-

摘要:

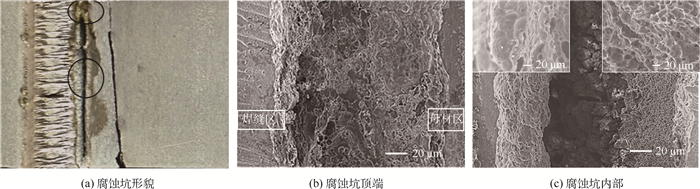

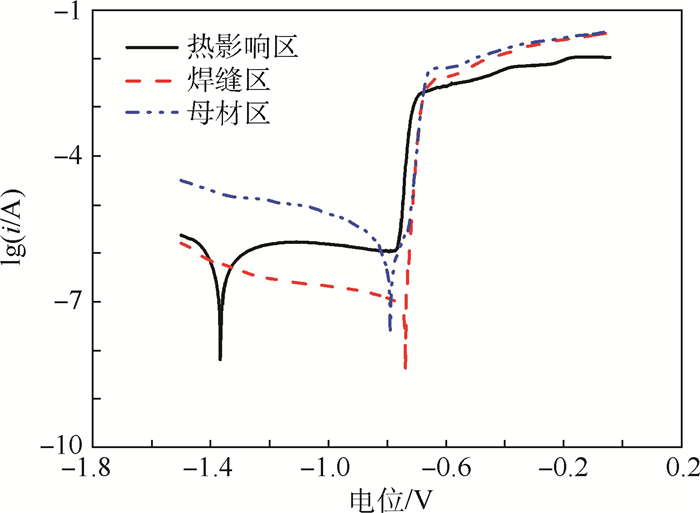

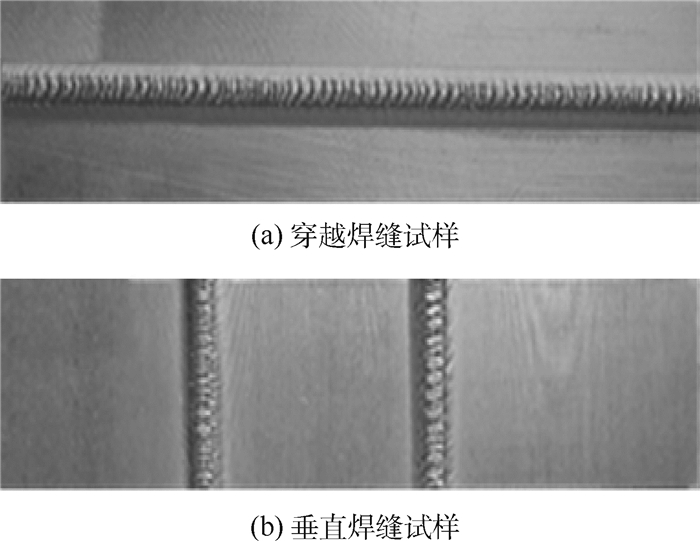

针对5A06铝合金焊接对腐蚀敏感性的影响,研究了载荷作用下的不同焊缝方向(垂直、穿越)的5A06铝合金试样在50℃的3.5% NaCl溶液中的腐蚀行为的影响和焊接接头的电化学腐蚀行为。结果表明,经过110 d的盐水溶液浸泡后,2种焊缝试样均是热影响区首先发生腐蚀,表面的腐蚀坑两侧由于材料组织的不同分别呈台阶式和韧窝状。穿越焊缝试样应力腐蚀敏感性较低,腐蚀坑顶端应力集中,有滑移台阶;垂直焊缝试样应力腐蚀敏感性较高,腐蚀坑沿焊缝贯穿试样表面,腐蚀坑两侧呈平行撕裂状态。电化学极化曲线表明,热影响区、母材区和焊缝区的自腐蚀电位分别为-1.369、-0.791和-0.740 V。

-

关键词:

- 铝合金 /

- 载荷 /

- 腐蚀敏感性 /

- 焊接 /

- 3.5%NaCl溶液

Abstract:Aimed at the aluminum alloy welding effect on corrosion sensitivity, we have applied loading on the 5A06 aluminum alloy with the welds in different directions (vertical, cross) and studied the effects of stress loading on the corrosion behavior of the alloy in 3.5%NaCl solution at 50℃ and the electrochemical corrosion behavior of the welded joints. The results show that after being soaked for 110 days in brine solution, heat-affected zone is firstly corroded and both sides of the corrosion pits on the surface exhibited step and dimple features respectively, because of the different material structure. The stress corrosion sensitivity of the cross weld specimen is relatively low and the stress concentration exists at the corrosion pit tip with a sliding step. Vertical weld specimen has higher sensitivity to stress corrosion with the corrosion pits across the surface along the weld. Both sides of the corrosion pits on the vertical weld specimen tear parallelly. The electrochemical polarization curves indicate that the corrosion potential of the heat-affected zone, base-metal zone and weld zone are -1.369 V, -0.791 V and -0.740 V, respectively.

-

Key words:

- aluminum alloy /

- loading /

- corrosion sensitivity /

- welding /

- 3.5%NaCl solution

-

表 1 试样腐蚀110 d后表面相同区域的腐蚀坑尺寸与数目

Table 1. Size of corrosion pits and number in the same surface zone of specimen after corrosion for 110 d

试样类型 腐蚀坑长度/mm 腐蚀坑面积/mm2 最大腐蚀坑深度/μm 腐蚀坑数目 穿越焊缝试样 14.72 23.55 2 345 3 垂直焊缝试样 30.58 50.12 2 727 9 表 2 5A06铝合金焊缝试样腐蚀坑元素分布结果

Table 2. Element distribution results of corrosion pits in 5A06 aluminum alloy weld specimens

% 元素分布点 O Mg Al Si 1 4.72 8.22 85.68 1.37 2 20.55 8.14 68.68 2.62 3 17.14 4.34 78.52 0 4 3.95 8.41 86.98 0.66 5 4.26 5.02 89.17 1.55 6 15.83 5.81 78.35 0 -

[1] NUNES A C, BAYLESS E O, JONES C S et al.Variable polarity plasma arc welding on the space shuttle external tank[J].Welding Journal, 1984, 63(9):27-35. [2] CHEN H H, WANG J Y, LEE J, et al.Superplasticity of AA5083 alloy as processed by equal channel angular extrusion[J].Journal of Alloys and Compounds, 2008, 460(1-2):305-308. doi: 10.1016/j.jallcom.2007.06.058 [3] SHARMA M M, ZIEMIAN C W.Pitting and stress corrosion cracking susceptibility of nanostructured Al-Mg alloys in natural and artificial environments[J].Journal of Materials Engineering and Performance, 2008, 17(6):870-878. doi: 10.1007/s11665-008-9215-7 [4] TANAKA H, NAGAI Y, OGURI Y, et al.Mechanical properties of 5083 aluminum alloy sheets produced by isothermal rolling[J].Materials Transactions, 2007, 48(8):2008-2013. doi: 10.2320/matertrans.L-MRA2007872 [5] LOMBARD H, HATTINGH D G, STEUWER A, et al.Optimising FSW process parameters to minimise defects and maximise fatigue life in 5083-H321 aluminum alloy[J].Engineering Fracture Mechanics, 2008, 75(3-4):341-354. doi: 10.1016/j.engfracmech.2007.01.026 [6] 张艾艾, 何晶靖, 刘天娇, 等.5A06铝镁合金海水腐蚀电化学特性[J].航空学报, 2015, 36(9):3147-3154.ZHANG A A, HE J J, LIU T J, et al.Electrochemical features of corrosion of 5A06 Al-Mg alloy in seawater[J].Acta Aeronautical et Astronautica Sinica, 2015, 36(9):3147-3154(in Chinese). [7] 陶斌武, 李松梅, 刘建华.LY6铝合金的局部腐蚀行为[J].材料保护, 2004, 37(11):15-17. doi: 10.3969/j.issn.1001-1560.2004.11.006TAO B W, LI S M, LIU J H.Local corrosion behaviors of LY6 aluminum alloy[J].Materials Protection, 2004, 37(11):15-17(in Chinese). doi: 10.3969/j.issn.1001-1560.2004.11.006 [8] HONG H, HAN Y, DU M, et al.Investigation on droplet momentum in VPPA-GMAW hybrid welding of aluminum alloys[J].International Journal of Advanced Manufacturing Technology, 2016, 86(5-8):2301-2308. doi: 10.1007/s00170-016-8381-2 [9] 韩永全, 郭龙, 陈树君, 等.变极性等离子弧穿孔熔池受力及焊缝成形稳定性[J].材料工程, 2011(12):83-86. doi: 10.3969/j.issn.1001-4381.2011.12.018HAN Y Q, GUO L, CHEN S J, et al.Weld formation stability and force in variable polarity plasma arc keyhole welding[J].Journal of Materials Engineering, 2011(12):83-86(in Chinese). doi: 10.3969/j.issn.1001-4381.2011.12.018 [10] KARTAL M E, LILJEDAHL C D M, GUNGOR S, et al.Determination of the profile of the complete residual stress tensor in a VPPA weld using the multi-axial contour method[J].Acta Materialia, 2008, 56(16):4417-4428. doi: 10.1016/j.actamat.2008.05.007 [11] 张秋霞. 铝合金焊接残余应力X射线衍射法检测参数优化研究[D]. 廊坊: 北华航天工业学院, 2015: 32-40.ZHANG Q X. Optimization of inspection parameters for welding residual stress of aluminum alloy by X ray diffraction[D]. Langfang: North China Institute of Aerospace Engineering, 2015: 32-40(in Chinese). [12] 李国伟, 韩永全, 陈芙蓉, 等.7075铝合金变极性等离子弧焊接头组织与性能[J].焊接学报, 2015, 36(10):5-8.LI G W, HAN Y Q, CHEN F R, et al.Microstructure and mechanical properties of VPPA welded 7075 aluminum alloy joint[J].Tarnsactions of the China Welding Instition, 2015, 36(10):5-8(in Chinese). [13] MALARVIZHI S, RAGHUKANDAN K, VISWANATHAN N.Effect of post weld aging treatment on tensile properties of electron beam welded AA2219 aluminum alloy[J].International Journal of Advanced Manufacturing Technology, 2008, 37(3-4):294-301. doi: 10.1007/s00170-007-0970-7 [14] 从保强, 齐铂金, 周兴国, 等.高强铝合金复合脉冲VPTIG焊缝组织和性能[J].北京航空航天大学学报, 2010, 36(1):1-5.CONG B Q, QI B J, ZHOU X G, et al.Microstructure and mechanical properties of hybrid pulse VPTIG arc welding of high strength aluminum alloy[J].Journal of Beijing University of Aeronautics and Astronautics, 2010, 36(1):1-5(in Chinese). [15] 赵红凯, 肖锋, 杨旭东, 等.AZ31B镁合金变极性等离子弧加丝焊接组织及腐蚀行为[J].焊接技术, 2011, 40(8):22-24. doi: 10.3969/j.issn.1002-025X.2011.08.005ZHAO H K, XIAO F, YANG X D, et al.Variable polarity plasma arc welding adding weld wire organization and corrosion behavior of AZ31B magnesium alloy[J].Welding Technology, 2011, 40(8):22-24(in Chinese). doi: 10.3969/j.issn.1002-025X.2011.08.005 [16] 郭凡. 2024铝合金不同厚度板材的应力腐蚀开裂特性研究[D]. 北京: 北京航空航天大学, 2015: 36-45.GUO F. Study on stress corrosion cracking characteristics of 2024 aluminum alloy different thickness plate[D]. Beijing: Beihang University, 2015: 36-45(in Chinese). [17] 张娟, 魏成富, 王在俊, 等.温度对2A12铝合金应力腐蚀开裂的影响[J].热加工工艺, 2008, 37(10):29-32. doi: 10.3969/j.issn.1001-3814.2008.10.010ZHANG J, WEI C F, WANG Z J, et al.Influence of temperature on stress corrosion crack of 2A12 aluminum alloy[J].Hot Working Techonology, 2008, 37(10):29-32(in Chinese). doi: 10.3969/j.issn.1001-3814.2008.10.010 [18] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 金属和合金的腐蚀应力腐蚀试验第2部分: 弯梁试样的制备与应用: GB/T 15970. 2-2000[S]. 北京: 中国标准出版社, 2000: 622-627.General Administration of Quality, Inspection and Quarantive of the People's Republic of China, Standardization Adminstration of the People's Republic of China. Corrosion of metals and alloys-stress corrosion testing Part 2: Preparation and use of bent-beam specimens: GB/T 15970. 2-2000[S]. Beijing: Standards Press of China, 2000: 622-627(in Chinese). [19] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 金属和合金的腐蚀腐蚀试样上腐蚀产物的清除: GB/T 16545-2015[S]. 北京: 中国标准出版社, 2005: 1-4.General Administration of Quality, Inspection and Quarantive of the People's Republic of China, Standardization Adminstration of the People's Republic of China. Corrosion of metals and alloys Removal of corrosion products from corrosion test specimens: GB/T 16545-2015[S]. Beijing: Standards Press of China, 2005: 1-4(in Chinese). [20] 刘道新.材料的腐蚀与防护[M].西安:西北工业大学出版社, 2005:152-168.LIU D X.Corrosion and protection of materials[M].Xi'an:Northwestern Polytechnical University Press, 2005:152-168(in Chinese). [21] 罗传孝, 王少刚, 翟伟国.轨道交通用6082铝合金焊接接头组织与性能[J].电焊机, 2011, 41(11):68-72. doi: 10.3969/j.issn.1001-2303.2011.11.016LUO C X, WANG S G, ZHAI W G.Microstructure and mechanical properties of welded joint of 6082 aluminum alloy for rail transportation[J].Electric Welding Machine, 2011, 41(11):68-72(in Chinese). doi: 10.3969/j.issn.1001-2303.2011.11.016 [22] 唐明君, 吉泽升, 吕新宇.5×××系铝合金的研究进展[J].轻合金加工技术, 2004, 32(7):1-7. doi: 10.3969/j.issn.1007-7235.2004.07.001TANG M J, JI Z S, LV X Y.The research progress of 5×××aluminum alloy[J].Light Alloy Fabrication Technology, 2004, 32(7):1-7(in Chinese). doi: 10.3969/j.issn.1007-7235.2004.07.001 [23] 左景伊.应力腐蚀破裂[M].西安:西安交通大学出版社, 1985:62-65.ZUO J Y.Stress corrosion cracking[M].Xi'an:Xi'an Jiaotong University Press, 1985:62-65(in Chinese). -

下载:

下载: