-

摘要:

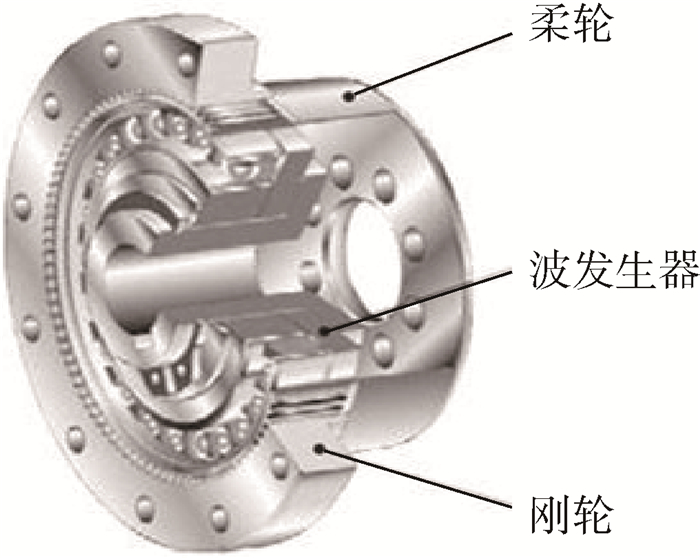

谐波减速器的动态精度不仅与其各个部件的制造公差和装配间隙有关,还必须考虑谐波减速器柔性和摩擦的影响。目前谐波减速器精度问题研究大多只考虑单一因素,在进行精度分析时没有考虑到模型参数的不确定性对精度的影响。本文研究了谐波减速器在静态因素(加工、装配)和动力学因素(柔性、摩擦)综合作用下的动态精度问题;建立了考虑静态误差、柔性的非线性动力学模型;利用多项式混沌展开(PCE)方法进行参数灵敏度分析和不确定性分析,并和Monte Carlo方法作了比较,结果表明PCE方法效率更高。并基于动态精度PCE进行可靠性分析,得到动态精度可靠度。

-

关键词:

- 谐波减速器 /

- 动态精度 /

- 多项式混沌展开(PCE) /

- 灵敏度分析 /

- 可靠性分析

Abstract:The dynamic accuracy of the harmonic reducer is related to the parts' tolerance and assembly clearance as well as the flexibility and friction of the harmonic reducer. Most of the published literatures consider only a single factor and do not take into account the influence of model parameter uncertainty. In this paper, the dynamic accuracy is researched considering static factors (machining and assembly) and dynamic characteristics (flexibility and friction). The nonlinear dynamic model is established, which contains static error and flexibility term. Polynomial chaos expansion (PCE) is used to handle the parameter sensitivity and uncertainty. By comparison, PCE is more efficient than Monte Carlo. Dynamic accuracy reliability is finally obtained through reliability analysis based on dynamic accuracy PCE.

-

表 1 谐波减速器动力学模型参数

Table 1. Parameters of harmonic reducer dynamic model

参数 数值 Jm/(kg·m2) 3.2×10-4 Jl/(kg·m2) 8.5×10-4 Bm/(N·m·s·rad-1) 1.7×10-4 Bl/(N·m·s·rad-1) 5.0×10-4 Bsp/(N·m·s·rad-1) 2.8×10-4 k1/(N·m·rad-1) 7 160 k2/(N·m·rad-3) 21 576 N 90 表 2 静态误差模型参数

Table 2. Parameters of static error model

参数 数值 Z2 182 Z1 180 αn/(°) 20 Ef/m 3.1×10-5 Ec/m 1.78×10-4 Eb/m 2.05×10-4 ΔFp2/m 3.6×10-5 Δf′f2/m 1.14×10-4 ΔFp1/m 3.6×10-5 Δf′f1/m 1.14×10-4 表 3 不同电机输入角下动态误差实验值与仿真值

Table 3. Experimental values and simulation values of dynamic errors under different motor input corners

电机

输入角/(°)动态误差

实验值/(°)动态误差

仿真值/(°)真实误差/

(°)相对

误差/%50 0.023 473 0.021 908 0.001 565 4.7 100 0.018 379 0.017 472 0.000 907 4.9 200 0.016 727 0.015 486 0.001 241 7.4 300 0.018 503 0.017 256 0.001 247 6.7 400 0.016 205 0.017 369 0.001 164 7.1 500 0.019 181 0.018 688 0.000 493 2.5 700 0.017 800 0.019 320 0.002 820 8.5 800 0.019 794 0.017 913 0.001 881 9.5 1 000 0.020 950 0.022 243 0.001 293 4.1 表 4 谐波减速器不确定性参数及分布

Table 4. Uncertainty parameters and distribution of harmonic reducer

参数 分布 均值 标准差 Bm 正态分布 1.7×10-4 N·m·s·rad-1 0.000 03 Jl 正态分布 8.5×10-4kg·m2 0.000 05 k1 正态分布 7.16×103 N·m·rad-1 200 k2 正态分布 2.157 6×104 N·m·rad-3 500 Bsp 正态分布 2.8 ×10-4 N·m·s·rad-1 0.000 04 Ef 正态分布 3.1 ×10-5 m 0.000 005 Ec 正态分布 1.78 ×10-4 m 0.000 04 Eb 正态分布 2.05 ×10-4 m 0.000 05 Δf′f1 正态分布 1.14×10-4 m 0.000 04 表 5 动态精度多项式混沌展开式配点

Table 5. Collocation of dynamic accuracy polynomial chaos expansion

参数 多项式混沌展开配点 Bm (0.000 187,0.000 17,0.000 152) Jl (0.000 879,0.000 85,0.000 821) k1 (0.000 721 8,0.000 716 0,0.000 710 2) k2 (0.020 999,0.021 576,0.022 153) Bsp (0.000 303,0.000 28,0.000 257) Ef (0.000 033 8,0.000 031,0.000 028 1) Ec (0.000 201,0.000 178,0.000 154) Eb (0.000 176 3,0.000 205,0.000 233 7) Δf′f1 (0.000 116 9,0.000 14,0.000 163 1) 表 6 动态精度

Table 6. Polynomial chaotic expansion coefficient of dynamic accuracy

项 系数 1 0.012 5 ξ1 0.032 8 ξ2 -0.154 0 ξ3 0.357 6 ξ4 -0.009 3 ξ5 0.000 9 ξ6 0.014 0 ξ7 0.074 9 ξ8 0.007 2 ξ9 0.102 3 表 7 动态误差

Table 7. Polynomial chaos expansion coefficients of dynamic error

项 系数 1 0.024 151 ζ1 -0.236 1 ζ2 0.036 6 ζ3 0.720 9 ζ4 -0.023 6 ζ5 -0.021 8 ζ1-1 0.0365 ζ2-1 -0.000 8 ζ3-1 0.049 0 ζ4-1 -0.000 2 ζ5-1 -0.001 5 ζ1ζ2 0.003 7 ζ1ζ3 -0.036 5 ζ1ζ4 0.000 6 ζ1ζ5 -0.005 3 ζ2ζ3 -0.005 4 ζ2ζ4 0.000 1 ζ2ζ5 0.001 5 ζ3ζ4 0.003 9 ζ3ζ5 0.004 2 ζ4ζ5 -0.000 5 表 8 FORM法可靠度计算结果

Table 8. Reliability calculation results based on FORM method

迭代次数 β 可靠度 1 2.783 0.997 3 2 1.782 0.962 6 3 1.737 0.958 8 4 1.732 0.958 4 5 1.732 0.958 4 表 9 Monte Carlo仿真实验估算失效概率

Table 9. Failure probability estimation under Monte Carlo simulation experiment

nt nf Pf 500 14 0.028 0 2 000 61 0.030 5 4 000 126 0.031 5 6 000 205 0.034 2 7 000 254 0.036 3 8 000 305 0.038 1 10 000 381 0.038 1 -

[1] NYE T, KRAML R. Harmonic drive gear error: Characterization and compensation for precision pointing and tracking[C]//Processing of the 25th Aerospace Mechanics, Symposium. Washington, D. C. : NASA, 1991: 237-252. [2] EMELYANOV A F.Calculation of the kinematic error of a harmonic gear transmission taking into account the compliance of elements[J].Soviet Engineering Research, 1983, 3(7):7-10. [3] GRAVAGNO F, MUCINO V H, PENNESSTRI E.Influence of wave generator profile on pure kinematic error and centrodes of harmonic drive[J].Mechanism and Machine Theory, 2016, 104:100-107. doi: 10.1016/j.mechmachtheory.2016.05.005 [4] 沙晓晨, 范元勋.谐波减速器传动误差的研究[J].机械制造, 2015, 44(5):50-54. http://www.cnki.com.cn/Article/CJFDTotal-ZZHD201505013.htmSHA X C, FAN Y X.Study of transmission error of harmonic drive reducer[J].Machine Building Automation, 2015, 44(5):50-54(in Chinese). http://www.cnki.com.cn/Article/CJFDTotal-ZZHD201505013.htm [5] HSIA L M. The analysis and design of harmonic gear drives[C]//Processing of the 1988 IEEE International Conference on Systems, Man, and Cybernetics. Piscataway, NJ: IEEE Press, 1988: 616-620. [6] TUTTLE T, SEERING W. Kinematic error, compliance, and friction in a harmonic drive gear transmission[C]//ASME Design Technical Conferences 19th Design Automation. New York: ASME, 1993: 319-324. [7] 游斌弟, 赵阳.考虑非线性因素的谐波齿轮传动动态误差研究[J].宇航学报, 2010, 31(5):1297-1282.YOU B D, ZHAO Y.Study on dynamic error of harmonic drive with nonlinear factors[J].Journal of Astronautics, 2010, 31(5):1297-1282(in Chinese). [8] PREISSNER C, ROYSTON T J, SHU D.A high-fidelity harmonic drive model[J].Journal of Dynamic Systems, Measurement, and Control, 2012, 134(1):011002. doi: 10.1115/1.4005041 [9] KIRCANSKI N, GOLDENBERG A, ANGELS J. Nonlinear modeling and parameter identification of harmonic drive gear transmissions[C]//Processing of the 32nd IEEE Conference on Robotics and Automatic. Piscataway, NJ: IEEE Press, 1995: 3027-3032. [10] 王爱东. 机器人用谐波齿轮传动装置的运动精度分析[D]. 北京: 中国科学院, 2001: 11-15.WANG A D. Kinematic accuracy analysis of gear transmission for harmonic reducer of robot[D]. Beijing: Chinese Academy of Sciences, 2001: 11-15(in Chinese). [11] FATHI H, PRASANNA S, FRIEDHELM A.On the kinematic error in harmonic drive gears[J].Journal of Mechanical Design, 2001, 123(1):90-97. doi: 10.1115/1.1334379 [12] WIENER N.The homogeneous chaos[J].American Journal of Mathematics, 1938, 60(4):897-936. doi: 10.2307/2371268 [13] 赵珂, 高正红, 黄江涛, 等.基于PCE方法的翼型不确定性分析及稳健设计[J].力学学报, 2014, 46(1):11-19.ZHAO K, GAO Z H, HUANG J T, et al.Uncertainty quantification and robust design of airfoil based on polynomial chaos technique[J].Chinese Journal of Theoretical and Applied Mechanics, 2014, 46(1):11-19(in Chinese). [14] LOEVETT T, PONCI F, MONTI A.A polynomial chaos approach to measurement uncertainty[J].IEEE Transations on Instrumentation and Measurement, 2006, 55(3):729-736. doi: 10.1109/TIM.2006.873807 [15] BENJAMIN L, HOSAM K, JEFFREY L.Recursive maximum likelihood parameter estimation for state space systems using polynomial chaos theory[J].Automatica, 2011, 47(11):2420-2424. doi: 10.1016/j.automatica.2011.08.014 [16] 陶海川, 来新民.基于Dymola的无刷直流电机仿真模型[J].计算机仿真, 2005, 22(5):63-65. doi: 10.3969/j.issn.1006-9348.2005.05.018TAO H C, LAI X M. Computer simulation of brushless DC motor system based on Dymola[J].Computer Simulation, 2005, 22 (5):63-65(in Chinese). doi: 10.3969/j.issn.1006-9348.2005.05.018 [17] SUDRET B.Global sensitivity analysis using polynomial chaos expansion[J].Reliability Engineering and System Safety, 2008, 93(7):964-979. doi: 10.1016/j.ress.2007.04.002 [18] PENG W S, ZHANG J G, ZHU D T.ABCLS methods for high-reliability aerospace mechanism with truncated random uncertainties[J].Chinese Journal of Aeronautics, 2015, 28(4):1066-1075. doi: 10.1016/j.cja.2015.06.012 -

下载:

下载: