Temperature rise characteristic of lithium battery integrated thermal management system combining phase change materials with air cooling

-

摘要:

锂电池在高倍率充放电过程中会产生大量热量,此热量不及时散出会导致电池超温进而影响电池的使用寿命,甚至导致安全事故。本文设计了一种新型相变材料/风冷综合热管理系统(TMS),并对综合热管理方式下的电池温升特性进行了实验和理论研究。基于集总参数法,结合电池生热及散热机理,建立了电池发热功率计算模型以及相变材料/风冷综合TMS电池温度场数学模型,计算了电池单体发热功率,分析了环境温度、电池充放电循环初始温度、相变温度、对流热阻以及电池和相变材料之间的导热热阻对电池综合TMS性能的影响。结果表明:综合TMS的冷却性能优于纯风冷热管理系统;电池充放电过程为非稳态传热过程,因此较高的初始温度带来超温风险;电池温度场数学模型能准确反映电池升温行为;较高的环境温度下,电池最大温升幅度降低,但可能导致电池最高温度超过安全温度;相变材料的相变温度越低,电池最大温升越低;减小导热热阻及对流热阻能显著提高TMS性能。

Abstract:A large amount of heat inside the lithium battery must be dissipated to ensure the safety of the battery by using high efficiency thermal management system (TMS) at high charging/discharging rates. A newly designed TMS integrating phase change material with air cooling was designed and its temperature rise characteristic was investigated theoretically and experimentally. Based on the lumped parameter method and the heat transfer mechanism, the mathematical models of temperature rise and heat generation power were developed for the battery. The battery heat generation power was calculated. The key parameters of ambient temperature, initial temperature, phase change temperature, convective resistance and conductive resistance between the battery and the phase change material affecting the performance of the integrated TMS were analyzed. The results indicate that the performance of the integrated TMS is superior to the pure air cooling system. In the non-steady process of temperature rise during charging and discharging, the higher initial temperature easily causes the battery to exceed the safe temperature. The mathematical model of the battery temperature field can accurately describe the battery temperature rise characteristic. At high ambient temperature, the maximum temperature rise of battery declined, but it may cause the maximum temperature to exceed the safe temperature. The higher phase change temperature is, the lower battery maximum temperature rise is. Reducing conductive resistance or convective resistance can significantly improve the performance of the TMS.

-

锂电池作为动力电池具有比能量高、比功率大、使用寿命长、工作范围宽、环境友好等特点[1],越来越广泛应用于手机、便携式电脑、电动汽车(BEV)、混合型电动汽车(HEV)、轨道交通、航空航天等领域,对锂离子动力电池的应用研究也越来越多。锂电池在广泛应用的同时,其安全性问题逐渐暴露出来。锂离子电池引发的安全事故主要是由于电池的热失控引起的[2-3]。锂电池电解液大多为有机易燃物,在大电流充放电过程中,会产生大量的热量,当热量不能及时有效散出时则会在电池局部产生高温,如温度超过电池允许的温度上限,会引发电池漏液、冒烟、着火、甚至爆炸等一系列安全问题,从而引发严重事故,给人员财产带来损失。热失控是锂离子电池大型化、动力化的主要障碍[4-5]。另外,锂离子电池的应用要综合考虑温度对电池性能和循环寿命的影响以确定电池最优工作范围。所以,在没有解决电池自发热之前,热管理问题成为了制约锂电池发展的技术瓶颈[6]。

电池热管理的目的是降低电池最高温度,保证电池组内部温度的均匀性,使得电池工作在最佳温度范围,从而提高电池寿命,避免电池出现安全性事故。目前,电池热管理的主要方式根据冷却介质的不同可分为:基于空气介质的电池热管理、基于液体介质的热管理、基于相变传热介质的热管理以及采用热管、冷板等设备的热管理系统(TMS)。不同方式各有优劣,但随着电池装机容量越来越大,电池组整体发热功率越来越高,单一热管理方式在维持电池合理工作温度方面效果有限,采用集成多种热管理方式的综合热管理系统成为解决问题的有效方法。另外,传统的以廉价空气、水为冷却介质的电池热管理方式需要额外能源驱动冷却介质循环,在电池热管理应用中往往是以牺牲电池容量和功率的代价换取电池安全工作温度,换取较长的运行寿命[7],而且这些传统的热管理方式系统复杂且占用的空间较大,而采用相变材料(PCM)的电池热管理系统则可克服这些缺点。综上所述,采用基于相变材料的综合热管理系统是电池热管理的重要发展方向。

应用相变材料的热管理系统是由Hallaj和Selman[8]首先提出并获得专利的,他们认为应用相变材料进行电池热管理,不仅热管理系统体积较小,散热效果也比风冷散热效果更为显著。Rao等[9]利用数值模拟的方法,考察了单个包覆相变材料的18650锂电池在自然对流条件下的散热效果,结果表明当电池的产热率为0.17 W/cm3、环境温度为25 ℃时,用热导率大于0.8 W/(m·K)的相变材料能将电池温度维持在50 ℃以下,而且相变材料的热导率越高,热量积聚越少,电池温度越低。由于相变材料充装有限并且相变材料导热系数较低,当相变材料完全融化后,相变材料将对电池“保温”,导致电池急剧升温。为此,一些研究人员在相变材料中嵌入了高导热率材料的骨架,以提高相变材料的有效导热系数,并降低相变材料完全融化后对电池的“保温”作用。文献[10]设计了以石蜡/泡沫铝为复合相变材料的热管理系统,结果表明该系统使电池的温度下降了25 ℃。此外,耦合了翅片散热与复合相变材料(石蜡/泡沫铝)的热管理系统,可以满足电池更高温度的工况条件,有效防范锂离子电池的热失效及其引发的安全事故。Ling等[11]研究了对流对相变热管理性能的影响,结果表明,强迫对流能及时将相变材料吸收的热量传递出去,有效保证了相变材料的持续工作。

本文以钛酸锂动力电池组为研究对象,针对其特定结构,设计了一种新型相变/风冷综合热管理系统,并对该系统性能进行了实验研究。在分析电池生热和散热机理的基础上,建立了电池发热功率计算模型以及相变/风冷热管理系统下电池温度场数学模型,计算了电池发热功率,分析了环境温度、电池充放电循环初始温度、相变温度、对流热阻、电池和相变材料交界面导热热阻对电池热管理性能的影响,研究结果可为电池热管理系统设计提供指导。

1. 实验系统

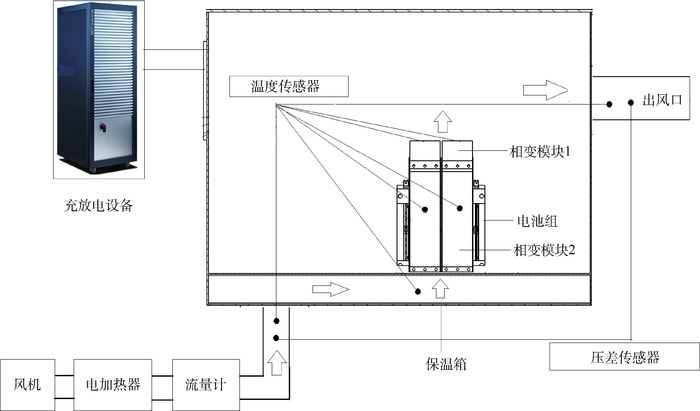

图 1为充放电-热性能耦合测量试验台。实验台系统由3部分组成,分别是热性能测试系统、充放电系统和数据采集系统。充放电系统电池充放电设备主要由可程控直流电源供应器以及可程控直流电子负载组成。放电过程中,电池模组以2 C/20 A、3 C/30 A、4 C/40 A恒流放电至18 V;充电过程中,以2 C、3 C、4 C恒流充电至33.6 V,然后以33.6 V恒压充电至0.05 A。热性能测试系统中由变频风机和电加热器输出恒温恒流空气。测试风量为0 m3/h(自然对流)、18 m3/h。进风温度分别为35 ℃和42 ℃。进风流量、系统压差、温度等参数使用Agilent数据采集仪(34 970 A)采集。

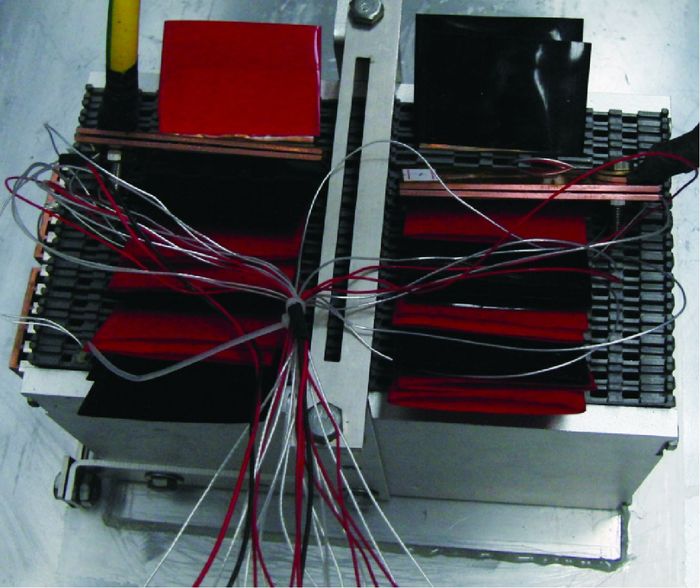

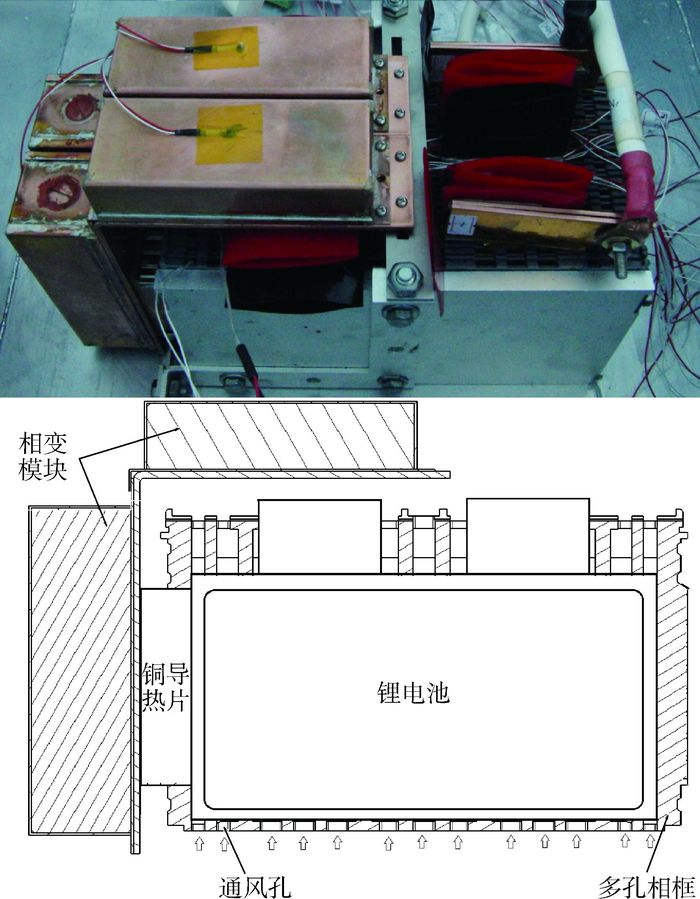

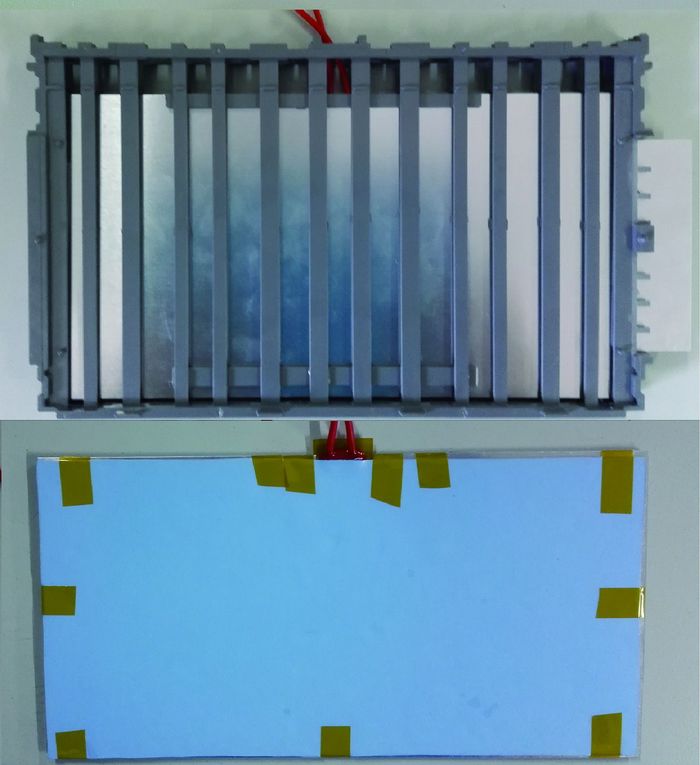

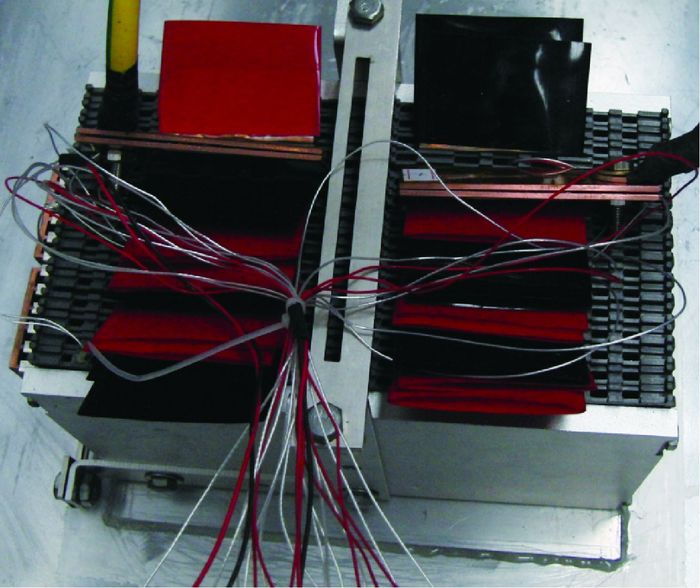

图 2为锂电池实验模组。电池模组由12片单体电池、铝片以及多孔相框组成。锂电池为商用钛酸锂电池,其电池参数如表 1所示。空气可通过多孔相框流经电池表面对电池散热。图 3为安装了基于相变材料的综合热管理系统的电池模组。两组相变单元布置在电池模组侧边以提高空间利用率,同时可减少相变单元对风冷气流的影响。每组相变单元由2个相变模块组成。每个相变模块采用由纯度为99%的正二十烷以及孔隙率为95%的镀镍泡沫铜构成的复合相变材料,相变模块由厚度为1 mm紫铜密封。相变材料的相变温度为36 ℃。相变模块与电池模组之间通过尺寸为2 mm×15 mm×80 mm铜导热片连接。

表 1 钛酸锂电池参数Table 1. Parameters of lithium titanate battery参数 数值 尺寸/(mm×mm×mm) 6.1×203×127 质量/g 285 标称电压/V 2.3 额定容量/(A·h) 10 推荐使用温度范围/℃ 充电-10~+45

放电-25~+55导热系数/(W·(m·K)-1) 5.22 图 4为测量热阻用电加热器。电加热器结构尺寸与电池单体相同,通过直接替换图 2与图 3中电池单体,进行纯风冷以及综合冷却2种状态下热阻测试。采用30 V/5 A可调直流稳压电源供电,单体加热器加热功率qsimu分别为2、3、4、5 W。测试环境为自然对流以及18 m3/h风量,环境温度为35℃。采用安捷伦数据采集仪采集加热器表面温度Telect及环境温度T∞。对于纯风冷状态,对流热阻Rh计算如下:

(1) 对于综合冷却状态,电池充放电过程中产生的热量一部分热量通过相框通风孔以空气对流形式传递,其对流热阻取决于风量大小。另一部分热量从电池表面通过铜导热片传递至相变模块,其大小与导热热阻有关。在本实验中,由于相变模块对风冷通道不会产生明显影响,因此,相同风量下,纯风冷热管理系统以及综合热管理系统有着相同的对流热阻。导热热阻Rp计算如下:

(2) 式中:TD为相变材料相变温度,K。在纯风冷系统中,不同加热功率下自然对流热阻平均值为13.87 K/W,18 m3/h风量下,对流热阻平均值为2.03 K/W。相变导热热阻为平均值为3.9 K/W。

2. 温升模型

2.1 电池发热功率模型

电池生热特性是内部复杂电化学反应以及电能-热能转换综合作用的结果,电池在充放电过程中产生的总热量由可逆的电化学反应热及不可逆的焦耳热组成[12-14]。假设电池正常充放电,不考虑电池内部副反应热,电池生热速率计算模型如下[15]:

(3)

(4) 式中:q为电池发热功率,W;i为充放电电流,A,充电过程为负,放电过程为正;t为充电时间,s;T为电池温度,K;E为电池开路电压,V;U为电池端电压,V。式(3) 中的不可逆焦耳热与直流内阻(式(4))相关,主要包括极化热以及欧姆热[16-17]。在测试直流内阻过程中为了充分获取动态工况下电池端电压的变化量,需要根据经验来选取合适时间长度的数据段用于计算直流内阻,时间长度的选取往往会引入不同程度的偏差,这种方法计算效率较低[18-19]。

配置风冷热管理系统后,电池在热量传递过程中,除了电池本体吸收一部分热量之外,电池和热管理系统之间还通过对流、辐射的方式进行热量交换。经计算,自然对流状态下电池毕渥数(Bi)为0.005,根据集总参数法原理,任意时刻,电池体温度均匀,则风冷热管理系统热平衡方程为

(5) 式中:ρ为电池密度,kg/m3;c为电池比热,J/(kg·K);V为电池体积,m3;ε为发射率;A为辐射换热面积,m2;σ为辐射常数。通常电池模块内部辐射传热量可忽略,则电池瞬态温度分布方程及分析解分别为

(6)

(7) 电池降温过程中q=0,电池瞬态温度分布方程及分析解分别为

(8)

(9) 电池发热功率计算如下:

(10) 式中:T0为电池初始温度,K;B=ρcVRh为时间常数。

2.2 综合热管理系统电池温升模型

相变-风冷综合热管理系统中,电池热量传递途径有3种,分别为空气对流、相变吸热,辐射传热。忽略辐射热,假设任意时刻,电池内部无温差,则电池温升方程及其分析解分别为

(11)

(12) 由分析解可知,电池发热功率、环境温度、时间常数、热阻、初始温度等参数是影响电池温升行为的关键参数。当上述参数已知的情况下,可预测电池温升行为,为热管理系统设计提供指导。

3. 结果与讨论

3.1 发热功率对电池温升的影响

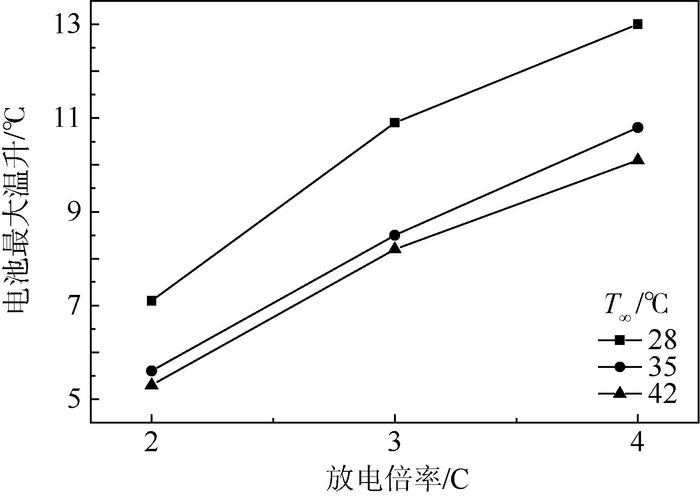

图 5为不同放电倍率、风量为18 m3/h、环境温度为28、35、42 ℃工况下的最大温升。结果显示,电池充放电倍率越大,其最大温升越高,但电池最大温升上升幅度变缓。当环境温度为28 ℃、4 C工况下电池最大温升达到13 ℃;35 ℃和42 ℃环境温度下,电池最大温升分别为11 ℃和10.3 ℃。可见环境温度越高,电池最大温升越小,但35 ℃和42 ℃环境温度下,电池组最大温升差异不大。产生上述现象的主要原因是不同环境温度以及充放电倍率下,电池发热功率不同。根据式(3) 电池发热功率主要受到电池温度以及充放电电流的影响。对于放电过程,环境温度越高,电池体温度越高,电池的发热功率越小。

3.2 不同热管理系统对电池温升影响

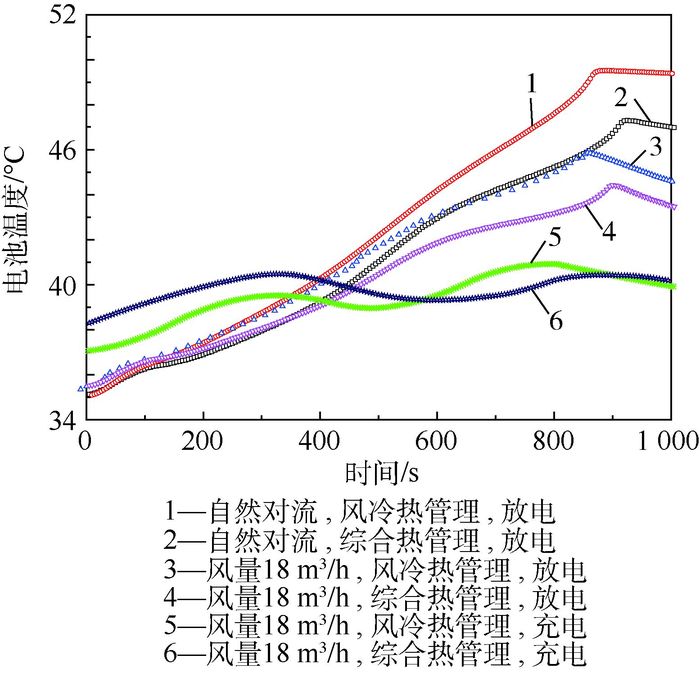

图 6表示电池在35 ℃环境温度、不同热管理系统及对流条件下,4 C充放电过程中电池温度变化。测试结果表明,2种热管理条件下,充放电过程电池均没有达到热稳定状态,表明电池耦合生热与散热过程为非稳态过程。4 C倍率下,完成充放电所需时间约900 s。在充放电循环中,电池升温速率发生变化,表明电池产热速率在发生变化。在电池放电工况中,电池持续升温,并在放电完成后电池温度达到最高。充电过程的电池最高温度远小于放电过程,并且电池温升曲线存在2个明显的峰值温度,其温度变化可分为3个阶段:在早期阶段,由于电池与环境温度之间相差不大,电池散热量小进而导致电池迅速升温;中间状态存在明显的降温过程,主要是因为电池生热速率小于散热速率;后期电池再次升温主要是由于电池内阻增加[20]。纯风冷热管理系统中,自然对流状态下,电池的最高温度为49.5 ℃;强迫对流条件下,电池最高温度46 ℃。增加风量能显著降低电池温度。与风冷热管理系统相比,综合热管理系统中,相变材料提供了额外的散热负荷,自然对流状态下最高温度为47.3 ℃;强迫对流条件下,电池最高温度为44.4 ℃。因此,相同对流条件下,综合热管理系统降温效果优于纯风冷热管理系统。

3.3 发热功率计算及模型验证

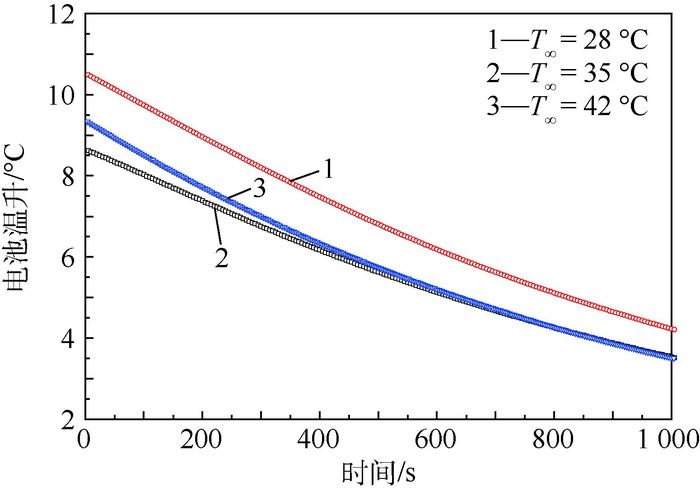

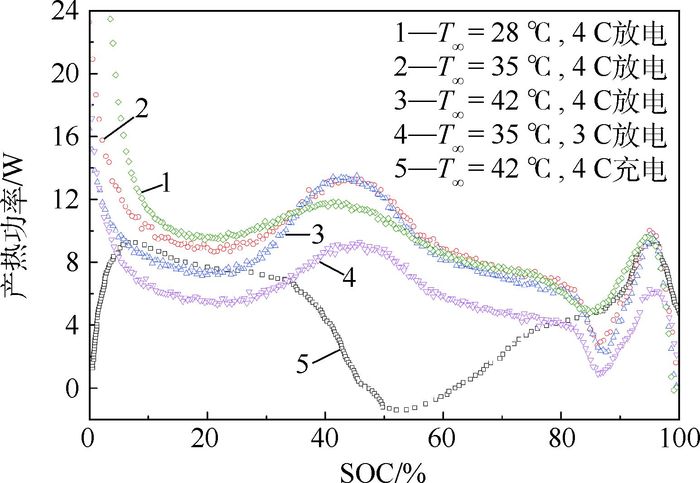

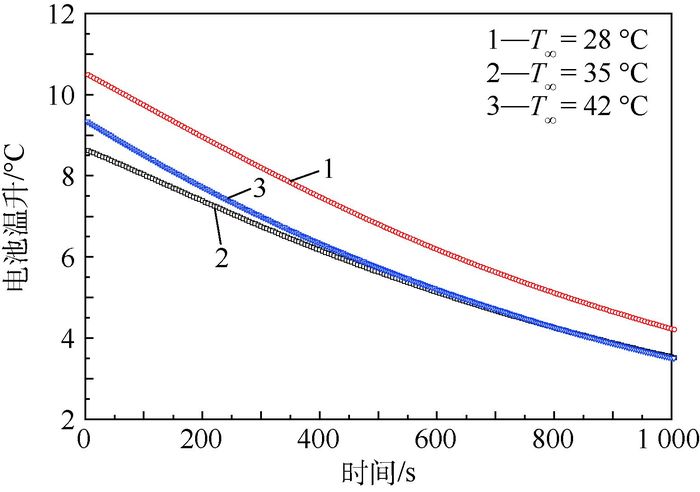

图 7为不同风量下,电池单体放电完成后温降变化情况。根据式(9) 及图 7,风量为18 m3/h, 环境温度为28、35以及42 ℃工况下,电池时间常数分别为1.053×103、1.075×103和1.031×103。结合电池时间常数及式(10),电池发热功率计算结果如图 8所示。结果显示,在4 C放电过程中,当荷电状态SOC<35%,不同温度下,电池发热功率随环境温度明显分化,环境温度越低,电池发热功率越大。当SOC≤10%,即放电接近完全时,电池的发热功率急剧上升,最高峰值功率出现在电池放电完成(SOC=0)。28℃温度下,峰值功率达到80 W,该发热功率下电池长时间工作极易导致电池超温,因此,实际应用中,放电过程应避免过度放电(SOC<10%)。当SOC>35%,42 ℃与35 ℃环境温度下,电池发热功率变化基本一致,电池产热功率差异较小。28 ℃情况下的最大发热功率略小于42 ℃和35 ℃情况下的最大发热功率。图 5中的实验结果也表明,42 ℃与35 ℃温度下,电池最大温升幅度相差不大。相同环境温度下,3 C放电过程中的产热功率明显小于4 C放电过程,表明放电电流越大,电池发热功率越高。充电过程电池平均发热功率小于放电过程,且当SOC=5%和SOC=90%,电池存在2个明显的峰值功率。当SOC=50%,电池充电过程发热功率最小,且出现负值,表明这一阶段放电过程中电化学反应吸热量大于不可逆焦耳热。当SOC>90%,电池产热量迅速减小,主要是由于电池在充电后期由恒流充电转为恒压充电,电池充电电流迅速减小。上述产热功率变化曲线与电池温度测试结果基本吻合。

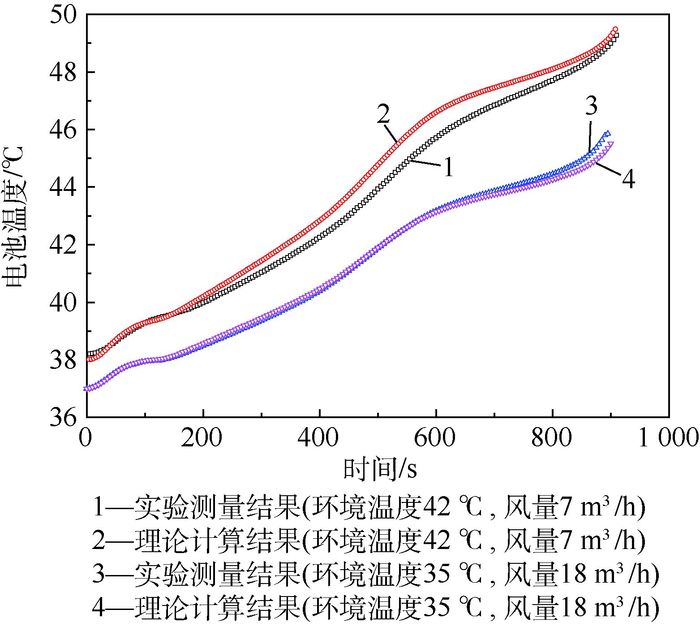

图 9为电池综合热管理系统温升理论计算结果与实验结果对比。结果显示,理论结算结果与实验结果符合较好,综合热管理系统温升模型能较为准确反映高倍率放电情况下电池温升特性。

3.4 电池温升特性影响因素

根据综合热管理系统温升模型以及测试结果,影响电池温升特性的主要参数除了电池自身发热功率之外,外部因素主要包括相变温度、环境温度、电池初始温度以及与热管理系统相关的对流和导热热阻。

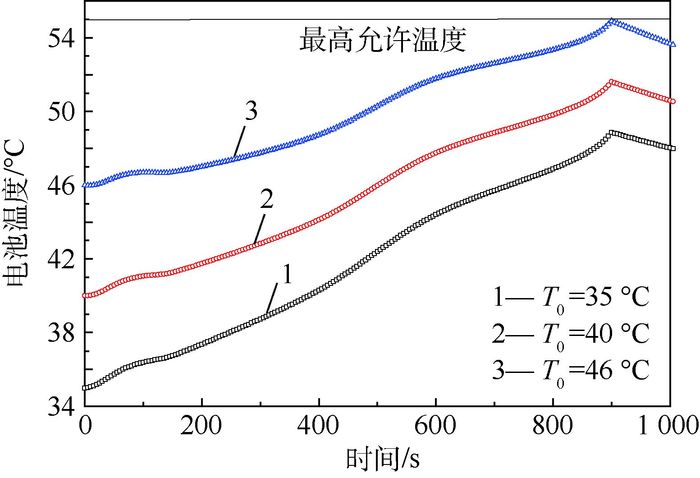

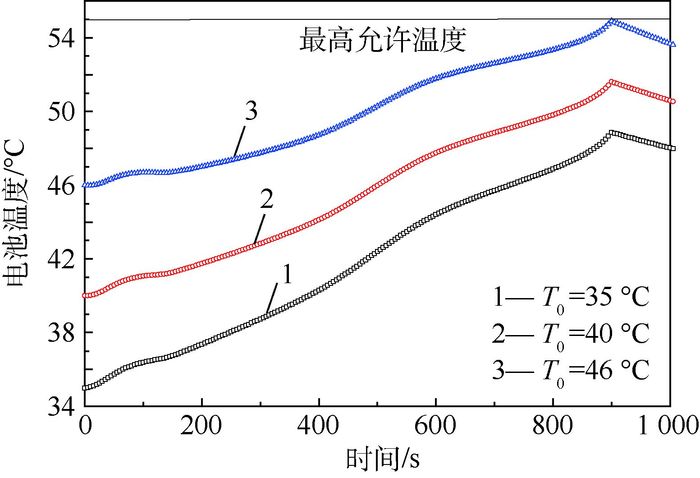

电池在充放电循环过程存在初始温度不一致的情况。图 10为T∞=35 ℃时,电池在不同T0、自然对流工况下电池温升计算结果。结果表明,初始温度为35 ℃,电池最高温度为48.9 ℃;随着初始温度增加,在放电期间电池的最高温度值逐渐增加;当初始温度达到46 ℃,电池达到电池允许的最高温度(55 ℃),进一步增加初始温度极易导致电池超温。初始温度越高,在放电期间电池的最高温度值越大。因此,电池在充放电循环过充中,应尽可能避免初始温度过高,试验极限初始温度为46 ℃。

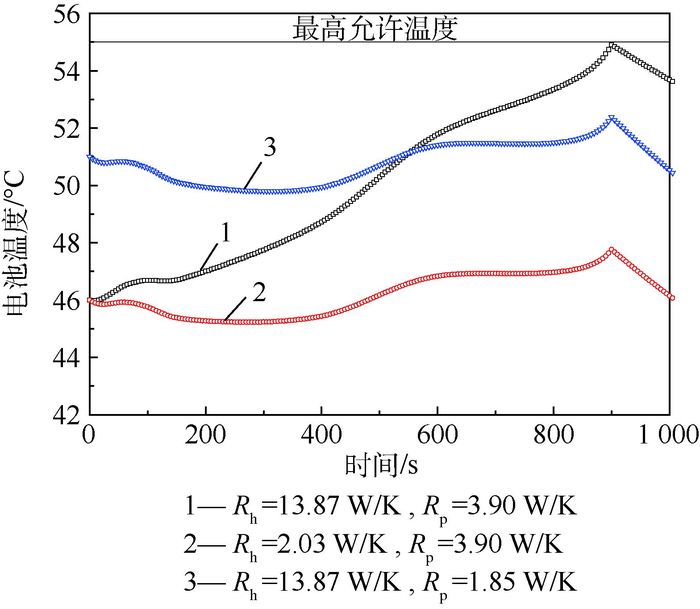

相变/风冷综合热管理系统中,对流热阻以及相变材料吸热过程中的导热热阻是影响电池温升特性的2个重要外部参数。图 11为不同对流热阻与导热热阻下,电池的温度变化曲线。结果显示,降低对流热阻以及导热热阻可以显著降低电池最高温度。当电池对流热阻降低至2.03 K/W,电池升温幅度较小,最高温度为48 ℃,电池可视为处于热平衡状态。当导热热阻降低至1.85 K/W,电池近似处于热平衡状态,最高温为52 ℃,2种工况下,电池的最高温度均小于最高允许温度(55 ℃)。因此,当对流热阻小于2.03 K/W或导热热阻小于1.85 K/W时,综合热管理可有效维持电池温度处于安全温度范围。

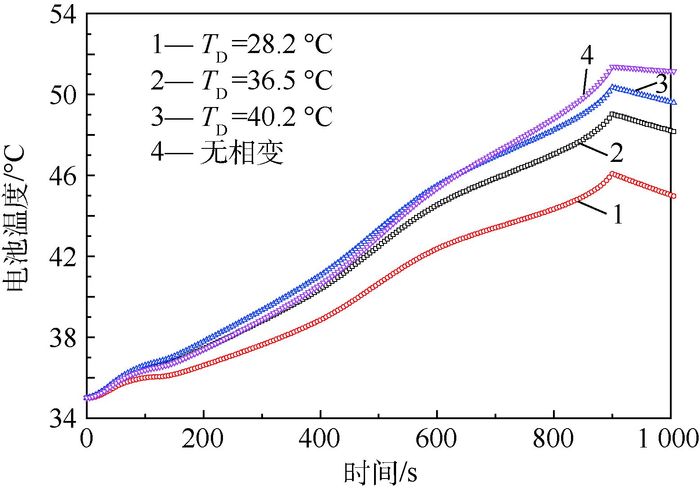

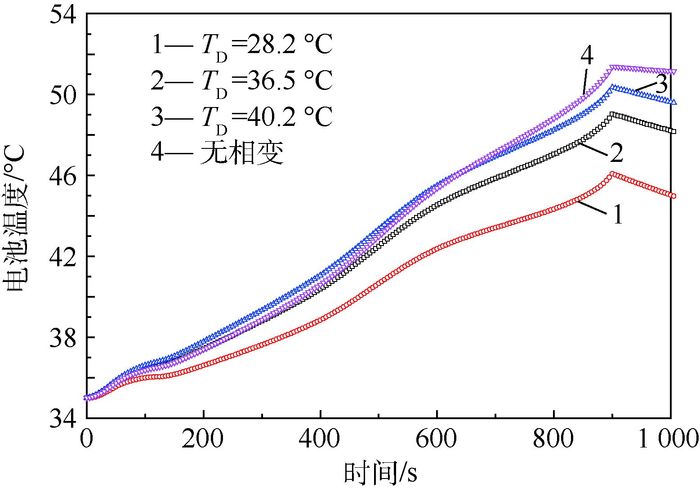

图 12为环境温度35℃温度下,不同相变温度对电池温升的影响。图中3个相变温度从高到低分别表示正十八烷、正二十烷、二十一烷的相变温度。从结果可以看出相变温度越高,电池最高温度值越大。当相变温度为40.2℃,电池温升幅度与无相变工况下相接近,表明相变材料未承担主要散热负荷。主要原因是,当相变温度过高时,相变材料融化吸热的量很少甚至不发生融化,导致相变材料承担散热负荷降低。因此,热管理系统设计时应避免选择相变温度过高的相变材料以避免相变热管理系统失效。当相变温度为28.2 ℃,电池最高温度明显下降。但过低的相变温度可能导致相变材料吸收环境热量,进而减小相变热管理系统整体工作时间,因此,相变材料选择时应保证其相变温度尽可能低,同时保证不受外界环境的影响。

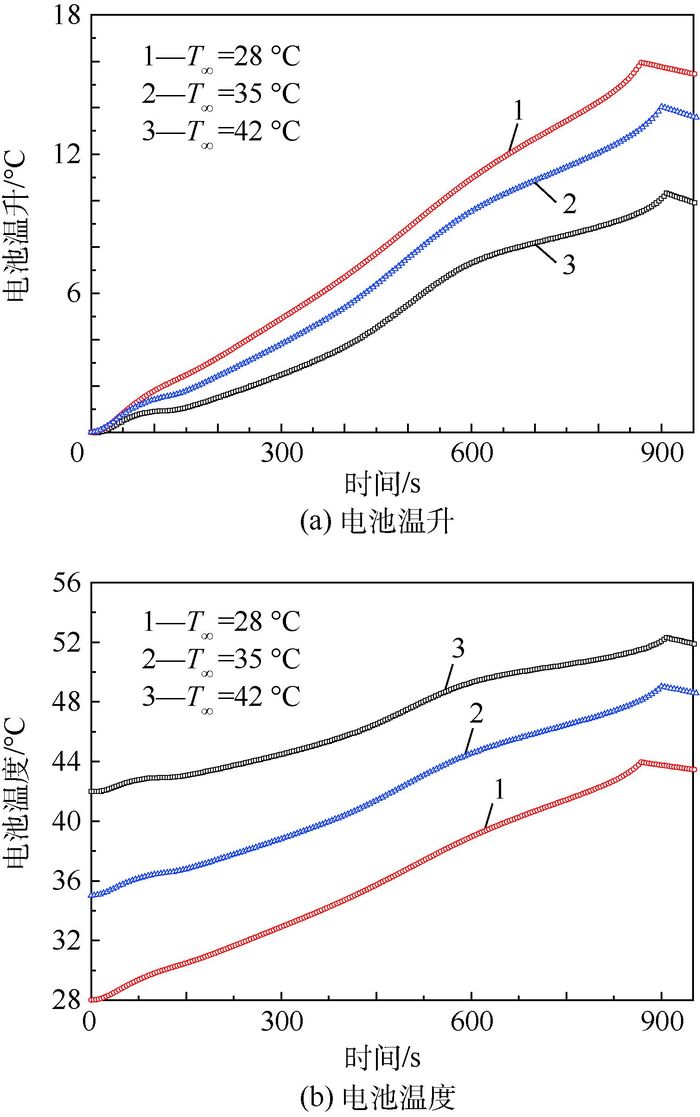

图 13为自然对流条件下,不同环境温度对综合热管理系统下电池温升的影响。图 13(a)显示,28、35与42 ℃工况下电池最大温升分别为16、14和10.3 ℃,电池最大温升之差为3.7 ℃。环境温度越高,综合热管理系统中电池最大温升越低。产生上述现象的主要原因是:与低温环境相比,高温环境下,相变材料承担了更多的散热负荷,进而导致电池温升幅度减小。另外,与图 5结果对比发现,42 ℃环境自然对流条件下,综合热管理系统与强迫风冷有着相似的冷却效果,但没有消耗额外的电池电量。图 13(b)显示,环境温度越高,电池最高温度越高。42 ℃情况下,电池最高温度接近安全温度极限值,表明高温环境下虽然电池生热率减小,相变材料吸热量增加,但并不足以使电池最高温度降低,因此,综合热管理系统中,应避免电池在高温环境下运行。

4. 结论

为提高锂离子电池组的热管理水平,本文设计了一种相变材料/风冷综合热管理系统,并对该系统下电池的温升特性进行了理论及实验研究,提出了电池发热功率理论计算模型以及电池温升模型,分析了影响电池温升特性的主要因素:

1) 相变材料/风冷综合热管理系统中,电池温升过程为非稳态过程,其热管理性能优于纯风冷热管理系统。

2) 电池发热功率是影响电池温升特性的重要内部因素。实验及理论计算结果表明,充放电倍率及电池体温度是影响锂离子电池发热功率的重要参数。电池体温度越高,充放电倍率越大,电池发热功率越大。由于放电后期电池发热功率迅速升高,电池应避免过度放电;充电过程电池发热功率小于放电过程。在充电中间阶段电池发热功率最小且存在负值区。

3) 电池温升数学模型能准确反映电池的温升特性。影响综合热管理系统下电池温升特性的参数主要有:环境温度、电池初始温度、对流及导热热阻、相变温度。提高环境温度,降低电池初始温度以及相变温度,减少热阻均能显著降低电池温升幅度,但较高环境温度可能导致电池最高温度超过安全温度。当对流热阻小于2.03 K/W或导热热阻小于1.85 K/W时,综合热管理系统可有效维持电池温度在安全温度范围。

-

表 1 钛酸锂电池参数

Table 1. Parameters of lithium titanate battery

参数 数值 尺寸/(mm×mm×mm) 6.1×203×127 质量/g 285 标称电压/V 2.3 额定容量/(A·h) 10 推荐使用温度范围/℃ 充电-10~+45

放电-25~+55导热系数/(W·(m·K)-1) 5.22 -

[1] 欧阳陈志, 梁波, 刘燕平, 等.锂离子动力电池热安全性研究进展[J].电源技术, 2014, 38(2):382-385. http://www.cnki.com.cn/Article/CJFDTOTAL-DYJS201402070.htmOUYANG C Z, LIANG B, LIU Y P, et al.Progress of thermal safety characteristics of high power lithium-ion batteries[J].Chinese Journal of Power Sources, 2014, 38(2):382-385(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-DYJS201402070.htm [2] 王宏伟, 邓爽, 肖海清, 等.国内电动车用动力锂离子电池现状[J].电子元件与材料, 2012, 31(6):84-86. http://www.cnki.com.cn/Article/CJFDTOTAL-DZAL201206030.htmWANG H W, DENG S, XIAO H Q, et al.Review on domestic power Li-ion battery[J].Electronic Components and Materials, 2012, 31(6):84-86(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-DZAL201206030.htm [3] 唐致远, 管道安, 张娜, 等.锂离子动力电池的安全性研究进展[J].化工进展, 2005, 24(10):1098-1102. doi: 10.3321/j.issn:1000-6613.2005.10.006TANG Z Y, GUAN D A, ZHANG N, et al.Research on safety characteristics of high power lithium-ion batteries[J].Chemical Industry and Engineering Progress, 2005, 24(10):1098-1102(in Chinese). doi: 10.3321/j.issn:1000-6613.2005.10.006 [4] BIENSAN P, SIMON B, PÉRÈS J P, et al.On safety of lithium-ion cells[J].Journal of Power Sources, 1999, 81-82(99):906-912. [5] 侯永涛, 赛羊羊, 孟令斐, 等.纯电动汽车锂离子电池热效应的建模及仿真[J].电源技术, 2016, 40(6):1185-1188.HOU Y T, SAI Y Y, MENG L F, et al.Modeling and simulation of thermal effects of lithium-ion battery for electric vehicles[J].Chinese Journal of Power Sources, 2016, 40(6):1185-1188(in Chinese). [6] SABBAH R, KIZILEL R, SELMAN J R, et al.Active (air-cooled) vs.passive (phase change material) thermal management of high power lithium-ion packs:Limitation of temperature rise and uniformity of temperature distribution[J].Journal of Power Sources, 2008, 182(2):630-638. doi: 10.1016/j.jpowsour.2008.03.082 [7] 张国庆, 张海燕.相变储能材料在电池热管理系统中的应用研究进展[J].材料导报, 2006, 20(8):9-12. http://www.cnki.com.cn/Article/CJFDTOTAL-CLDB200608003.htmZHANG G Q, ZHANG H Y.Progress in application of phase change materials in battery module thermal management system[J].Materials Review, 2006, 20(8):9-12(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-CLDB200608003.htm [8] HALLAJ S A, SELMAN J R.A novel thermal management system for electric vehicle batteries using phase-change material[J].Journal of the Electrochemical Society, 2000, 147(9):3231-3236. doi: 10.1149/1.1393888 [9] RAO Z H, WANG S F, ZHANG Y L.Simulation of heat dissipation with phase change material for cylindrical power battery[J].Journal of the Energy Institute, 2016, 85(1):38-43. doi: 10.1179/1743967111Z.0000000008?scroll=top&needAccess=true [10] KHATEEB S A, AMIRUDDIN S, FARID M, et al.Thermal management of Li-ion battery with phase change material for electric scooters:Experimental validation[J].Journal of Power Sources, 2005, 142(1):345-353. [11] LING Z, WANG F, FANG X, et al.A hybrid thermal management system for lithium ion batteries combining phase change materials with forced-air cooling[J].Applied Energy, 2015, 148:403-409. doi: 10.1016/j.apenergy.2015.03.080 [12] HUANG Q, YAN M, JIANG Z.Thermal study on single electrodes in lithium-ion battery[J].Journal of Power Sources, 2006, 156(2):541-546. doi: 10.1016/j.jpowsour.2005.05.083 [13] ONDA K, OHSHIMA T, NAKAYAMA M, et al.Thermal behavior of small lithium-ion battery during rapid charge and discharge cycles[J].Journal of Power Sources, 2006, 158(1):535-542. doi: 10.1016/j.jpowsour.2005.08.049 [14] 刘恒伟, 李建军, 谢潇怡, 等.加速量热仪在锂离子电池热测试中的应用[J].集成技术, 2015, 4(1):51-59. http://www.cnki.com.cn/Article/CJFDTOTAL-JCJI201501007.htmLIU H W, LI J J, XIE X Y, et al.Application of accelerating rate calorimeter in the lithium-ion battery thermal test[J].Journal of Integration Technology, 2015, 4(1):51-59(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JCJI201501007.htm [15] BERNARDI D, PAWLIKOWSKI E, NEWMAN J.A general energy balance for battery systems[J].Journal of the Electrochemical Society, 1984, 132(1):5-12. [16] DONG H J, BAEK S M.Thermal modeling of cylindrical lithium ion battery during discharge cycle[J].Energy Conversion & Management, 2011, 52(8):2973-2981. [17] FORGEZ C, DO D V, FRIEDRICH G, et al.Thermal modeling of a cylindrical LiFePO4/graphite lithium-ion battery[J].Journal of Power Sources, 2010, 195(9):2961-2968. doi: 10.1016/j.jpowsour.2009.10.105 [18] 林成涛, 王军平, 陈全世.电动汽车SOC估计方法原理与应用[J].电池, 2004, 34(5):376-378. http://www.cnki.com.cn/Article/CJFDTOTAL-DACI200405027.htmLIN C T, WANG J P, CHEN Q S.Methods for state of charge estimation of EV batteries and their application[J].Battery Bimonthly, 2004, 34(5):376-378(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-DACI200405027.htm [19] 何志超, 杨耕, 卢兰光, 等.基于恒流外特性和SOC的电池直流内阻测试方法[J].清华大学学报(自然科学版), 2015, 55(5):532-537. http://www.cnki.com.cn/Article/CJFDTOTAL-QHXB201505009.htmHE Z C, YANG G, LU L G, et al.Battery DC internal resistance test method based on the constant current external characteristics and SOC[J].Journal of Tsinghua University (Science and Technology), 2015, 55(5):532-537(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-QHXB201505009.htm [20] 高明, 张宁, 王世学, 等.翅片式锂电池热管理系统散热性能的实验研究[J].化工进展, 2016, 35(4):1068-1073. http://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ201604016.htmGAO M, ZHANG N, WANG S X, et al.Experiment on heat dispersion of finned lithium battery thermal management system[J].Chemical Industry and Engineering Progress, 2016, 35(4):1068-1073(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ201604016.htm 期刊类型引用(15)

1. 黄燕琴,聂金泉,王敖,刘建强,李银银. 锂离子电池不一致性综述. 时代汽车. 2022(05): 102-107 .  百度学术

百度学术2. 张浩文,秦永法,翁佳昊,曾励. 车用锂离子电池相变冷却技术研究综述. 汽车工艺与材料. 2021(02): 43-48 .  百度学术

百度学术3. 吴波,张丰华,田沣,醋强一. 航空电子模块储热器工作时间预测. 工程设计学报. 2021(01): 48-55 .  百度学术

百度学术4. 田鑫,王有镗,赵冲,郑斌,周鹏,李龙飞. 动力电池直冷系统单/双膨胀阀影响效应分析. 内燃机与配件. 2021(07): 49-51 .  百度学术

百度学术5. 王佳杰,杨亮,刘道平,胡尚尚. 十四醇相变强化三元锂电池散热性能. 高校化学工程学报. 2021(03): 440-447 .  百度学术

百度学术6. 余剑武,胡仕港,范光辉,包有玉,陈亚玲. 基于流固热耦合的中心回转流道液冷板散热性能研究. 湖南大学学报(自然科学版). 2021(12): 1-9 .  百度学术

百度学术7. 张晓光,王一宇,时海军,潘晓楠,何燕. 充放电周期中相变材料包覆锂电池的散热模拟. 机械与电子. 2020(05): 9-12+17 .  百度学术

百度学术8. 陈雪莲,张存善,安然. 电池热管理及电池安全技术. 电源技术. 2020(08): 1177-1181 .  百度学术

百度学术9. 黄富霞,赵津,袁征,王超,张航. 动力电池微细通道散热数值分析研究. 热科学与技术. 2020(04): 347-352 .  百度学术

百度学术10. 陈杨华,赵烽,戈敏荣,王朝贺,高周. 基于相变材料的锂电池保温数值模拟. 北京化工大学学报(自然科学版). 2020(06): 107-114 .  百度学术

百度学术11. 赵磊,朱茂桃,徐晓明,胡东海,李仁政. 空气域与流体域耦合作用下双层电池包散热特性. 北京航空航天大学学报. 2019(01): 200-211 .  本站查看

本站查看12. 王炎,高青,王国华,张天时,苑盟. 混流集成式电池组热管理温均特性增效仿真. 吉林大学学报(工学版). 2018(05): 1339-1348 .  百度学术

百度学术13. 张睿,周永勤,李然. 基于Delphi-变异系数组合赋权法的电池性能评估研究. 汽车工程. 2018(08): 884-891+917 .  百度学术

百度学术14. 宋亚豪,谷正气,石佳琦. 计及热辐射的电动汽车电池包散热与改进研究. 电子机械工程. 2018(06): 22-26 .  百度学术

百度学术15. 王传经,丁旺,吴敏,王超,王联珠. 探讨纯电动汽车锂离子动力电池热原理及温度控制方式. 科技资讯. 2018(36): 90-91 .  百度学术

百度学术其他类型引用(20)

-

下载:

下载:

下载:

下载:

百度学术

百度学术