-

摘要:

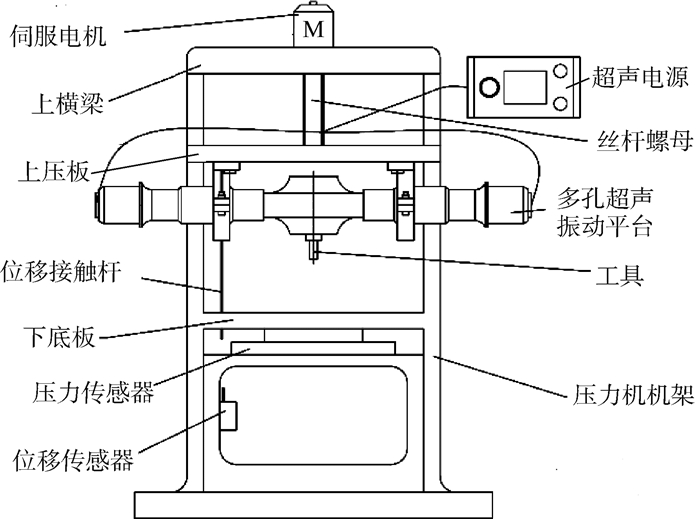

超声辅助塑性成形近年来已经成为塑性成形领域的重要研究方向。为了满足超声辅助塑性成形过程中的超声设备与工件安装需求,在自行研制的多孔超声振动平台基础上,设计开发了10 kN超声辅助塑性成形压力机。采用C++语言和Qt软件平台开发了压力机的控制系统及人机交互界面,并利用该压力机进行了T2紫铜超声应力软化试验和AZ31镁合金超声辅助压缩试验。结果表明,所设计的压力机可满足超声辅助塑性成形需求,工具辅助超声振动可有效改变镁合金的压缩断裂特性。

Abstract:Ultrasonic vibration assisted plastic forming has become an important research direction of plastic forming in recent years. In order to meet the installation requirements of ultrasonic equipments and workpiece, a 10 kN ultrasonic-assisted plastic forming press machine was designed and developed in this paper, which was based on the self-developed porous ultrasonic vibration platform. The control system and human-computer interaction interface of the press machine were designed and developed based on C++ language and Qt software platform. The ultrasonic stress softening test of T2 copper and the ultrasonic vibration assisted compression test of AZ31 magnesium alloy were carried out on the press machine. The experimental results show that the plastic forming press can meet the requirement of ultrasonic-assisted plastic forming. And the tool ultrasonic vibration can change the compression fracture characteristics of magnesium alloy effectively.

-

Key words:

- plastic forming /

- press machine /

- ultrasonic vibration platform /

- control system /

- compression

-

表 1 AZ31镁合金化学成分

Table 1. Chemical constituents of AZ31 magnesium alloy

成分 Al Zn Mn Fe Si Cu Ni Mg 质量分数/% 3.123 0.929 0.385 0.002 0.006 0.002 0.001 平衡 -

[1] 单德彬, 徐杰, 王春举, 等.塑性微成形技术研究进展[J].中国材料进展, 2016, 35(4):251-260. http://d.old.wanfangdata.com.cn/Periodical/zgcljz201604002SHAN D B, XU J, WANG C J, et al.Research progress of plastic microforming technology[J].Progress of Materials in China, 2016, 35(4):251-260(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/zgcljz201604002 [2] LI P Y, HE J, LIU Q, et al.Evaluation of forming forces in ultrasonic incremental sheet metal forming[J].Aerospace Science and Technology, 2017, 63:132-139. doi: 10.1016/j.ast.2016.12.028 [3] LIU S, TIAN Z J, GAO X S, et al.Effect of ultrasonic peening on microstructure and properties of laser rapid forming GH4169[J].Optik, 2018(172):443-448. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=f09e7a0c7ac174e2c75e7a47e982ad76 [4] HAN G C, LI K, PENG Z, et al.A new porous block sonotrode for ultrasonic assisted micro plastic forming[J].International Journal of Advanced Manufacturing Technology, 2017, 89(5-8):2193-2202. doi: 10.1007/s00170-016-9179-y [5] 刘艳雄.超声波辅助大塑性变形细化材料晶粒研究[D].武汉: 武汉理工大学, 2012. http://cdmd.cnki.com.cn/Article/CDMD-10497-1013134732.htmLIU Y X.Study on ultrasound-assisted grain refinement in large plastic deformation[D].Wuhan: Wuhan University of Technology, 2012(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10497-1013134732.htm [6] BUNGET C, NGAILE G.Influence of ultrasonic vibration on micro-extrusion[J].Ultrasonics, 2011, 51(5):606-616. doi: 10.1016/j.ultras.2011.01.001 [7] POPOV V L, STARCEVIC J, FILIPPOV A E.Influence of ultrasonic in-plane oscillations on static and sliding friction and intrinsic length scale of dry friction processes[J].Tribology Letters, 2010, 39(1):25-30. doi: 10.1007/s11249-009-9531-6 [8] TEIDELT E, STARCEVIC J, POPOV V L.Influence of ultrasonic oscillation on static and sliding friction[J].Tribology Letters, 2012, 48(1):51-62. http://cn.bing.com/academic/profile?id=8b8553578af9550452f8cf975dc89a18&encoded=0&v=paper_preview&mkt=zh-cn [9] HUANG Y M, CHANG Y M.The reducing of spring back angle on micro-bending process with ultrasonic assistance[J].Journal of the Chinese Society of Mechanical Engineers, 2014, 35(4):321-325. [10] 崔良玉.聚合物微器件超声微焊接压印工艺研究[D].天津: 天津大学, 2014. http://cdmd.cnki.com.cn/Article/CDMD-10056-1015041159.htmCUI L Y.Study on ultrasonic micro-welding embossing process of polymer microdevices[D].Tianjin: Tianjin University, 2014(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10056-1015041159.htm [11] 李凯辉.金属薄板超声柔性冲头微冲压成形方法应用与质量评估[D].深圳: 深圳大学, 2015. http://cdmd.cnki.com.cn/Article/CDMD-10590-1015419130.htmLI K H.Application and quality evaluation of micro-press forming method for thin metal sheet ultrasonic ultrasonic punch[D].Shenzhen: Shenzhen University, 2015(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10590-1015419130.htm [12] HUANG Z, LUCAS M, ADAMS M J.Influence of ultrasonics on upsetting of a model paste[J].Ultrasonics, 2002, 40(1-8):43-48. doi: 10.1016/S0041-624X(02)00245-7 [13] 付佳伟, 齐乐华, 周计明, 等.微挤压成形系统的设计与实现[J].塑性工程学报, 2010, 17(1):32-35. doi: 10.3969/j.issn.1007-2012.2010.01.008FU J W, QI L H, ZHOU J M, et al.Design and implementation of micro-extrusion forming system[J].Journal of Plastic Engineering, 2010, 17(1):32-35(in Chinese). doi: 10.3969/j.issn.1007-2012.2010.01.008 [14] 王春举, 曲东升, 周健, 等.精密微塑性成形系统的研制[J].锻压技术, 2005(3):56-59. doi: 10.3969/j.issn.1000-3940.2005.03.018WANG C J, QU D S, ZHOU J, et al.Development of precision microplastic forming system[J].Forging Technology, 2005(3):56-59(in Chinese). doi: 10.3969/j.issn.1000-3940.2005.03.018 [15] 李广, 周天丰, 梁志强, 等.超声振动辅助微塑性成形系统设计与开发[J].电加工与模具, 2017(1):44-47. http://d.old.wanfangdata.com.cn/Periodical/djgymj201701009LI G, ZHOU T F, LIANG Z Q, et al.Design and development of ultrasonic vibration assisted microplastic forming system[J].Electrical Processing and Mold, 2017(1):44-47(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/djgymj201701009 [16] 韩光超, 李凯, 王新云, 等.一种双换能器驱动超声振动平台: 201520071898.1[P].2015-07-08.HAN G C, LI K, WANG X Y, et al.An ultrasonic vibration platform driving by two ultrasonic transducers: 201520071898.1[P].2015-07-08(in Chinese). [17] 韩光超, 雷玉兰, 彭卓, 等.一种复合超声振动辅助微挤压成形加工设备: 201710897301.2[P].2017-12-01.HAN G C, LEI Y L, PENG Z, et al.An compound ultrasonic vibration assisted micro-extrusion forming processing equipment: 201710897301.2[P].2017-12-01(in Chinese). [18] 魏丽.超声振动对AZ31镁合金室温塑性变形过程的影响[D].重庆: 重庆大学, 2010. http://cdmd.cnki.com.cn/Article/CDMD-10611-2010217187.htmWEI L.Effects of ultrasonic vibration on plastic deformation of AZ31 magnesium alloy[D].Chongqing: Chongqing University, 2010(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10611-2010217187.htm [19] 曹春虎.镁合金热塑性成形开裂机制研究[D].太原: 中北大学, 2016. http://d.wanfangdata.com.cn/Periodical/D01009895CAO C H.Research on the cracking mechanism of magnesium alloy during hot plastic forming[D].Taiyuan: North University of China, 2016(in Chinese). http://d.wanfangdata.com.cn/Periodical/D01009895 -

下载:

下载: