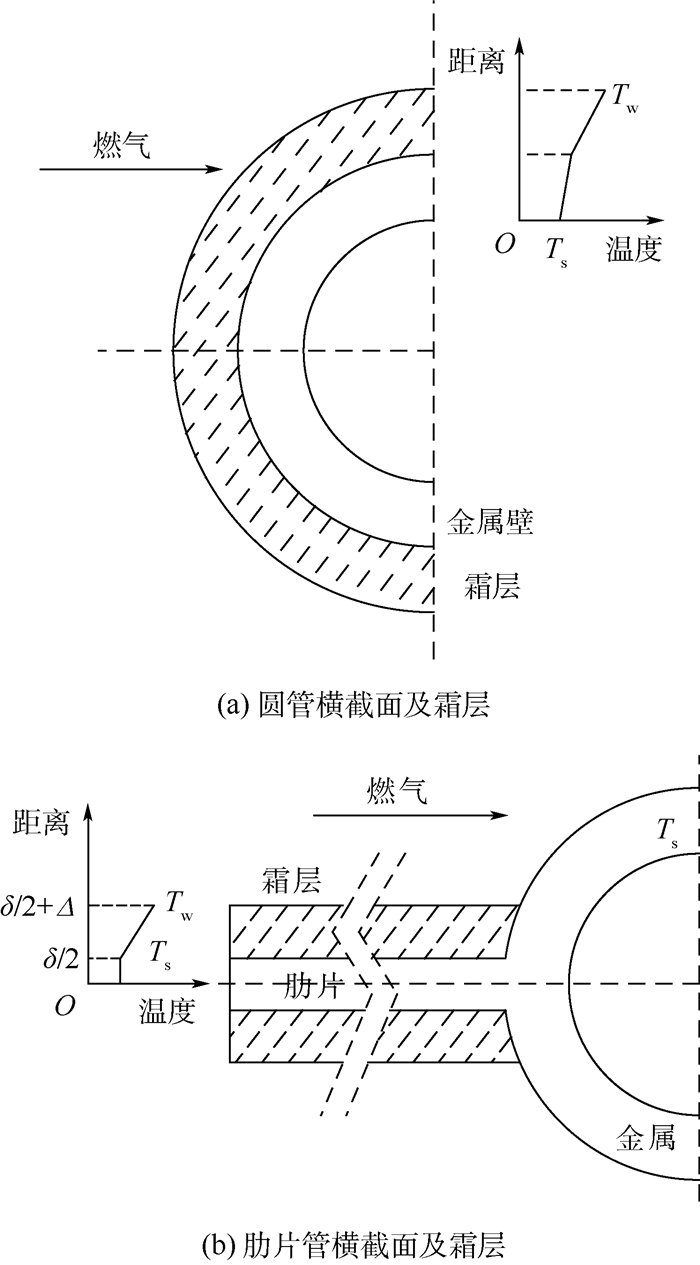

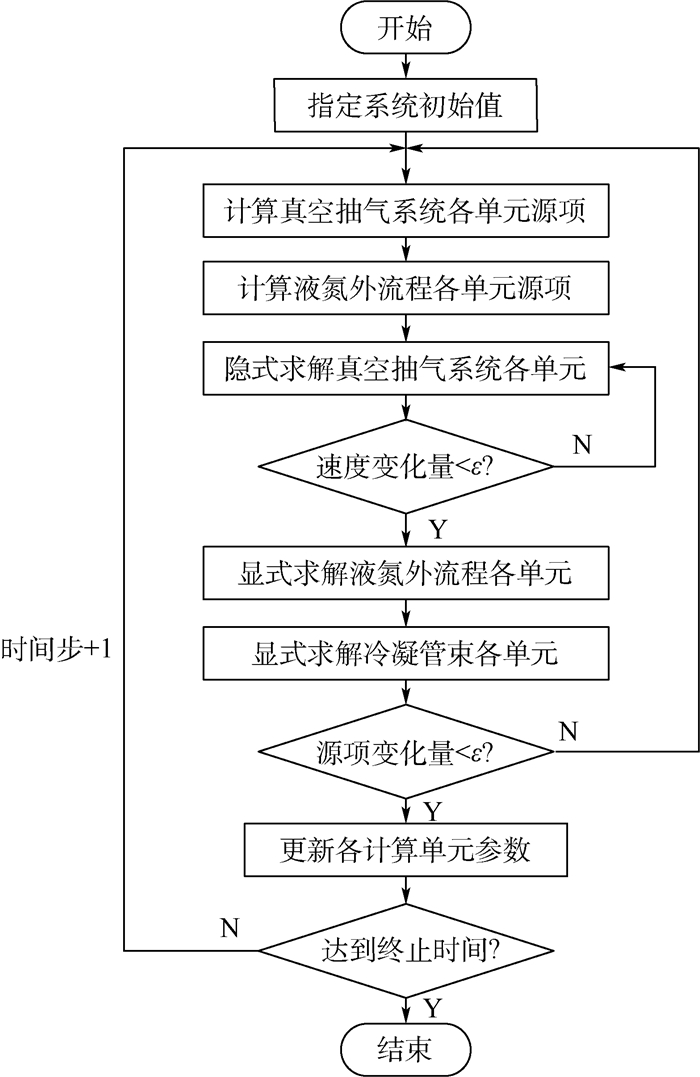

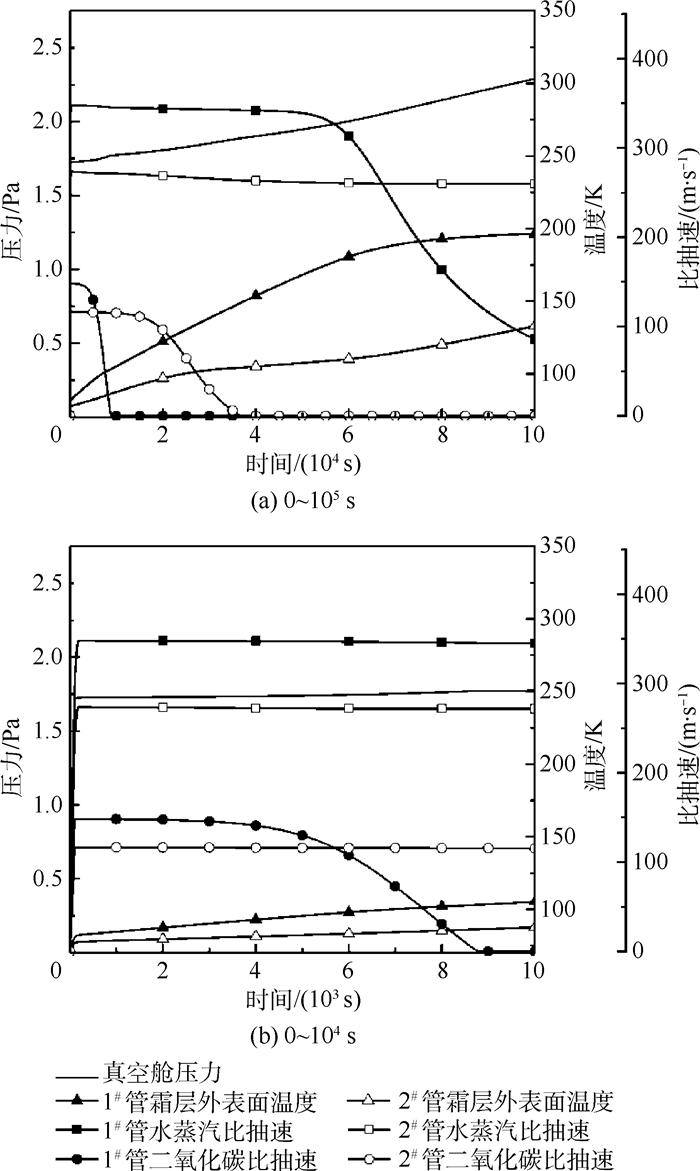

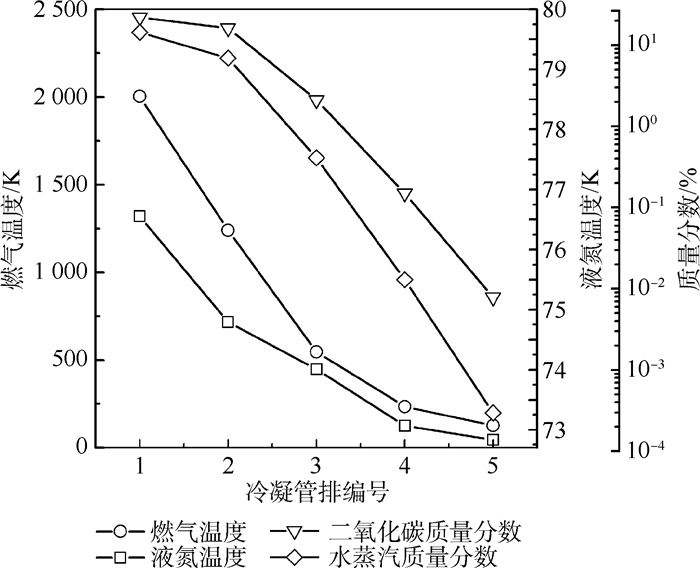

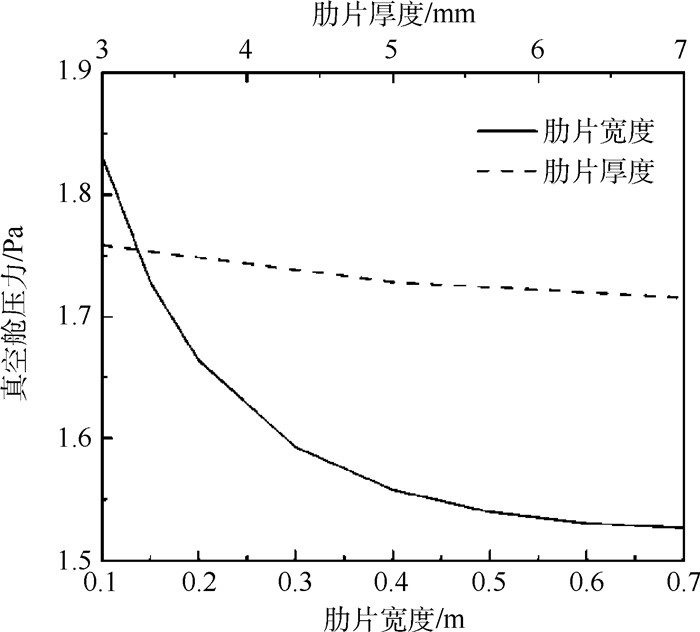

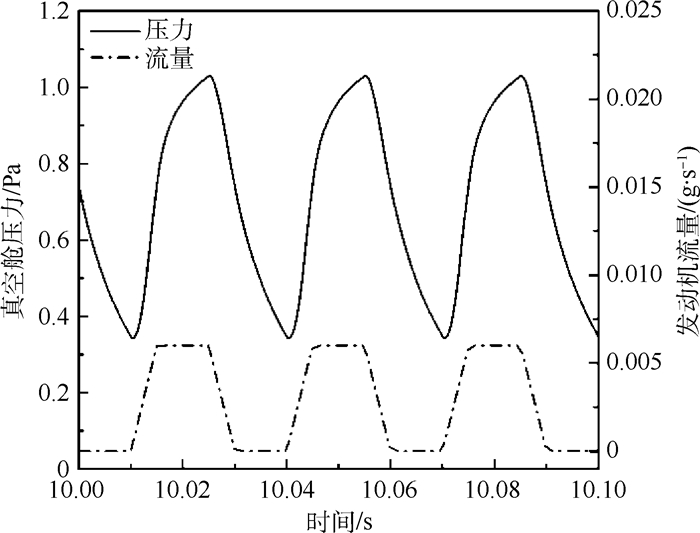

为研究液体姿控发动机76 km高空模拟试验系统的工作性能,建立了考虑燃气相变的试验系统集中参数动态仿真模型。模型由真空抽气系统、冷凝管束和液氮外流程3个子模型组成。根据燃气、霜、液氮之间的传热和传质过程将各子模型耦合在一起。以四氧化二氮/甲基肼双组元姿控发动机为实例,计算了稳态和脉冲点火试验时系统的工作参数,分析了关键设计参数对其工作性能的影响。结果表明:试验系统能够为最大流量6.4 g/s(推力约16.5 N)的发动机提供脉冲和6×104 s长程稳态试验环境;在长程稳态试验中,冷凝管束霜层将依次饱和,失去对二氧化碳和水蒸汽的抽吸能力,导致真空舱压力逐渐升高;在脉冲点火试验中,真空舱压力将随发动机工作而脉冲波动,15 ms开关脉冲时的压力波动幅度约70%。研究结果为液体姿控发动机高空模拟试验系统的设计与改进提供了参考。

Abstract:To study the performance of a 76 km high-altitude test system for attitude-control liquid rocket engines, a transient test system simulation model with lumped parameters was built, which considers the phase change of the exhaust. The system model consists of a vacuum pumping sub-model, a liquid nitrogen flow sub-model and a condensing pipe sub-model. The sub-models were coupled through the heat and mass transfer process between the gas, frost and liquid nitrogen. The system working parameters during the steady and the pulsed tests of a bipropellant nitrogen-tetroxide/mono-methylhydrazine attitude-control engine were calculated, and effects of the important system design parameters on working performance were explored. The results show that the current test system could provide environment for the engine pulse tests and 6×104 s steady tests with a maximum propellant flow rate of 6.4 g/s (trust is about 16.5 N); in long-term test, the frost on the surface of condensing pipes will get saturated and lose the ability to absorb carbon dioxide and water vapor, leading to the gradually increase of the vacuum tank pressure; during the engine pulsed test, the vacuum tank pressure will fluctuate with the pulses, up to about 70% in the 15 ms pulse case. The conclusion of the study could be a guide in the design and upgrade of the high-altitude test system for the liquid attitude-control engines.

-

表 1 试验系统主要设计参数

Table 1. Main design parameters of test system

参数 数值 真空舱直径/m 3 真空舱长度/m 10 机械泵抽速/(m3·s-1) 150 液氮流量/(L·s-1) 15 圆管排数 2 肋片管排数 3 每排管数 35 肋片宽度/cm 15 肋片厚度/mm 5 表 2 发动机及喷管出口燃气主要参数

Table 2. Main parameters of engine andexhaust at nozzle outlet

参数 数值 总流量/(g·s-1) 5.8 真空推力/N 15 真空比冲/(m·s-1) 2 587.5 绝热燃烧温度/K 3 053 氮气质量分数/% 42 水蒸汽质量分数/% 26 二氧化碳质量分数/% 19 一氧化碳质量分数/% 11 氢气质量分数/% 2 -

[1] 郭霄峰.液体火箭发动机试验[M].北京:中国宇航出版社, 2005:319-320.GUO X F.Liquid rocket engine test[M].Beijing:China Astronautic Publishing House, 2005:319-320(in Chinese). [2] 李殿东.76 km高空环境模拟试验舱的研制[J].真空, 2002(5):41-45. http://www.cnki.com.cn/Article/CJFDTOTAL-ZKZK200205011.htmLI D D.Design of 76 km high-altitude space simulation test module[J].Vacuum, 2002(5):41-45(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-ZKZK200205011.htm [3] 凌桂龙, 蔡国飙, 张建华.基于真空羽流试验的洁净真空系统设计[J].航空动力学报, 2013, 28(5):1173-1179. http://www.cnki.com.cn/Article/CJFDTOTAL-HKDI201305028.htmLING G L, CAI G B, ZHANG J H.Oil-free vacuum system design based on vacuum plume experiment[J].Journal of Aerospace Power, 2013, 28(5):1173-1179(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKDI201305028.htm [4] ROBERT C F, ARTHUR D H, THOMAS A K.Space environment facility for electric propulsion systems research:NASA TN D-2774[R].Washington, D.C.:NASA, 1965. [5] JOHN M S, JOHN A H, THOMAS W H.Performance evaluation of the Russian SPT-100 Thruster at NASA LeRC:NASA-TM-106401[R].Washington, D.C.:NASA, 1993. [6] JAMES E.A mission profile life test facility[C]//Proceeding of 13th International Electric Propulsion Conference.Reston:AIAA, 1978:1-9. [7] 韩战秀, 李艳霞, 王海峰.模拟空间环境试验真空获得技术研究[J].航天器环境工程, 2009, 26(增刊):38-40. http://www.cnki.com.cn/Article/CJFDTOTAL-HTHJ2009S1011.htmHAN Z X, LI Y X, WANG H F.Vacuum technology of space simulation test[J].Spacecraft Environment Engineering, 2009, 26(s1):38-40(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HTHJ2009S1011.htm [8] 王文龙, 凌桂龙, 蔡国飙.大型容器单轴双铰链式大门机构设计与分析[J].北京航空航天大学学报, 2011, 37(4):399-404.WANG W L, LING G L, CAI G B.Design and analysis of single-axis-double-pin hinged door for large-scale container[J].Journal of Beijing University of Aeronautics and Astronautics, 2011, 37(4):399-404(in Chinese). [9] 张莘艾, 汤海滨, 施陈波, 等.低功率N2H4电弧加热发动机高空模拟试验系统[J].北京航空航天大学学报, 2010, 36(8):977-995.ZHANG X A, TANG H B, SHI C B, et al.High altitude simulation experiment system for low power hydrazine arcjet[J].Journal of Beijing University of Aeronautics and Astronautics, 2010, 36(8):977-995(in Chinese). [10] 庞贺伟, 孟宪红, 张行.热沉结构管接头的应力计算与实验验证[J].北京航空航天大学学报, 2009, 35(1):70-73.PANG H W, MENG X H, ZHANG X.Numerical calculation and experimental verification of stress at joint between two pipes of thermal shrouds[J].Journal of Beijing University of Aeronautics and Astronautics, 2009, 35(1):70-73(in Chinese). [11] 姜传胜, 王浚.大型空间环模器热沉设计研究[J].北京航空航天大学学报, 2001, 27(3):305-308.JIANG C S, WANG J.Quantitative thermal design of heat sinks in large space simulations[J].Journal of Beijing University of Aeronautics and Astronautics, 2001, 27(3):305-308(in Chinese). [12] 王文龙, 周建平, 蔡国飙.内置式深冷泵抽速计算及数值模拟研究[J].真空科学与技术学报, 2012, 32(5):442-446. http://www.cnki.com.cn/Article/CJFDTOTAL-ZKKX201205018.htmWANG W L, ZHOU J P, CAI G B.Direct simulation Monte Carlo study of pumping speed of internalcryogenic fins[J].Chinese Journal of Vacuum Science and Technology, 2012, 32(5):442-446(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-ZKKX201205018.htm [13] 李兆慈, 徐烈.高空模拟试验舱中燃气流动过程的分析与计算[J].推进技术, 2000, 21(5):16-18. http://www.cnki.com.cn/Article/CJFDTOTAL-TJJS200005004.htmLI Z C, XU L.Analysis and calculation for process of exhaust gas flowing in the outer space simulator[J].Journal of Propulsion Technology, 2000, 21(5):16-18(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-TJJS200005004.htm [14] 张育林, 刘昆.液体火箭发动机动力学理论与应用[M].北京:科学出版社, 2005:113-115.ZHANG Y L, LIU K.Theory and application of liquid rocket engine dynamics[M].Beijing:Science Press, 2005:113-115(in Chinese). [15] 达道安.真空设计手册[M].北京:国防工业出版社, 2004:416-417.DA D A.Vaccum design manul[M].Beijing:National Defence Industry Press, 2004:416-417(in Chinese). 期刊类型引用(5)

1. 景凤,郭婧娟. 基于BIM的高铁工程量清单EBS\WBS研究. 铁道标准设计. 2020(02): 68-74 .  百度学术

百度学术2. 周泽鑫,孙志强,徐冰,洪扬. 空间光学遥感器真空热试验工装模块化设计. 北京航空航天大学学报. 2019(08): 1544-1551 .  本站查看

本站查看3. 张秋雁,张俊玮,丛中笑,宋锡强,曾招辉,王忠义. 符合智能制造硬件要求的积木式单相智能电能表设计研究. 自动化与仪器仪表. 2018(06): 37-40 .  百度学术

百度学术4. 田启华,梅月媛,杜义贤,周祥曼. 基于聚类分析的大容量耦合设计任务规划的研究. 中国机械工程. 2018(05): 544-551 .  百度学术

百度学术5. 刘航,何铭鑫,聂仕麟. 基于模块化技术的复杂产品融合设计方案研究——以斯特林发动机为例. 管理工程师. 2017(06): 28-31 .  百度学术

百度学术其他类型引用(11)

-

下载:

下载:

百度学术

百度学术