Kinematic analysis and workspace optimization of a novel 2-2PRUR parallel mechanism

-

摘要:

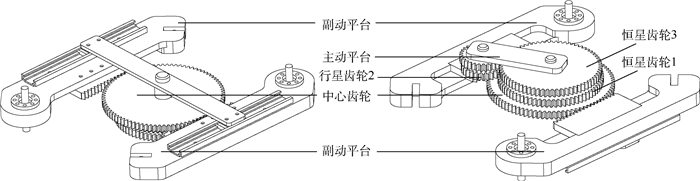

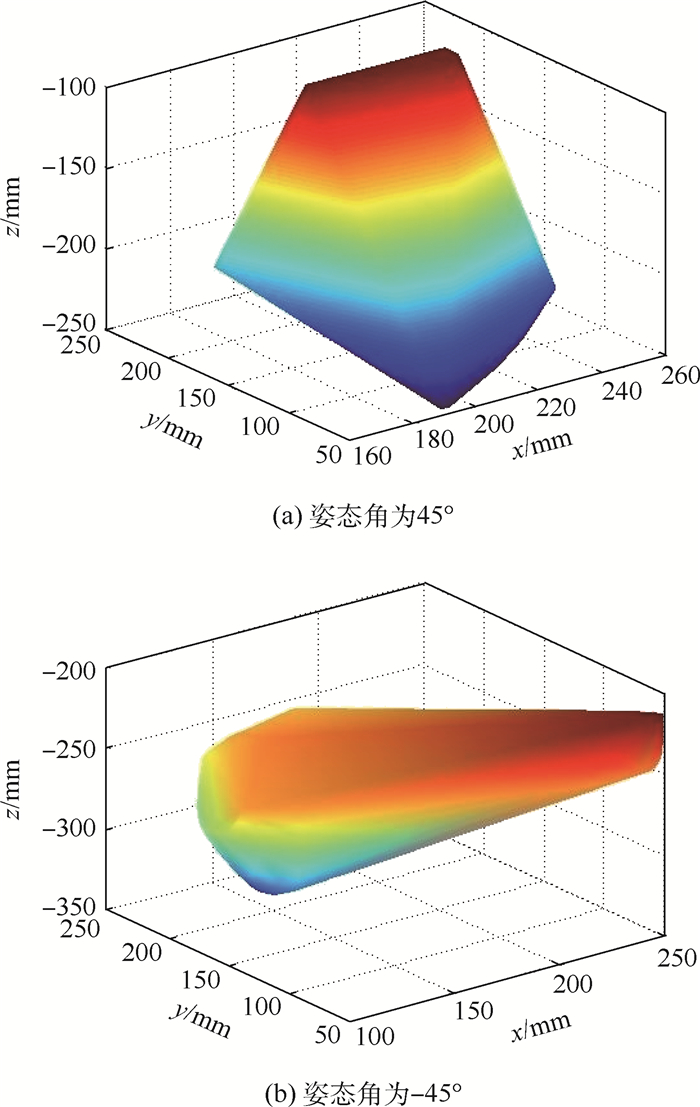

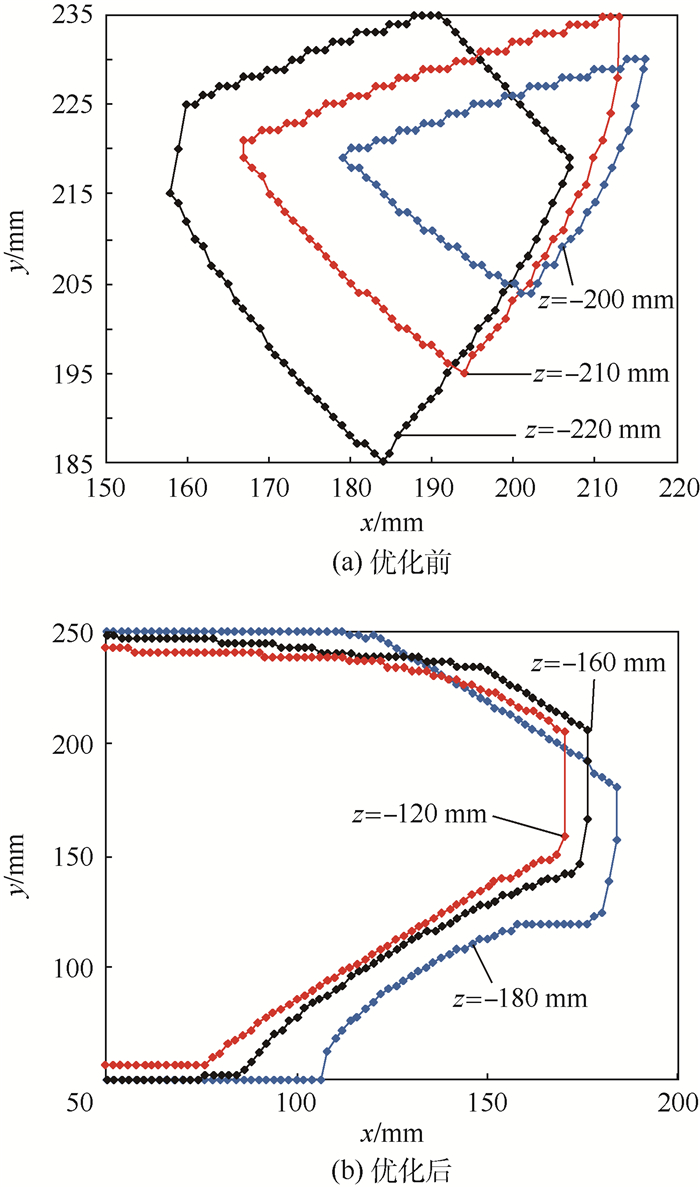

基于工业生产线实际需求,设计了新型2-2PRUR并联机构,进行运动学分析的同时基于散点图对工作空间进行了优化。提出了通过拆分动平台为两部分并加装行星轮系以解决四自由度并联机构过约束及增大转动自由度转角的方法;运用坐标法写出机构约束方程并求解位置正反解;利用位置反解方程解的散点画出机构工作空间,同时以散点数最大为原则运用遗传算法对工作空间进行优化,获得了合理的结构参数。为此类并联机构的研究和应用奠定了基础。

Abstract:A novel 2-2PRUR parallel mechanism is proposed to fit the actual demand of industrial production line. Kinematics analysis and workspace optimization are performed based on scatter plot. A method is presented by splitting the moving platform into two parts and adding planetary gear train, which could solve the over-constraints of four degrees of freedom parallel mechanism and increase the turning angle. The constraint equations are obtained using the coordinate method. The inverse-forward solutions of the mechanism are worked out. And the workspace is obtained by using the scatter plot of inverse kinematic solutions. Meanwhile, reasonable structural parameters are obtained by optimizing workspace with the principle of maximizing scattered points based on genetic algorithm. This work would lay the foundation for the future research and application of this type of parallel mechanism.

-

表 1 2-2PRUR并联机构位置反解结果

Table 1. Inverse kinematic solutions of 2-2PRUR parallel mechanism

mm x y1 y2 z l1 l2 l3 l4 160 100 200 -150 106.0144 66.5415 21.0464 95.1702 140 100 200 -150 105.2031 21.0464 66.5415 108.8730 150 90 190 -150 105.9616 66.5415 21.0464 103.9075 150 110 210 -150 105.9616 21.0464 66.5415 99.04466 160 110 210 -120 136.0012 79.3318 79.3318 120.7044 140 100 200 -120 135.2031 51.0464 96.5415 138.8730 表 2 2-2PRUR并联机构位置正解结果

Table 2. Forward kinematic solutions of 2-2PRUR parallel mechanism

mm l1 l2 l3 l4 x y1 y2 z 106 66 21 95 160.0099 100.0035 200.3694 -150.0141 105 21 66 108 146.8173 107.2413 206.5883 -148.6636 105 66 21 103 149.9972 90.1848 189.6942 -150.9609 105 21 66 99 149.3046 109.5547 209.1319 -150.9323 136 79 79 120 160.5072 110.3637 210.6410 -119.9843 135 51 96 138 146.8173 107.2413 206.5883 -178.6636 表 3 2-2PRUR并联机构初始参数值

Table 3. Initial parameter values of 2-2PRUR parallel mechanism

参数 初始值 kij/mm 150 a/mm 300 l/mm 100 r/mm 50 li/mm 0≤li≤100 P(x,y,z)运动范围/mm 50≤x≤250 50≤y≤250 -400≤z≤-100 表 4 2-2PRUR并联机构参数及散点数目值

Table 4. Parameters of 2-2PRUR parallel mechanism and scatter number

参数 初始值 优化值 k11/mm 150 58.21356151 k12/mm 150 128.4783055 k21/mm 150 57.12848677 k22/mm 150 116.0951255 a/mm 300 226.6077689 l/mm 100 148.1780424 r/mm 50 149.8667562 m 37852×3 161928×3 -

[1] 房海蓉, 方跃法, 郭胜.四自由度对称并联机器人结构综合方法[J].北京航空航天大学学报, 2005, 31(3):346-350.FANG H R, FANG Y F, GUO S.Structural synthesis method for 4-degrees-of-freedom symmetrical parallel manipulators[J].Journal of Beijing University of Aeronautics and Astronautics, 2005, 31(3):346-350(in Chinese). [2] 郭江真, 王丹, 樊锐, 等.3PRS/UPS冗余驱动并联机器人刚度特性分布[J].北京航空航天大学学报, 2014, 40(4):500-506.GUO J Z, WANG D, FAN R, et al.Stiffness characteristics distribution of 3PRS/UPS parallel manipulator with actuation redundancy[J].Journal of Beijing University of Aeronautics and Astronautics, 2014, 40(4):500-506(in Chinese). [3] CLAVEL R.Delta, a fast robot with parallel geometry[C]//Proceedings of the 18th International Symposium on Industrial Robots.Bedford:IFS Publications, 1988:91-100. [4] ANGELES J.The qualitative synthesis of parallel manipulators[J].Journal of Mechanical Design, 2004, 126(4):617-624. doi: 10.1115/1.1667955 [5] KONG X, GOSSELIN C.Type synthesis of 3T1R 4-DOF parallel manipulators based on screw theory[J].Journal of Robotic Systems, 2005, 22(10):535-547. doi: 10.1002/(ISSN)1097-4563 [6] GOGU G.Structural synthesis of fully-isotropic parallel robots with Sch nflies motions via theory of linear transformations and evolutionary morphology[J].European Journal of Mechanics-A/Solids, 2007, 26(2):242-269. doi: 10.1016/j.euromechsol.2006.06.001 [7] SALGADO O, ALTUZARRA O, PETUYA V, et al.Type synthesis of a novel 3T1R fully-parallel manipulator[J].Journal of Mechanical Design, 2008, 130(4):042305-1-042305-8. doi: 10.1115/1.2839005 [8] PIERROT F, NABAT V, COMPANY O, et al.Optimal design of a 4-DOF parallel manipulator:From academia to industry[J].IEEE Transactions on Robotics, 2009, 25(2):213-224. doi: 10.1109/TRO.2008.2011412 [9] PIERROT F, COMPANY O.H4:A new family of 4-DOF parallel robots[C]//Proceedings of IEEE/ASME International Conference on Advanced Intelligent Mechatronics.Piscataway, NJ:IEEE Press, 1999:508-513. [10] COMPANY O, KRUT S, PIERROT F.Internal singularity analysis of a class of lower mobility parallel manipulators with articulated traveling plate[J].IEEE Transactions on Robotics, 2006, 22(1):1-11. doi: 10.1109/TRO.2005.858862 [11] ROLLAND L.The Manta and the Kanuk:Novel 4-DOF parallel mechanisms for industrial handling[C]//Proceedings of International Mechanical Engineering Congress and Exposition.New York, NY:ASME, 1999:831-844. [12] KRUT S, COMPANY O, BENOIT M, et al.I4:A new parallel mechanism for Scara motions[C]//Proceedings of the IEEE International Conference on Robotics & Automation.Piscataway, NJ:IEEE Press, 2003:1875-1880. [13] KRUT S, NABAT V, COMPANY O, et al.A high-speed parallel robot for Scara motions[C]//Proceedings of IEEE International Conference on Robotics and Automation.Piscataway, NJ:IEEE Press, 2004:4109-4115. [14] CORADINI C, FAUROUX J C, KRUT S, et al.Evalution of a 4 degree of freedom parallel manipulator stiffness[C]//Proceedings of the 11th World Congress in Mechanism and Machine Science.Beijing:China Machinery Press, 2004:1857-1861. [15] GUO S, FANG Y, QU H.Type synthesis of 4-DOF non-overconstrained parallel mechanisms based on screw theory[J].Robotica, 2012, 30(1):31-37. doi: 10.1017/S0263574711000439 [16] 黄真, 刘婧芳, 李艳文.论机构自由度[M].北京:科学出版社, 2011:90-103.HUANG Z, LIU J F, LI Y W.Mobility of mechanisms[M].Beijing:Science Press, 2011:90-103(in Chinese). [17] 黄真, 孔令富, 方跃法.并联机器人机构学理论及控制[M].北京:机械工业出版社, 1997:18-29.HUANG Z, KONG L F, FANG Y F.Mechanism theory and control of parallel manipulator[M].Beijing:China Machine Press, 1997:18-29(in Chinese). [18] 郭宗和, 段建国, 郝秀清, 等.4-PTT并联机构位置正反解与工作空间分析[J].农业机械学报, 2008, 39(7):144-148. http://www.cnki.com.cn/Article/CJFDTOTAL-NYJX200807033.htmGUO Z H, DUAN J G, HAO X Q, et al.Analysis on position and workspace of 4-PTT parallel mechanism[J].Transactions of the Chinese Society of Agricultural Machinery, 2008, 39(7):144-148(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-NYJX200807033.htm [19] 鄔昌峰. 6-SPS并联机器人工作空间研究及其优化设计[D]. 合肥: 合肥工业大学, 2003.WU C F.6-SPS parallel mechanism workspace research and optimization[D].Hefei:Hefei University of Technology, 2003(in Chinese). [20] 陈海真, 邹忠月, 宋宏鹏.基于遗传算法3-RCR并联机器人的结构参数优化设计[J].机械设计与制造, 2012(7):49-51. http://www.cnki.com.cn/Article/CJFDTOTAL-JSYZ201207020.htmCHEN H Z, ZOU Z Y, SONG H P.Parameters optimization design of 3-RCR parallel robot mechanism based on genetic algorithm[J].Machinery Design & Manufacture, 2012(7):49-51(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JSYZ201207020.htm -

下载:

下载: