Aerodynamic and cooling performance of a novel step-shaped slot film cooling geometry

-

摘要:

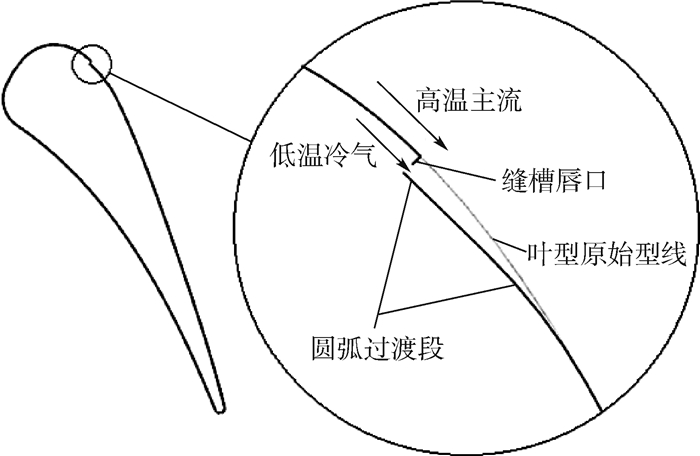

为了抑制气膜冷却过程中耦合涡的产生,提出了一种切向出流台阶缝冷却结构,并对其在涡轮导叶吸力面、压力面上布置时的气动性能及冷却特性进行了数值研究。结果表明:在吸力面叶栅通道喉部附近布置时仅使总压损失增加约2%;在压力面布置则能使总压损失、能量损失在低吹风比工况各降低约2.5%,同时出口气流角的增加不到0.1%,而且损失系数和出口气流角对吹风比的变化也不敏感。吸力面、压力面缝后冷却效率均较高,在高吹风比工况平均都有约8%轴向弦长的叶片表面冷却效率接近1.0。

Abstract:In order to permanently reduce the coupling vortices in film cooling, a novel step-shaped slot cooling geometry with tangential coolant ejection was introduced and its aerodynamic and cooling performance was numerically investigated. The effects of slot location at the suction and pressure side of a turbine vane and cooling air blowing ratio on these performances were also analyzed. The results show that slot injection from the suction side near-throat region only increases the total pressure loss by about 2%, while injection from the pressure side decreases both the kinetic loss and total pressure loss by about 2.5% with the air exit angle increasing less than 0.1% for low blowing ratios. Meanwhile, the loss coefficient and the air exit angle are not sensitive to the variation of blowing ratios. Additionally, cooling effectiveness downstream of the slot on both suction side and pressure side is rather high and it reaches almost 1.0 for about 8% axial chord of the vane surface on average in high blowing ratio cases.

-

Key words:

- turbine vane /

- film cooling /

- coupling vortices /

- step-shaped slot /

- aerodynamic loss /

- cooling effctiveness /

- numerical simulation

-

-

[1] GOLDSTEIN R J.Filmcooling[J].Advances in Heat Transfer, 1971, 7:321-379. doi: 10.1016/S0065-2717(08)70020-0 [2] BUNKER R S.A review of shaped hole turbine film-cooling technology[J].Journal of Heat Transfer, 2005, 127(4):441-453. doi: 10.1115/1.1860562 [3] KUSTERER K, BOHN D, SUGIMOTO T, etal.Double-jet ejection of cooling air for improved film cooling[J].Journal of Turbomachinery, 2007, 129(4):809-815. doi: 10.1115/1.2720508 [4] HEIDMANN J D, EKKAD S.A novel antivortex turbine film-cooling hole concept[J].Journal of Turbomachinery, 2008, 130(3):031020. doi: 10.1115/1.2777194 [5] ELY M J, JUBRAN B A.A numerical study on improving large angle film cooling performance through the use of sister holes[J].Numerical Heat Transfer, Part A:Applications, 2009, 55(7):634-653. doi: 10.1080/10407780902821532 [6] HAVEN B A, KUROSAKA M. Kidney and anti-kidney vortices in crossflow jets[J].Journal of Fluid Mechanics, 1997, 352(1):27-64. http://adsabs.harvard.edu/abs/1997JFM...352...27H [7] BERNSDORF S, ROSE M G, ABHARI R S.Modeling of film cooling-Part 1:Experimental study of flow structure[J].Journal of Turbomachinery, 2005, 128(1):141-149. http://gasturbinespower.asmedigitalcollection.asme.org/article.aspx?articleid=1467156 [8] 侯伟涛, 乔渭阳.尾缘冷却跨声速涡轮气动特性的数值模拟[J].推进技术, 2010, 31(5):567-571. http://mall.cnki.net/magazine/Article/RQWL201605004.htmHOU W T, QIAO W Y.Numerical simulation of the trailing edge cooled transonic turbine aerodynamic characteristic[J].Journal of Propulsion Technology, 2010, 31(5):567-571(in Chinese). http://mall.cnki.net/magazine/Article/RQWL201605004.htm [9] 杨林, 曾军, 谭洪川, 等.大膨胀比跨声速涡轮流动结构及损失的数值研究[J].推进技术, 2014, 35(5):632-640. http://d.wanfangdata.com.cn/Periodical_tjjs201405009.aspxYANG L, ZENG J, TAN H C, et al.Numerical study of flow structure and loss of large expansion ratio transonic turbine[J].Journal of Propulsion Technology, 2014, 35(5):632-640(in Chinese). http://d.wanfangdata.com.cn/Periodical_tjjs201405009.aspx [10] 石德永, 宋文艳, 浮强.导向器叶片尾缘厚度对涡轮性能影响研究[J].机械设计与制造, 2013(11):102-104. doi: 10.3969/j.issn.1001-3997.2013.11.031SHI D Y, SONG W Y, FU Q.Research of stator trailing edge thickness effects on turbine performance[J].Machinery Design & Manufacture, 2013(11):102-104(in Chinese). doi: 10.3969/j.issn.1001-3997.2013.11.031 [11] 高炎, 晏鑫, 李军.燃气透平叶片尾缘开缝结构冷却性能的数值研究[J].西安交通大学学报, 2016, 50(3):29-37. doi: 10.7652/xjtuxb201603005GAO Y, YAN X, LI J.Numerical investigation on the cooling performance of trailing edge cutback in gas turbine blade[J].Journal of Xi'an Jiaotong Univeristy, 2016, 50(3):29-37(in Chinese). doi: 10.7652/xjtuxb201603005 [12] HYLTON L D, MILLEC M S, TURNER E R, et al. Analytical and experimental evaluation of the heat transfer distribution over surface of turbine vanes: NASA-CR-168015[R]. Washington, D. C. : NASA, 1983. [13] HYLTON L D, NIRMALAN V, SULTANIAN B K, et al. The effect of leading edge and downstream film cooling on turbine vane heat transfer: NASA-CR-182133[R]. Washington, D. C. : NASA, 1988. [14] 姚玉. 收敛缝形孔气膜冷却特性研究[D]. 南京: 南京航空航天大学, 2010.YAO Y. Research on film cooling characteristic of converging slot hole[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2010(in Chinese). [15] MAYLE R E, KOPPER F C, BLAIR M F, et al.Effect of streamline curvature on film cooling[J].Journal of Engineering for Power, 1977, 99(1):77-82. doi: 10.1115/1.3446255 -

下载:

下载: