-

摘要:

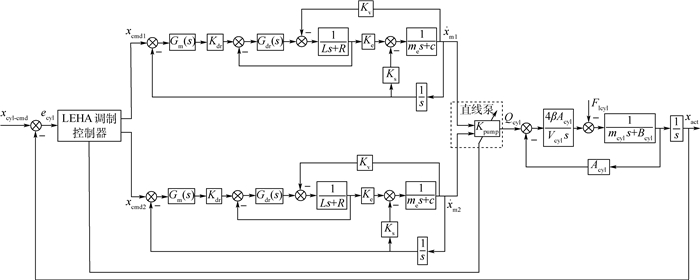

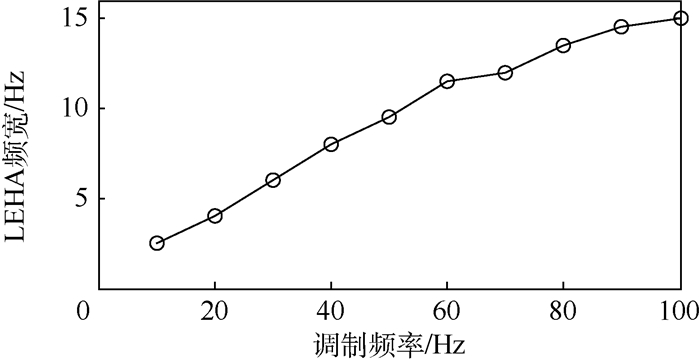

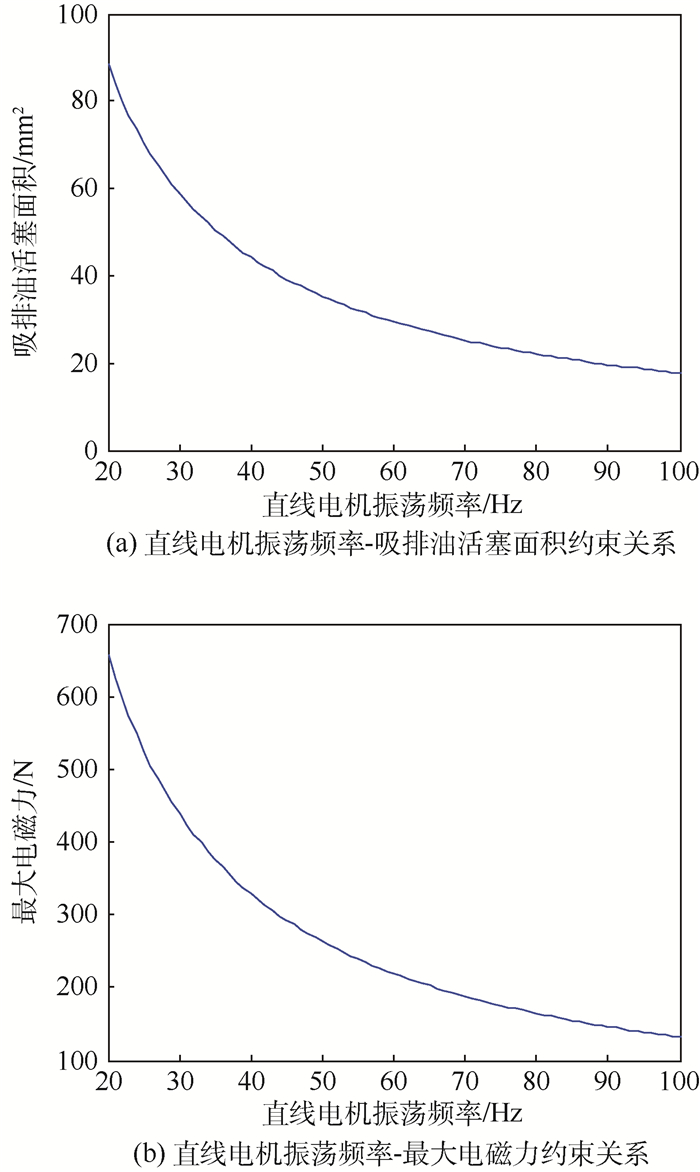

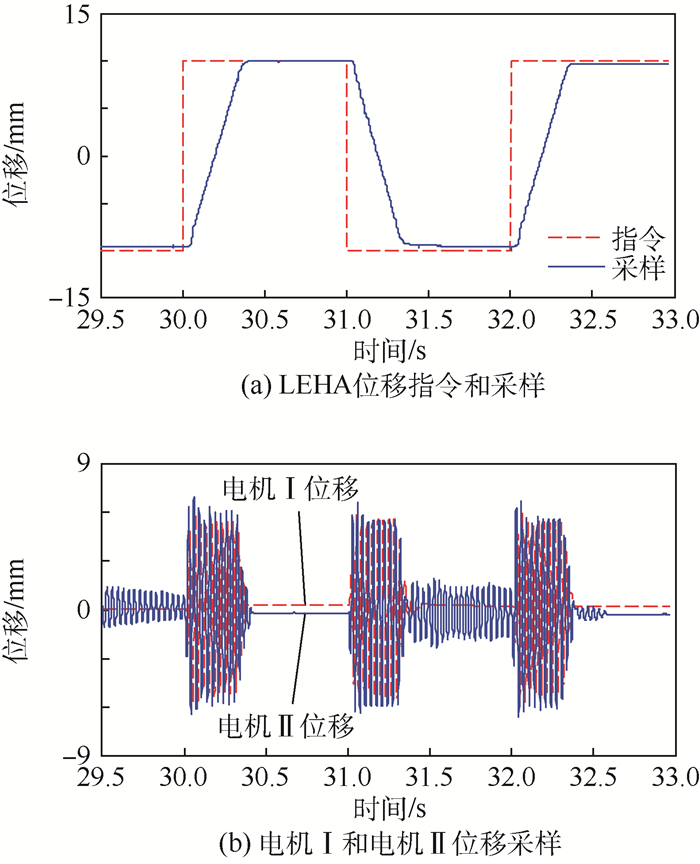

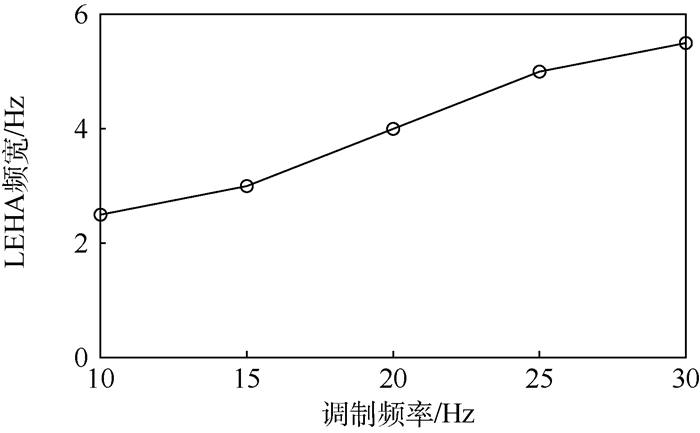

电静液作动器(EHA)是一种高度集成的泵控传动系统,A380和F35等机型已经利用EHA驱动主飞控舵面。但传统的以旋转电机和柱塞泵构成的EHA面临低频响的问题,以一种具有良好动态特性的新原理直线驱动电静液作动器(LEHA)为对象,研究其参数匹配设计问题。LEHA的关键特征在于新型的直线协同配流泵,以及采用直线电机直接驱动泵的吸排油和配流组件。首先,从静态指标匹配性上考虑LEHA的参数设计规则,得到最大空载速度约束条件、最大静态输出力约束条件、系统最高压力约束条件;然后,根据系统模型分析系统各参数对频宽的影响,得到LEHA的动态性能匹配设计规则,具体是指LEHA频宽指标对直线电机振荡频率的约束条件;最后,分析LEHA的功率约束条件,给出了LEHA对惯性负载、弹性负载和黏性阻尼负载在输出力-速度坐标下的功率包络条件,得到LEHA的负载匹配设计约束。LEHA参数设计的6项匹配设计约束条件能够为LEHA的设计过程提供理论依据。

-

关键词:

- 电静液作动器(EHA) /

- 设计规则 /

- 参数设计 /

- 直线泵 /

- 直线振荡电机

Abstract:Electro-hydrostatic actuator (EHA) is a highly integrated pump controlled transmission system, and it has been successfully applied to A380 and F35 to drive main flight control surface. However, the traditional EHA composed by rotary motor and axial piston pump has limited dynamic response. This paper introduces a novel linear-driven electro-hydrostatic actuator (LEHA) with fast dynamic response, and studies the parameter design rules of LEHA. The key feature of LEHA is the novel linear pump with collaborative rectification principle. Pistons and valve spools in collaborative rectification pump are directly driven by linear motor. The parameter design rules of LEHA are firstly considered from the static index matching rules, and the constraint conditions of the maximum no-load speed, the constraint condition of the maximum static output force and the constraint condition of the maximum pressure of the system are deduced. According to LEHA's mathematic model, the influence of each parameter on the bandwidth of the LEHA is analyzed, and the dynamic performance design rule of LEHA is obtained, which is the constraint condition of the LEHA bandwidth index to the resonance frequency of the linear motor. The power constraint condition of LEHA is analyzed finally, and the power envelope condition of LEHA for inertial load, elastic load and viscous damping load is given in the output force-velocity coordinates, from which the power matching design rule of the LEHA is obtained. In conclusion, the 6 matching design constraints of LEHA parameter design rule can provide a theoretical basis for the design process of LEHA.

-

表 1 LEHA性能指标

Table 1. Performance parameter of LEHA

参数 符号 作动器最大空载速度 vact-max 作动器最大静态输出力 Fact-max 作动器最大角功率 Pact-max -3 dB, -90°频宽 fband 系统最高压力 pmax 表 2 LEHA的关键参数

Table 2. Key parameters of LEHA

参数 符号 直线泵吸排油活塞面积 Ap 吸排油活塞振幅 Sp 直线电机振荡频率 fm 直线电机最大电磁力 Fe-max 作动筒活塞面积 Acyl 作动筒行程 Scyl 表 3 LEHA参数设计的6项约束条件

Table 3. Six constraint conditions for LEHA parameter design

项目 约束条件内容 条件1:速度约束 vact-max=8ηpηcApSpfm/Acyl 条件2:压力约束 pmax=ηm-pηmFe-max/(ηpAp) 条件3:输出力约束 Fact-max=pmaxAcyl 条件4:频宽约束 fm≥Kfrepfband, Kfrep=f(fband) 条件5:角功率约束 Pact-max=8ηmηm-pηcFe-maxSpfm 条件6:

负载约束惯性负载

弹性负载

黏性阻尼负载

表 4 LEHA性能指标需求

Table 4. Performance parameter requirement of LEHA

参数 数值 作动器最大空载速度vact-max/(m·s-1) 0.06 作动器最大静态输出力Fact-max/kN 6 作动器最大角功率Pact-max/W 360 -3 dB, -90°频宽fband/Hz 6 表 5 LEHA负载参数

Table 5. Parameters of LEHA load

负载类型 参数值 负载条件取值 惯性负载

x=x0sin(ωlt)mobj=60 kg

x0=0.002 m

ωl=14π1.87 N·m·s-1 弹性负载

F=Kx

x=x0sin(ωlt)K=1.5×105 N·m-1

x0=0.04 m

ωl=π65.3 N·m·s-1 黏性阻尼负载

x=x0sin(ωlt)Bl=600 N·m-1·s

x0=0.04 m

ωl=4π26.3 N·m·s-1 表 6 LEHA的关键参数取值

Table 6. Key parameter values of LEHA

参数 数值 直线泵吸排油活塞面积Ap/mm2 59 吸排油活塞振幅Sp/mm ±5 直线电机振荡频率Fm/Hz 30 直线电机最大电磁力Fe-max/N 439 作动筒活塞面积Acyl/mm2 954 作动筒行程Scyl/mm ±40 -

[1] WHEELER P, BOZHKO S.The more electric aircraft:Technology and challenges[J].IEEE Electrification Magazine, 2014, 2(4):6-12. doi: 10.1109/MELE.2014.2360720 [2] WHEELER P. Technology for the more and all electric aircraft of the future[C]//IEEE International Conference on Automatica. Piscataway, NJ: IEEE Press, 2016: 1-5. [3] SARLIOGLU B, MORRIS C T.More electric aircraft:Review, challenges, and opportunities for commercial transport aircraft[J].IEEE Transactions on Transportation Electrification, 2015, 1(1):54-64. doi: 10.1109/TTE.2015.2426499 [4] DERRIEN J C, SECURITE S D. Electro-mechanical actuator (EMA) advanced technologies for flight controls[C]//28th International Congress of the Aeronautical Sciences, 2012: 1-10. [5] ALLE N, HIREMATH S S, MAKARAM S, et al.Review on electro hydrostatic actuator for flight control[J].International Journal of Fluid Power, 2016, 17(2):125-145. doi: 10.1080/14399776.2016.1169743 [6] BOTTEN S L, WHITLEY C R, KING A D.Flight control actuation technology for next-generation all-electric aircraft[J].Technology Review Journal, 2000, 23(6):55-68. [7] CHAKRABORTY I, TRAWICK D R, JACKSON D, et al. Electric control surface actuator design optimization and allocation for the more electric aircraft[C]//2013 Aviation Technology, Integration, and Operations Conference. Reston: AIAA, 2013: 4283. [8] VAN DEN BOSSCHE D. The A380 flight control electro-hydrostatic actuators, achievements and lessons learnt[C]//25th International Congress of the Aeronautical Sciences, 2006: 1-8. [9] ANDERSON J A. Variable displacement electro-hydrostatic actuator[C]//IEEE Aerospace and Electronics Conference. Piscataway, NJ: IEEE Press, 1991: 529-534. [10] SHEN W, MAI Y, SU X, et al.A new electric hydraulic actuator adopted the variable displacement pump[J].Asian Journal of Control, 2016, 18(1):178-191. doi: 10.1002/asjc.v18.1 [11] JIANG J H, LIU Q, LIU J L, et al.Performance comparison of displacement and speed control in electro-hydrostatic actuator[J].Applied Mechanics and Materials, 2015, 779:205-211. doi: 10.4028/www.scientific.net/AMM.779 [12] HANKAN C, TUNA B, BULENT E P. A complete analysis for single rod electro hydrostatic actuators[C]//10th International Fluid Power Conference. Dresden: IFAS, 2016: 119-132. [13] NAVARRO R. Performance of an electro-hydrostatic actuator on the F-18 systems research aircraft: NASA/TM-97-206224[R]. Edwards: Dryden Flight Research Center, 1997: 1-37. [14] MCCULLOUGH. Design and characterization of a dual electro-hydrostatic actuator[D]. Hamilton: McMaster University, 2011: 4-11. [15] ANDERSON E, LINDLER J. Smart material actuator with long stroke and high power output[C]//43rd Structures, Structural Dynamics, and Materials Conference. Reston: AIAA, 2002: 1354. [16] JOHN S, SIROHI J, WANG G, et al.Comparison of piezoelectric, magnetostrictive, and electrostrictive hybrid hydraulic actuators[J].Journal of Intelligent Material Systems and Structures, 2007, 18(10):1035-1048. doi: 10.1177/1045389X06072355 [17] KAN J, TANG K, REN Y, et al.Study on a piezohydraulic pump for linear actuators[J].Sensors and Actuators A:Physical, 2009, 149(2):331-339. doi: 10.1016/j.sna.2008.12.008 [18] CHAUDHURI A, WERELEY N M.Experimental validation of a hybrid electrostrictive hydraulic actuator analysis[J].Journal of Vibration and Acoustics, 2010, 132(2):021006. doi: 10.1115/1.4000778 [19] KIM G W, WANG K W.Helmholtz resonance in a piezoelectric-hydraulic pump-based hybrid actuator[J].Smart Materials and Structures, 2010, 20(1):015010. [20] TAN H, HURST W, LEO D.Performance modeling of a piezohydraulic actuation system with active valves[J].Smart Materials and Structures, 2004, 14(1):91-110. [21] LI Y, JIAO Z, YAN L, et al.Conceptual design and composition principles analysis of a novel collaborative rectification structure pump[J].Journal of Dynamic Systems, Measurement, and Control, 2014, 136(5):054507. doi: 10.1115/1.4027504 [22] LIANG H, JIAO Z, YAN L, et al.Design and analysis of a tubular linear oscillating motor for directly-driven EHA pump[J].Sensors and Actuators A:Physical, 2014, 210:107-118. doi: 10.1016/j.sna.2014.01.026 -

下载:

下载: