Acquisition and analysis of aluminum alloy property in thermal environment based on biaxial tension

-

摘要:

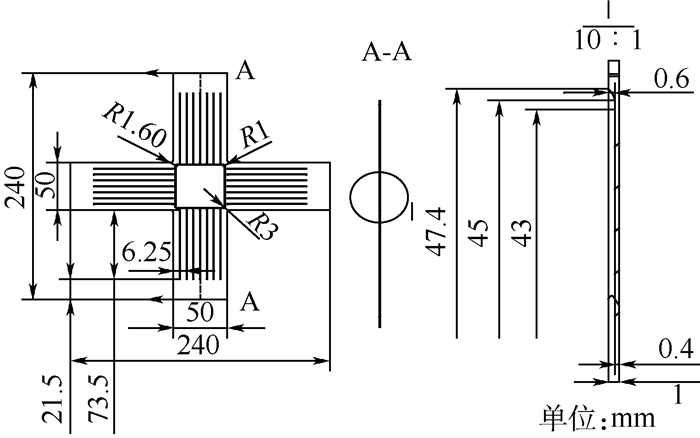

板材成形加工时通常承受复杂载荷,一般采用单拉试验获取材料性能,由于材料变形时仅承受单向载荷,与实际情况差距较大。为获取更加真实的复杂加载时材料性能,通过十字形试件双向拉伸试验,研究了热环境双向变比例加载时AA6016铝合金材料力学性能和变形行为,包括优化设计十字形试件、相关试验方法和设备以及结果分析等。在25、150和250℃温度下进行了拉伸速率比例为1:1、3:2、2:3、1:3和3:1的双向拉伸试验和单向拉伸试验,得到了不同拉伸速率比例和温度下的应力应变关系、屈服规律和各向异性,建立了屈服准则,并且通过与试验结果对比,讨论分析了几个典型屈服准则及其适用性。

Abstract:When sheet metal is forming, it usually bears complex loads. However, uniaxial tension test is usually used to obtain material properties, because the material only bears unidirectional load when deforming, which is far from the actual situation. In order to obtain more real material properties under complex loading, mechanical properties and deformation behavior of AA6016 aluminum alloy material under different stretching rates in thermal environment were studied using biaxial tensile test, including optimized design of cruciform specimen, relevant test method and equipment, analysis of test results, etc. The biaxial tensile tests and uniaxial tensile test were carried out under different temperatures of 25℃, 150℃ and 250℃ and different stretching rate of 1:1, 3:2, 2:3, 1:3 and 3:1. The stress-strain relationship, yield criterion and anisotropy at different tension rate ratios and different temperatures were obtained. Further by comparison with the test results, the several typic yield criteria and their suitability were discussed.

-

Key words:

- thermal environment /

- cruciform specimen /

- optimized design /

- biaxial tension /

- yield criterion

-

表 1 AA6016铝合金各向异性系数

Table 1. Anisotropy coefficient of AA6016 aluminium alloy

T/℃ r0 r45 r90 r 25 0.87 0.46 0.73 0.63 150 1.22 0.65 0.96 0.87 250 1.86 1.03 1.29 1.302 5 注:T为试验温度。 -

[1] SHIRATORI E, IKEGAMI K. A new biaxial tensile testing machine with flat specimen[J].Bulletin of the Tokyo Institute of Technology, 1967, 82(10):5-18. [2] ISO.Metallic materials-sheet and strip-biaxial tensile testing method using a cruciform test piece: ISO 16842: 2014[S].Switzerland: ISO, 2014. [3] MERKLEIN M, BIASUTTI M.Development of a biaxial tensile machine for characterization of sheet metals[J]. Journal of Materials Processing Technology, 2013, 213(6):939-946. doi: 10.1016/j.jmatprotec.2012.12.005 [4] TERRIAULT P, SETTOUANE K, BRAILOVSKI V.Biaxial testing at different temperatures of cruciform Ti-Ni samples[C]//Proceedings of the International Conference on Shape Memory and Superelastic Technologies.New York: ASM International, 2004: 247-257. [5] CHEVALIER L, CALLOCH S, HILD F, et al.Digital image, correlation used to analyze the multiaxial behavior of rubber-like materials[J].European Journal of Mechanics A/Solids, 2001, 20(2):169-187. doi: 10.1016/S0997-7538(00)01135-9 [6] 吴向东.不同加载路径下各向异性板料塑性变形行为的研究[D].北京: 北京航空航天大学, 2004. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y674424WU X D.Research on the plastic deformation behavior of anisotropic sheet metal under different loading paths[D].Beijing: Beihang University, 2004(in Chinese). http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y674424 [7] 万敏, 周贤宾.复杂加载路径下板料屈服强化及成形极限的研究进展[J].塑性工程学报, 2000, 7(2):35-39. doi: 10.3969/j.issn.1007-2012.2000.02.010WAN M, ZHOU X B.Research progress on the yielding hardening and forming limit of sheet metals under complex loading paths[J].Journal of Plasticity Engineering, 2000, 7(2):35-39(in Chinese). doi: 10.3969/j.issn.1007-2012.2000.02.010 [8] SHIRATORI E, IKEGAMI K.Experimental study of the subsequent yield surface by using cross-shaped specimens[J].Journal of the Mechanics and Physics of Solids, 1968, 16(6):373-394. doi: 10.1016/0022-5096(68)90002-1 [9] DEMMERLE S, BOEHLER J P.Optimal design of biaxial tensile cruciform specimens[J].Journal of the Mechanics and Physics of Solids, 1993, 41(1):143-181. doi: 10.1016/0022-5096(93)90067-P [10] 韩非, 万敏, 吴向东.基于极限应力分析的十字形双向拉伸试件设计[J].北京航空航天大学学报, 2007, 33(5):600-604. doi: 10.3969/j.issn.1001-5965.2007.05.023HAN F, WAN M, WU X D.FEM design of cruciform biaxial tensile specimen based on limit stress analysis[J].Journal of Beijing University of Aeronautics and Astronautics, 2007, 33(5):600-604(in Chinese). doi: 10.3969/j.issn.1001-5965.2007.05.023 [11] 洪强.十字形双向拉伸试件有限元优化设计[D].北京: 北京航空航天大学, 2000. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y343006HONG Q.Finite element optimal design of cross shaped double direction drawing specimen[D].Beijing: Beihang University, 2000(in Chinese). http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y343006 [12] MULLER W, POHRANDT K.New experiment for determining yield loci of sheet metal[J].Journal of Materials Processing Technology, 1996, 60:643-648. doi: 10.1016/0924-0136(96)02399-0 [13] SZCZEPINSKI W. Experimental methods in mechanics of solids[M].Amsterdam:Elsevier, 1990. [14] MAKINDE A, THIBODEAU L, NEALE K.Development of an apparatus for biaxial testing using cruciform specimens[J].Experimental Mechanics, 1992, 32(2):138-144. doi: 10.1007/BF02324725 [15] LI D M, GHOSH J L.Biaxial warm forming behavior of aluminum sheet alloys[J].Journal of Materials Processing Technology, 2004, 145(3):281-293. doi: 10.1016/j.jmatprotec.2003.07.003 [16] HANNON A, TIERNAN P.A review of planar biaxial tensile test systems for sheet metal[J]. Journal of Materials Processing Technology, 2008, 198(1-3):1-13. doi: 10.1016/j.jmatprotec.2007.10.015 [17] XIAO R, LI X X, LANG L H, et al.Design of biaxial tensile cruciform specimen based on simulation optimization[C]//Proceedings of the International Conference on Machinery, Materials Engineering, Chemical Engineering and Biotechnology, F, 2016. [18] XIAO R, LI X X, LANG L H, et al.Forming limit in thermal cruciform biaxial tensile testing of titanium alloy[J]. Journal of Materials Processing Technology, 2017, 240(3):54-61. https://www.sciencedirect.com/science/article/pii/S092401361630365X [19] SMITS A, VAN HEMELRIJCK D, PHILIPPIDIS T P, et al.Design of a cruciform specimen for biaxial testing of fibre reinforced composite laminates[J].Composites Science and Technology, 2006, 66(7-8):964-975. doi: 10.1016/j.compscitech.2005.08.011 [20] GREEN D E, NEALE K W, MACEWEN S R, et al.Experimental investigation of the biaxial behaviour of an aluminum sheet[J].International Journal of Plasticity, 2004, 20(8-9):1677-1706. doi: 10.1016/j.ijplas.2003.11.012 [21] 吴向东, 万敏, 王文平.板材等效应力-等效应变曲线的建立及分析[J].材料科学与工艺, 2009, 17(2):236-238. http://www.cnki.com.cn/Article/CJFDTotal-CLKG200902023.htmWU X D, WAN M, WANG W P.Establishment and analysis of equivalent stress-equivalent strain curves of sheetmetal[J]Journal of Materials Science and Technology, 2009, 17(2):236-238(in Chinese). http://www.cnki.com.cn/Article/CJFDTotal-CLKG200902023.htm [22] HILL R.A theory of the yielding and plastic flow of anisotropic metals[J].Proceedings of the Royal Society of London Series A, Mathematical and Physical Sciences, 1948, 193(1033):281-297. doi: 10.1098/rspa.1948.0045 [23] HOSFORD W.A generalized isotropic yield criterion[J].Archive of Applied Mechanics, 1972, 39(2):607-609. doi: 10.1115/1.3422732 [24] BARLAT F, LIAN K.Plastic behavior and stretchability of sheet metals.Part Ⅰ:A yield function for orthotropic sheets under plane stress conditions[J].International Journal of Plasticity, 1989, 5(1):51-66. doi: 10.1016/0749-6419(89)90019-3 [25] LIAN J, BARLAT F, BAUDELET B.Plastic behaviour and stretchability of sheet metals. Part Ⅱ:Effect of yield surface shape on sheet forming limit[J].International Journal of Plasticity, 1989, 5(2):131-147. doi: 10.1016/0749-6419(89)90026-0 -

下载:

下载: