Formation mechanism of Faraday wave on thin liquid film excited by ultrasonic vibration

-

摘要:

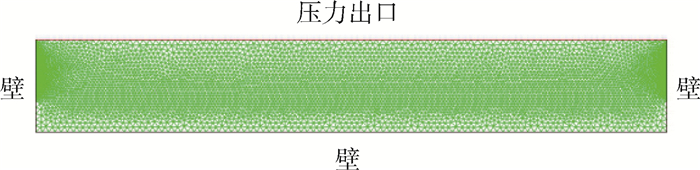

针对35 kHz超声激励薄液膜形成的Faraday波,采用实验和有限元仿真,对Faraday波的形成机理进行探究。建立超声激励下的两相流计算模型,采用计算流体力学(CFD)方法对Faraday波的形成过程进行有限元仿真,通过分析相图和流线图,探讨Faraday波的形成机理,得到Faraday波的振动频率约为超声激励频率的1/2。液体惯性的存在,导致超声激励与液体表面波存在不断变化的相位差,相位差变化周期约等于2个超声激励周期。通过35 kHz超声激励薄液膜实验,在薄液膜表面观察到排列整齐的Faraday波图案,通过测量Faraday波的波长,得出实验获得的Faraday波频率约为超声激励频率的1/2,与有限元仿真结果一致。

-

关键词:

- Faraday波 /

- 超声激励 /

- 薄液膜 /

- 计算流体力学(CFD) /

- 形成机理

Abstract:Aimed at the Faraday wave formed by 35 kHz ultrasonic excitation on thin liquid film, the formation mechanism of Faraday wave was explored by experiments and finite element simulation. The two-phase flow calculation model under ultrasonic excitation was established. The finite element simulation of the formation process of Faraday wave was carried out by CFD method. The formation mechanism of Faraday wave was discussed by analyzing the phase diagram and streamline diagram. The vibration frequency of Faraday wave was about 1/2 of the drive frequency. The existence of liquid inertia resulted in a constantly varying phase difference between the ultrasonic excitation and the liquid surface wave, and the phase difference variation period was about two ultrasonic excitation periods. Through the 35 kHz ultrasonic excitation experiment on thin liquid film, a well-arranged Faraday wave array pattern was observed on the surface of the thin liquid film. By measuring the wavelength of the Faraday wave, it was deduced that the surface wave frequency obtained by the experiment was about 1/2 of the ultrasonic frequency, and consistent with the results of finite element simulation.

-

-

[1] 雷成龙.利用液-固界面效应制备球形金属粉末及其性能研究[D].南京: 南京大学, 2016: 14-25. http://cdmd.cnki.com.cn/Article/CDMD-10284-1016123733.htmLEI C L.Preparation of spherical metal powder by liquid-solid interface effect and its properties[D]. Nanjing: Nanjing University, 2016: 14-25(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10284-1016123733.htm [2] 乐国敏, 李强, 董鲜峰.适用于金属增材制造的球形粉体制备技术[J].稀有金属材料与工程, 2017, 46(4):1162-1168. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=xyjsclygc201704050LE G M, LI Q, DONG X F.Preparation of spherical powders for metal additive manufacturing[J]. Rare Metal Materials and Engineering, 2017, 46(4):1162-1168(in Chinese). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=xyjsclygc201704050 [3] 高正江, 周香林, 李景昊, 等.高性能球形金属粉末制备技术进展[J].热喷涂技术, 2018, 10(3):1-9. doi: 10.3969/j.issn.1674-7127.2018.03.001GAO Z J, ZHOU X L, LI J H, et al.Advances in preparation technology of high performance spherical metal powders[J]. Thermal Spraying Technology, 2018, 10(3):1-9(in Chinese). doi: 10.3969/j.issn.1674-7127.2018.03.001 [4] 张海庆.均匀颗粒成型法(UDS)原理及应用[J].天津冶金, 2001(1):39-40. doi: 10.3969/j.issn.1006-110X.2001.01.011ZHANG H Q.Principle and application of uniform particle forming method (UDS)[J]. Tianjin Metallurgy, 2001(1):39-40(in Chinese). doi: 10.3969/j.issn.1006-110X.2001.01.011 [5] SONG W, SHUMLAK U.Ultrasonically aided electrospray source for charged particles approaching monodisperse distributions[J]. Journal of Propulsion & Power, 2012, 26(2):353-363. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=af7485ec5a8c6a984b978c992594c5f5 [6] FARADAY M.On the forms and states of fluids on vibrating elastic surfaces[J]. Proceedings of the Royal Society of London, 1831, 121:299-340. [7] BENJAMIN T B, URSELL F.The stability of the plane free surface of a liquid in vertical periodic motion[J]. Proceedings of the Royal Society of London, 1954, 225(1163):505-515. doi: 10.1098/rspa.1954.0218 [8] EISENMENGER W.Dynamic properties of surface tension of water and aqueous solutions of surface active agents with standing capillary waves in the frequency range from 10kHz to 1.5 MHz[J]. Acoustica, 1959, 9:327-340. [9] PESKIN R L, RACO R J.Ultrasonic atomization of liquids[J]. The Journal Acoustical Society of America, 1963, 34(1):6-15. doi: 10.1121-1.1918700/ [10] SINDAYIHEBURA D, BOLLE L.Theoretical and experimental study of the behavior of liquid film free surfaces driven by transverse ultrasonic vibrations[J]. WIT Transactions on Modelling and Simulation:Computational Modelling of Free and Moving Boundary Problems, 1995, 13:67-74. [11] SINDAYIHEBURA D, BOLLE L, CORNET A, et al.Theoretical and experimental study of transducers aimed at low-frequency ultrasonic atomization of liquids[J]. The Journal of the Acoustical Society of America, 1998, 103(3):1442-1448. doi: 10.1121/1.421300 [12] 菅永军, 鄂学全, 柏威.参数激励圆柱形容器中的非线性Faraday波[J].应用数学和力学, 2003, 24(10):1057-1068. doi: 10.3321/j.issn:1000-0887.2003.10.009JIAN Y J, E X Q, BAI W.Nonlinear Faraday waves in parameter-excited cylindrical vessels[J]. Applied Mathematics and Mechanics, 2003, 24(10):1057-1068(in Chinese). doi: 10.3321/j.issn:1000-0887.2003.10.009 [13] JIAN Y J, E X Q.Instability analysis of nonlinear surface waves in a circular cylindrical container subjected to a vertical excitation[J]. European Journal of Mechanics B-Fluids, 2005, 24(6):683-702. doi: 10.1016/j.euromechflu.2005.03.002 [14] 长龙, 菅永军, 刘全生.圆柱形容器中垂直激励的弱黏性流体界面波[J].内蒙古大学学报(自然版), 2014, 45(4):353-359. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=nmgdxxb201404004CHANG L, JIAN Y J, LIU Q S.The interface of weakly viscous fluids with vertical excitation in cylindrical vessels[J]. Journal of Inner Mongolia University (Natural Science Edition), 2014, 45(4):353-359(in Chinese). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=nmgdxxb201404004 [15] HIGGINBOTHAM A P, GUILLEN A, JONES N, et al.Evidence of the harmonic Faraday instability in ultrasonic atomization experiments with a deep, inviscid fluid[J]. The Journal of the Acoustical Society of America, 2011, 130(5):2694. doi: 10.1121/1.3643816 [16] LI Y, UMEMURA A.Two-dimensional numerical investigation on the dynamics of ligament formation by Faraday instability[J]. International Journal of Multiphase Flow, 2014, 60:64-75. doi: 10.1016/j.ijmultiphaseflow.2013.12.002 [17] 刘财兴, 杜会静, 王怀翔.垂直激励低黏度硅油的法拉第波研究[J].大学物理, 2016, 35(4):52-59. http://www.cnki.com.cn/Article/CJFDTOTAL-DXWL201604013.htmLIU C X, DU H J, WANG H X.Faraday wave study of vertically excited low viscosity silicone oil[J]. University Physics, 2016, 35(4):52-59(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-DXWL201604013.htm [18] SHELDRAKE M, SHELDRAKE R.Determinants of Faraday wave-patterns in water samples oscillated vertically at a range of frequencies from 50-200 Hz[J]. Water, 2017, 9:1-27. [19] 赵文定, 王思慧, 范周游, 等.理想流体的法拉第波模态[J].物理实验, 2017, 37(1):13-18. doi: 10.3969/j.issn.1005-4642.2017.01.003ZHAO W D, WANG S H, FAN Z Y, et al.Faraday wave modes of ideal fluids[J]. Physics Experiment, 2017, 37(1):13-18(in Chinese). doi: 10.3969/j.issn.1005-4642.2017.01.003 [20] TADRIST L, SHIM J B, GILET T, et al.Faraday instability and subthreshold Faraday waves:Surface waves emitted by walkers[J]. Journal of Fluid Mechanics, 2018, 848:906-945. doi: 10.1017/jfm.2018.358 [21] DUMOUCHEL C, SINDAYIHEBURA D, BOLLE L.Application of the maximum entropy formalism on sprays produced by ultrasonic atomizers[J]. Particle & Particle Systems Characterization, 2003, 20(2):150-161. doi: 10.1002-ppsc.200390012/ [22] RAYLEIGH J W S B, LINDSAY R B.The theory of sound[M]. New York:Dover Publications, 1945:344. [23] EHRHORN J, SEMKE W.Numerical modeling of vibration induced atomization of liquids[J]. Folia Parasitologica, 2013, 45(3):196-198. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=CC0213811149 [24] YULE A J, AL-SULEIMANI Y.A CFD prediction of wave development and droplet production on surface under ultrasonic excitation[C]//Preceding of Institute for Liquid Atomization and Spray Systems-Europe, 2002. [25] HONG Y, JIE H, GU X Z, et al.Study on ultrasonic spray technology for the coating of vascular stent[J]. Science China Technological Sciences, 2011, 54(12):3358-3370. doi: 10.1007/s11431-011-4580-0 [26] 蔡耀中.超声微泡发生方法及装置设计研究[D].杭州: 杭州电子科技大学, 2014: 46. http://cdmd.cnki.com.cn/Article/CDMD-10336-1014229101.htmCAI Y Z.The design and study of ultrasonic micro bubbles generator and technique[D]. Hangzhou: Hangzhou Dianzi University, 2014: 46(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10336-1014229101.htm -

下载:

下载: