-

摘要:

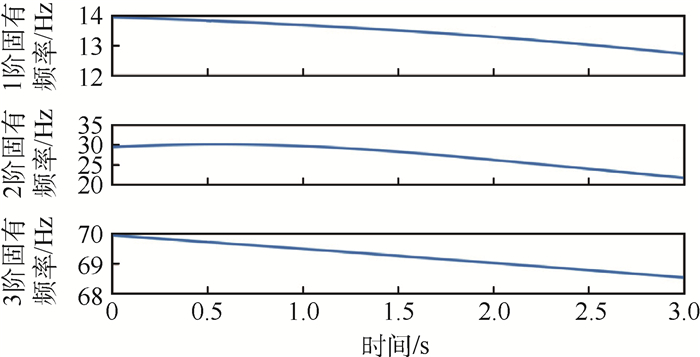

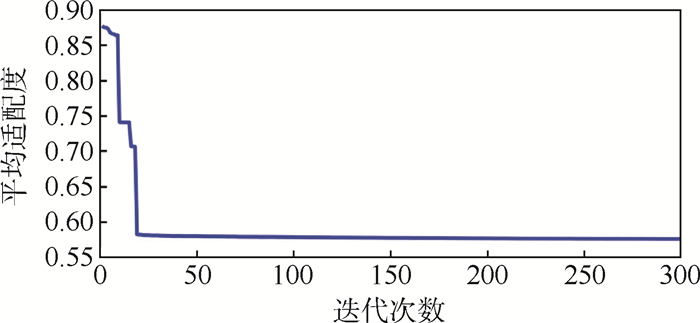

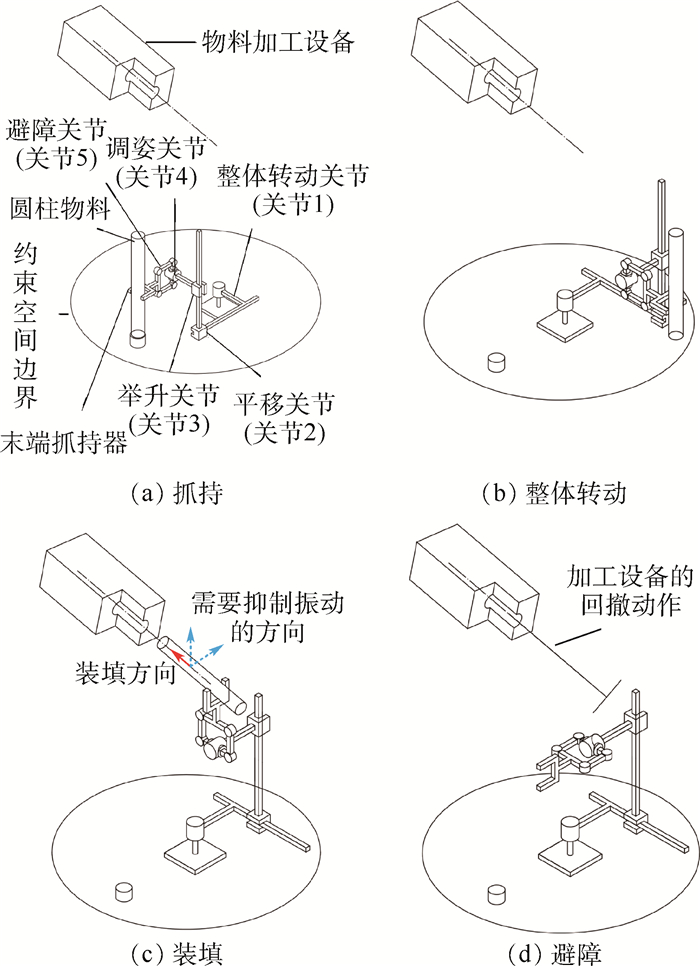

为提高载具内的物料装填效率,提出了一种在载具内受限空间中使用的新型圆柱物料装填机器人,并通过优化关节轨迹,对机器人末端残余振动进行抑制。首先,给出物料装填机器人的总体设计方案和工作流程。然后,结合物料装填机器人的结构特点,应用拉格朗日方法建立封闭形式的刚柔耦合动力学模型,并应用模态分析方法得到机器人末端动态响应计算方法。最后,以物料装填机器人关节残余弹性势能最小为优化目标,使用最大最小蚂蚁系统,对机器人关节轨迹进行优化,并对优化结果进行仿真验证。仿真结果表明,优化后的关节轨迹,在满足快速装填要求的基础上,可以降低约34.4%的关节残余弹性势能和约37.6%的机器人末端振动振幅。

Abstract:In order to improve the material loading efficiency in vehicles, this paper proposes a new cylindrical material loading robot used in confined space. The residual vibration of the end-effector has been suppressed by optimizing the joint trajectory. Firstly, the overall design scheme and work flow of the material loading robot are given. Then, combined with the structural characteristics of material loading robot, a closed-form rigid-flexible coupling dynamic model is established according to Lagrange method. The calculation method of end-effector's dynamic response is obtained by modal analysis method. Finally, taking the minimization of the sum of the robot joints' residual elastic potential energy as the optimization target, max-min ant system was taken to optimize the trajectory of the robot joint. The optimization results were verified by simulation. Simulation results show that the optimized joint trajectory can reduce about 34.4% of the joint residual elastic potential energy and about 37.6% of vibration amplitude of the end-effector, while satisfying the demand for fast loading.

-

表 1 物料装填机器人物理参数定义

Table 1. Physical parameter definition of material loading robot

变量 物理意义 数值 θ1/rad 关节1关节角 d2/m 关节2关节位移 d3/m 关节3关节位移 θ4/rad 关节4关节角 θ5/rad 关节5关节角 m1/kg 关节1质量 90.8 m2/kg 关节2质量 64.1 m3/kg 关节3质量 13.4 m4/kg 关节4质量 26.2 m5/kg 关节5和末端抓持器等效质量 46.4 k1/((N·m)·rad-1) 关节1等效线性刚度 15 000 k2/(N·m-1) 关节2等效线性刚度 15 000 k3/(N·m-1) 关节3等效线性刚度 15 000 k4/((N·m)·

rad-1)关节4等效线性刚度 10 000 k5/((N·m)·

rad-1)关节5等效线性刚度 15 000 I1/(kg·m2) 关节1在坐标系O1x1y1z1中相对于质心的惯量

I2/(kg·m2) 关节2在坐标系O2x2y2z2中相对于质心的惯量

I3/(kg·m2) 关节3在坐标系O3x3y3z3中相对于质心的惯量

I4/(kg·m2) 关节4在坐标系O4x4y4z4中相对于质心的惯量

I5/(kg·m2) 关节5在坐标系O5x5y5z5中相对于质心的惯量

表 2 轨迹插值点

Table 2. Trajectory interpolation points

插值点序号 关节2相对位移/mm 关节3相对位移/mm 关节4相对位移/(°) 0 0 0 0 1 195 0 0 2 305 200 50 3 405 386 90 表 3 插值时间取值范围

Table 3. Value range of interpolation time

s 运动时间 最大值 最小值 t1 2 0.5 t2 2 0.5 t3 2 0.5 表 4 优化前后参数的对比

Table 4. Comparison of parameters before and after optimization

参数 优化前 优化后 运动时间t1/s 2.04 1.77 运动时间t2/s 1.96 1.23 运动时间t3/s 1.02 1.17 时间和t/s 5.02 4.17 残余弹性势能Ek/J 0.878 0.576 x方向误差幅值/mm 5.771 3.487 z方向误差幅值/mm 3.28 2.238 -

[1] KANG B S, PARK G J, ARORA J. A review of optimization of structure subjected to transient loads[J].Structural and Multidisciplinary Optimization, 2006, 31(2):81-95. doi: 10.1007/s00158-005-0575-4 [2] BRIDGES M M, DAWSON D M, ABDALLAH C T.Control of rigid-link, flexible-joint robots:A survey of backstepping approaches[J].Journal of Robotic Systems, 1995, 12(3):199-216. doi: 10.1002/rob.4620120305 [3] SINGHOSE W.Command shaping for flexible systems:A review of the first 50 years[J].International Journal of Precision Engineering and Manufacturing, 2009, 10(4):153-168. doi: 10.1007/s12541-009-0084-2 [4] 易江, 朱秋国, 吴俊, 等.基于最优控制的仿人机器人行走振动抑制[J].机器人, 2018, 40(2):129-135.YI J, ZHU Q G, WU J, et al.Walking vibration suppression for humanoid robot based on optimal control[J].Robot, 2018, 40(2):129-135(in Chinese). [5] ZHANG L J, CHEN L.Adaptive time varying sliding mode control and vibration suppression for space manipulator with fully flexible arms and uncertain parameters[J].Revista de la Facultad de Ingenieria, 2016, 31(9):232-245. [6] 陈志勇, 张婷婷, 郭益深.弹性基和弹性关节空间机器人的自适应鲁棒抗扰控制及振动抑制[J].自动化学报, 2018, 44(7):1271-1281.CHEN Z Y, ZHANG T T, GUO Y S.Adaptive robust anti-interference control and vibration suppression for an elastic-base elastic-joint space robot[J].Acta Automatica Sinica, 2018, 44(7):1271-1281(in Chinese). [7] REW K H, KIM K S.Using asymmetric S-curve profile for fast and vibrationless motin[C]//IEEE International Conference on Robotics and Automation.Piscataway, NJ: IEEE Press, 2011: 1-4. [8] FEDERICO C, CORRADO G, MARCO L.Minimum-jerk online planning by a mathematical programming approach[J] Engineering Optimization, 2014, 46(6):763-783. doi: 10.1080/0305215X.2013.806916 [9] WISNU A, KAZUHIKO T.An implementation of cubic spline optimization with floating via points and vibration suppression for trajectory planning of industrial robot arm[C]//SICE Annual Conference, 2013: 288-293. [10] GUO C Q, GAO H B, NI F L, et al.A vibration suppression method for flexible joints manipulator based on trajectory optimization[C]//Proceedings of 2016 IEEE International Conference on Mechatronics and Automation.Piscataway, NJ: IEEE Press, 2016: 338-343. [11] 吴明月, 刘延杰, 蔡鹤皋.基于最优S型曲线轨迹的硅片传输机器人末端振动抑制方法[J].机器人, 2014, 36(4):446-454.WU M Y, LIU Y J, CAI H G.Method of vibration suppression of the end-effector of wafer handling robot based on optimal S-curve profile[J].Robot, 2014, 36(4):446-454(in Chinese). [12] 解则晓, 商大伟, 任凭.基于Lame曲线的Delta并联机器人拾放操作轨迹的优化与试验验证[J].机械工程学报, 2015, 51(1):52-59. http://www.cnki.com.cn/Article/CJFDTotal-JXXB201501007.htmXIE Z X, SHANG D W, REN P.Optimization and experimental verification of pick-and-place trajectory for a Delta parallel robot based on Lame curves[J].Journal of Mechanical Engineering, 2015, 51(1):52-59(in Chinese). http://www.cnki.com.cn/Article/CJFDTotal-JXXB201501007.htm [13] 孙增圻, 邓志东, 张再兴.智能控制理论与技术[M].2版.北京:清华大学出版社, 2011:387-398.SUN Z Q, DENG Z D, ZHANG Z X.Intelligent control theory and technology[M].2nd ed.Beijing:Tsinghua University Press, 2011:387-398(in Chinese). [14] 鲍文博, 白泉, 陆海燕.振动力学基础与MATLAB应用[J].北京:清华大学出版社, 2015:157-170.BAO W B, BAI Q, LU H Y.Vibration mechanics foundation and application of MATLAB[J].Beijing:Tsinghua University Press, 2015:157-170(in Chinese). [15] 熊有伦.机器人技术基础[M].武汉:华中科技大学出版社, 1996:72-92.XIONG Y L.Robot technology foundation[M].Wuhan:Huazhong University of Science and Technology Press, 1996:72-92(in Chinese). -

下载:

下载: