-

摘要:

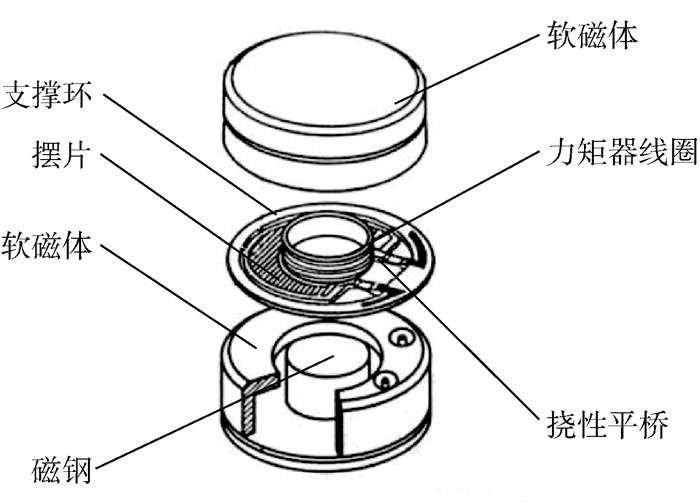

以典型惯导产品加速度计贮存寿命评估为例,提出了一种基于故障行为模型的加速退化试验设计方法,解决了缺乏预试验数据情况下试验应力水平设计的问题。在通过对产品特性和主机理分析基础上,确定表征产品贮存寿命特征参数及试验应力,构建了考虑材料等分散性的加速度计故障行为模型,用以描述参数加速时变规律的特性。在试验应力最高水平确定的情况下,基于给定置信度和故障行为模型,以高应力水平下退化量的置信下限与低应力水平下退化量的置信上限不交叉为原则,采用基于仿真的加速退化试验设计方法,优化确定低应力和中间应力水平,从而设计给出试验剖面,并给出了加速退化试验方案优选流程,最终从备选方案集中确定加速度计试验最优方案。通过实际案例分析,验证了该方法的有效性。

Abstract:This paper proposed a failure-behavior-model based accelerated degradation test designing method for assessing the storage life of accelerometer for inertial navigation products, which determines test stress levels while lacking of the preliminary experimental data. On the basis of analyzing the product characteristics and main mechanisms, the storage life characteristic parameters and test stress types are determined. An accelerometer failure behavior model which takes the material dispersion into consideration is established to describe the time-varying law. Given the highest stress level, based on the given confidence level and failure behavior model, a simulation accelerated degradation test design method is proposed to determine the lowest and intermediate stress levels with the constraint that the upper bound of degradation under lower stress level is lower than the lower bound of degradation under high stress level. Following the proposed framework, the experimental profile is designed, and then a best test plan is finally obtained. The validity of the proposed method is verified by a case study.

-

Key words:

- failure behavior model /

- inertial navigation products /

- test design /

- plan optimization /

- accelerometer

-

表 1 备选方案T2, T3温度设置

Table 1. Optional plan of temperature setting of T2, T3

℃ T2 T3 75 60, 55, 50, 45, 40, 35, 30 70 55, 50, 45, 40, 35, 30 65 50, 45, 40, 35, 30 60 45, 40, 35, 30 55 40, 35, 30 50 35, 30 45 30 -

[1] YU H.Designing an accelerated degradation experiment by optimizing the estimation of the percentile[J]. Quality and Reliability Engineering International, 2003, 19(3):197-214. doi: 10.1002/(ISSN)1099-1638 [2] YU H.Designing an accelerated degradation experiment with a reciprocal Weibull degradation rate[J]. Journal of Statistical Planning and Inference, 2006, 136(1):282-297. doi: 10.1016/j.jspi.2004.06.030 [3] WEAVER B P, MEEKER W Q.Methods for planning repeated measures accelerated degradation tests[J]. Applied Stochastic Models in Business and Industry, 2014, 30(6):658-671. doi: 10.1002/asmb.2061 [4] HU C, LEE M, TANG J.Optimum step-stress accelerated degradation test for Wiener degradation process under constraints[J]. European Journal of Operational Research, 2015, 241(2):412-421. doi: 10.1016/j.ejor.2014.09.003 [5] WANG H, WANG G, DUAN F.Planning of step-stress accelerated degradation test based on the inverse Gaussian process[J]. Reliability Engineering & System Safety, 2016, 154:97-105. https://www.sciencedirect.com/science/article/pii/S0951832016300874 [6] TSAI T, SUNG W, LIO Y L, et al.Optimal two-variable accelerated degradation test plan for Gamma degradation processes[J]. IEEE Transactions on Reliability, 2016, 65(1):459-468. doi: 10.1109/TR.2015.2435774 [7] LING M H, TSUI K L, BALAKRISHNAN N.Accelerated degradation analysis for the quality of a system based on the Gamma process[J]. IEEE Transactions on Reliability, 2015, 64(1):463-472. doi: 10.1109/TR.2014.2337071 [8] SHI Y, MEEKER W Q.Bayesian methods for accelerated destructive degradation test planning[J]. IEEE Transactions on Reliability, 2012, 61(1):245-253. doi: 10.1109/TR.2011.2170115 [9] SHI Y, MEEKER W Q.Accelerated destructive degradation test planning[J]. Technometrics, 2009, 51(1):1-13. doi: 10.1198/TECH.2009.0001 [10] LI Q, KECECIOGLU D B.Design of an optimal plan for an accelerated degradation test:A case study[J]. International Journal of Quality & Reliability Management, 2013, 23(4):426-440. http://cn.bing.com/academic/profile?id=a42216da05a94ac74bc812e7058a6a07&encoded=0&v=paper_preview&mkt=zh-cn [11] NASIR E A, PAN R.Simulation-based Bayesian optimal ALT designs for model discrimination[J]. Reliability Engineering & System Safety, 2015, 134(2):1-9. https://asu.pure.elsevier.com/en/publications/simulation-based-bayesian-optimal-alt-designs-for-model-discrimin [12] WANG Y, ZHANG C, ZHANG S, et al.Optimal design of constant stress accelerated degradation test plan with multiple stresses and multiple degradation measures[J]. Journal of Risk and Reliability, 2015, 229(1):83-93. doi: 10.1177/1748006X14552312 [13] ZENG Z G, KANG R, WEN M, et al. Measuring reliability during product development considering aleatory and epistemic uncertainty[C]//Proceedings of the Annual Reliability and Maintainability Symposium. Piscataway, NJ: IEEE Press, 2015: 1-6. [14] XU D, CHEN Y X, KANG R.Quartz flexible accelerometer stability duration prediction on storage condition based on accelerated degradation test[J]. Chemical Engineering Transactions, 2013, 33(1):541-546. https://www.researchgate.net/publication/278058772_Quartz_Flexible_Accelerometer_Stability_Duration_Prediction_on_Storage_Condition_Based_on_Accelerated_Degradation_Test [15] 许丹, 廖寻, 陈云霞, 等.加速度计贮存稳定期分析[J].北京航空航天大学学报, 2013, 39(2):173-177. http://bhxb.buaa.edu.cn/CN/abstract/abstract12525.shtmlXU D, LIAO X, CHEN Y X, et al.Analysis of the storage stability of accelerometers[J]. Journal of Beijing University of Aeronautics and Astronautics, 2013, 39(2):173-177(in Chinese). http://bhxb.buaa.edu.cn/CN/abstract/abstract12525.shtml -

下载:

下载: