-

摘要:

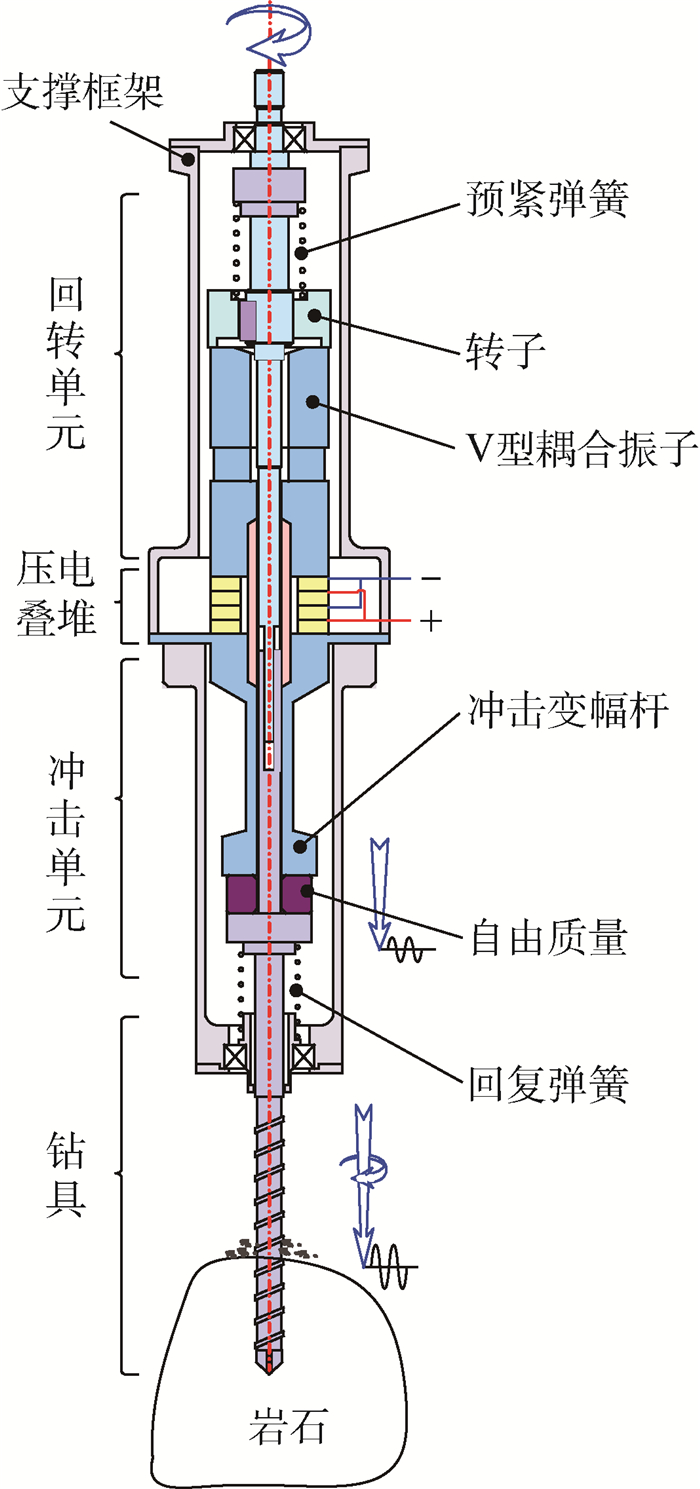

为提高冲击式超声波钻的排屑效率,基于压电驱动原理提出了一种单压电叠堆驱动的回转冲击超声波钻(RPUD)。RPUD仅利用单一压电叠堆两侧的振动实现了钻具的回转冲击运动,将一侧振动转变为回转运动,另一侧振动转变为冲击运动,且回转运动和冲击运动可单独调节。为实现超声波钻回转运动和冲击运动的同步谐振,借助有限元方法,对超声波钻换能器进行模态分析和瞬态分析。基于优选的结构设计参数,研制了RPUD样机并开展了钻进实验研究。实验结果验证了RPUD的钻进功能,并利用响应面方法分析了钻压力等各钻进参数对钻进效率的影响。

Abstract:To improve the chip removal efficiency of percussive ultrasonic drilling, a rotary-percussive ultrasonic drill (RPUD) is proposed based on piezoelectric driving principle, which is driven by single piezoelectric stack. The proposed RPUD uses the vibration on both sides of the single piezoelectric stack to realize the rotary-percussive motion of the drilling tool, and transfers one side of vibration into rotary motion and the other side into percussive motion. Rotary motion and percussive motion can be regulated independently. To realize the synchronous resonance of rotary motion and percussive motion, the modal analysis and transient analysis of ultrasonic drilling transducer are carried out by the finite element method. A prototype of rotary-percussive ultrasonic drilling machine was developed, and the drilling experiment was carried out based on the optimized structural design parameters. The experimental results verify the drilling function of the RPUD, and response surface method is used to analyze the influence of the drilling parameters such as weight on bit on the drilling efficiency.

-

表 1 钻进实验因素水平

Table 1. Factors and levels of drilling experiment

水平 A/N B/g C/N D/(N·mm-1) E/(N·mm-1) F/N -1 6 6 7 0.18 0.41 1 0 7 8 10 0.30 0.65 2 1 8 10 13 0.41 0.95 3 表 2 响应面实验设计及结果

Table 2. Experimental design and results for response surface

实验序号 A/N B/g C/N D/(N·mm-1) E/(N·mm-1) F/N Yd/mm 1 6 6 10 0.18 0.65 2 17.80 2 8 6 10 0.18 0.65 2 19.50 3 6 10 10 0.18 0.65 2 19.68 4 8 10 10 0.18 0.65 2 19.80 5 6 6 10 0.41 0.65 2 16.20 6 8 6 10 0.41 0.65 2 18.80 7 6 10 10 0.41 0.65 2 19.20 8 8 10 10 0.41 0.65 2 18.36 9 7 6 7 0.30 0.41 2 16.74 10 7 10 7 0.30 0.41 2 18.80 11 7 6 13 0.30 0.41 2 17.82 12 7 10 13 0.30 0.41 2 19.12 13 7 6 7 0.30 0.95 2 15.90 14 7 10 7 0.30 0.95 2 19.10 15 7 6 13 0.30 0.95 2 18.10 16 7 10 13 0.30 0.95 2 19.20 17 7 8 7 0.18 0.65 1 14.70 18 7 8 13 0.18 0.65 1 19.60 19 7 8 7 0.41 0.65 1 15.50 20 7 8 13 0.41 0.65 1 18.30 21 7 8 7 0.18 0.65 3 16.10 22 7 8 13 0.18 0.65 3 20.20 23 7 8 7 0.41 0.65 3 13.80 24 7 8 13 0.41 0.65 3 20.00 25 6 8 10 0.18 0.41 2 17.04 26 8 8 10 0.18 0.41 2 18.32 27 6 8 10 0.41 0.41 2 14.22 28 8 8 10 0.41 0.41 2 17.04 29 6 8 10 0.18 0.95 2 17.92 30 8 8 10 0.18 0.95 2 19.17 31 6 8 10 0.41 0.95 2 14.44 32 8 8 10 0.41 0.95 2 19.24 33 7 6 10 0.30 0.41 1 13.52 34 7 10 10 0.30 0.41 1 19.40 35 7 6 10 0.30 0.95 1 16.80 36 7 10 10 0.30 0.95 1 19.32 37 7 6 10 0.30 0.41 3 13.60 38 7 10 10 0.30 0.41 3 19.22 39 7 6 10 0.30 0.95 3 18.40 40 7 10 10 0.30 0.95 3 19.20 41 6 8 7 0.30 0.65 1 14.40 42 8 8 7 0.30 0.65 1 19.72 43 6 8 13 0.30 0.65 1 15.64 44 8 8 13 0.30 0.65 1 20.30 45 6 8 7 0.30 0.65 3 15.70 46 8 8 7 0.30 0.65 3 18.80 47 6 8 13 0.30 0.65 3 15.80 48 8 8 13 0.30 0.65 3 20.10 49 7 8 10 0.30 0.65 2 24.30 50 7 8 10 0.30 0.65 2 24.10 51 7 8 10 0.30 0.65 2 23.60 52 7 8 10 0.30 0.65 2 24.60 53 7 8 10 0.30 0.65 2 25.10 54 7 8 10 0.30 0.65 2 23.80 表 3 方差分析

Table 3. Variance analysis

方差来源 平方和 自由度 均方 f值 P值 模型 364.58 17 21.45 13.46 <0.000 1 A 40.33 1 40.33 25.31 <0.000 1 B 30.78 1 30.78 19.32 <0.000 1 C 25.81 1 25.81 16.20 0.000 3 D 9.07 1 9.07 5.69 0.022 4 E 5.97 1 5.97 3.75 0.060 8 F 0.60 1 0.60 0.38 0.542 7 AB 3.16 1 3.16 1.99 0.167 4 AD 1.58 1 1.58 0.99 0.325 8 AF 0.85 1 0.85 0.53 0.471 1 BC 2.03 1 2.03 1.65 0.126 7 BE 1.29 1 1.29 1.06 0.159 6 A2 40.86 1 40.86 25.65 <0.000 1 B2 17.99 1 17.99 11.29 0.001 9 C2 41.88 1 41.88 26.29 <0.000 1 D2 52.92 1 52.92 33.22 <0.000 1 E2 81.43 1 81.43 51.11 <0.000 1 F2 74.37 1 74.37 46.69 <0.000 1 残差 57.35 36 1.59 失拟项 55.86 31 1.80 6.03 0.026 8 纯误差 1.50 5 0.30 总离差 421.93 53 -

[1] 叶培建, 彭兢.深空探测与我国深空探测展望[J].中国工程科学, 2006, 8(10):13-18. doi: 10.3969/j.issn.1009-1742.2006.10.003YE P J, PENG J.Deep space exploration and its prospect in China[J].Engineering Sciences, 2006, 8(10):13-18(in Chinese). doi: 10.3969/j.issn.1009-1742.2006.10.003 [2] 徐伟彪, 赵海斌.小行星深空探测的科学意义和展望[J].地球科学进展, 2005, 20(11):31-38.XU W B, ZHAO H B.Deep space exploration of asteroids:The science perspectives[J].Advances in Earth Science, 2005, 20(11):31-38(in Chinese). [3] 朱恩涌, 孙国江, 果琳丽, 等.我国小行星探测发展思路及关键技术探讨[J].航天器工程, 2012, 21(3):96-100. doi: 10.3969/j.issn.1673-8748.2012.03.037ZHU E Y, SUN G J, GUO L L, et al.Study on development idea of Chinese asteroid exploration and key technologies[J].Spacecraft Engineering, 2012, 21(3):96-100(in Chinese). doi: 10.3969/j.issn.1673-8748.2012.03.037 [4] FINZI A E, ZAZZERA F B, DAINESE C, et al.SD2-How to sample a comet[J].Space Science Reviews, 2007, 128(1-4):281-299. doi: 10.1007/s11214-006-9134-6 [5] 李京霖, 丁希仑, 张文明, 等.一种多功能小行星采样器的设计[J].机械工程学报, 2015, 51(13):167-175.LI J L, DING X L, ZHANG W M, et al.Design of a multi-function minor planet soil sampler[J].Journal of Mechanical Engineering, 2015, 51(13):167-175(in Chinese). [6] BERRY K, SUTTER B, MAY A, et al.Osiris-rex touch-and-go (tag) mission design and analysis[C]//Proceedings of 36th Annual AAS Guidance and Control Conference.Springfield: AAS Press, 2013: 1-12. [7] KAWAGUCHI J I, FUJIWARA A, UESUGI T.Hayabusa-Its technology and science accomplishment summary and Hayabusa-2[J].Acta Astronautica, 2008, 62(11-12):639-647. [8] ZHANG T, ZHANG W, WANG K, et al.Drilling, sampling, and sample-handling system for China's asteroid exploration mission[J].Acta Astronautica, 2017, 137:192-204. doi: 10.1016/j.actaastro.2017.04.017 [9] ZACNY K, BAR-COHEN Y, BRENNAN M, et al.Drilling systems for extraterrestrial subsurface exploration[J].Astrobiology, 2008, 8(2):665-706. [10] 丁希仑, 李可佳, 尹忠旺.面向月壤采集的多杆深层采样器[J].宇航学报, 2009, 30(3):1189-1194. doi: 10.3873/j.issn.1000-1328.2009.03.058DING X L, LI K J, YIN Z W.Multi-rod deep driller for lunar subsurface sampling[J].Journal of Astronautics, 2009, 30(3):1189-1194(in Chinese). doi: 10.3873/j.issn.1000-1328.2009.03.058 [11] ZHANG T, DING X L.Drilling forces model for lunar regolith exploration and experimental validation[J].Acta Astronautica, 2017, 131:190-203. doi: 10.1016/j.actaastro.2016.11.035 [12] BAO X, BAR-COHEN Y, CHANG Z, et al.Modeling and computer simulation of ultrasonic/sonic driller/corer (USDC)[J].IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, 2003, 50(9):1147-1160. doi: 10.1109/TUFFC.2003.1235326 [13] HARKNESS P, LUCAS M.A brief overview of space applications for ultrasonics[J].Ultrasonics, 2012, 52(8):975-979. doi: 10.1016/j.ultras.2012.09.004 [14] BAR-COHEN Y, SHERRIT S, DOLGIN B P, et al.Ultrasonic/sonic driller/corer (USDC) as a sampler for planetary exploration[C]//Proceedings of Aerospace Conference.Bellingham: SPIE Press, 2012: 263-271. [15] THOMAS P N H.Magna parva and ESA's ultrasonic drill tool for planetary surface exploration[C]//Proceedings of Earth and Space: Engineering, Science, Construction, and Operations in Challenging Environments.Reston: ASCE Press, 2010: 1235-1245. [16] 杨康.基于超声波/声波能量耦合机理的钻探器研究[D].南京: 南京航空航天大学, 2012: 1-58.YANG K.Research on drilling corer based on ultrasonic/acoustic energy coupling mechanism[D].Nanjing: Nanjing University of Aeronautics & Astronautics, 2012: 1-58(in Chinese). [17] 全齐全, 李贺, 邓宗全, 等.用于星体表面岩石采样的超声波钻进取心器的研制[J].中南大学学报(自然科学版), 2016, 47(12):4081-4089.QUAN Q Q, LI H, DENG Z Q, et al.An ultrasonic coring tool for rock-sampling on extraterrestrial planets[J].Journal of Central South University (Science and Technology), 2016, 47(12):4081-4089(in Chinese). [18] CARDONI A, HARKNESS P, LUCAS M.Ultrasonic rock sampling using longitudinal-torsional vibrations[J].Physics Procedia, 2010, 3(1):123-134. [19] HARKNESS P, LUCAS M, CARDONI A.Coupling and degenerating modes in longitudinal-torsional step horns[J].Ultrasonics, 2010, 52(8):980-988. [20] BADESCU M, BAR-COHEN Y, SHERRIT S, et al.Percussive augmenter of rotary drills(PARoD)[C]//Proceedings of SPIE Smart Structures and Materials Nondestructive Evaluation and Health Monitoring.Bellingham: SPIE Press, 2013: 1-8. [21] ZACNY K, PULSEN G, BAR-COHEN Y, et al.Wireline deep drill for exploration of Mars, Europa, and Enceladus[C]//Proceedings of Aerospace Conference.Bellingham: SPIE Press, 2013: 1-14. [22] BADESCU M, SHERRIT S, BAO X, et al.Auto-Gopher: A wire-line rotary-hammer ultrasonic drill[C]//Proceedings of SPIE Smart Structures and Materials Nondestructive Evaluation and Health Monitoring.Bellingham: SPIE Press, 2011: 1-8. [23] TIMONEY R, HARKNESS P, LI X, et al.The development of the european uitrasonic planetary core drill (UPCD): AIAA-2005-4553[R].Reston: AIAA, 2005. doi: 10.2514/6.2015-4553 [24] LI X, WORRALL K, HARKNESS P, et al.A motion control system design for an ultrasonic planetary core drill (UPCD) unit: AIAA-2015-4554[R].Reston: AIAA, 2015. [25] SHERRIT S, DOMM L, BAO X, et al.Single piezo-actuator rotary-hammering (SPaRH) drill[C]//Proceedings of SPIE Smart Structures and Materials Nondestructive Evaluation and Health Monitoring.Bellingham: SPIE Press, 2012: 1-11. [26] LIU Y, YANG X, CHEN W, et al.A bonded-type piezoelectric actuator using the first and second bending vibration modes[J].IEEE Transactions on Industrial Electronics, 2016, 63(3):1676-1693. doi: 10.1109/TIE.2015.2492942 [27] TSUJINO J.Ultrasonic motor using a one-dimensional longitudinal-torsional vibration converter with diagonal slits[J].Smart Materials and Structures, 1998, 7(3):345-351. doi: 10.1088/0964-1726/7/3/009 -

下载:

下载: