-

摘要:

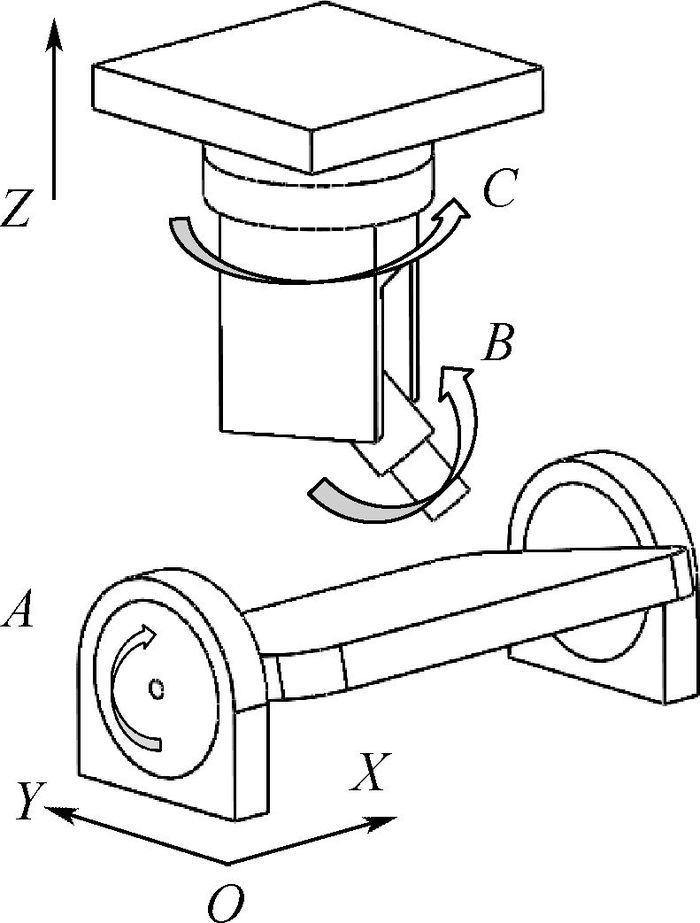

为扩展4轴机床的加工能力,使4轴机床具有使用鼓形刀具加工叶轮类零件的能力,将4轴机床扩展至4+2轴机床。从机构学角度对4+2轴机床进行运动学分析,证明了4+2轴加工方法的刀具姿态具有一个可优化的角度。根据机床运动链模型,推导了机床半联动轴参数与刀具姿态角度、联动轴运动参数之间的运动变换关系,得到了求解切触点处刀位信息的方法。根据对复杂曲面的几何分析、刀具干涉和机床运动范围,给出了一种4+2轴加工叶片的2个半联动轴参数选择方法。推导了4+2轴加工方法的刀轨生成算法。通过4+2轴叶轮加工实验,验证了4+2轴加工方法的可行性。实验结果表明,4+2轴加工方法生成的刀轨可用,使用4+2轴加工方法加工叶轮叶片的方案是可行的,具有生产应用价值。

Abstract:The purpose of this study is to enhance the machine tool's processing capability by improving the machine tool from 4-axis to 4+2-axis, which endows the machine tool the ability to process impeller using the barrel cutter. We first analyzed the dynamic performance of the 4+2-axis machine tool with theory of mechanism, which demonstrates that the tool position has one optimizable parameter. Then, we derived the relationship among the half-linkage axis parameters, the tool position, and the linkage axis movement parameters, and obtained a method for solving the position at the cutter contact point. Based on the geometrical analysis of the complex surface, mechanical interference and the movement range of the machine tool, we provided a method to choose the parameters of two half-linkage axes when processing the impeller by using 4+2-axis, and deduced an algorithm for generating the tool path. We finally tested the tool path by experiments. The results show that the proposed 4+2-axis machining method for processing impeller blade is feasible and has promising production and application value.

-

-

[1] 宋春华.数控技术的现状及发展趋势[J].装备制造技术, 2011(3):114-117. http://youxian.cnki.com.cn/yxdetail.aspx?filename=ZGBY2016062201U&dbname=CAPJ2015SONG C H.Status and developing trend of NC technology[J].Equipment Manufacturing Technology, 2011(3):114-117(in Chinese). http://youxian.cnki.com.cn/yxdetail.aspx?filename=ZGBY2016062201U&dbname=CAPJ2015 [2] 程奎. 四轴数控机床运动分析及加工应用研究[D]. 西安: 西安理工大学, 2010. http://cdmd.cnki.com.cn/Article/CDMD-10700-2010141110.htmCHENG K.Motion analysis and processing application research of four-axis numerical control machine tool[D].Xi'an:Xi'an University of Technology, 2010(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10700-2010141110.htm [3] 曾志迎. 复杂曲面的五坐标数控加工关键技术研究[D]. 太原: 太原科技大学, 2012. http://cdmd.cnki.com.cn/Article/CDMD-10109-1012427015.htmZENG Z Y.The key research on five-axis NC machining technology of complex curved surface[D].Taiyuan:Taiyuan University of Science & Technology, 2012(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10109-1012427015.htm [4] 王晶, 张定华, 罗明, 等.复杂曲面零件五轴加工刀轴整体优化方法[J].航空学报, 2013, 34(6):1452-1462. http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201306026.htmWANG J, ZHANG D H, LUO M, et al.A global tool orientation optimization method for five-axis CNC machining of sculptured surfaces[J].Acta Aeronautica et Astronautica Sinica, 2013, 34(6):1452-1462(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201306026.htm [5] 修春松, 安鲁陵, 戚家亮.整体叶轮鼓形刀五坐标数控加工刀位轨迹生成[J].机械制造与自动化, 2011, 40(4):165-168. http://www.cnki.com.cn/Article/CJFDTOTAL-ZZHD201104050.htmXIU C S, AN L L, QI J L.Tool path strategy for integrated impeller using barrel cutter in 5-axis NC system[J].Machine Building & Automation, 2011, 40(4):165-168(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-ZZHD201104050.htm [6] 金曼, 张俐, 陈志同.圆环面刀具五坐标加工端点误差控制刀位优化[J].北京航空航天大学学报, 2006, 32(9):1125-1128. http://bhxb.buaa.edu.cn/CN/abstract/abstract9826.shtmlJIN M, ZHANG L, CHEN Z T.End-points error controlling method for torus tool position optimization in five-axis NC machining[J].Journal of Beijing University of Aeronautics and Astronautics, 2006, 32(9):1125-1128(in Chinese). http://bhxb.buaa.edu.cn/CN/abstract/abstract9826.shtml [7] 石巍, 宁涛, 陈志同.环面工具加工叶根过渡曲面的刀位可行域[J].航空学报, 2014, 35(12):3470-3479. http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201412029.htmSHI W, NING T, CHEN Z T.Research on feasible area of torus tool position in machining of blade root area and its application[J].Acta Aeronautica et Astronautica Sinica, 2014, 35(12):3470-3479(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201412029.htm [8] SUH H S, LEE J.Five-axis part machining with three-axis CNC machine and indexing table[J].Journal of Manufacturing Science and Engineering, 1998, 120(1):120-128. doi: 10.1115/1.2830087 [9] SUH S H, LEE J J, KIM S K.Multiaxis machining with additional-axis NC system:Theory and development[J].The International Journal of Advanced Manufacturing Technology, 1998, 14(12):865-875. doi: 10.1007/BF01179075 [10] 朱燏, 宁涛, 陈志同.圆柱坐标数控机床加工整体叶轮的运动学分析[J].航空学报, 2014, 35(8):2364-2374. http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201408031.htmZHU Y, NING T, CHEN Z T.Kinematic analysis of cylindrical coordinate CNC machine in integral impeller machining[J].Acta Aeronautica et Astronautica Sinica, 2014, 35(8):2364-2374(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201408031.htm [11] 韩飞燕, 张定华, 吴宝海, 等.高缠绕叶轮流道4+1轴高效分段开槽方法[J].航空学报, 2015, 36(5):1684-1694. http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201505031.htmHAN F Y, ZHANG D H, WU B H, et al.High-efficiency section-by-section method for 4+1-axis NC machining of high-wrap impeller channel[J].Acta Aeronautica et Astronautica Sinica, 2015, 36(5):1684-1694(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201505031.htm [12] 吴宝海, 王尚锦.自由曲面叶轮的四坐标数控加工研究[J].航空学报, 2007, 28(4):993-998. http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB200704041.htmWU B H, WANG S J.Research on 4-axis numerical control machining of free form surface impellers[J].Acta Aeronautica et Astronautica Sinica, 2007, 28(4):993-998(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB200704041.htm [13] ZHU Y, CHEN Z T, NING T, et al.Tool orientation optimization for 3+2-axis CNC machining of sculptured surface[J].Computer-Aided Design, 2016, 77(C):60-72. http://www.sciencedirect.com/science/article/pii/S0010448516300021 [14] 陈东祥, 肖延萍, 沈兆光, 等.万向转头机构的旋转定位算法[J].机械设计, 2004, 21(11):55-56. doi: 10.3969/j.issn.1001-2354.2004.11.021CHEN D X, XIAO Y P, SHEN Z G, et al.Rotating positioning algorithm of universal head mechanism[J].Machine Design, 2004, 21(11):55-56(in Chinese). doi: 10.3969/j.issn.1001-2354.2004.11.021 [15] 李正强, 陈志同, 肖俊.鼓形刀宽行刀位优化纬线分割算法[J].北京航空航天大学学报, 2007, 33(6):731-735. http://bhxb.buaa.edu.cn/CN/abstract/abstract9514.shtmlLI Z Q, CHEN Z T, XIAO J.Latitude distribution algorithm of cutter position optimization on drum-like cutter for strip-maximization[J].Journal of Beijing University of Aeronautics and Astronautics, 2007, 33(6):731-735(in Chinese). http://bhxb.buaa.edu.cn/CN/abstract/abstract9514.shtml [16] 孟凡军, 陈志同, 宁涛, 等.基于纬线法的鼓形刀具刀位误差分布计算[J].航空学报, 2015, 36(12):4014-4024. http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201512025.htmMENG F J, CHEN Z T, NING T, et al.Calculation of tool position error distribution of barrel cutter based on latitude approach[J].Acta Aeronautica et Astronautica Sinica, 2015, 36(12):4014-4024(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201512025.htm [17] 陈果, 陈志同.复杂母线鼓形刀具宽行侧铣加工算法[J].航空精密制造技术, 2010, 46(5):34-38. http://www.cnki.com.cn/Article/CJFDTOTAL-HJZJ201005010.htmCHEN G, CHEN Z T.Flank milling with complex generatrix barrel cutter[J].Aviation Precision Manufacturing Technology, 2010, 46(5):34-38(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HJZJ201005010.htm [18] 杨志强. 基于UG二次开发的数控加工刀具轨迹生成系统的研究[D]. 沈阳: 沈阳工业大学, 2007. http://cdmd.cnki.com.cn/Article/CDMD-10142-2008204182.htmYANG Z Q.Tool-path programming research based on UG redevelopment in NC machining[D].Shenyang:Shenyang University of Technology, 2007(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10142-2008204182.htm -

下载:

下载: