-

摘要:

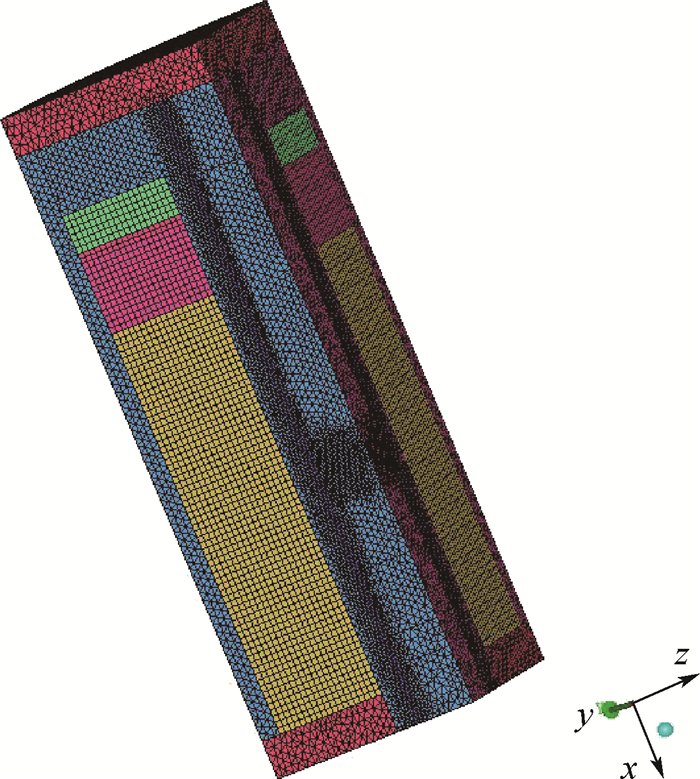

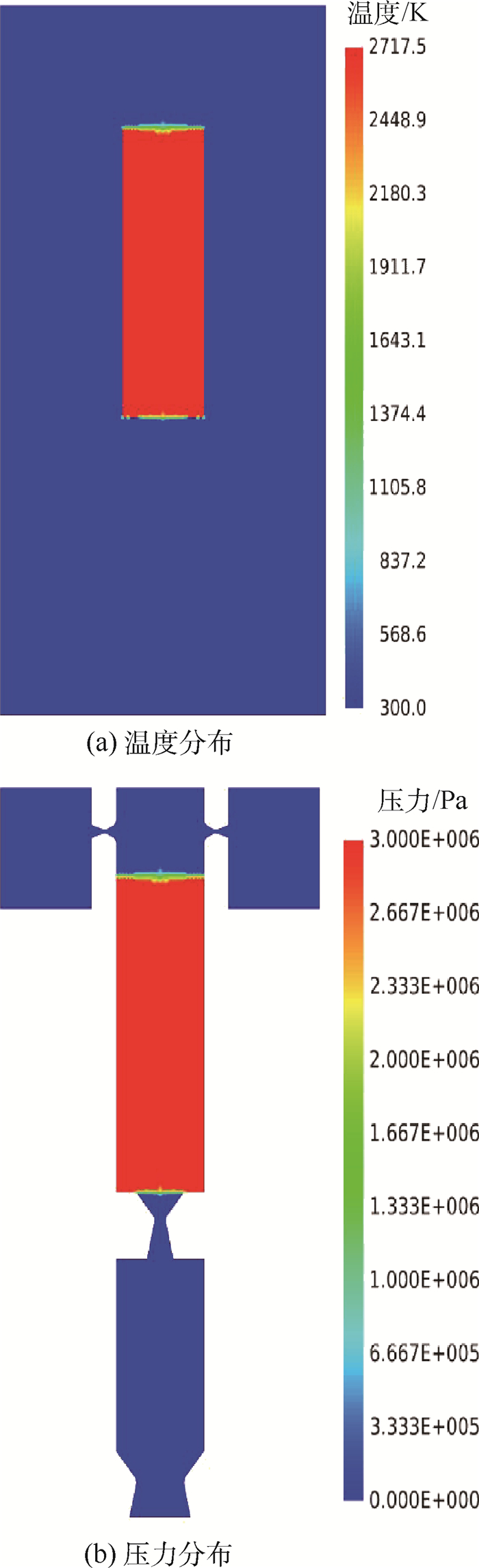

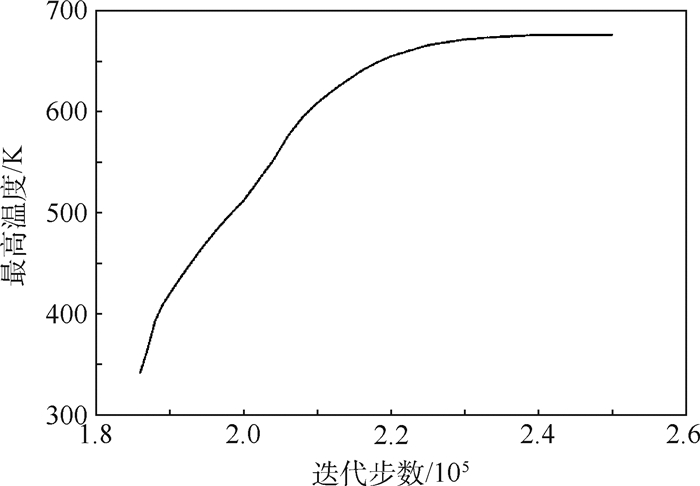

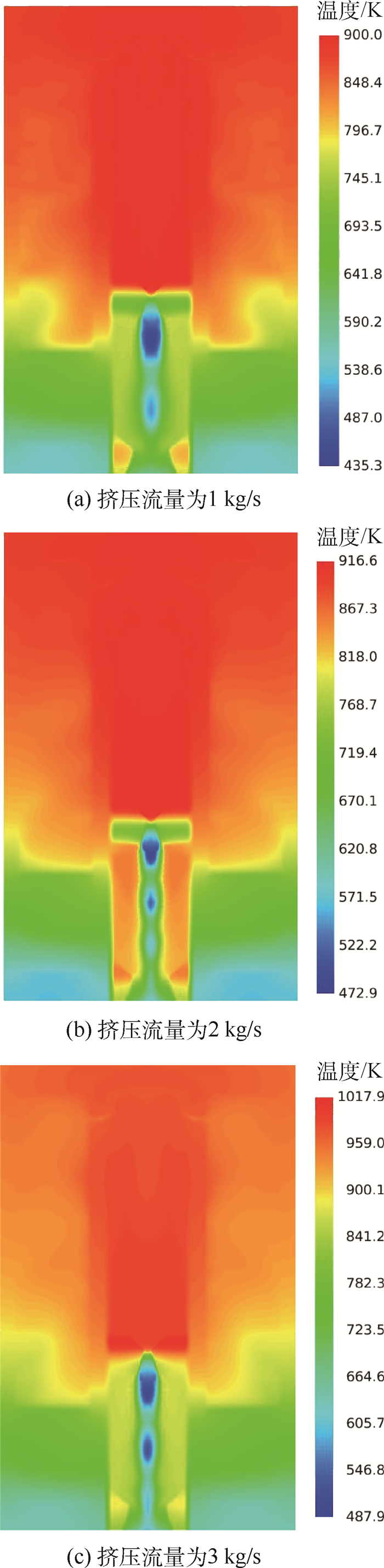

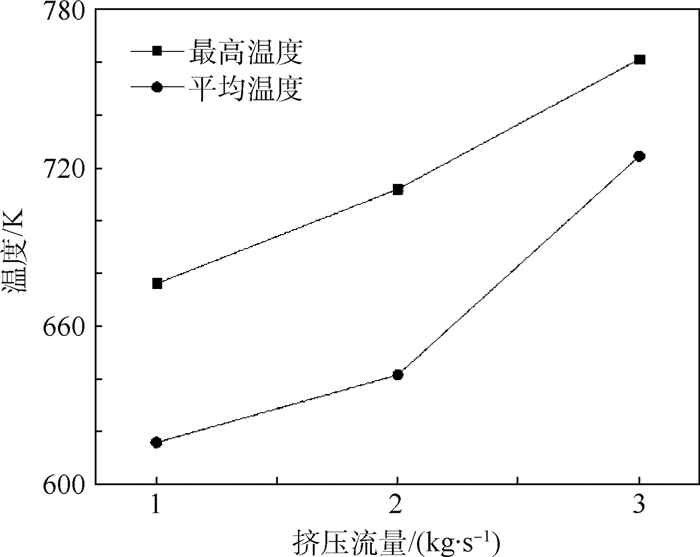

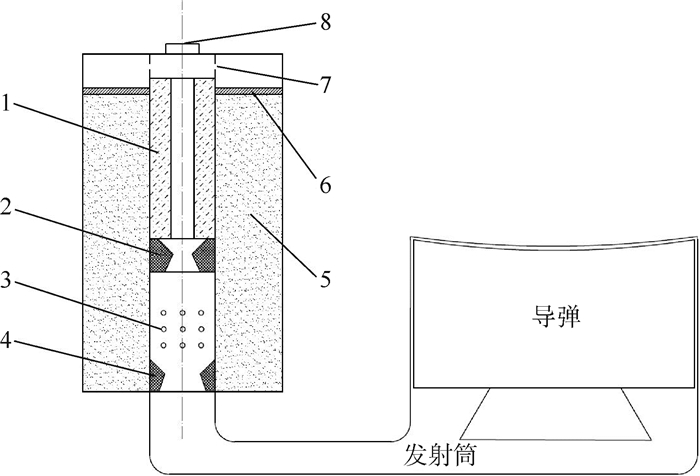

固-膏体燃气发生器是一种新型的燃气发生系统,是潜地导弹变深度弹射系统中的核心部件。为了研究固-膏体燃气发生器工作后膏体储存室的温度分布情况,采用源项法结合动网格技术、RNG

k-ε 湍流模型和离散坐标(DO)辐射模型对固-膏体燃气发生器的工作过程进行了数值仿真,并对不同膏体推进剂挤压流量下的膏体推进剂的温度分布作了对比研究。结果表明,传入膏体储存室的热量大部分来自于挤压室内的高温燃气,且整体热量的传导主要在轴向进行。随着膏体推进剂挤压流量增加,膏体储存室内的最高温度和平均温度均有所增加。研究结果可以为该型号固-膏体燃气发生器的热防护设计和改进提供相关参考。Abstract:Solid-gelled propellant gas generator is a new and special gas generator, and is the core component of the variable-depth missile ejection system. In order to study the temperature distribution of storage space of solid-gelled propellant gas generator, the source term method, the dynamic mesh method, the RNG

k-ε turbulent model and the discrete ordinates (DO) radiation model were used to numerically simulate the working process of the solid-gelled propellant gas generator. And temperature distributions under different flow rates of gelled propellant were studied and compared. The results show that most of heat that the gelled propellant obtained comes from the high-temperature gas in the extrusion chamber, and the main heat transfer happens in the axial direction. As the extrusion flow rate of gelled propellant increases, the highest and average temperatures of the gelled propellant storage space increase. The results of this study can provide a reference for the thermal protective design and improvement of this type of solid-gelled propellant gas generator. -

-

[1] 赵险峰, 王俊杰.潜地弹道导弹发射系统内弹道学[M].哈尔滨:哈尔滨工程大学出版社, 2001:149-166.ZHAO X F, WANG J J.Interior ballistics of under water ballistic missile launching system[M].Harbin:Harbin Engineering University Press, 2001:149-166(in Chinese). [2] 芮守祯, 邢玉明, 梁材.高温高压超声速气液两相流场数值模拟[J].航空动力学报, 2011, 26(5):991-996.RUI S Z, XING Y M, LIANG C.Numerical simulation of gas-liquid two-phase flow in high temperature and high pressure supersonic cross flow[J].Journal of Aerospace Power, 2011, 26(5):991-996(in Chinese). [3] 芮守祯, 邢玉明.导弹弹射装置冷却器中液滴轨迹及特性的数值模拟[J].舰船科学技术, 2010, 32(4):113-116.RUI S Z, XING Y M.The simulation of droplet trajectory and properties in cooler of missile launch system[J].Ship Science and Technology, 2010, 32(4):113-116(in Chinese). [4] 胡晓磊, 乐贵高, 马大为, 等.水下燃气-蒸汽弹射气液两相流场数值研究[J], 航空动力报, 2015, 30(1):164-170.HU X L, LE G G, MA D W, et al.Numerical study of gas-steam ejection gas-liquid two-phase flow field under water[J].Journal of Aerospace Power, 2015, 30(1):164-170(in Chinese). [5] 李咸海, 王俊杰.潜地导弹发射动力系统[M].哈尔滨:哈尔滨工程大学出版社, 2000:30-37.LI X H, WANG J J.Under water ballistic missile launching system[M].Harbin:Harbin Engineering University Press, 2000:30-37(in Chinese). [6] LAMBERT G, FOX R, RAINS W. Rocket propellant and method: US 3717518DA[P]. 1973-02-20. [7] NATION B, RAHIMI S.The status of gel propellants in year 2000[J].Internation Journal of Energetic Materials & Chemical Propulsion, 2002, 5(6):172-194. [8] 肖金武, 张文刚.PEPA/AP膏体推进剂配方研究[J].固体火箭技术, 2001, 24(4):46-49. doi: 10.3969/j.issn.1006-2793.2001.04.012XIAO J W, ZHANG W G.Study on PEPA/AP pasty propellant formulation[J].Journal of Solid Rocket Technology, 2001, 24(4):46-49(in Chinese). doi: 10.3969/j.issn.1006-2793.2001.04.012 [9] 张家仙. 膏体推进剂火箭发动机工作过程研究[D]. 南京: 南京理工大学, 2009: 32-47.ZHANG J X. Reserch on working process of pasty propellant rocket motor[D]. Nanjing: Nanjing University of Science & Technology, 2009: 32-47(in Chinese). [10] 张家仙, 鞠玉涛, 周超, 等.膏体推进剂模拟液直圆管流动特性[J].固体火箭技术, 2009, 32(4):439-442.ZHANG J X, JU Y T, ZHOU C, et al.Pasty propellant simulacrum flow characteristic in straight round pipe[J].Journal of Solid Rocket Technology, 2009, 32(4):439-442(in Chinese). [11] MISHRA D P, PATYAL A, PADHWAL M.Effects of gellant concentration on the burning and flame structure of organic gel propellant droplets[J].Fuel, 2011, 90(5):1805-1810. doi: 10.1016/j.fuel.2010.12.021 [12] KUMMITHA O R.Numerical analysis of solid rocket motor core flow with large eddy simulation viscous model[J].Materials Today, 2016, 3(10):3820-3825. doi: 10.1016/j.matpr.2016.11.034 [13] 杨乐, 余贞勇, 何景轩.基于FLUENT的固体火箭发动机点火瞬态内流场仿真影响因素分析[J].固体火箭技术, 2011, 34(4):474-477.YANG L, YU Z Y, HE J X.A FLUENT analysis of influencing factors for SRM inner flow field simulation at ignition[J].Journal of Solid Rocket Technology, 2011, 34(4):474-477(in Chinese). [14] 武晓松, 陈军, 王栋.固体火箭发动机工作过程数值仿真[M].北京:高等教育出版社, 2006:93-122.WU X S, CHEN J, WANG D.Numerical simulation of working progress of solid rocket engine[M].Beijing:Higher Education Press, 2006:93-122(in Chinese). [15] 郑亚, 陈军, 鞠玉涛.固体火箭发动机传热学[M].北京:北京航空航天大学出版社, 2006:100-136.ZHENG Y, CHEN J, JU Y T.Solid rocket engine heat transfer[M].Beijing:Beihang University Press, 2006:100-136(in Chinese). [16] 赵雁鹏, 王学智, 刘少伟, 等.垂直弹射系统弹射初始阶段内流场数值分析[J].空军工程大学学报(自然科学版), 2014, 15(4):5-8.ZHAO Y P, WANG X Z, LIU S W, et al.A numerical analysis for the initial stage inner flow field in vertical ejection system[J].Journal of Air Force Engineering University(National Science Edition), 2014, 15(4):5-8(in Chinese). -

下载:

下载: