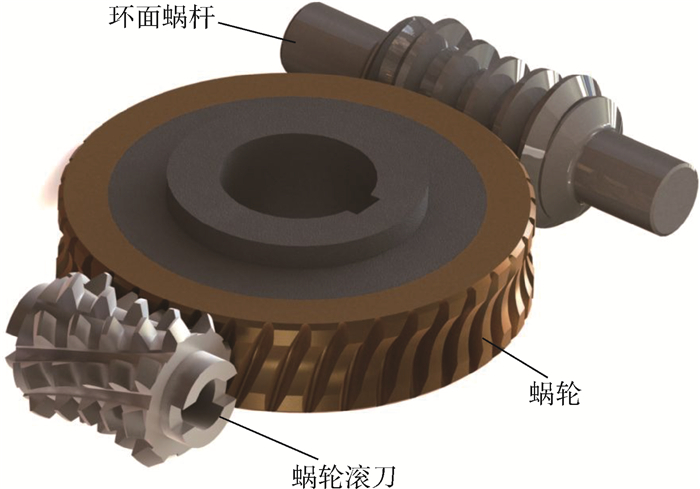

Design and correction method of spiral flute rake face of an hourglass worm gear hob

-

摘要:

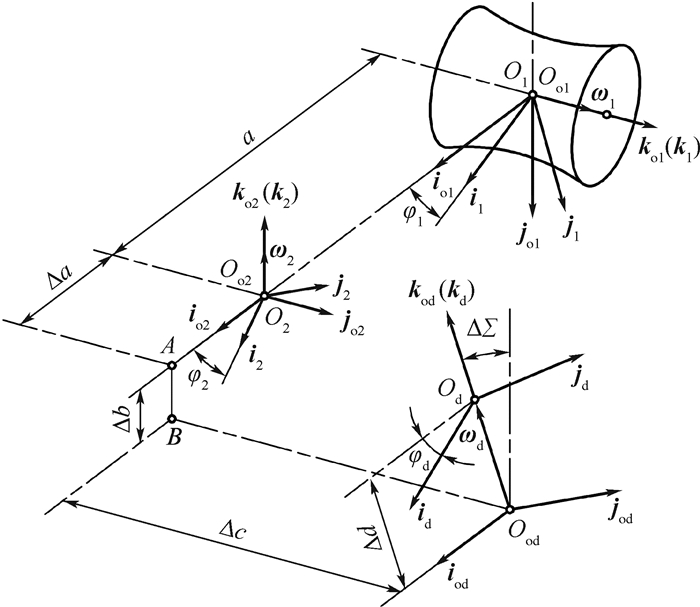

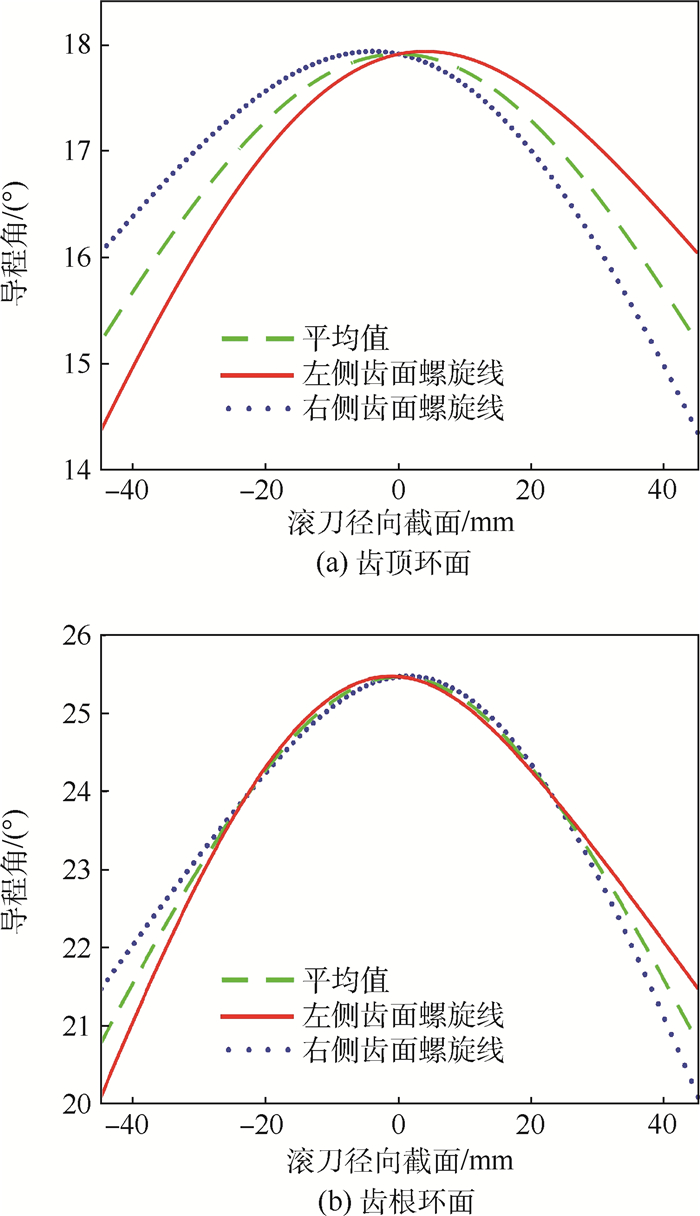

为提高环面蜗轮滚刀的切削性能及滚齿效率,将滚刀的容屑槽设计成螺旋槽,减小刀齿两侧前角的绝对值,均衡两侧刃的切削条件。根据齿轮啮合理论和环面蜗杆成形原理,以滚刀基本蜗杆分度环面螺旋线的导程角和前刀面曲线的导程角互余为依据,提出一种由圆柱产形面变传动比展成环面蜗轮滚刀螺旋槽前刀面的方法;计算得到滚刀分度环面处的前角近似为0°,而刀齿左侧的前角从齿顶到齿根由正值变为负值,右侧前角从齿顶到齿根由负值变为正值,并且正前角和负前角的绝对值较大。进一步对滚刀前刀面进行修正,将修正后的滚刀模型导入VERICUT软件中,测量其前角,验证设计方法的正确性。结果表明,该方法能够解决滚刀两侧前角绝对值较大的问题,各刀齿左右两侧的前角控制在-0.6°~0.5°之间。

Abstract:To improve the cutting performance and hobbing efficiency of an hourglass worm gear hob, it is necessary to design the flutes of the hob into spiral groove, reduce the absolute value of the rake angle on both sides of the cutting teeth, and equalize the cutting conditions on both sides of the blade. Based on the hourglass worm forming method and the gear meshing theory, a method for developing a helical groove with a cylindrical generating surface by changing the transmission ratio is proposed, and the idea behind the method is to ensure that the lead angles of the worm helix and the rake face curve are complementary in any cross section of the basic hob worm. The rake angles on the indexing cycle were both approximately zero, while the rake angles on the left side of the cutting tooth varied from positive to negative from the tooth top to the tooth root, and the rake angles on the right side of the cutting tooth varied from negative to positive from the tooth top to the tooth root. And the absolute values of positive and negative rake angles were larger. The rake face of the hob was further modified, and the modified hob model was introduced into the VERICUT software. The rake angles were measured to verify the correctness of the design method. The results show that the method can solve the problem that the absolute value of the rake angle on both sides of the hob is relatively large, and the rake angles on both sides of the cutting teeth are controlled between -0.6° and 0.5°.

-

Key words:

- hourglass worm gear hob /

- spiral flute /

- rake angle /

- cylindrical generating surface /

- VERICUT

-

表 1 平面二次包络环面蜗轮滚刀基本参数

Table 1. Basic parameters of plane double enveloping hourglass worm gear hob

参数 数值 中心距a/mm 160 传动比i12 10 滚刀头数z1 4 蜗轮分度圆压力角α/(°) 21.866 7 蜗轮分度圆直径d2/mm 255 蜗杆分度圆直径d1/mm 65 滚刀齿顶圆弧半径Ra1/mm 122.24 滚刀齿根圆弧半径Rf1/mm 133.24 滚刀工作长度Lw/mm 90 滚刀喉部分度圆导程角γm/(°) 21.420 5 产形平面轴线倾角β/(°) 22.5 主基圆直径db/mm 95 表 2 定传动比加工螺旋槽前刀面对应分度环面上各刀齿左右两侧的前角

Table 2. Rake angles on both sides of cutting teeth on indexing torus of spiral flute rake face processed by fixed transmission ratio

齿序号 左侧 右侧 前角/(°) 轴向位置Zi/mm 前角/(°) 轴向位置Zi/mm 1号齿 1.708 83 -38.171 39 -5.341 03 -30.950 36 2号齿 -0.060 04 -21.520 36 -1.637 29 -13.517 04 3号齿 -0.501 66 -4.226 86 -0.085 59 3.920 86 4号齿 1.129 17 13.246 70 -0.667 29 21.148 44 5号齿 4.830 84 30.652 93 -2.642 67 37.881 56 表 3 变传动比加工螺旋槽前刀面对应分度环面上各刀齿左右两侧的前角

Table 3. Rake angles on both sides of cutting teeth on indexing torus of spiral flute rake face processed by variable transmission ratio

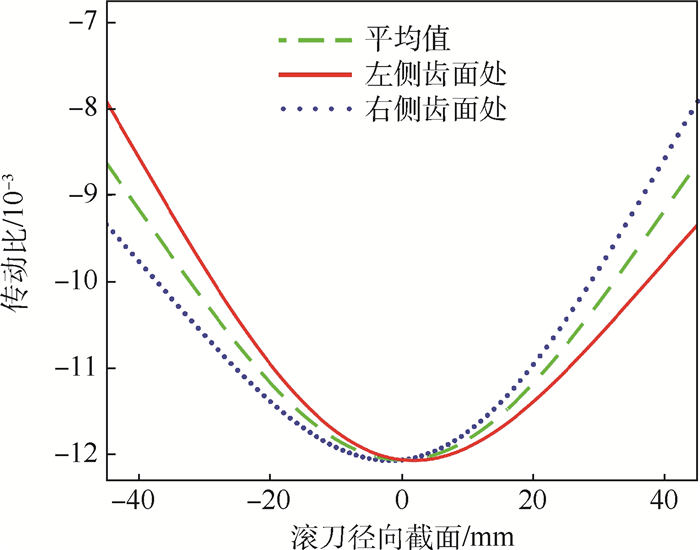

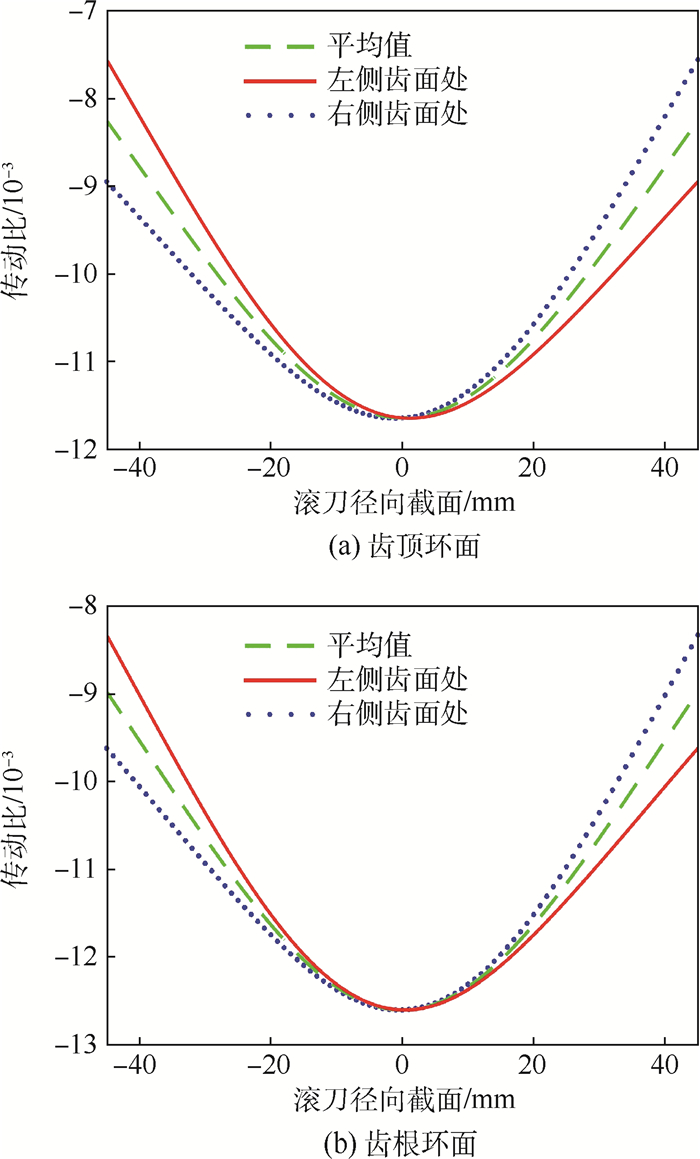

齿序号 左侧 右侧 前角/(°) 轴向位置Zi/mm 前角/(°) 轴向位置Zi/mm 1号齿 0.445 06 -38 -0.378 63 -31 2号齿 0.067 97 -21 -0.116 36 -13 3号齿 -0.036 67 -4 0.087 35 4 4号齿 0.131 01 13 -0.062 32 21 5号齿 0.411 12 31 -0.511 75 38 表 4 变传动比加工螺旋槽滚刀对应的前角

Table 4. Rake angles of spiral flute hob processed by variable transmission ratio

(°) 齿序号 前角类型 不同环面的Ri值 122.24 mm 124 mm 126 mm 127.5 mm 129 mm 131 mm 132.24 mm 1号齿 左侧前角 7.025 7 5.088 7 2.614 5 0.445 1 -2.024 5 -6.025 4 -8.589 3 右侧前角 -5.082 5 -3.736 9 -1.985 1 -0.378 6 1.405 1 4.081 5 5.744 1 2号齿 左侧前角 5.978 7 4.364 7 2.052 5 0.068 0 -2.140 9 -5.414 3 -7.523 2 右侧前角 -4.134 5 -3.016 4 -1.422 3 -0.116 4 1.066 4 2.958 2 4.167 5 3号齿 左侧前角 4.879 0 3.545 8 1.613 1 -0.036 7 -1.965 0 -4.761 3 -6.593 1 右侧前角 -6.584 7 -4.642 2 -2.027 5 0.087 4 2.166 4 5.054 4 6.760 8 4号齿 左侧前角 4.178 1 3.022 8 1.435 6 0.131 0 -1.413 2 -3.730 5 -5.314 0 右侧前角 -6.183 8 -4.516 3 -2.106 9 -0.062 3 2.159 2 5.557 6 7.692 8 5号齿 左侧前角 5.360 6 3.935 0 2.047 6 0.411 1 -1.593 7 -4.552 7 -6.391 6 右侧前角 -6.899 1 -4.953 6 -2.504 0 -0.511 8 1.900 8 5.554 3 7.985 6 表 5 以齿顶环面处传动比加工螺旋槽前刀面对应各刀齿左右两侧的前角

Table 5. Rake angles on both sides of cutting teeth corresponding to spiral flute rake face processed by transmission ratio on tooth top torus

齿序号 左侧 右侧 前角/(°) 轴向位置Zi/mm 前角/(°) 轴向位置Zi/mm 1号齿 0.462 56 -38 -0.483 52 -31 2号齿 -0.038 43 -21 0.131 94 -13 3号齿 -0.114 90 -4 0.176 31 4 4号齿 0.267 71 13 -0.204 22 21 5号齿 0.333 19 31 -0.430 43 38 表 6 以齿根环面处传动比加工螺旋槽前刀面对应各刀齿左右两侧的前角

Table 6. Rake angles on both sides of cutting teeth corresponding to spiral flute rake face processed by transmission ratio on tooth root torus

齿序号 左侧 右侧 前角/(°) 轴向位置Zi/mm 前角/(°) 轴向位置Zi/mm 1号齿 0.511 02 -38 -0.420 14 -31 2号齿 0.239 34 -21 -0.135 27 -13 3号齿 -0.068 67 -4 0.170 25 4 4号齿 0.125 45 13 0.076 51 21 5号齿 0.395 23 31 -0.558 03 38 表 7 测量螺旋槽滚刀对应的前角

Table 7. Measurement of rake angles of hob with spiral flute

(°) 齿序号 前角类型 不同环面的Ri值 122.24 mm 125 mm 127.5 mm 130 mm 132.24 mm 1号齿 左侧前角 0.227 9 0.405 1 0.315 2 -0.376 6 -0.144 6 右侧前角 0.031 3 -0.188 5 -0.502 7 0.125 0 0.076 3 2号齿 左侧前角 0.276 0 0.147 4 0.091 1 0.041 9 0.153 8 右侧前角 -0.222 8 0.095 6 0.184 8 -0.081 8 0.260 1 3号齿 左侧前角 -0.098 1 -0.073 3 0.132 2 -0.137 1 -0.190 1 右侧前角 0.171 5 -0.130 6 -0.210 7 0.195 5 -0.061 2 4号齿 左侧前角 0.305 6 0.233 4 -0.086 0 -0.122 4 0.382 8 右侧前角 -0.150 8 0.082 1 -0.254 3 0.265 3 0.115 5 5号齿 左侧前角 0.418 4 0.166 6 0.320 1 -0.177 6 -0.160 4 右侧前角 -0.185 2 -0.332 7 -0.267 3 0.289 1 0.256 2 -

[1] 董学朱.环面蜗杆传动设计和修形[M].北京:机械工业出版社, 2004:14-15.DONG X Z.Design and modification of enveloping worm gearing[M].Beijing:Machine Industry Press, 2004:14-15(in Chinese). [2] 李海涛, 董李扬.二次包络环面蜗轮滚刀侧后角面的设计方法: 201310172562.X[P].2013-05-10.LI H T, DONG L Y.Design method of the relief surfaces of double enveloping hourglass worm gear hob: 201310172562.X[P].2013-05-10(in Chinese). [3] 李海涛, 柳冠伊.平面二次包络环面蜗轮滚刀侧后角面的数控磨削加工方法: 201410613061.5[P].2015-03-25.LI H T, LIU G Y.CNC grinding method of the relief surfaces of plane double enveloping hourglass worm gear hob: 201410613061.5[P].2015-03-25(in Chinese). [4] 唐建生.金属切削与刀具[M].武汉:武汉理工大学出版社, 2009:188-189.TANG J S.Cutting and cutting tools[M].Wuhan:Wuhan University of Technology Press, 2009:188-189(in Chinese). [5] ZHAO Y P, SU D Z, ZHANG Z.Meshing analysis and technological parameters selection of dual tori double-enveloping toroidal worm drive[J].Mechanism and Machine Theory, 2010, 45(9):1269-1285. doi: 10.1016/j.mechmachtheory.2010.04.004 [6] 周良墉.环面蜗杆修型原理及制造技术[M].长沙:国防科技大学出版社, 2005:558-559.ZHOU L Y.The modification principle and manufacturing technology of hourglass worm[M].Changsha:National University of Defense Technology Press, 2005:558-559(in Chinese). [7] 董李扬.包络环面蜗杆副蜗轮滚刀数控加工技术的研究[D].北京: 中国农业大学, 2013: 15-20.DONG L Y.Research on NC machining technology of enveloping worm gear hob[D].Beijing: China Agricultural University, 2013: 15-20(in Chinese). [8] 柳冠伊.包络环面蜗轮滚刀数控成形理论及技术研究[D].北京: 中国农业大学, 2016: 13-14.LIU G Y.Research on CNC relief grinding technology of enveloping worm gear hob[D].Beijing: China Agricultural University, 2016: 13-14(in Chinese). [9] GUNAY M.Investigation of the effect of rake angle on main cutting force[J].International Journal of Machine Tools & Manufacture, 2004, 44(9):953-959. [10] GUNAY M.Experimental investigation of the effect of cutting tool rake angle on main cutting force[J].Journal of Materials Processing Technology, 2005, 166(1):44-49. doi: 10.1016/j.jmatprotec.2004.07.092 [11] SAGLAM H, UNSACAR F, YALDIZ S.Investigation of the effect of rake angle and approaching angle on main cutting force and tool tip temperature[J].International Journal of Machine Tools and Manufacture, 2006, 46(2):132-141. doi: 10.1016/j.ijmachtools.2005.05.002 [12] CHANG S L.Helix gash of hob cutter manufactured by milling[J].Journal of Materials Processing Technology, 2003, 142(2):569-575. doi: 10.1016/S0924-0136(03)00661-7 [13] 陈就, 刘丰林, 康权.一种滚刀径向铲磨优化方法[J].中国机械工程, 2014, 25(14):1883-1887. doi: 10.3969/j.issn.1004-132X.2014.14.008CHEN J, LIU F L, KANG Q.An optimization method for hob relief grinding[J].China Mechanical Engineering, 2014, 25(14):1883-1887(in Chinese). doi: 10.3969/j.issn.1004-132X.2014.14.008 [14] DONG L Y, WANG J Y, LIU P Y, et al.An NC rough turning method of an enveloping toroidal worm[J].International Journal of Production Engineering, 2012, 6(2):129-135. doi: 10.1007/s11740-012-0368-8 [15] LIU G Y, WEI W J, DONG X Z, et al.Relief grinding of planar double-enveloping worm gear hob using a four-axis CNC grinding machine[J].International Journal of Advanced Manufacturing Technology, 2016, 89(9-12):1-10. doi: 10.1007/s00170-016-9325-6 [16] YANG J, LI H T, RUI C J, et al.Research on a generating method of spiral flutes of hourglass worm gear hob[C]//Proceedings of the ASME Design Engineering Technical Conference.New York: ASME Press, 2017: V010T11A023. [17] RUI C J, LI H T, YANG J, et al.Research on incomplete design and generating theory of the relief surfaces of dual-cone double enveloping hourglass worm gear hob[C]//Proceedings of the ASME Design Engineering Technical Conference.New York: ASME Press, 2017: V010T11A022. [18] 舒勤业.双锥面二次包络环面蜗杆副及其关键制造装备的设计与研究[D].杭州: 浙江大学, 2015: 21-30.SHU Q Y.Design and research of dual-cone doublehourglass worm gear pair and its key manufacturing equipment[D].Hangzhou: Zhejiang University, 2015: 21-30(in Chinese). [19] 姜正健, 张伟, 李铸宇.微钻的前角计算及其钻削试验[J].大连工业大学学报, 2011, 30(2):145-147. doi: 10.3969/j.issn.1674-1404.2011.02.019JIANG Z J, ZHANG W, LI Z Y.Calculation of the rake angle of micro drill and drilling test[J].Journal of Dalian Institute of Light Industry, 2011, 30(2):145-147(in Chinese). doi: 10.3969/j.issn.1674-1404.2011.02.019 -

下载:

下载: