Numerical simulation of melting process of phase change energy storage unit under microgravity

-

摘要:

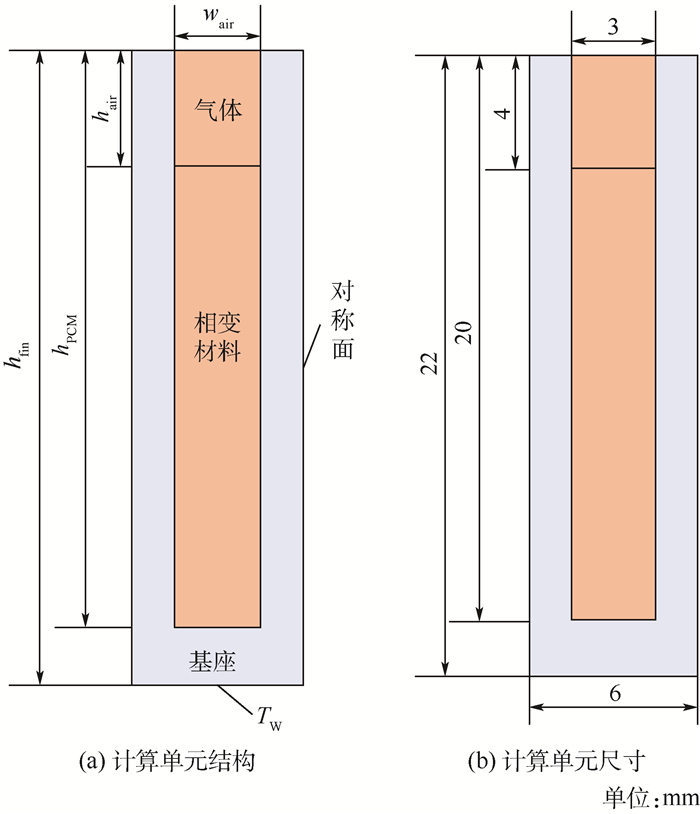

为探究微重力环境中,通过肋片强化了传热的相变储能单元中相变材料融化过程,通过数值模拟方法探究了微重力作用时相变材料融化过程中传热特性。通过地面实验与重力作用下数值模拟结果对比验证数值模拟方法的准确性,对比重力和微重力作用2种情况下数值模拟结果以揭示微重力环境中相变材料融化过程的特性。结果表明,当相变储能单元受微重力作用时,相变材料融化速率明显下降,热量主要通过热传导传递,融化的相变材料从顶端膨胀溢出向空间扩散,局部低温区域在相变储能单元中上部。

Abstract:In order to explore the melting process of phase change materials in the phase change energy storage unit with fins in microgravity environment, the heat transfer and flow characteristics of phase change materials in microgravity environment are investigated by numerical simulation. The accuracy of the numerical simulation was verified by comparing the numerical simulation results and experimental results in gravity environment. The numerical simulation results under both gravity and microgravity effects were compared to reveal the characteristics of the phase change material melt process in microgravity environment. The results show that when the phase change energy storage unit is in microgravity environment, the melting rate of the phase change material obviously decreases, and the heat is mainly transferred by the heat conduction. The expansion of the melted phase change material extends from the top to the space, and the local low temperature zone is in the upper-middle of the phase change energy storage unit.

-

表 1 各物质物性参数

Table 1. Physical parameters of various materials

物质 导热系数/

(W·m-1·K-1)密度/

(kg·m-3)比热/(J·kg-1·K-1) 动力黏度/

(kg·m-1·s-1)相变温度/℃ 相变潜热/

(kJ·kg-1)十八烷 0.1507

2160 0.00346 27~29 244 铝 202.4 2719 871 空气 2.42×10-5 1.2×10-8T2-1.134×10-5+3.498×10-3 1.006 -

[1] 闵桂荣, 郭舜.航天器热控制[M].北京:科学出版社, 1998:320-357.MIN G R, GUO S.Thermal control technology of spacecraft[M]. Beijing:Science Press, 1998:320-357(in Chinese). [2] 王磊, 菅鲁京.相变材料在航天器上的应用[J].航天器环境工程, 2013, 30(5):522-528. doi: 10.3969/j.issn.1673-1379.2013.05.013WANG L, JIAN L J.Application of phase change materials in spacecraft[J]. Spacecraft Environment Engineering, 2013, 30(5):522-528(in Chinese). doi: 10.3969/j.issn.1673-1379.2013.05.013 [3] 侯增祺, 胡金刚.航天器热控制技术原理及其应用[M].北京:中国科学技术出版社, 2007:177-188.HOU Z Q, HU J G.Principle and application of thermal control technology of spacecraft[M]. Beijing:China Science and Technology Press, 2007:177-188(in Chinese). [4] LEIMKUEHLER T O, STEPHAN R A, HANSEN S.Development, testing, and failure mechanisms of a replicative ice phase change material heat exchanger[C]//40th International Conference on Enviromental Systems.Reston: AIAA, 2010: 1-14. [5] LEE S A, LEIMKUEHLER T O, STEPHAN R A, et al.Thermal vacuum test of ice as a phase change material integrated with a radiator[C]//40th International Conference on Enviromental Systems.Reston: AIAA, 2010: 1-10. [6] YE W B, ZHU D S, WANG N.Numerical simulation on phase-change thermal storage/release in a plate-fin unit[J]. Applied Thermal Engineering, 2011, 31(1):3871-3884. [7] YE W B, ZHU D S, WANG N.Fluid flow and heat transfer in a latent thermal energy unit with different phase change material (PCM) cavity volume fractions[J]. Applied Thermal Engineering, 2012, 42(3):49-57. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=JJ0226609061 [8] ISMAIL K A R, ALVES C L F, MODESTO M S.Numerical and experimental study on the solidification of PCM around a vertical axially finned isothermal cylinder[J]. Applied Thermal Engineering, 2001, 21(1):53-77. doi: 10.1016/S1359-4311(00)00002-8 [9] ABDULJALIL A A, MAT S, SOPIAN K, et al.Numerical study of PCM solidification in a triplex tube heat exchanger with internal and external fins[J]. International Journal of Heat and Mass Transfer, 2013, 61(1):684-695. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=JJ0229860515 [10] ASSIS E, KATSMAN L, ZISKIND G, et al.Numerical and experimental study of melting in a spherical shell[J]. International Journal of Heat and Mass Transfer, 2007, 50(9-10):1790-1804. doi: 10.1016/j.ijheatmasstransfer.2006.10.007 [11] ASSIS E, ZISKIND G, LETAN R.Numerical and experimental study of solidification in a spherical shell[J]. Journal of Heat Transfer, 2009, 131(2):273-289. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=JJ028171163 [12] HUMPHRIES W R, GRIGGS E I.A design handbook for phase change thermal control and energy storage devices[M]. New York:NASA Scientific and Technical Information Office, 1977:155-160. [13] BERTRAND O, BINET B, COMBEAU H, et al.Melting driven by natural convection.A comparison exercise:First results[J]. International Journal of Thermal Science, 1999, 38(1):5-26. doi: 10.1016/S0035-3159(99)80013-0 [14] BRENT A D, VOLLER V R, REID K J.Enthalpy-porosity technique for modeling convection-diffusion phase change:Application to the melting of a pure metal[J]. Numerical Heat Transfer, 1988, 13(3):297-318. doi: 10.1080/10407788808913615 [15] SHATIKIAN V, ZISKIND G, LETAN R.Numerical investigation of a PCM-based heat sink with internal fins[J]. International Journal of Heat and Mass Transfer, 2005, 48(17):3689-3706. doi: 10.1016/j.ijheatmasstransfer.2004.10.042 -

下载:

下载: