-

摘要:

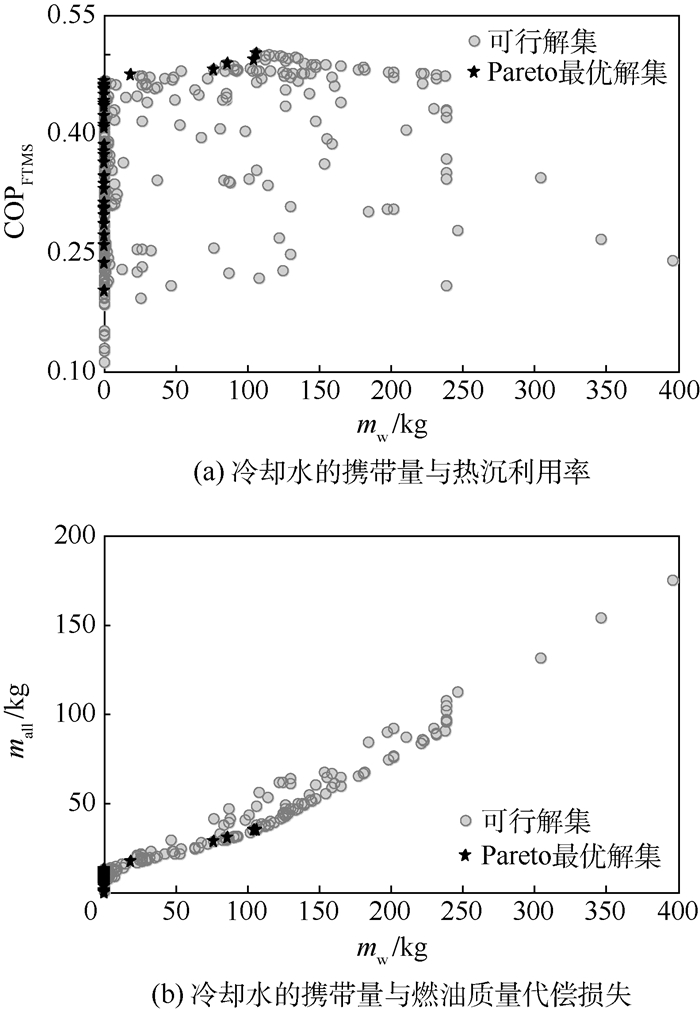

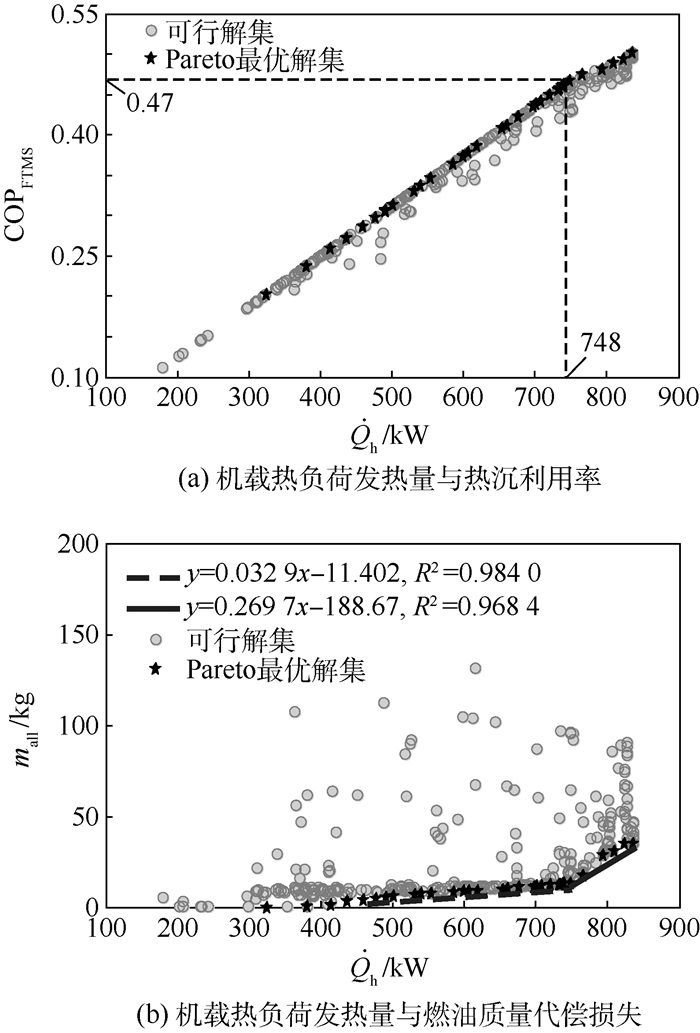

燃油热管理系统设计随着运载器多电化与机载高能电子设备的发展已经得到高度重视,其中燃油的热承载能力是最关键因素。针对喷气推进式高速运载器,提出了一种大范围、多任务的燃油热管理系统多目标优化配置方法,其以热沉利用率最高和燃油质量代偿损失最小为目标函数,以循环回路的燃油最大质量流量、冷却水携带量和机载热负荷发热量为优化变量,采用改进的遗传算法NSGA-Ⅱ,在不同飞行任务规划下进行双目标优化设计,所获得的目标函数Pareto最优解集,满足预期的燃油热管理系统模式选择原则,且通过分析优化变量与优化目标间的相关性,可以量化燃油热管理系统优化配置准则与可达到的最小燃油质量代偿损失,可应用于支持多热沉重构的机载高效燃油热管理系统。

Abstract:With the rapid development of multi-electrification of aircraft and airborne high-energy electronic equipment, the design of fuel heat management system has been paid great attention to. The most critical factor is the thermal load capacity of fuel. For jet propulsion high-speed aircraft, this paper presents a multi-objective optimal allocation method for a large-scale and multi-task fuel heat management system. The thermal carrying capacity of fuel decreases with the increase of flight time, due to the dual effect of airborne thermal load and aerodynamic heating. In this paper, the improved genetic algorithm NSGA-Ⅱ is used to optimize the design of two targets under different flight mission planning. The objective function is heat sink efficiency and fuel compensation loss. The optimization variables are the maximum flow rate of the fuel cycle, the consumption of coolant and the heat load on board. The objective function Pareto optimal solution set is obtained to meet the expected model selection principle of the fuel heat management system. By analyzing the correlation between the optimized variable and the optimization target, the optimization configuration criterion and the minimum fuel compensation loss can be quantified, and the airborne efficient heat management system supporting the multiple heat sink reconstruction is designed.

-

Key words:

- high-speed aircraft /

- heat management system /

- fuel heat sink /

- flight time length /

- expendable coolant

-

表 1 燃油热管理系统多目标优化配置仿真参数

Table 1. Simulation parameters for multi-objective optimal configuration of fuel heat management system

参数 数值 仿真时间τdesign/s 4 200 仿真步长Δτ/s 2 升阻比K 4.62 油箱侧壁面积A1/m2 94.5 油箱底面面积A2/m2 46.25 燃油泵增压ΔP/Pa 1 000 油箱壁面发射率ε 0.9 油箱外壁面厚度δ3/mm 1.2 燃油初始质量m0/kg 23 560 燃油初始温度T0/℃ 20 冷却水初始温度Tw, 0/℃ 20 冷却水饱和温度Tsat/℃ 60 燃油泵效率η 0.8 油箱内壁面厚度δ1/mm 1.2 表 2 NSGA-Ⅱ算法参数设定

Table 2. NSGA-Ⅱ algorithm parameter setting

参数 设定值 种群个数 10 种群代数 100 交叉概率 0.9 实数向量变异概率 1.0 二进制字符串变异概率 1.0 实数交叉分配指数 20 实数变异分配指数 20 -

[1] MAHEFKEY T, YERKES K, DONOVAN B, et al.Thermal management challenges for future military aircraft power systems[C]//Power Systems Conference.Warrendale, PA: SAE International, 2004: 3204. [2] VAN GRIETHUYSEN V J, GLICKSTEIN M R, PETLEY D H, et al.High-speed flight thermal management[M]//MURTHY S N B, CURRAN E T.Developments in high-speed vehicle propulsion.Reston: AIAA, 1996, 165: 517-579. [3] DOOLEY M, LUI N, NEWMAN R, et al.Aircraft thermal managementheat sink challenge[C]//SAE 2014 Aerospace Systems and Technology Conference.Warrendale, PA: SAE International, 2014: 2193. [4] GANEV E, KOERNER M.Power and thermal management for future aircraft[C]//SAE 2013 AeroTech Congress & Exhibition. Warrendale, PA: SAE International, 2013: 2273. [5] FISCHER A.Design of a fuel thermal management system for long range air vehicles: AIAA-2005-5647[R].Reston: AIAA, 2005. [6] YU S, GANEV E.Next generation power and thermal management system[J].SAE International Journal of Aerospace, 2009, 1(1):1107-1121. [7] DOOLEY M, LUI C, NEWMAN R.Efficient propulsion, power, and thermal management integration[C]//49th AIAA/ASME/SAE/ASEE Joint Propulsion Conference.Reston: AIAA, 2013: 1-8. [8] SPROUSE J.F-22 environmental control/thermal management fluid transport optimization[C]//30th Internationnal Conference on Environmental Systems.Warrendale, PA: SAE International, 2000: 2266. [9] 高峰, 袁修干.高性能战斗机燃油热管理系统[J].北京航空航天大学学报, 2009, 35(11):1353-1356.GAO F, YUAN X G.Fuel thermal management system of high performance fighter aircraft[J].Journal of Beijing University of Aeronautics and Astronautics, 2009, 35(11):1353-1356(in Chinese). [10] BLACKBIRD H, FLIGHT A S. SR-71 flight manual[EB/OL].SR-71 Online, 2001: 1-57[2001-12-11]. [11] EDWARDS T.Liquid fuels and propellants for aerospace propulsion:1903-2003[J].Journal of Propulsion and Power, 2003, 19(6):1089-1107. doi: 10.2514/2.6946 [12] LAMM F P, VANDERSPURT T H.Catalytic fuel deoxy-genation system: US20060196174[P].2006-09-07. [13] MORRIS R, MILLER J, LIMAYE S.Fuel deoxygenation and aircraft thermal management[C]//International Energy Conversion Engineering Conference and Exhibit. Reston: AIAA, 2006: 26-29. [14] RHEAUME J, CORDATOS H.Fuel deoxygenation systems: US 20180016025[P].2018-01-18. [15] LETLOW J T, JENKINS L C.Development of an integrated environmental control system[C]//International Conference on Environmental Systems.Warrendale, PA: SAE International, 1998: 981544. [16] DOMAN D B.Fuel flow topology and control for extending aircraft thermal endurance[J].Journal of Thermophysics and Heat Transfer, 2018, 32(1):35-50. [17] ROUKIS J G, BOCCHICCHIO R L.The performance of the water bubbler heat sink for the EF-111 aircraft[C]//ASME 7th Intersociety Conference on Environmental Systems.New York: ASME, 1977: 1-5. [18] HARRISON W E, BINNS K E, ANDERSON S D, et al.High heat sink fuels for improved aircraft thermal management[C]//International Conference on Environmental Systems.Warrendale, PA: SAE International, 1993: 932084. [19] HO Y H, LIN T, HILL B, et al.Thermal benefits of advanced integrated fuel system using JP-8+100 fuel[C]//World Aviation Congress.Warrendale, PA: SAE International, 1997: 975507. [20] DEB K, PRATAP A, AGARWAL S, et al.A fast and elitist multiobjective genetic algorithm:NSGA-Ⅱ[J].IEEE Transactions on Evolutionary Computation, 2002, 6(2):182-197. doi: 10.1109-4235.996017/ -

下载:

下载: