Robust design method for mechanical characteristics of power turbine rotor structural system

-

摘要:

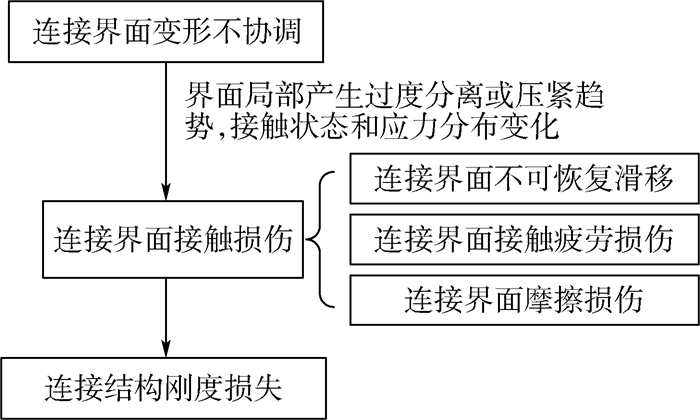

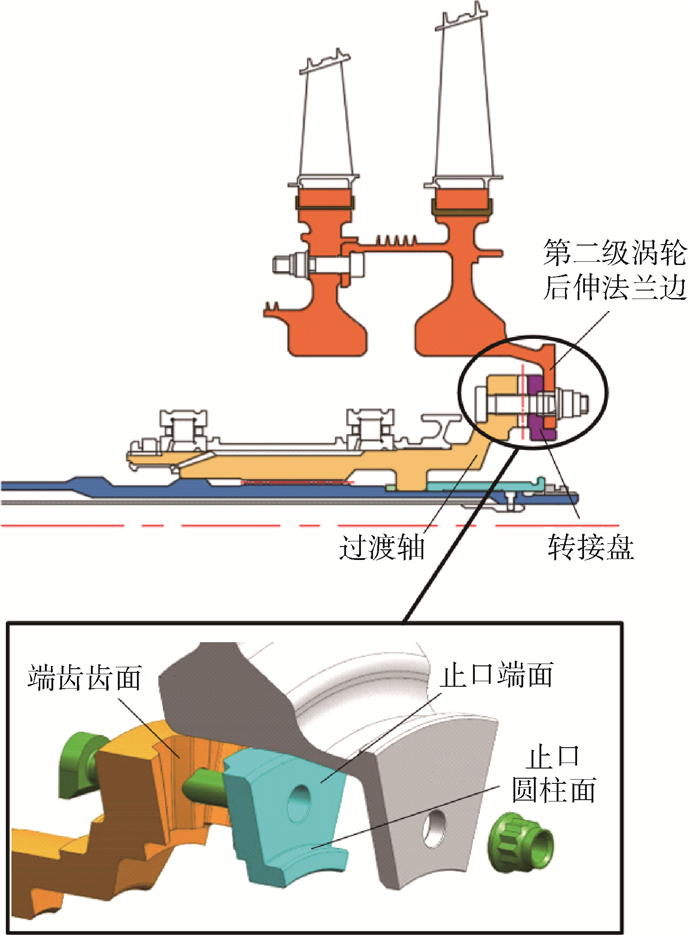

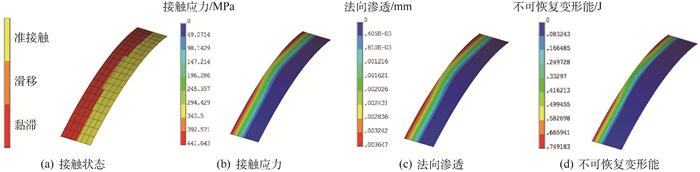

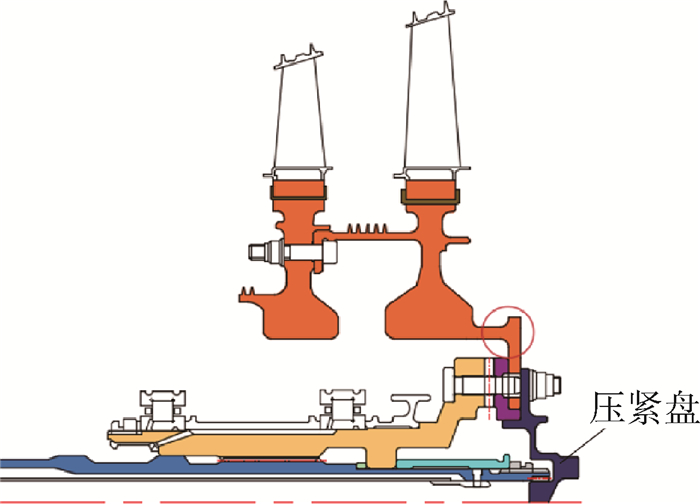

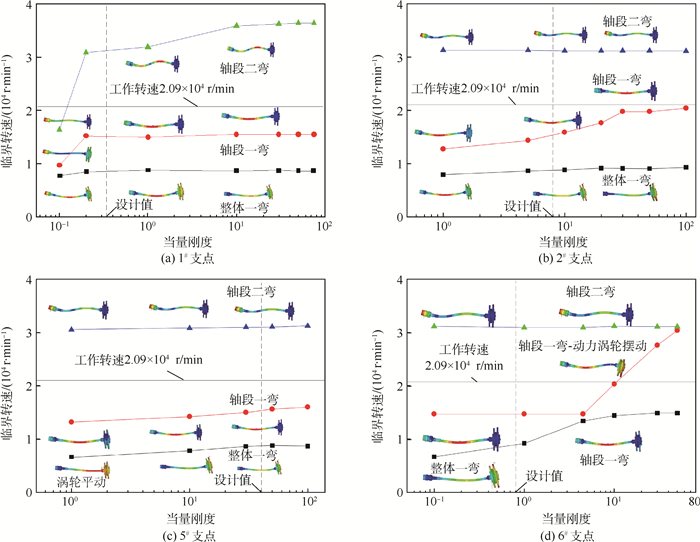

航空涡轴/涡桨发动机动力涡轮转子是典型多支点支承、具有连接界面、质量/刚度分布不均匀的高速柔性转子系统,其连接结构力学特性和支承刚度的分散性可导致转子系统动力特性恶化。针对典型动力涡轮转子结构系统,指出不可恢复滑移、疲劳、摩擦等连接界面接触损伤是连接结构力学特性产生分散性的内在原因,提出了接触状态系数、接触应力、不可恢复变形能和接触摩擦功等工程适用的定量评估参数。通过对多支点柔性转子-支承系统临界转速分布及其对各支点支承刚度敏感度的影响规律分析,提出了基于支承刚度低敏感区择优的动力特性稳健设计方法,所提方法提高了转子结构系统的稳健性。

Abstract:The power turbine rotor of aero turbojet engine and turboprop engine is a typical high-speed flexible rotor structural system with multi-support, connecting interface and uneven mass/stiffness distribution. The dispersity of mechanical characteristics of joint structure and bearing stiffness can cause the dynamic cha-racteristics of the rotor structural system to deteriorate. According to the typical power turbine rotor structural system, it is pointed out that the interface contact damage, such as non-recoverable slip, fatigue and friction, is the intrinsic reason for the dispersity of the mechanical properties of the connecting structure, and the quantitative evaluation parameters including contact state coefficient, contact stress, non-recoverable deformation energy and contact friction work are put forward. Based on the analysis of the critical speed distribution of multi-support flexible rotor-bearing system and its influence on the stiffness sensitivity of each support, a robust design method of dynamic characteristics based on the selection of the low-sensitivity region of support stiffness is proposed, which improves the robustness of the rotor structure system.

-

Key words:

- robust design /

- connecting interface /

- contact damage /

- bearing stiffness /

- rotor system

-

表 1 装配状态下端齿和止口端面接触状态系数和应力分布统计

Table 1. Statistical analysis of contact state coefficient and stress distribution of and tooth and end face of rabbet in assembly condition

连接界面 接触状态系数/% 最大接触应力/

MPa平均接触应力/

MPa黏滞 滑移 准接触 端齿齿面

(靠近螺栓孔)58.0 29.7 12.3 58 43 端齿齿面

(远离螺栓孔)78.5 21.5 — 180 90 止口端面 — 53.6 46.4 96 47 表 2 工作转速下端齿和止口端面接触状态系数和应力分布统计

Table 2. Statistical analysis of contact state coefficient and stress distribution of end tooth and end face of rabbet at working speed

连接界面 接触状态系数/% 最大接触应力/

MPa平均接触应力/

MPa黏滞 滑移 准接触 端齿齿面

(靠近螺栓孔)64.8 24.0 11.2 183 42 端齿齿面

(远离螺栓孔)10.8 3.9 85.3 146 35.8 止口端面 — 56.9 43.1 170 39 -

[1] 洪杰, 马艳红, 张大义.航空燃气轮机总体结构设计与动力学分析[M].北京:北京航空航天大学出版社, 2014:436.HONG J, MA Y H, ZHANG D Y.Structure design and dynamic analysis of aero gas turbine engines[M].Beijing:Beihang University Press, 2014:436(in Chinese). [2] 付才高, 郑大平, 欧园霞.航空发动机设计手册第19册:转子动力学及整机振动[M].北京:航空工业出版社, 2000.FU C G, ZHENG D P, OU Y X.Aero engine design manual 19th:Rotordynamics and whole engine vibration[M].Beijing:Aviation Industry Press, 2000(in Chinese). [3] TRUMAN C E, BOOKER J D.Analysis of a shrink-fit failure on a gear hub/shaft assembly[J].Engineering Failure Analysis, 2007, 14(4):557-572. doi: 10.1016/j.engfailanal.2006.03.008 [4] WANG J, KANG J, TANG L.Theoretical and experimental studies for wind turbine's shrink disk[J].Proceedings of the Institution of Mechanical Engineers, Part C:Journal of Mechanical Engineering Science, 2014, 229(2):325-334. [5] 洪杰, 徐筱李, 梁天宇, 等.转子结构系统界面失效分析及稳健设计方法[J].航空动力学报, 2018, 33(3):649-656.HONG J, XU X L, LIANG T Y, et al.Interface failure analysis and robust design methodology in rotor structural system[J].Journal of Aerospace Power, 2018, 33(3):649-656(in Chinese). [6] 尹泽勇, 欧圆霞, 李彦, 等.端齿轴段刚度及其对转子动力特性的影响[J].振动工程学报, 1993, 6(1):63-67. http://www.cnki.com.cn/Article/CJFDTOTAL-ZDGC199301010.htmYIN Z Y, OU Y X, LI Y, et al.Stiffness of a shaft section with end tooth and its effect on dynamic characteristic of a rotor[J].Journal of Vibration Engineering, 1993, 6(1):63-67(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-ZDGC199301010.htm [7] WANG C, ZHANG D, ZHU X, et al.Study on the stiffness loss and the dynamic influence on rotor system of the bolted flange joint[C]//ASME Turbo Expo 2014: Turbine Technical Conference and Exposition.New York: ASME, 2014: V07AT31A020. [8] QIN Z, HAN Q, CHU F.Bolt loosening at rotating joint interface and its influence on rotor dynamics[J].Engineering Failure Analysis, 2016, 59:456-466. doi: 10.1016/j.engfailanal.2015.11.002 [9] SHIAU T N, HWANG J L.Minimum weight design of a rotor bearing system with multiple frequency constraints[J].Journal of Engineering for Gas Turbines and Power, 1988, 110(4):592-599. doi: 10.1115/1.3240176 [10] LIN Y H, LIN S C.Optimal weight design of rotor systems with oil-film bearings subjected to frequency constraints[J].Finite Elements in Analysis and Design, 2001, 37(10):777-798. doi: 10.1016/S0168-874X(00)00072-X [11] SHIAU T N, CHANG J R.Multiobjective optimization of rotor-bearing system with critical speeds constraints[J].Journal of Engineering for Gas Turbines and Power, 1991, 2(2):246-255. [12] STOCKI R, SZOLC T, TAUZOWSKI P, et al.Robust design optimization of the vibrating rotor-shaft system subjected to selected dynamic constraints[J].Mechanical Systems and Signal Processing, 2012, 29:34-44. doi: 10.1016/j.ymssp.2011.07.023 [13] 杨隽, 臧朝平, 刘永泉, 等.基于Taguchi方法的转子系统动力学容差设计[J].航空动力学报, 2014, 29(7):1583-1590.YANG J, ZANG C P, LIU Y Q, et al.Taguchi method based to-lerance design for rotor system dynamics[J].Journal of Aerospace Power, 2014, 29(7):1583-1590(in Chinese). [14] 陈立周.稳健设计[M].北京:机械工业出版社, 2000.CHEN L Z.Robust design[M].Beijng:China Machine Press, 2000(in Chinese). [15] 于欢, 马艳红, 肖森, 等.高速柔性转子支承松动力学特征及动力特性[J].北京航空航天大学学报, 2017, 43(8):1677-1683.YU H, MA Y H, XIAO S, et al.Mechanical and dynamic cha-racteristics of bearing with looseness on high-speed flexible rotor[J].Journal of Beijing University of Aeronautics and Astronautics, 2017, 43(8):1677-1683(in Chinese). 期刊类型引用(4)

1. 杨海,韩卓荦,王永锋,邓旺群,洪杰. 弹性环支承阻尼结构对悬臂动力涡轮转子动力学影响研究. 战术导弹技术. 2025(01): 75-82+93 .  百度学术

百度学术2. 白忠恺,孙凯,付仲议,杨哲夫,洪杰. 高转速动力涡轮盘间螺栓连接结构稳健性分析. 燃气涡轮试验与研究. 2024(02): 55-62 .  百度学术

百度学术3. 张占领,张艳琴,郭怀宫. 高效率镁合金轮毂压铸件大批量化生产工艺研究. 铸造. 2022(06): 694-697 .  百度学术

百度学术4. 乔乔,李晓秀,周江伟,金福艺. 螺栓连接预紧力对结构疲劳性能的影响. 失效分析与预防. 2021(03): 166-172 .  百度学术

百度学术其他类型引用(5)

-

下载:

下载:

百度学术

百度学术