-

摘要:

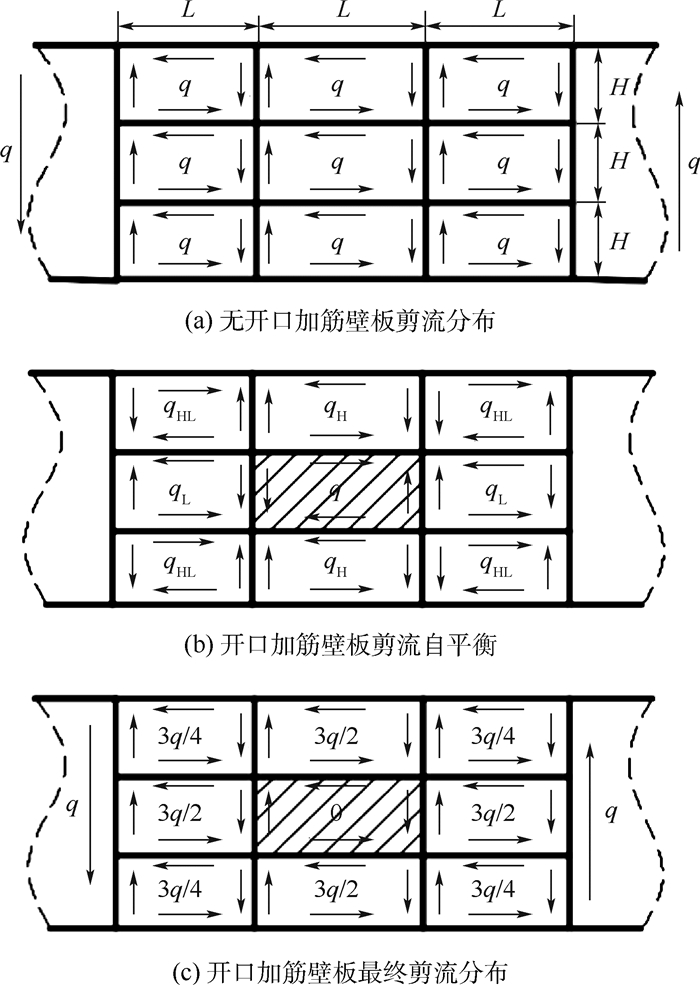

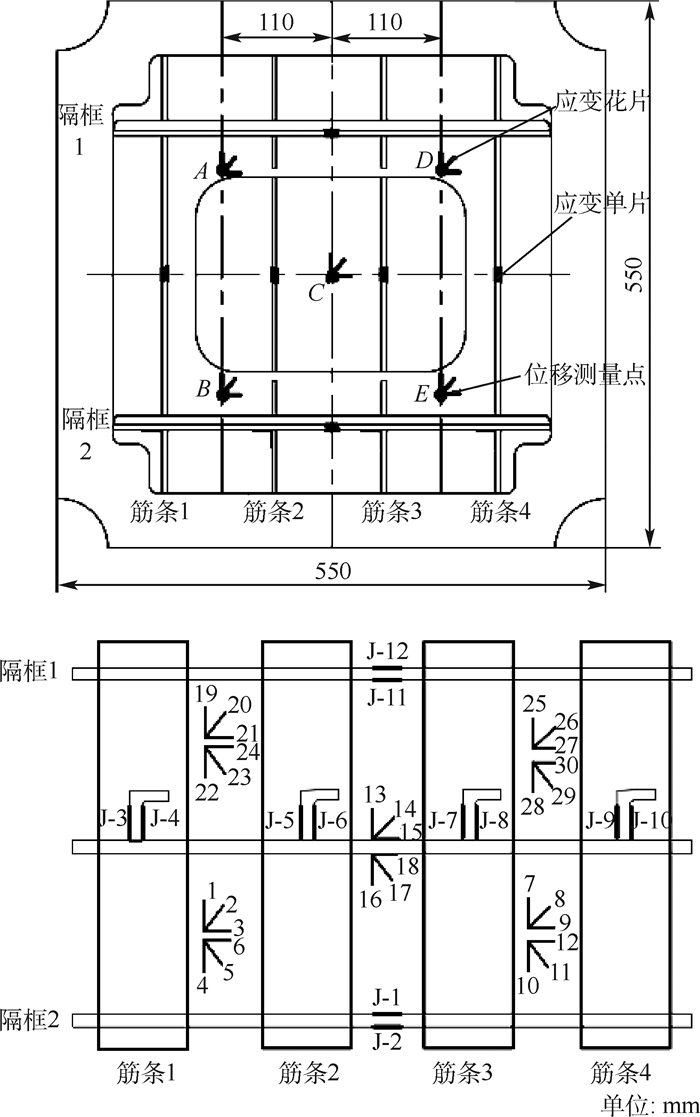

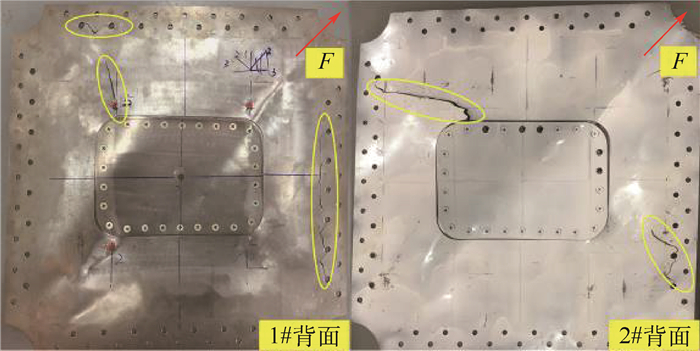

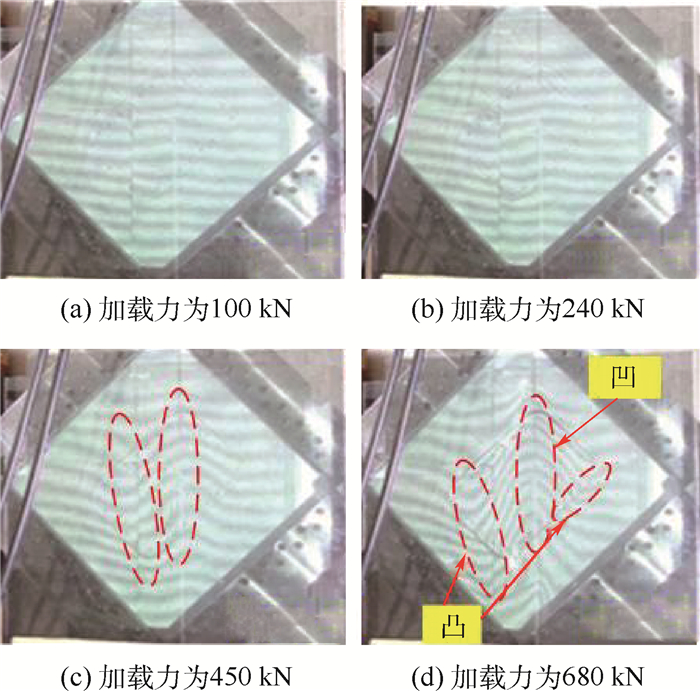

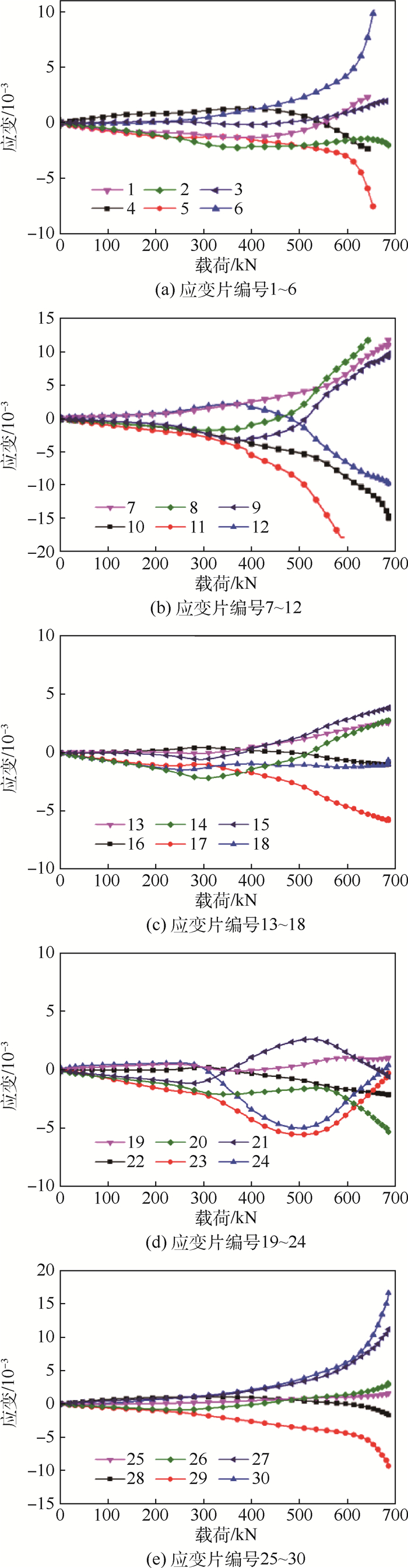

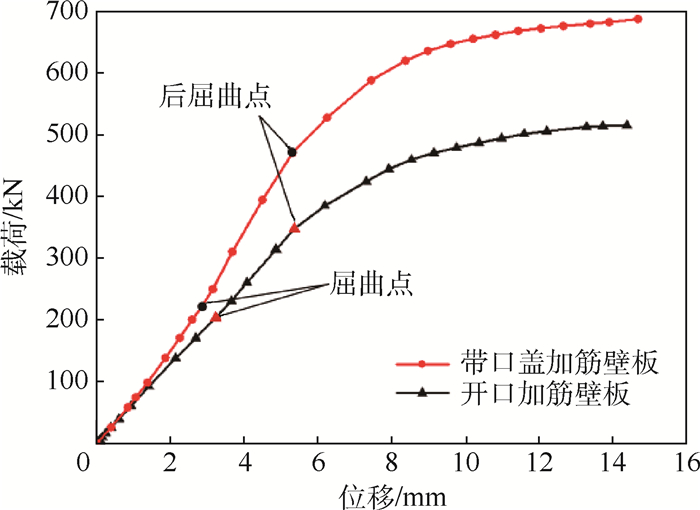

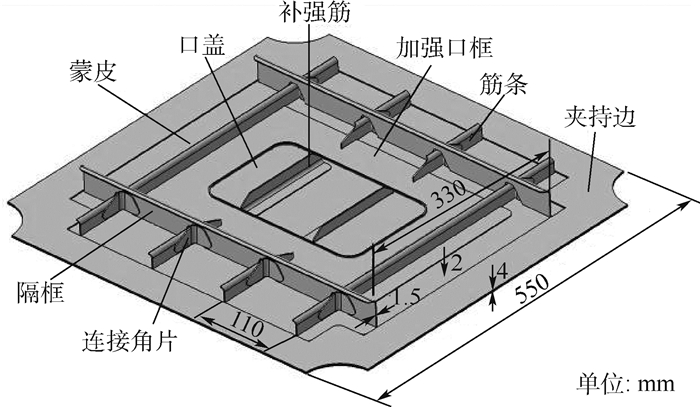

针对双光束激光焊接带口盖加筋壁板开展了剪切稳定性试验,分析了带口盖加筋壁板在受剪状态下的屈曲载荷、屈曲形式、后屈曲承载能力及破坏形式。建立了壁板与剪切夹具的有限元模型,对壁板的剪切失稳形式及后屈曲承载能力进行仿真计算,并探究了口盖对加筋壁板的承载能力、应力变化及面外变形的影响。结果表明:带口盖加筋壁板在剪切状态下,当屈曲比达到1.95时,加筋壁板进入后屈曲,最终破坏载荷约为屈曲载荷的2.98倍。仿真与试验得到的载荷-位移曲线较为吻合,有限元法得到的屈曲载荷和破坏载荷与试验平均值误差分别为8.7%、1.02%。开口壁板的承载能力及刚度均下降,螺栓紧固口盖对加筋壁板的应力与面外变形影响较大。

Abstract:Shear stability test was carried out on the dual beam laser welding stiffened panel with cover. The buckling load, buckling form, post-buckling carrying capacity and failure modes of the stiffened panel with cover under shear loading were analyzed. A finite element method was utilized to model the stiffened panel and shear fixture. Simulation calculation of shear instability modes and post-buckling carrying capacity of stiffened panel. Meanwhile, the effects of cover on the carrying capacity, stress distribution and deformation of cutout stiffened panels were investigated. The results show that, in the sheared state of the stiffened panel with cover, when the buckling ratio reaches 1.95, the stiffened panel enters into post-buckling and the final failure load is approximately 2.98 times the buckling load. The load-displacement curves obtained from simulation and test are in good agreement, and the errors for the buckling loads and failure loads obtained from the numerical calculations compared with the test average value are 8.7% and 1.02%, respectively. The rigidity and load-carrying capacity of open stiffened panel reduce, and the bolt fastening cover has a great influence on the stress and out-of-plane deformation.

-

Key words:

- stiffened panel /

- cover /

- shear loading /

- finite elements /

- buckling property

-

表 1 带口盖钛合金加筋壁板剪切试验结果

Table 1. Test results of titanium alloy stiffened panel with cover under shear loading

kN 试件编号 屈曲载荷 后屈曲载荷 破坏载荷 1# 240 451 687 2# 220 447 685 平均值 230 449 686 表 2 试验平均值与有限元法计算值比较

Table 2. Comparison of test average values and calculated values by finite element method

方法 屈曲载荷/kN 后屈曲载荷/kN 破坏载荷/kN 试验 230 449 686 有限元法 250 490 693 相对误差/% 8.7 9.1 1.02 表 3 带口盖加筋壁板与开口加筋壁板对比

Table 3. Comparison of stiffened panel with cover and cutout stiffened panel

壁板 屈曲载荷/kN 后屈曲载荷/kN 破坏载荷/kN 带口盖加筋壁板 250 490 693 开口加筋壁板 220 340 505 下降比/% 12 30.6 27.1 -

[1] JUN S M, HONG C S.Buckling behavior of laminated composite cylindrical panels under axial compression[J].Computers & Structures, 1988, 29(3):479-490. [2] 王平安.复合材料加筋板在剪切载荷下的屈曲与后屈曲研究[D].西安: 西北工业大学, 2007: 3-4.WANG P A.Buckling and post-buckling of composite stiffened plates under shear load[D].Xi'an: Northwestern Polytechnical University, 2007: 3-4(in Chinese). [3] 刘从玉.复合材料加筋板的屈曲后屈曲分析及承载能力研究[D].南京: 南京航空航天大学, 2009: 1-3.LIU C Y.Post-buckling buckling analysis and bearing capacity of composite stiffened plates[D].Nanjing: Nanjing University of Aeronautics and Astronautics, 2009: 1-3(in Chinese). [4] 牛春匀.实用飞机结构工程设计[M].北京:航空工业出版社, 2008:205-210.NIU C Y.Airframe structural design[M].Beijing:Aviation Industry Press, 2008:205-210(in Chinese). [5] ANKUR J, LAKSHMI P, GIRISH K E.Damage tolerance evaluation of a stiffened panel with a passenger window cutout of a transport airframe fuselage structure[J].International Journal of Engineering Development and Research, 2014, 2(2):1598-1609. [6] KUSUGAL S, KADADEVARMATH R S, MALLAPUR D G.Stress and damage tolerance analysis of stiffened panel with passenger door cutout in airframe structure using FEA[J].Materials Today Proceedings, 2017, 4(10):10696-10703. doi: 10.1016/j.matpr.2017.08.016 [7] SAAD-ELDEEN S, GARBATOV Y, SOARES C G.Experimental compressive strength analyses of high tensile steel thin-walled stiffened panels with a large lightening opening[J].Thin-Walled Structures, 2017, 113:61-68. doi: 10.1016/j.tws.2017.01.005 [8] 吴存利, 段世慧, 孙侠生, 等.一种简易实用的开口剪切腹板有限元建模方法[J].机械强度, 2011, 33(4):613-617.WU C L, DUAN S H, SUN X S, et al.New concise finite element modeling method of shearing plate with cutout[J].Journal of Mechanical Strength, 2011, 33(4):613-617(in Chinese). [9] 郭瑜超, 聂小华, 吴存利, 等.机翼典型开口加筋壁板承载能力研究[J].强度与环境, 2016, 43(3):9-16. doi: 10.3969/j.issn.1006-3919.2016.03.002GUO Y C, NIE X H, WU C L, et al.Study on carrying capacity of wing stiffened panel with typical opening[J].Structure & Environment Engineering, 2016, 43(3):9-16(in Chinese). doi: 10.3969/j.issn.1006-3919.2016.03.002 [10] 程超.弯剪载荷下薄壁梁屈曲与后屈曲的结构参数化研究[D].哈尔滨: 哈尔滨工业大学, 2015: 22-30.CHENG C.Research of structural parameters on buckling and post-buckling for thin-walled beams under bending and shearing load[D].Harbin: Harbin Institute of Technology, 2015: 22-30(in Chinese). [11] 郭俊, 关志东, 黎增山, 等.带口盖加筋复合材料壁板剪切性能[J].复合材料学报, 2016, 33(2):399-407.GUO J, GUAN Z D, LI Z S, et al.Shear properties of composite stiffened panel with cover[J].Acta Materiae Compositae Sinicat, 2016, 33(2):399-407(in Chinese). [12] GUO J, GUAN Z D, QIU C.Buckling response of reinforce composite stiffened panel with cover in shear load[C]//2015 International Conference on Material Engineering and Mechanical Engineering.Singapore: World Scientific Publishing Co.Pte.Ltd., 2016: 682-696. [13] 袁伟, 王志瑾.受剪复合材料层合板开口应力应变分析研究[J].飞机设计, 2010, 30(3):11-17. doi: 10.3969/j.issn.1673-4599.2010.03.003YUAN W, WANG Z J.Study of stress and strain for composite laminated plates with cutout subjected to shear load[J].Aircraft Design, 2010, 30(3):11-17(in Chinese). doi: 10.3969/j.issn.1673-4599.2010.03.003 [14] 袁伟.开口对受剪复合材料层合板受力特性影响的研究[D].南京: 南京航空航天大学, 2009: 22-49.YUAN W.Research on mechanical characteristics for composite laminated plates with cutouts subjected to shear load[D].Nanjing: Nanjing University of Aeronautics and Astronautics, 2009: 22-49(in Chinese). [15] 柳醉.民用飞机机身中等开口结构的设计与研究[J].民用飞机设计与研究, 2014(2):62-65. doi: 10.3969/j.issn.1674-9804.2014.02.018LIU Z.The design and research of the middle-size cutout fuselage structure for civil aircraft[J].Civil Aircraft Design & Research, 2014(2):62-65(in Chinese). doi: 10.3969/j.issn.1674-9804.2014.02.018 -

下载:

下载: