A thermodynamic modeling method of electro-hydrostatic actuator and law of oil temperature rise

-

摘要:

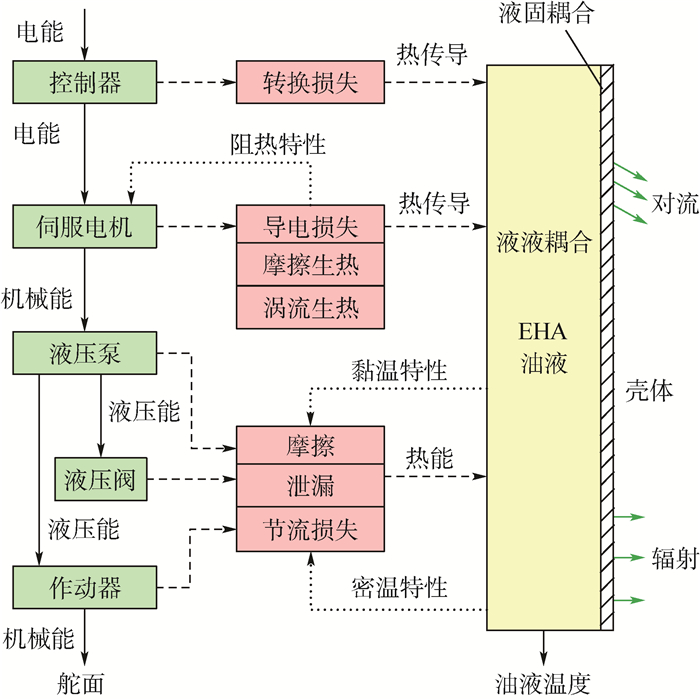

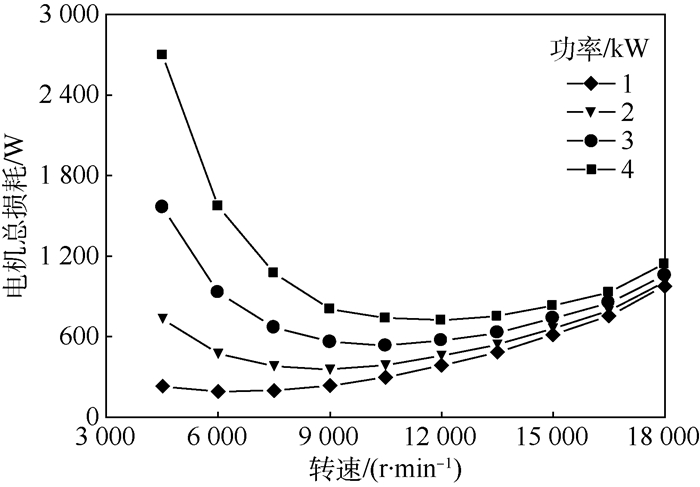

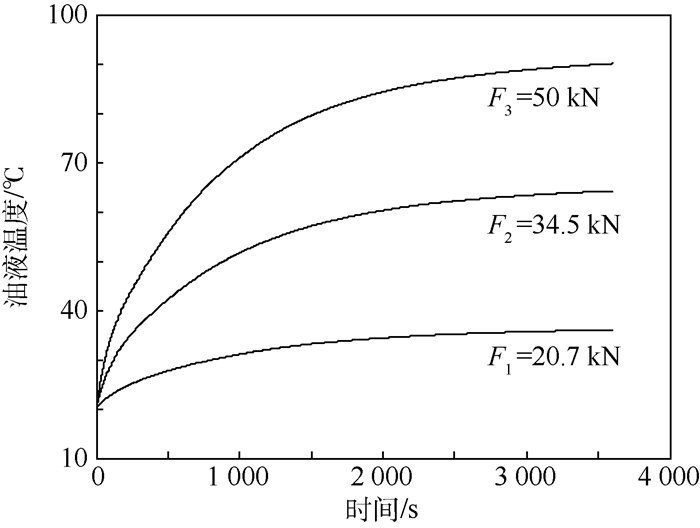

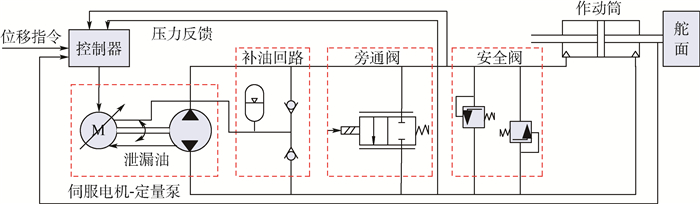

电动静液作动器(EHA)是多电飞机关键子系统之一,其高度集成设计在减小体积和质量的同时,大幅降低换热能力,导致EHA油液温度过高、功能丧失。针对目前EHA一维热力学建模不足问题,以油冷电机驱动的EHA为研究对象,提出EHA的“三维+一维+三维”的热力学建模方法。首先,分析EHA能量转换及传递规律,探究EHA热能产生和扩散途径,在考虑参数时变基础上提出EHA的“三维+一维+三维”热力学建模方法;其次,基于ANSYS平台建立EHA电机生热和壳体对流换热的三维热力学模型;然后,建立柱塞泵、液压缸、阀和增压油箱等一维热力学模型;最后,在AMESim平台上搭建EHA的“三维+一维+三维”的热力学模型。仿真和实验验证了EHA的“三维+一维+三维”热力学建模方法的正确性,揭示了EHA油液温升规律,为EHA的热设计提供了理论依据。

-

关键词:

- 电动静液作动器(EHA) /

- 热力学建模方法 /

- 电机 /

- 温升规律 /

- 柱塞泵

Abstract:Electro-hydrostatic actuator (EHA), one of the key subsystems in the more electric aircraft, can reduce the size and weight of airborne equipment because of its highly compact design. However, the heat dissipation is weakened simultaneously, which can easily lead to an extremely rapid temperature increase and loss of function. In view of the drawbacks of traditional 1D thermal model, a "3D-1D-3D" thermal modeling method was proposed in order to research on the temperature rise of EHA driven by oil-cooled motor. Firstly, the conversion and transfer of energy in EHA were analyzed, aiming to find out the heat source and its diffusion. Further, the "3D-1D-3D" thermal modeling method was proposed considering that the parameters varied with time. Secondly, the 3D thermal model of EHA motor was established in ANSYS including the heat generation module and dissipation module, while the other components, for instance piston pump, hydraulic cylinder, valves, pressurized tank, etc., were studied with 1D thermal models. Finally, the whole "3D-1D-3D" thermal model of EHA was integrated on AMESim platform, and validated by experimental results. The results from simulations and experiments reveal the law of temperature rise in EHA, which provides the theoretical guidance for thermal design of EHA.

-

表 1 EHA参数

Table 1. EHA parameters

参数 数值 柱塞泵排量/(mL·r-1) 4.3 定子绕组电阻/Ω 1.15 定子环电感/H 0.01 磁链/Wb 0.134 晶体管正向压降/V 1 晶体管电阻/Ω 0.013 活塞直径/mm 65 作动器行程/mm 50 二极管电阻/Ω 0.008 7 二极管正向压降/V 1.3 表 2 EHA运动规律

Table 2. Motion laws of EHA

正弦信号序号 幅值/mm 频率/Hz 周期/s 持续时间/s 1 2.1 1 1 506 2 7 2/3 1.5 33 3 28 1/3 3 51 4 42 1/5 5 10 -

[1] TODESCHI M. A380 flight control actuation lessons learned on EHAs design[C]//Proceedings of the International Conference on Recent Advances in Aerospace Actuation Systems and Components, 2007: 21-26. [2] TAKEBAYASHI W, HARA Y. Thermal design tool for EHA[C]//Proceedings of the International Conference on Recent Advances in Aerospace Actuation Systems and Components, 2004: 15-19. [3] LI J, ZHANG X, YIN Y B. Dynamic temperature simulation of an accumulator in aircraft hydraulic systems[C]//2011 International Conference on Fluid Power and Mechatronics (FPM). Piscataway, NJ: IEEE Press, 2011: 653-657. [4] STADLBAUER K, POLTSCHAK F, RAFETSEDER D, et al. A spice-based lumped parameter thermal model with geometrically distributed elements for electro-hydraulic actuators[C]//2012 International Symposium on Power Electronics, Electrical Dri-ves, Automation and Motion(SPEEDAM). Piscataway, NJ: IEEE Press, 2012: 511-516. [5] LI C G, JIAO Z X.Calculation method for thermal-hydraulic system simulation[J].Journal of Heat Transfer, 2008, 130(8):084503. doi: 10.1115/1.2928006 [6] SCOTT T, UPHOLD J. Thermal modeling of power steering system performance[C]//SAE World Congress & Exhibition, 2008: 1039-1044. [7] LANA E D, DE NEGRI V J. A new evaluation method for hydraulic gear pump efficiency through temperature measurements[C]//SAE 2006 Commercial Vehicle Engineering Congress & Exhibition, 2006: 3503. [8] LI J, XU J L, ZHANG X, et al. An estimation method of the fluid temperature for commercial aircraft hydraulic systems[C]//2010 International Conference on Mechanic Automation and Control Engineering (MACE). Piscataway, NJ: IEEE Press, 2010: 2962-2965. [9] 卢宁, 付永领, 孙新学.基于AMEsim的双压力柱塞泵的数字建模与热分析[J].北京航空航天大学学报, 2006, 32(9):1054-1058.LU N, FU Y L, SUN X X.Digital modeling and thermal analysis of double pressure piston pump based on AMEsim[J].Journal of Beijing University of Aeronautics and Astronautics, 2006, 32(9):1054-1058(in Chinese). [10] 李永林, 徐浩军, 曹克强, 等.航空柱塞泵全工况效率分析及热力学建模[J].北京航空航天大学学报, 2010, 36(12):1470-1472.LI Y L, XU H J, CAO K Q, et al.Efficiency analysis and thermodynamic modeling of aircraft piston pump in all conditions[J].Journal of Beijing University of Aeronautics and Astronautics, 2010, 36(12):1470-1472(in Chinese). [11] NAVARRO R. Performance of an electro-hydrostatic actuator on the F-18 systems research aircraft: NASA/TM-97-206224[R]. Washington, D. C. : NASA, 1997. [12] ANDERSSON J, KRUS P, NILSSON K, et al. Modelling and simulation of heat generation in electro-hydrostatic actuation systems[C]//Proceedings of the 4th JHPS International Symposium on Fluid Power, 1999: 537-542. [13] JOHANSSON B, ANDERSSON J, KRUS P. Thermal modelling of an electro-hydrostatic actuation system[C]//Proceedings of the International Conference on Recent Advances in Aerospace Actuation Systems and Components, 2001: 48-53. [14] ENGELHARDT J. Thermal simulation of an aircraft fluid power system with hydraulic-electrical power conversion units[C]//Proceedings of the 1st FPNI-PhD Symposium, 2000: 435-448. [15] LI K, LV Z, LU K, et al. Thermal-hydraulic modeling and simulation of piston pump in electro-hydrostatic actuator system[C]//2015 International Conference on Fluid Power and Mechatronics (FPM). Piscataway, NJ: IEEE Press, 2015: 1097-1101. [16] 盛敬超.液压流体力学[M].北京:机械工业出版社, 1980.SHENG J C.Hydraulic fluid mechanics[M].Beijing:China Machine Press, 1980(in Chinese). -

下载:

下载: