-

摘要:

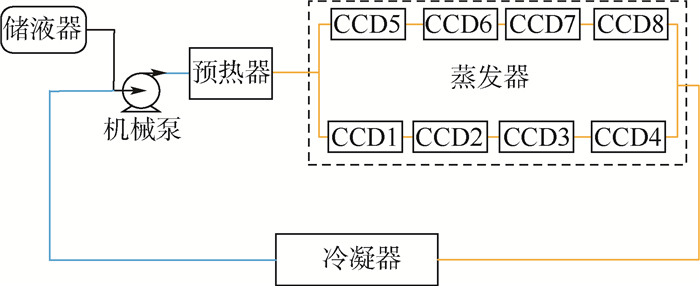

电荷耦合元件(CCD)作为航天光学遥感器的核心部件之一,其工作性能受温度影响很大,传统的热控产品难以满足大功率CCD的精密控温需求。通过仿真与试验系统研究了机械泵驱动两相流体回路(MPTL)用于CCD控温时的启动特性、运行状态、内部工质的流动及传热特性。结果表明:MPTL可以通过干度的调节来吸收冷凝器外热流和CCD工作模式的影响;MPTL的控温精度可以达到±1℃,蒸发器并联支路、蒸发器负载和冷凝器温度在一定范围内变化等均不会对系统运行稳定性产生影响,其仍可将CCD器件控制在所需温度;通过仿真与试验对比,发现仿真模型的误差在±1℃以内,验证了模型的有效性和准确度。MPTL可以很好地满足航天光学遥感器CCD的控温要求,能够保证CCD始终具有较好的温度稳定性和均匀性,且系统具有良好的运行特性和鲁棒性,其在CCD精密控温方面具有很好的应用前景。

-

关键词:

- 电荷耦合元件(CCD) /

- 遥感器热控 /

- 精密控温 /

- 机械泵驱动两相流体回路(MPTL) /

- 两相流动与传热

Abstract:As one of the core components of spaceflight optical remote sensor, the temperature of the charge-coupled device (CCD) will affect the working performance. Therefore, traditional thermal control products have gradually been difficult to meet the needs of high-power CCD precise temperature control. In this paper, the start-up characteristics, operation status, flow and heat transfer characteristics of internal working fluid of mechanically pumped two-phase loop (MPTL) used in temperature control of CCD are studied by simulation and test. The results show that MPTL can absorb the influence of external heat flow of condenser and working mode of CCD by adjusting quality, and the temperature control accuracy of MPTL can reach ±1℃. The parallel branch of the evaporator, the load of the evaporator and the temperature change of the condenser in a certain range will not affect the stability of the system, and the CCD can still be controlled at the required temperature. By comparing the simulation with the experiment, it is found that the error of the simulation model is within ±1℃, which verifies the validity and accuracy of the model. MPTL can satisfy the requirement of temperature control of space optical remote sensor CCD very well. It can ensure that the CCD always has good temperature stability and uniformity, and the system has good operational characteristics and robustness. It has a good application prospect in the precision temperature control of CCD.

-

表 1 验证试验工况

Table 1. Verification test condition

工况 试验项目 试验内容 1 启动特性

验证流体回路启动性能, 验证流体回路内存在气相时系统启动性能2 控温特性 验证蒸发器温度随储液器温度变化的响应能力 3 运行特性 验证蒸发器并联支路对系统运行特性的影响, 验证冷凝器温度波动对系统运行特性的影响 -

[1] 赵英时.遥感应用分析原理与方法[M].北京:科学出版社, 2002.ZHAO Y S.Principles and methods of remote sensing application analysis[M].Beijing:Science Press, 2002(in Chinese). [2] 赵振明, 雷文平.环路热管在CCD热设计中的应用[C]//第十二届全国热管会议, 2010: 301-306.ZHAO Z M, LEI W P. Loop heat pipe application in CCD thermal design[C]//12th Chinese Heat Pipe Conference, 2010: 301-306(in Chinese). [3] 童叶龙, 李国强, 余雷, 等.CCD组件的热分析和热试验[J].航天返回与遥感, 2014, 35(5):46-53. doi: 10.3969/j.issn.1009-8518.2014.05.007TONG Y L, LI G Q, YU L, et al. Heat dissipation and precise temperature control for high-power CCD assembly[J].Spacecraft Recovery & Remote Sensing, 2014, 35(5):46-53(in Chinese). doi: 10.3969/j.issn.1009-8518.2014.05.007 [4] 陈恩涛, 卢锷.空间遥感器CCD组件热设计[J].光学精密工程, 2000, 8(6):522-525. doi: 10.3321/j.issn:1004-924X.2000.06.003CHEN E T, LU E. Thermal engineering design of CCD component of space remote-sensor[J]. Optics and Precision Engineering, 2000, 8(6):522-525(in Chinese). doi: 10.3321/j.issn:1004-924X.2000.06.003 [5] GAO T, YANG T, ZHAO S L.The design and application of temperature control loop heat pipe for space CCD camera[C]//International Symposium of Spaces Optical Instrument and Application, 2017: 15-20. [6] DELIL A A M, PAUW A, WOERING A A.AMS-2 tracker thermal control system-design and thermal modeling of the mechanically pumped two-phase CO2 loop: AIAA-2003-345[R].Reston: AIAA, 2003. [7] LIU J, PEI N Q, GUO K H, et al.Experimental investigation on a mechanically pumped two-phase cooling loop with dual-evaporator[J].International Journal of Refrigeration, 2008, 31(7):1176-1182. doi: 10.1016/j.ijrefrig.2008.02.014 [8] ZHANG Z, SUN X H, TONG G N, et al.Stable and self-adaptive performance of mechanically pumped CO2 two-phase loops for AMS-02 tracker thermal control in vacuum[J].Applied Thermal Engineering, 2011, 31:3783-3791. doi: 10.1016/j.applthermaleng.2011.07.015 [9] HUANG Z C, HE Z H, MO D C, et al.Coupling between an accumulator and a loop in a mechanically pumped carbon dioxide two-phase loop[J].Microgravity Science and Technology, 2009, 21(1):23-29. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=fe1639a30b1e312cf0a52f791dd12e3c [10] 刘杰.航天机械泵驱动两相流冷却环路循环特性的研究[D].上海: 上海交通大学, 2008: 115-117. http://d.wanfangdata.com.cn/Thesis/Y1415517LIU J.Investigations on running characteristics of the mechanically pumped two-phase cooling loop for space applications[D].Shanghai: Shanghai Jiao Tong University, 2008: 115-117(in Chinese). http://d.wanfangdata.com.cn/Thesis/Y1415517 [11] VAN ES J, PAUW A, VAN DONK G.AMS02 tracker thermal control cooling system test results of the AMS02 thermal vacuum test in the LSS at ESA ESTEC: AIAA-2012-3577[R].Reston: AIAA, 2012. [12] MO D C, XIAO W J, HUANG Z C, et al.Comparison of pressure drop between calculation and experiment for a two-phase carbon dioxide loop[J].Microgravity Science and Technology, 2008, 20(3-4):183-186. doi: 10.1007/s12217-008-9019-2 [13] SUN X H, HE Z H, HUANG Z C, et al.Analysis of temperature oscillations in parallel evaporators of a carbon dioxide two-phase loop[J].Microgravity Science and Technology, 2009, 21(Supl 1):299-304. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=cb55f4ff633042adfc554e01fea151fc [14] KU J T.Operating characteristics of loop heat pipes[C]//29th International Conference on Environmental Systems, 1999: 1991-01-2007. [15] 庄礼贤, 尹协远, 马晖扬.流体力学[M].2版.合肥:中国科学技术大学出版社, 2009:65-89.ZHUANG L X, YIN X Y, MA H Y.Fluid mechanics[M].2nd ed.Hefei:University of Science and Technology of China Press, 2009:65-89(in Chinese). [16] FRIEDEL L.Improved friction pressure drop correlation for horizontal and vertical two-phase pipe flow[C]//European Two-Phase Flow Group Meeting, 1979: 1158-1162. [17] MENG Q L, YANG T, LI C L, et al.Numerical simulations and analyses of temperature control loop heat pipe for space CCD camera[J].Journal of Thermal Science, 2016, 25(5):402-409. doi: 10.1007/s11630-016-0877-4 -

下载:

下载: