Separation flow and blade dynamic response characteristic of compressor at high attack angle

-

摘要:

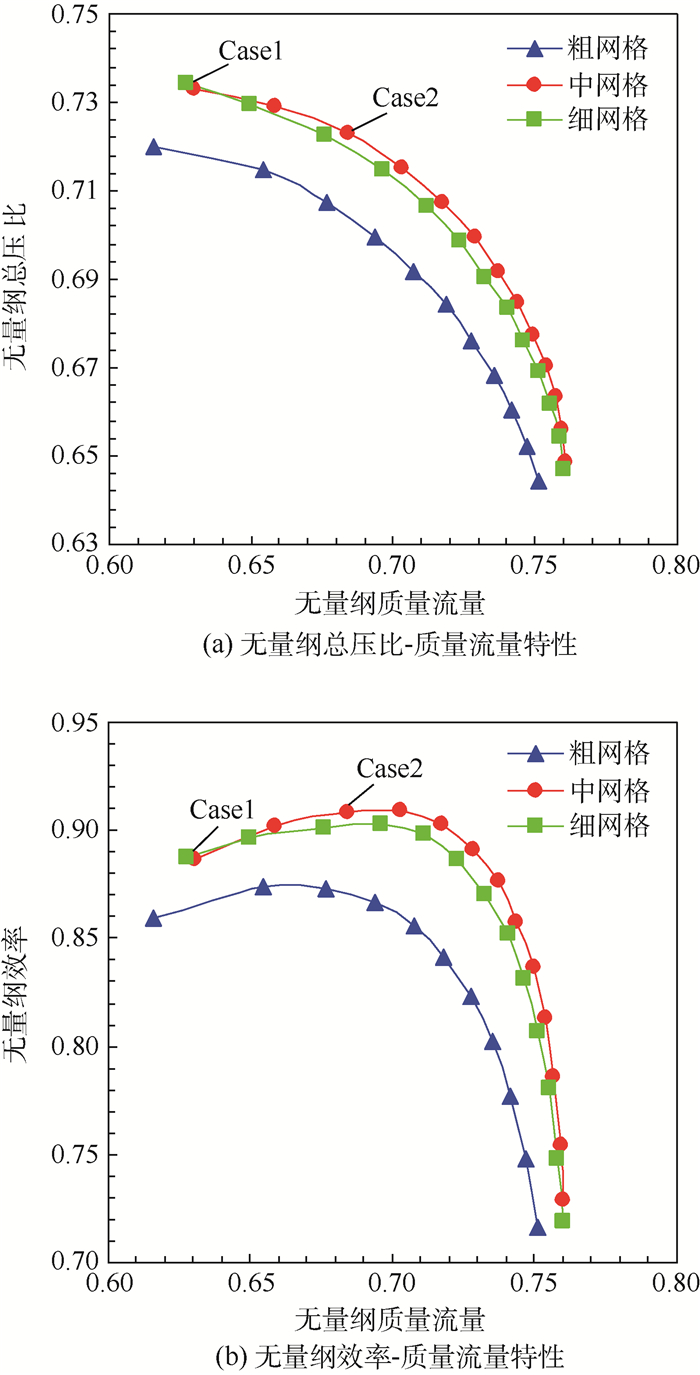

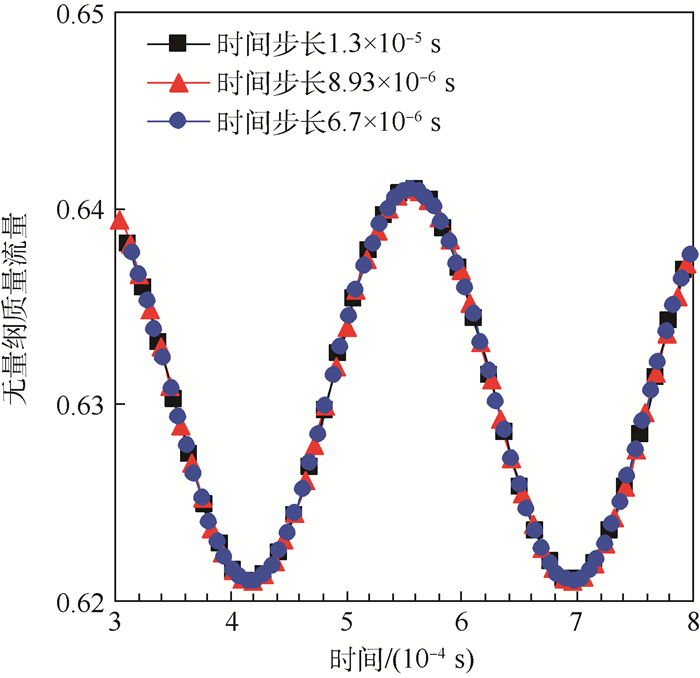

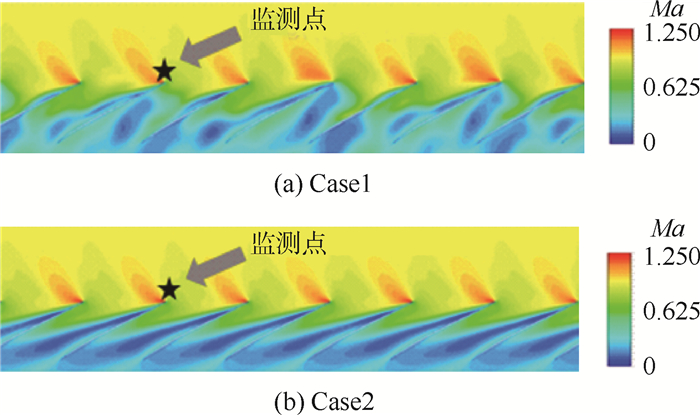

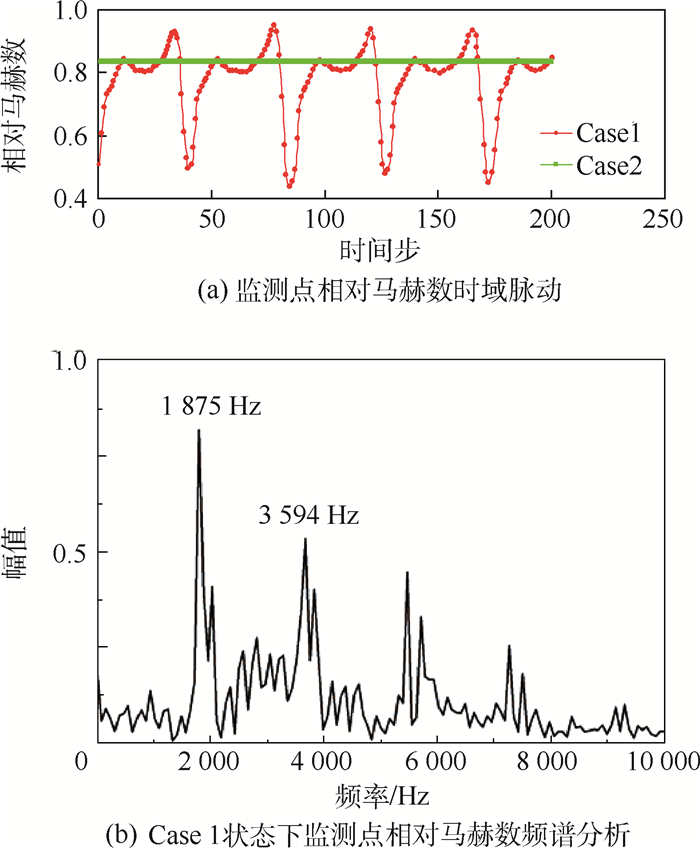

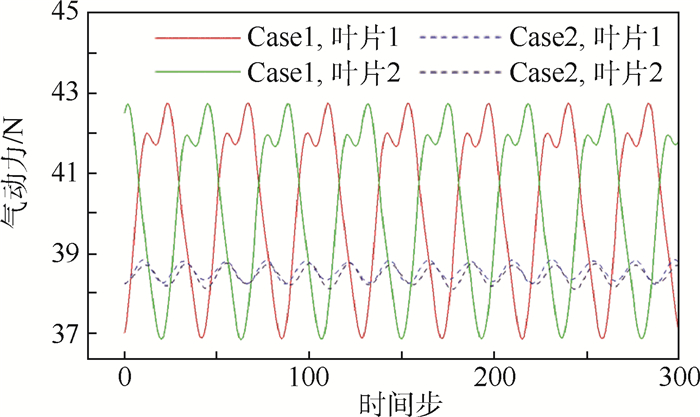

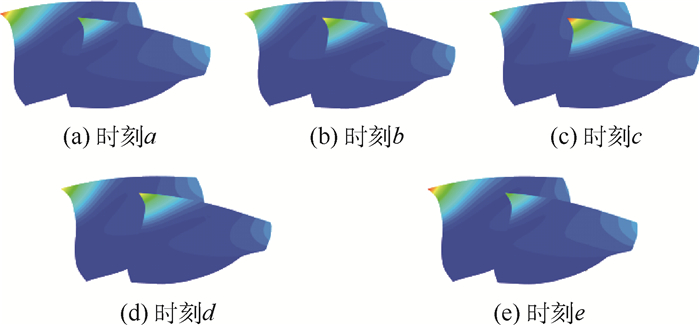

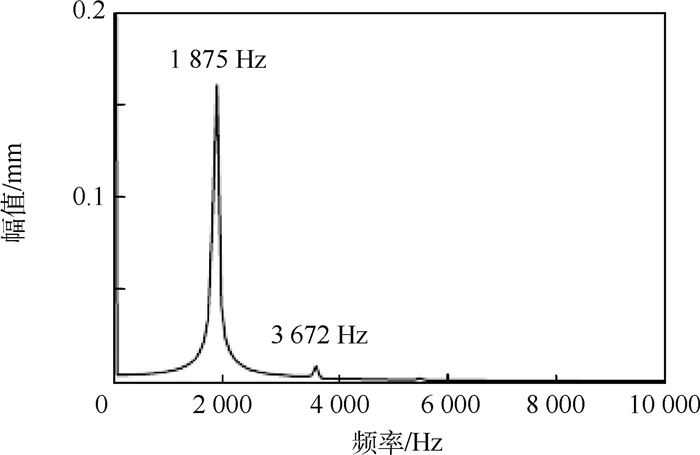

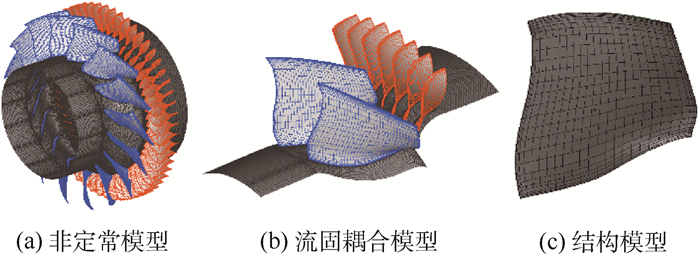

为研究大攻角状态压气机转子内部分离区的脱落和传播过程及转子叶片对其动力响应问题,对某跨声速压气机级进行了非定常数值模拟和双向迭代流固耦合数值模拟。研究结果表明,在近失速状态,转子叶片通道内会周期性地发生2次叶背分离区的脱落和传播现象。第1个分离区主要表现出轴向传播特性,其会对下游流场产生影响;第2个分离区主要表现出周向传播特性,其会作用于周向相邻的转子叶片,对转子叶排自身产生激励作用,进而影响叶片表面压力分布,引起叶片较强的动力响应,对叶片结构强度的影响不可忽略。非定常/流固耦合计算手段能够较全面地预测流场中激励源的频率、幅值与位置等,在压气机设计阶段应对此类预测工作予以重视,以期更准确地预测叶片共振及动力响应等问题。

Abstract:In order to study the shedding and propagation of compressor rotors at high angle of attack, as well as the dynamic response under this transient process, a model with a stage of transonic compressor was simulated with unsteady numerical method and double direction iteration fluid-structure coupled numerical method. The results show that under near-stall condition, the separation regions at suction side move and shed periodically along axial and circumferential directions. The axial separation may influence the flow field and vibration performance of downstream blade rows, while the circumferential separation can impact the adjacent rotor blade, with an excitation brought on rotor row itself and an influence on the pressure distribution of rotor blades. Furthermore, the circumferential separation may cause violent dynamic response which could threaten the structural strength of rotor blades. Unsteady/FSI simulation technology has the ability to forecast frequencies, amplitudes and locations of the excitation sources in flow field. This kind of work should be emphasized during design procedure to assess the resonance and dynamic response of compressor blades.

-

表 1 转子叶片材料属性

Table 1. Material property of rotor blades

参数 弹性模量/GPa 泊松比 密度/(kg·m-3) 数值 120 0.32 4370 表 2 叶片固有频率与振型

Table 2. Natural frequency and vibration mode of blade

阶数 固有频率/Hz 振型 1 1840

2 3011

3 4865

4 5341

-

[1] 夏联, 崔健, 顾扬.可调静叶对压气机低速性能影响的试验研究[J].燃气涡轮试验与研究, 2005, 18(1):31-34. http://www.cnki.com.cn/Article/CJFDTOTAL-RQWL200501006.htmXIA L, CUI J, GU Y.An experimental investigation on the effect of variable stator vane angle on compressor performance at low speed[J]. Gas Tirbine Experiment and Reasearch, 2005, 18(1):31-34(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-RQWL200501006.htm [2] VALKOV T V, TAN C S.Effect of upstream rotor vortical disturbances on the time-averaged performance of axial compressor stator.Part 2:Rotor tip vortex/streamwise vortex-stator blade interactions[J]. Journal of Turbomachinery, 1999, 121(3):387-397. doi: 10.1115/1.2841331 [3] GBADEBO S A, CUMPSTY N A, HYNES T P.Three-dimensional separations in axial compressors[J]. Journal of Turbomachinery, 2005, 127(2):331-339. doi: 10.1115/1.1811093 [4] MAILACH R, LEHMANN I, VOGELER K.Periodical unsteady flow within a rotor blade row of an axial compressor.Part 2:Wake-tip clearance vortex interaction[J]. Journal of Turbomachinery, 2008, 130(4):041005. doi: 10.1115/1.2812330 [5] HAH C, BERGNER J, SCHIFFER H P.Tip clearance vortex oscillation, vortex shedding and rotating instabilities in an axial transonic compressor rotor[C]//ASME Turbo Expo 2008.New York:ASME, 2008:57-65. [6] KIELB R E, BARTWE J W, THOMAS J P, et al.Blade excitation by aerodynamic instabilities—A compressor blade study[C]//ASME Turbo Expo 2003.New York:ASME, 2003:399-406. [7] MAILACH R, VOGELER K.Unsteady aerodynamic blade excitation at the stability limit and during rotating stall in an axial compressor[C]//ASME Turbo Expo 2006.New York:ASME, 2006:1701-1711. [8] HOLZINGER F, WARTZEK F, JUNGST M, et al.Self-excited blade vibration experimentally investigated in transonic compressors:Rotating instabilities and flutter[J]. Journal of Turbomachinery, 2015, 138(4):041006-1-041006-9. [9] 张章. 风扇/压气机气动弹性动力响应的机理与应用研究[D]. 北京: 北京航空航天大学, 2013.ZHANG Z.Investigation on the mechanism and application of aeroelastic dynamic respones in fan/compressor[D]. Beijing:Beihang University, 2013(in Chinese). [10] 张明明. 轴流压气机气动弹性失稳机理研究[D]. 北京: 北京航空航天大学, 2012.ZHANG M M.Investigation on the mechanism of aeroelasticity instability in axial compressor[D]. Beijing:Beihang University, 2012(in Chinese). [11] YANG X D.Flow field and vibration behavior of the rotor due to mistuning IGV in a transonic compressor[C]//Proceeding of ASME 2012 International Mechanical Engineering Congress & Exposition.New York:ASME, 2012:267-274. [12] ZHANG M M, HOU A P, LI J X, et al.Analysis of blade vibration response induced by rotating stall in axial compressor[J]. Journal of Aerospace Power, 2012, 27(10):2269-2277. [13] 杜鹃. 跨音压气机/风扇转子叶顶泄漏流动的非定常机制研究[D]. 北京: 中国科学院工程热物理研究所, 2010.DU J.Investigation on the unsteady mechanism of tip leakage flow in transonic compressor/fan rotors[D]. Beijing:Institute of Engineering Thermalphysics, Chinese Academy of Sciences, 2010(in Chinese). [14] BOHNE A, NIEHUIS R.Experimental off-design investigation of unsteady secondary flow phenomena in a three stage axial compressor at 68% nominal speed[C]//ASME Turbo Expo 2004.New York:ASME, 2004:857-866. [15] MAILACH R, LEHMANN I, VOGELER K.Rotating instabilities in an axial compressor originating from the fluctuating blade tip vortex[J]. Journal of Turbomachinery, 2000, 123 (3):453-463. [16] LEE S, RUNEHAL A K, KIM H J, et al.Large eddy simulation of unsteady flows in turbomachinery[J]. Proceedings of the Institution of Mechanical Engineers, Part A:Journal of Power and Energy, 2006, 218(7):463-475. -

下载:

下载: