Burr characteristics of robotic rotary ultrasonic drilling aluminum alloy stacked components

-

摘要:

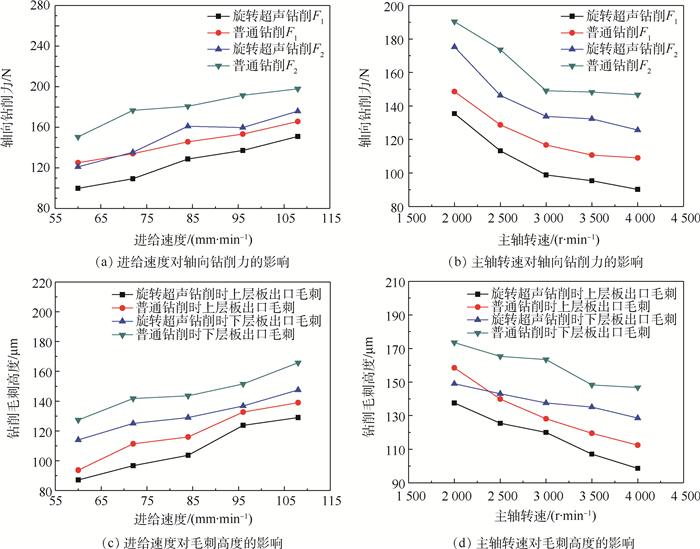

针对铝合金叠层构件机器人制孔容易产生钻削毛刺,严重影响飞机装配精度和效率等问题,提出基于弱刚度环境下机器人旋转超声制孔毛刺高度的计算方法。首先,通过实验验证了高频的振动冲击对毛刺高度的影响规律,建立了机器人旋转超声钻削铝合金叠层构件的钻削力经验公式。然后,结合经典薄板弯曲理论和能量法,分析了超声振动及钻削位置刚性对机器人钻削铝合金叠层板毛刺形成的影响机制。实验结果显示:所提计算方法的相对误差在13%以内,具有较高的精度。

Abstract:It is easy to generate burr on the edge of holes when industrial robot drills the aluminum alloy stacked component. The assembly accuracy and efficiency of aircraft are severely affected. Aimed at the problem of robotic low stiffness, a model is developed to compute the burr height of holes produced by robotic rotary ultrasonic drilling. First, the impact of high frequency vibration on the burr height is invesgated by drilling experiments. Then, the empirical formula of drilling force in robotic rotary ultrasonic drilling aluminum alloy stacked component is obtained by analysing the experimental results. Furthermore, based on the classical thin plate bending theory and energy method, the influence mechanism of ultrasonic vibration and drilling position rigidity on the burr height of drilling is clarified. Finally, verification experiments are carried out and the results show that this method has high calculation accuracy and the relative error is within 13%.

-

Key words:

- stacked component /

- drilling burr /

- calculation method /

- robot /

- ultrasonic vibration

-

表 1 实验中的因素和水平

Table 1. Factors and levels in experiment

实验 因素 水平 A B C D E 单因素

实验主轴转速/(r·min-1) 2 000 2 500 3 000 3 500 4 000 进给速度/(mm·min-1) 60 72 84 96 108 超声电流/mA 0 200 机器人位姿 P1 正交

实验主轴转速/(r·min-1) 1 000 2 000 3 000 4 000 5 000 进给速度/(mm·min-1) 36 48 60 72 84 超声电流/mA 150 175 200 225 250 机器人位姿 P1 P2 P3 P4 P5 表 2 各位姿下机器人在轴相关坐标系中的坐标

Table 2. Coordinates in axis-dependent coordinate system of robot under different position and posture

位姿 机器人相邻两轴夹角/(°) θ1 θ2 θ3 θ4 θ5 θ6 P1 -0.86 -77.31 76.6 0 90.72 -15.86 P2 -0.86 -77.3 77.06 0 90.25 -15.86 P3 -0.86 -77.3 77.55 0 89.76 -15.86 P4 -0.86 -77.27 78.0 0 89.29 -15.86 P5 -0.86 -77.23 78.42 0 88.83 -15.86 表 3 毛刺高度计算方法的相对误差

Table 3. Relative error of burr height calculation method

上下层板 序号 毛刺高度/μm 相对

误差/%预测值 实测值 上层板 1 116.24 124.10 6.33 2 115.98 125.04 7.25 3 114.45 130.91 12.57 4 117.98 119.50 1.27 5 122.45 124.13 1.35 下层板 1 168.45 158.38 6.36 2 169.03 154.55 9.37 3 180.89 169.47 6.74 4 180.22 160.93 11.99 5 147.28 143.52 2.62 -

[1] OZER A, SEMERCIGIL S E, KUMAR R P, et al.Delaying tool chatter in turning with a two-link robotic arm[J].Journal of Sound and Vibration, 2013, 332(6):1405-1417. doi: 10.1016/j.jsv.2012.08.006 [2] 董辉跃, 曹国顺, 曲巍崴, 等.工业机器人自动钻孔及锪窝一体化加工[J].浙江大学学报(工学版), 2013, 47(2):201-208. doi: 10.3785/j.issn.1008-973X.2013.02.002DONG H Y, CAO G S, QU W W, et al.Processing research of industry robots drilling and countersinking automaticly[J].Journal of Zhejiang University(Engineering Science), 2013, 47(2):201-208(in Chinese). doi: 10.3785/j.issn.1008-973X.2013.02.002 [3] 方强, 李超, 费少华, 等.机器人镗孔加工系统稳定性分析[J].航空学报, 2015, 37(2):727-737.FANG Q, LI C, FEI S H, et al.Stability analysis of robot boring system[J].Acta Aeronautica et Astronautica Sinica, 2015, 37(2):727-737(in Chinese). [4] 卜泳, 许国康, 肖庆东.飞机结构件的自动化精密制孔技术[J].航空制造技术, 2009(24):61-64. doi: 10.3969/j.issn.1671-833X.2009.24.011PU Y, XU G K, XIAO Q D.Automatic precision drilling technology of aircraft structural part[J].Aviation Manufacturing Technology, 2009(24):61-64(in Chinese). doi: 10.3969/j.issn.1671-833X.2009.24.011 [5] 李哲, 张德远, 姜兴刚.钛合金旋转超声辅助钻削的出口毛刺[J].北京航空航天大学学报, 2017, 43(7):1380-1386. doi: 10.13700/j.bh.1001-5965.2016.0556LI Z, ZHANG D Y, JIANG X G.Exit burr in rotary ultrasonic-assisted drilling of titanium alloys[J].Journal of Beijing University of Aeronautics and Astronautics, 2017, 43(7):1380-1386(in Chinese). doi: 10.13700/j.bh.1001-5965.2016.0556 [6] 王珉, 薛少丁, 陈文亮, 等.面向飞机自动化装配的单向压紧制孔毛刺控制技术[J].航空制造技术, 2011(9):26-29. doi: 10.3969/j.issn.1671-833X.2011.09.001WANG M, XUE S D, CHEN W L, et al.One-side pressed burrless drilling technology for aircraft automatic assembly[J].Aviation Manufacturing Technology, 2011(9):26-29(in Chinese). doi: 10.3969/j.issn.1671-833X.2011.09.001 [7] DONG S, ZHENG K, LIAO W H.Stability of lateral vibration in robotic rotary ultrasonic drilling[J].International Journal of Mechanical Sciences, 2018, 145:346-352. doi: 10.1016/j.ijmecsci.2018.07.004 [8] 胡坚.航空材料制孔缺陷抑制及工艺研究[D].南京: 南京航空航天大学, 2016: 11-12.HU J.Research on defect inhibition and technologyin drilling of aeronauticmaterials[D].Nanjing: Nanjing University of Aeronautics and Astronautics, 2016: 11-12(in Chinese). [9] TIAN W, HU J, LIAO W, et al.Formation of interlayer gap and control of interlayer burr in dry drilling of stacked aluminum alloy plates[J].Chinese Journal of Aeronautics, 2016, 29(1):283-291. doi: 10.1016/j.cja.2015.11.002 [10] KIM J, DORNFELD D A.Development of an analytical model for drilling burr formation in ductile materials[J].Journal of Engineering Materials & Technology, 2002, 124(2):192-198. [11] 吴丹, 黄诗剑, 高雨浩, 等.铝合金叠层板钻削层间毛刺高度预测模型[J].清华大学学报(自然科学版), 2017, 57(6):33-38.WU D, HUANG S J, GAO Y H, et al.Predictive model for the interlayer burr height during drilling of stacked aluminum plates[J].Tsinghua Science and Technology, 2017, 57(6):33-38(in Chinese). [12] HELLSTERN C.Investigation of interlayer burr formation in the drilling of stacked aluminum sheets[D].Atlanta: Georgia Institute of Technology, 2009: 15-20. [13] 张飞龙, 贺云, 李秋实, 等.空间站载荷转移机构机器人的力加载控制方法[J].机器人, 2018, 40(2):249-256.ZHANG F L, HE Y, LI Q S, et al.The control method of force loading of robot on load transfer mechanism of space station[J].Robot, 2018, 40(2):249-256(in Chinese). [14] 曹双倩, 袁培江, 陈冬冬, 等.激光测距传感器光束矢向和零点位置标定方法[J].北京航空航天大学学报, 2018, 44(6):1321-1327. doi: 10.13700/j.bh.1001-5965.2017.0450CAO S Q, YUAN P J, CHEN D D, et al.Calibration method for laser beam direction and zero point of laser displacement sensor[J].Journal of Beijing University of Aeronautics and Astronautics, 2018, 44(6):1321-1327(in Chinese). doi: 10.13700/j.bh.1001-5965.2017.0450 [15] 倪风雷, 邹添, 孙永军, 等.空间大型机械臂末端12维传感器设计及应用[J].机器人, 2017, 39(3):257-264.NI F L, ZOU T, SUN Y J, et al.Design and application of a 12-DOF sensor on the end of large space manipulator[J].Robot, 2017, 39(3):257-264(in Chinese). [16] 张业明, 蔡茂林.基于最小二乘法的执行器系统机械属性评价[J].北京航空航天大学学报, 2014, 40(7):881-886. doi: 10.13700/j.bh.1001-5965.2013.0493ZHANG Y M, CAI M L.Mechanical properties evaluation based on least squares for actuators system[J].Journal of Beijing University of Aeronautics and Astronautics, 2014, 40(7):881-886(in Chinese). doi: 10.13700/j.bh.1001-5965.2013.0493 -

下载:

下载: