-

摘要:

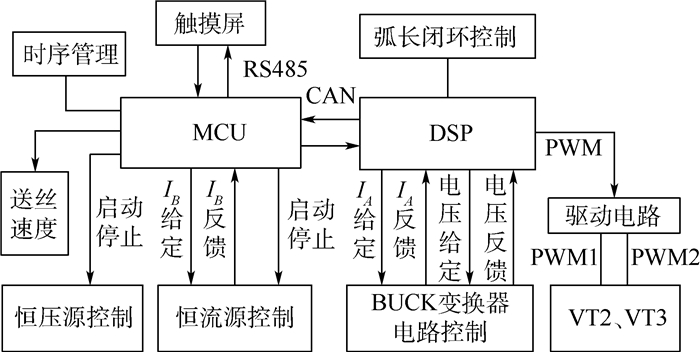

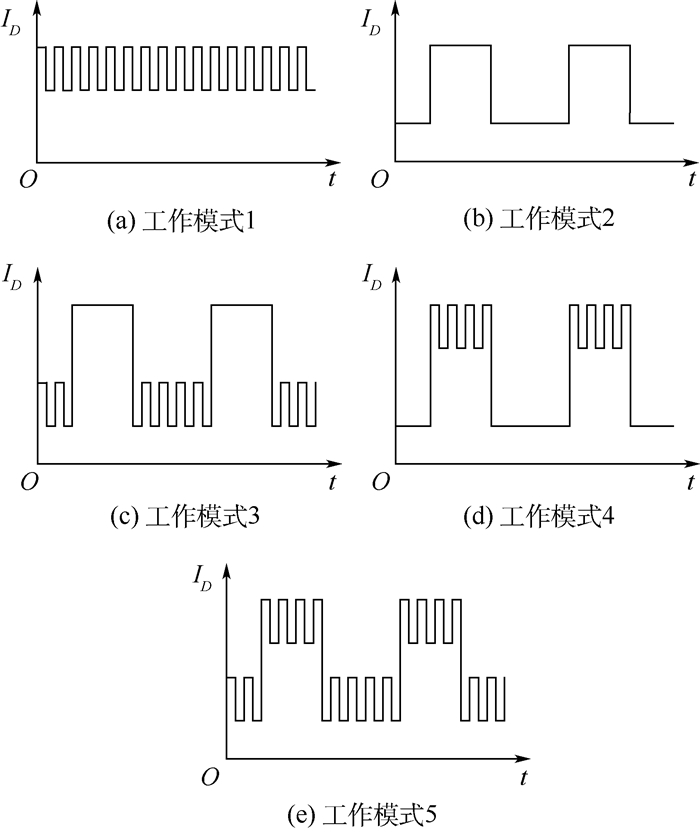

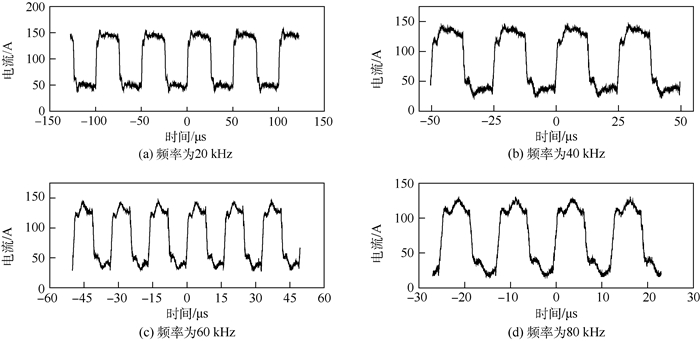

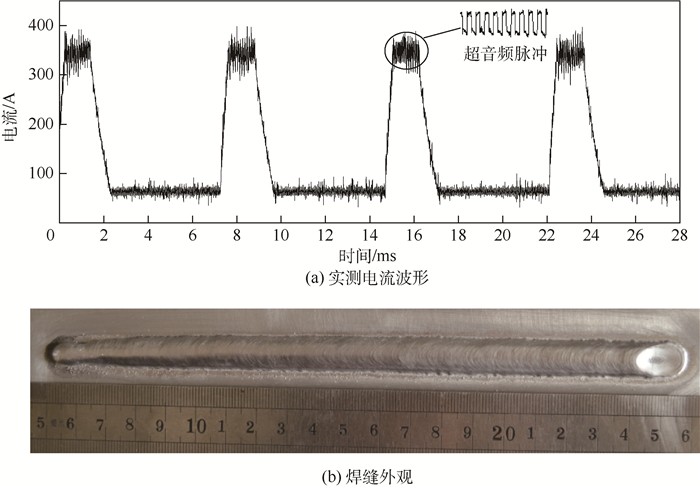

提出了一种全新的脉冲熔化极气体保护焊(GMAW)方法,并研制出新型超音频复合脉冲GMAW电源,即在传统脉冲GMAW电流基础上复合叠加频率为20~80 kHz、电流幅值为0~100 A、占空比为0%~100%的连续可调的超音频脉冲电流。设计了并联结构的主电路拓扑及MCU+DSP双处理器数字化控制系统,通过软件编程实现了电流给定信号与PWM信号的同步输出及不同逻辑组合,可实现不同工作模式的焊接电流波形输出。对电源输出电流波形的测试结果表明:本文所设计的超音频复合脉冲GMAW电源输出电流波形满足不同工作模式的设计目标,超音频脉冲电流频率在80 kHz时,仍保持较快的电流上升沿与下降沿变化速率。初步进行了铝合金平板堆焊试验,焊缝成形良好。

Abstract:A new type of gas metal arc welding (GMAW) method was proposed and a novel hybrid ultrasonic frequency pulsed GMAW power source was developed. In this method, an ultrasonic frequency pulse current was superposed upon the conventional pulsed GMAW current with frequency from 20 to 80 kHz, current amplitude from 0 to 100 A, and duty cycle from 0% to 100%. Main circuit topology in parallel structure and dual-processor digital control system consisting of MCU and DSP were designed. Synchronized output and different logical combinations of current given signal and PWM signal were realized through software programming, resulting in several output current waveforms for different work modes. Testing results of the output current indicate that output current waveforms of the designed hybrid ultrasonic frequency pulsed GMAW power source satisfy the requirement of different work modes with a fast current rising and falling rate even at ultrasonic frequency pulse current frequency of 80 kHz. Aluminium alloy bead-on-plate experiment was conducted with this power source and a good weld bead appearance was obtained.

-

Key words:

- pulsed GMAW /

- ultrasonic frequency pulse /

- welding power source /

- parallel topology /

- dual-processor

-

表 1 焊接电流参数

Table 1. Welding current parameters

参数 Ip/A Ib/A Tp/ms Tb/ms Ipp/A f/kHz D/% 数值 325 60 1.5 5.8 50 20 50 -

[1] KAH P, SUORANTA R, MARTIKAINEN J.Advanced gas metal arc welding processes[J].International Journal of Advanced Manufacturing Technology, 2013, 67(1-4):655-674. doi: 10.1007/s00170-012-4513-5 [2] PRAVEEN P, YARLAGADDA P K D V, KANG M J.Advancements in pulse gas metal arc welding[J].Journal of Materials Processing Technology, 2005, 164-165:1113-1119. doi: 10.1016/j.jmatprotec.2005.02.100 [3] GHOSH P K, DORN L, HVBNER M, et al.Arc characteristics and behaviour of metal transfer in pulsed current GMA welding of aluminium alloy[J].Journal of Materials Processing Technology, 2007, 194(1-3):163-175. doi: 10.1016/j.jmatprotec.2007.04.113 [4] 袁鹤然, 杨春利, 谢伟峰, 等.功率超声在电弧焊接领域中的应用[J].热加工工艺, 2015, 44(9):6-10. http://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201509002.htmYUAN H R, YANG C L, XIE W F, et al.Application of power ltrasonic in arc welding[J].Hot Working Technology, 2015, 44(9):6-10(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201509002.htm [5] 吴敏生, 何龙标, 李路明, 等.电弧超声焊接技术[J].焊接学报, 2005, 26(6):40-44. http://www.cnki.com.cn/Article/CJFDTOTAL-HJXB200506012.htmWU M S, HE L B, LI L M, et al.Arc ultrasonic welding technology[J].Transactions of the China Welding Institution, 2005, 26(6):40-44(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HJXB200506012.htm [6] 孙清洁, 林三宝, 杨春利, 等.超声TIG复合焊接装置的研制与应用[J].焊接学报, 2010, 31(2):79-82. http://www.cnki.com.cn/Article/CJFDTOTAL-HJXB201002026.htmSUN Q J, LIN S B, YANG C L, et al.Investigation and application of ultrasonic-TIG hybrid welding equipment[J].Ttransactions of the China Welding Institution, 2010, 31(2):79-82(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HJXB201002026.htm [7] FAN Y Y, FAN C L, YANG C L, et al.Research on short circuiting transfer mode of ultrasonic assisted GMAW method[J].Science and Technology of Welding and Joining, 2012, 17(3):186-190. doi: 10.1179/1362171811Y.0000000058 [8] YUAN H R, LIN S B, YANG C L, et al.Microstructure and porosity analysis in ultrasonic assisted TIG welding of 2014 aluminum alloy[J].China Welding, 2011, 20(1):39-43. [9] WEN T, LIU S Y, CHEN S, et al.Influence of high frequency vibration on microstructure and mechanical properties of TIG welding joints of AZ31 magnesium alloy[J].Transactions of Nonferrous Metals Society of China, 2015, 25(2):397-404. doi: 10.1016/S1003-6326(15)63616-0 [10] 齐铂金, 许海鹰, 黄松涛, 等.超音频脉冲TIG焊电源拓扑及电弧焊适用性[J].北京航空航天大学学报, 2009, 35(1):61-64.QI B J, XU H Y, HUANG S T, et al.Ultrasonic frequency pulse tungsten inert gas welding power source topology and welding applicability[J].Journal of Beijing University of Aeronautics and Astronautics, 2009, 35(1):61-64(in Chinese). [11] 齐铂金, 从保强.新型超快变换复合脉冲变极性弧焊电源拓扑[J].焊接学报, 2008, 29(11):57-60. doi: 10.3321/j.issn:0253-360X.2008.11.015QI B J, CONG B Q.A novel ultrafast-convert complex-pulse variable-polarity arc welding power topology[J].Transactions of the China Welding Institution, 2008, 29(11):57-60(in Chinese). doi: 10.3321/j.issn:0253-360X.2008.11.015 [12] 齐铂金, 王强. 一种超音频复合脉冲GMAW焊接电源装置: CN105880802A[P]. 2016-08-24.QI B J, WANG Q.An apparatus of pulsed GMAW power source with hybrid ultrasonic frequency pulse current:CN105880802A[P].2016-08-24(in Chinese). [13] 赵家瑞, 李义丹.高频脉冲TIG焊的电弧控制及高频效应[J].天津大学学报, 1989(3):25-32. http://www.cnki.com.cn/Article/CJFDTOTAL-TJDX198903003.htmZHAO J R, LI Y D.Control over arc of pulsed high frequency TIG welding and high frequency effect[J].Journal of Tianjin University, 1989(3):25-32(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-TJDX198903003.htm [14] PALANI P K, MURUGAN N.Selection of parameters of pulsed current gas metal arc welding[J].Journal of Materials Processing Technology, 2006, 172(1):1-10. doi: 10.1016/j.jmatprotec.2005.07.013 [15] 黄石生.弧焊电源及其数字化控制[M].北京:机械工业出版社, 2011.HUANG S S.Arc welding power source and its digital control[M].Beijing:Mechanical Industry Press, 2011(in Chinese). [16] 任勇, 王永东, 何伟.单片机原理及应用:使用Freescale S12X构建嵌入式系统[M].北京:清华大学出版社, 2012.REN Y, WANG Y D, HE W.Fundamentals of mono-chip computers & applications:Establish embedded system with Free-scale S12X[M].Beijing:Tsinghua University Press, 2012(in Chinese). -

下载:

下载: