-

摘要:

高精度主轴的回转误差和测试系统的噪声常处于同一水平,这极大地影响了用频域三点法测量主轴回转误差的准确性。针对同步误差(SEM),提出了对含噪声信号进行等角度采样重构、集合平均和小波滤波的组合降噪处理方法,提出了根据传感器和被测主轴直径定量确定小波分解层数的方法,经仿真实验证明其具有良好的去噪效果。针对异步误差(ASEM),提出了消除测试系统噪声的方法,研究了圈数对异步误差测试结果的影响规律。此外,搭建了测试系统,验证了所提方法的有效性。

Abstract:Since the error motion of the high-precision spindles is often in the same order as the noise of the test system, the measuring accuracy of the three-point method is greatly reduced by the noise signals. With the synchronous error motion (SEM), a combined processing algorithm with equal angle sampling and reconstruction, ensemble average filtering and wavelet filtering for noise-containing signal is proposed. A method for quantitatively determining the wavelet decomposition layer based on the diameters of both sensor and measured spindle is proposed. The simulation results show that the new combined method has good denoising effect. With the asynchronous error motion (ASEM), a method for eliminating the noise of the test system is proposed, and the influence of the number of test cycles on ASEM is studied. In addition, a test system was built and the effectiveness of the proposed methods was experimentally verified.

-

Key words:

- error motion /

- three-point method /

- error separation /

- ensemble average /

- wavelet denoising

-

在主轴的回转误差测试中,被测信号一般由同步误差(SEM)、异步误差(ASEM)、圆度误差、偏心量和系统噪声组成。同步误差为回转误差中转频整数倍的成分,反映回转中心的平均涡动轨迹。异步误差为回转误差中转频非整数倍成分,反映回转体径向随机运动的大小。为了测量亚微米级的同步误差和异步误差,必须将被测信号中其他成分分离出来。因此,误差分离技术是回转误差测试技术的关键[1-3]。三点法误差分离技术是比较常用的手段,但是在实际应用中其精度会受被测信号中的随机成分影响。因此需要在误差分离之前对被测信号进行除噪处理。针对这一问题,文献[4]向传感器信号中加入噪声信号,并分析噪声信号能量,以减小噪声对分离结果的影响。文献[5]提出了对数据进行有效性检验、集合平均和无附加相移数字滤波器等措施。文献[6]测量了刀具切削时主轴的回转误差,利用基于自适应阈值的小波包算法去除加工时噪声的影响。文献[7]分析了测量误差的来源及影响,并对主轴倾角运动误差进行了研究。

然而对于径向跳动中的非同频成分,即异步误差的研究相对较少。异步误差作为回转误差中的随机成分,与环境噪声混叠。对于高精度主轴,其异步误差幅值的量级(数十纳米)与传感器噪声量级相近,如果不对异步误差进行除噪,必定使测量结果失真。3C行业的发展对主轴异步误差提出了更高的要求。例如,异步误差直接影响高光加工的质量。本文提出了一种去除系统噪声的分离技术,以提高异步误差和同步误差的测试精度。

1. 三点法误差分离技术

1.1 三点法误差分离原理

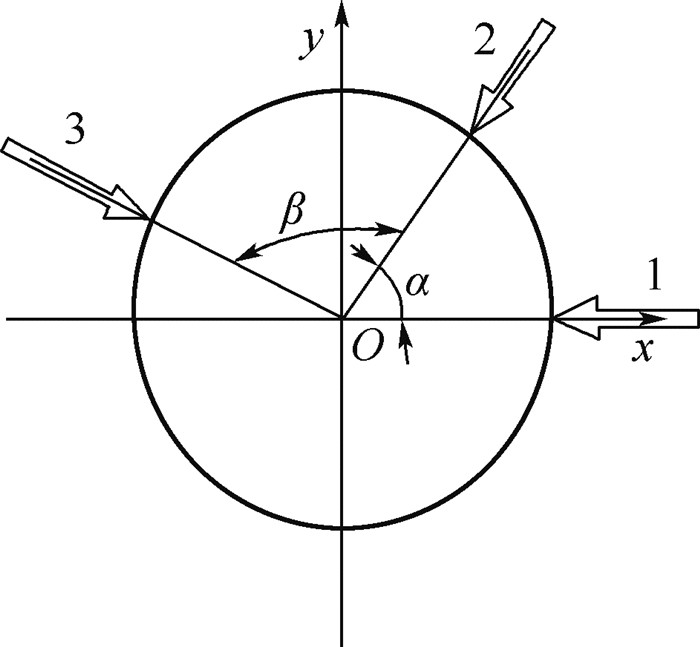

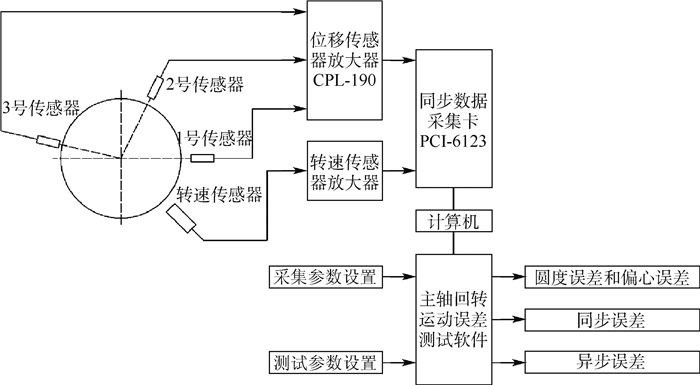

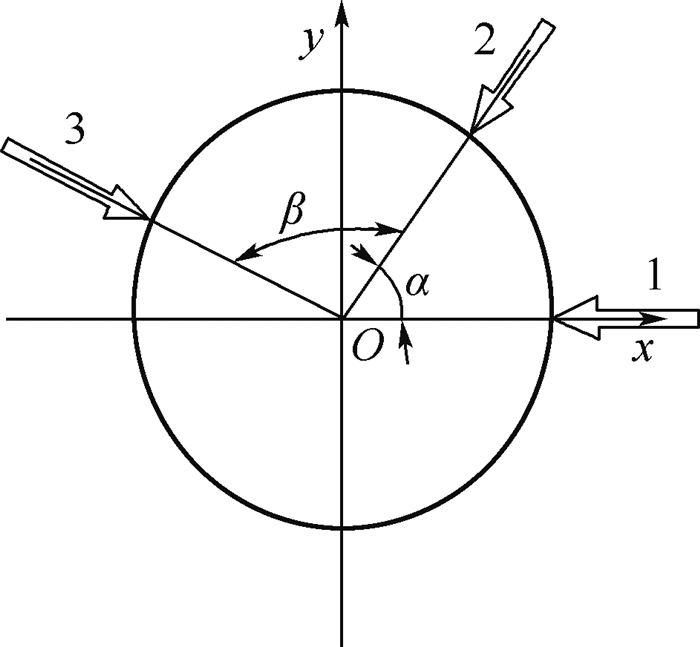

三点法误差分离技术的基本原理是:将3支传感器沿径向按一定角度布置于被测截面,利用同步采集的3个传感器信号数据的加权组合来消除转子回转误差,从而得到圆度误差[8],其示意图如图 1所示。以1号传感器轴线为x轴,传感器交点为坐标原点O建立平面直角坐标系。假设无安装偏心造成的偏心量,主轴顺时针旋转,相邻2支传感器轴线的夹角分别为α和β。回转误差在x、y方向上的分量分别为x(θ)、y(θ),被测截面的圆度误差为r(θ),其中θ为转子当前角度,则各传感器的信号可表示为[3]

(1) 则三路信号的加权和为

(2) 要消去信号中的回转误差,则c1、c2、c3为

(3)

(4) 根据傅里叶变换的时延相移性质,对式(4)进行离散傅里叶变换可得

(5) 式中:R(k)为圆度数据序列的傅里叶级数;W(k)为权函数序列的傅里叶级数。

对式(5)进行傅里叶逆变换,则圆度误差为

(6) 当k=1时,无论α、β取何值,W(1)≡0。这导致式(6)中r(θ)的一阶谐波被抑制,分量恒为零。这将使得分离得到的圆度误差的最小二乘圆心与测量坐标系原点自动重合。一般情况下,一阶谐波分量由被测件的安装偏心引起,而一阶谐波分量被抑制正好消除了偏心误差对圆度误差的影响,使圆度误差的评价更加方便[9]。另外,一阶谐波分量被抑制将导致分离后的回转误差中含有偏心误差,必须将其消除。假设被测截面的几何中心在当前坐标系中的坐标为(A, B),则原始信号可表示为

(7)

(8) 由式(7)和式(8)可得

(9) 令

(10) 为去除式(10)中回转误差项x(θ)、y(θ),并注意到y(θ)/x(θ)=tan θ,则可得

(11) 式(11)两边乘sin(2θ),进行离散化处理,应用正弦函数在一个周期内面积为零的性质,在每圈采样数据内取平均即可求出A。同理,式(11)两边乘cos(2θ),可求出B。A、B可表示为[10]

(12)

(13) 式中:N为每圈采样点数;i为角度θ对应的采样点,且

从而可知,回转误差为

(14)

(15) 1.2 系统噪声对分离误差的影响

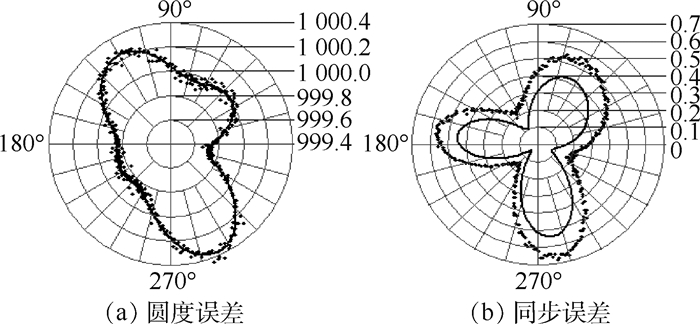

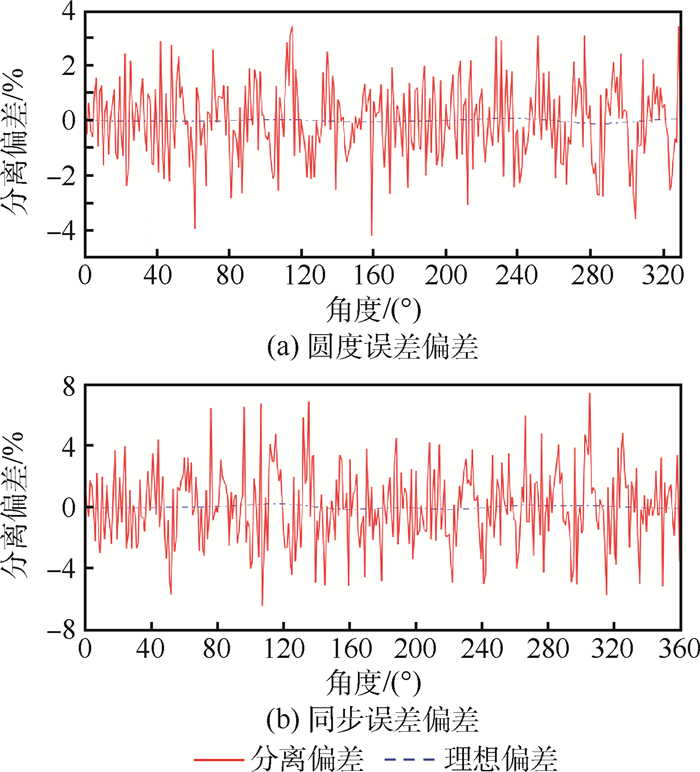

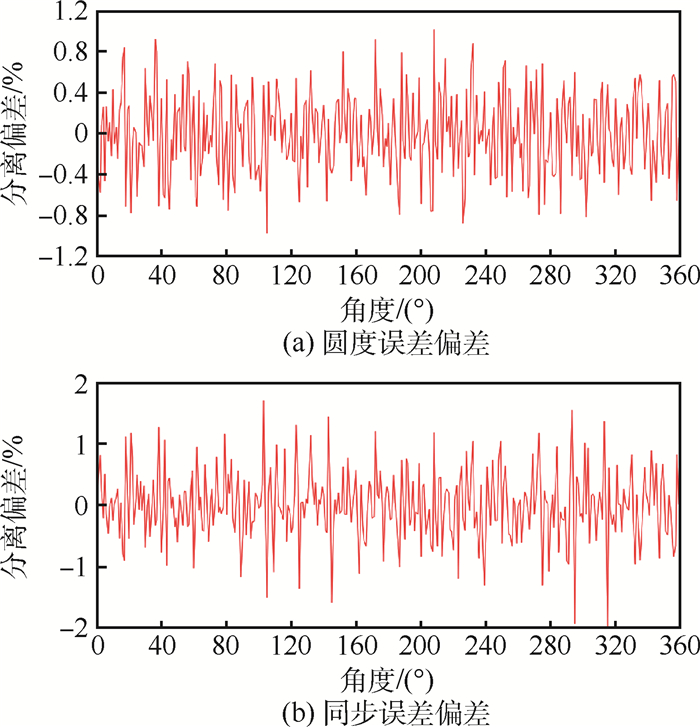

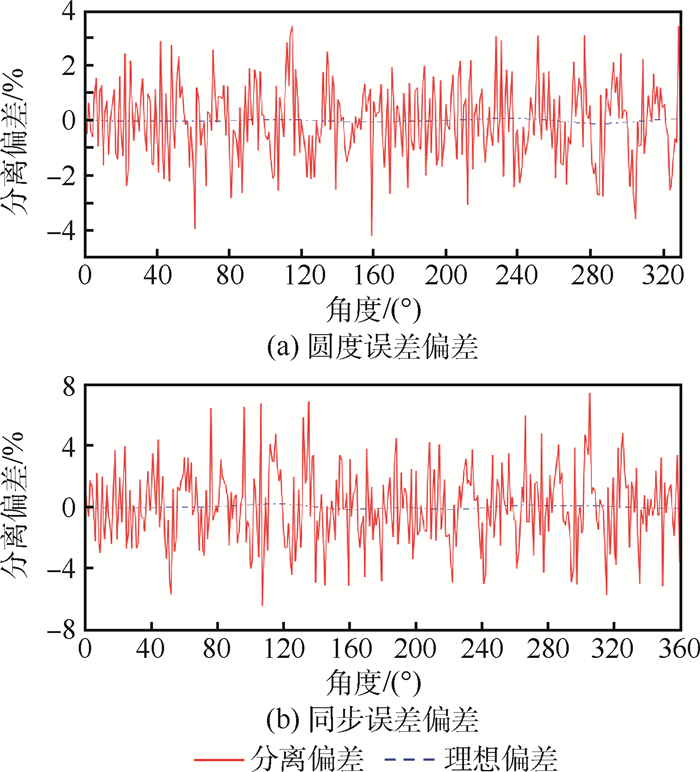

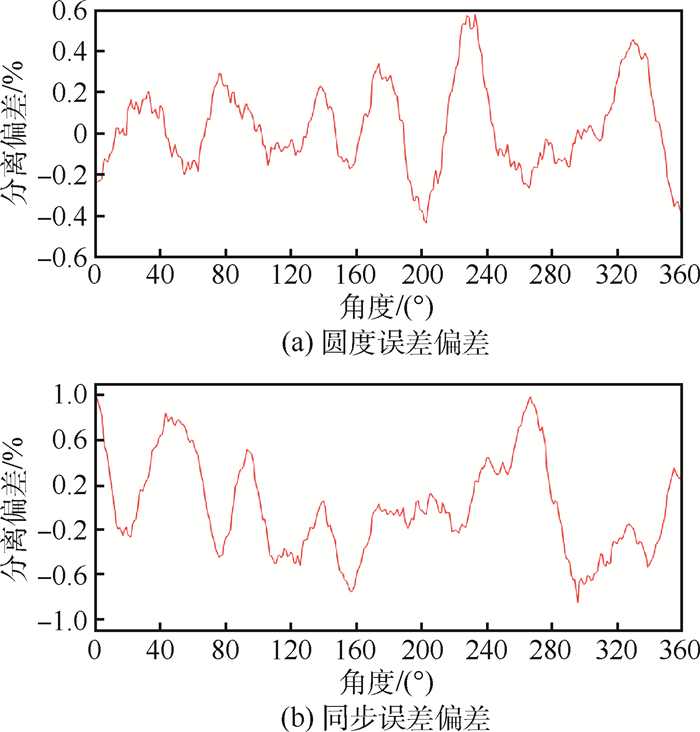

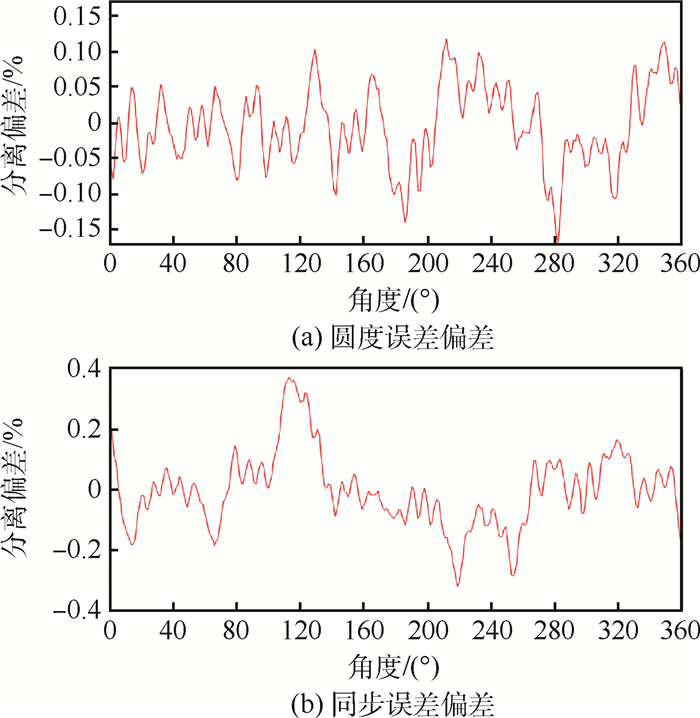

为研究噪声信号对三点法分离精度的影响,本文以表 1所示的函数作为圆度误差和回转误差的周期成分,以δR~N(0, 0.022)作为随机噪声信号,以α=62.35°,β=106.76°作为传感器夹角,ω为转速为12000r/min时的角速度, 生成3支传感器的模拟信号,对其进行误差分离。设定每圈采样点数为360,数据圈数为20圈。分离后的圆度误差和同步误差如图 2所示,其中实线为不含噪声信号(理想)结果,虚线为含噪声信号结果。可以看出,噪声会使分离结果出现毛刺,并引起同步误差幅值失真。图中:90°~270°为极坐标角度值,999.4~ 1000.4, 0~0.7为无量纲位移量。图 3为圆度和同步误差的分离偏差,实线为含噪声信号的分离偏差,虚线为不含噪声信号分离后的偏差。可以看出,含噪声信号的分离效果较差,圆度误差最大偏差约占峰峰值的4.9%,同步误差最大偏差约占峰峰值的6.8%。因此,若要提高圆度误差和同步误差的分离精度,需要尽可能去除原始信号中的噪声成分。

表 1 仿真信号成分Table 1. Simulated signal components信号类型 周期成分 圆度误差 r(t)=1.3cos(ωt)-0.8sin(ωt)+0.16cos(2ωt)+

0.12sin(2ωt)+0.05cos(3ωt)-

0.07sin(3ωt)+0.05cos(4ωt)-0.1sin(4ωt)回转误差 v(t)=0.01cos(ωt)+0.05sin(ωt)-

0.06cos(2ωt)+0.02sin(2ωt)-

0.14cos(3ωt)+0.1sin(3ωt)+0.08cos(4ωt)2. 去除系统噪声的分离技术

2.1 等周期采样转化为等角度采样

在实际测试中,由于主轴存在转速波动,等周期采样无法保证每圈的采样点数相同。等角度采样能保证每圈离散数据的傅里叶变化级数相同。同时,等角度采样是集合平均方法的必要条件,能够提高信噪比。常用方法有2种:一种是硬件重采样,即通过编码器信号触发等角度间隔采样;另一种是软件重采样[11-12],即先进行等周期采样,在数据处理时转化为等角度采样。

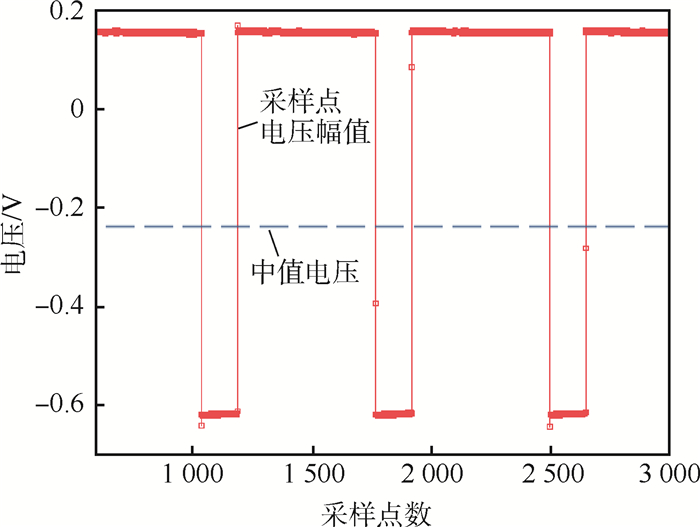

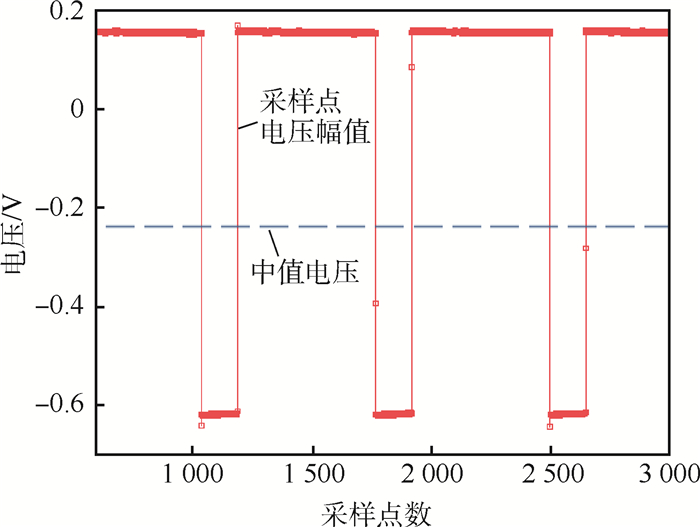

本文采用软件重采样方法,具体方法为:引入转速传感器以获取主轴转速脉冲信号,并同步采集转速脉冲信号和三路位移信号。实测转速传感器波形如图 4所示,实线为各采样点的电压幅值,虚线为中值电压。未触发条件下电压约为0.15V,主轴标记点触发后将产生约0.86V的压降。取每次小于中值电压的第1点为每圈采样起点,则可将采样序列分隔成多个采样周期,得到各周期采样点数。由于转速存在波动,所以各周期采样点数不同,取其中的最大值作为重采样点数,并对其余样本周期进行插值处理,从而保证各周期采样点数相同,实现等角度采样。

2.2 集合平均方法

集合平均方法是一种常用的除噪方法,能提高信号的信噪比[13-14]。等角度采样后的信号可看作由周期性信号c(t)和随机性信号n(t)叠加而成,假设n(t)~N(0, σn2),表示为

(16) 取m圈等角度采样的信号,计算各个角度的平均值,作为一圈信号,其方差为

(17) 经过集合平均,信号的方差减小,其中周期性信号的信噪比得到提高。这对于提高三点法误差分离精度是有利的。同时,集合平均方法可以使测试信号的信噪比高于原有传感器的水平,降低测试设备的成本。

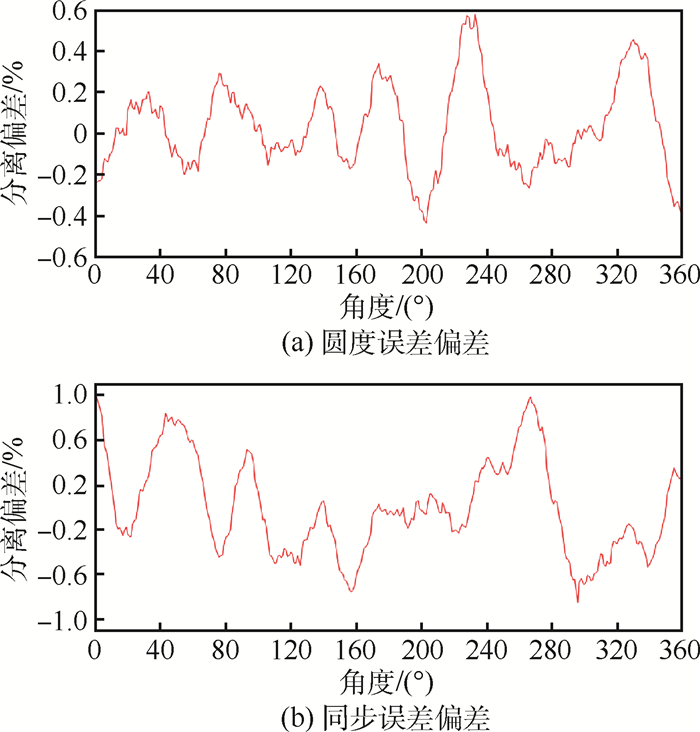

保证设定参数不变,对含噪声仿真信号进行集合平均处理并进行误差分离,以观察其降噪效果。其中m的选择比较重要,m太小降噪效果不明显;m太大需要采集的数据量过大,计算时间长。参考实测情况取m=20,即取20圈信号平均值,以剔除非周期信号。保证计算圈数为20圈不变,故需要生成400圈仿真信号。其分离结果如图 5所示,可以看出偏差明显减少,且波形中高频分量较多。圆度误差最大偏差约占峰峰值的1%,同步误差最大偏差约占峰峰值的2%。

2.3 小波阈值去噪方法

对于高信噪比的信号,小波阈值去噪方法可以有效地抑制噪声信号,同时保留信号的峰值点信息。其基本思想:将原始信号经过小波变换,得到包含原信号重要信息的小波系数。其中有效信号的小波系数较大,而噪声信号的小波系数较小。因此,可以通过选取合适的阈值,保留大于阈值的小波系数,置零小于阈值的小波系数,进行小波逆变换得到重构信号,达到去除噪声的目的[15]。小波阈值去噪方法优于Butterworth低通滤波的地方在于其保留了信号的高频细节特征。

小波阈值去噪方法的基本步骤如下:

步骤1 进行含噪声信号的正交小波变换。先选择合适的小波基函数[16],然后根据原始信号中包含的最大阶数和需要保留的信号最大阶数确定小波分解层数w,对信号进行w层小波分解运算。小波分解层数w为

(18) 式中:f为传感器在当前测试条件下能测出的最大谐波阶次。

设被测轴直径为D,传感器探芯直径为d,则传感器可探测到的最大谐波数为D/d,根据香农采样定理,最大谐波阶次应满足:

(19) 步骤2 对小波系数进行非线性阈值处理。为保持信号的整体形状不变,保留所有低频系数,取阈值

(20) 对每个小波系数进行软阈值处理,即将含噪声信号小波系数与所选定的阈值Ω进行比较。软阈值处理后的小波系数η(j)为

(21) 步骤3 进行小波逆变换。由所有低频尺度系数,以及经由阈值处理后的小波系数做逆小波变换进行重构,得到恢复的原始信号估计值[17]。

保证设定参数不变,对含噪声仿真信号进行小波阈值去噪并进行误差分离,以观察其降噪效果。分离结果如图 6所示。可以看出偏差减小,波形中的高频分量明显减少。圆度误差最大偏差约占峰峰值的0.59%,同步误差最大偏差约占峰峰值的1%。

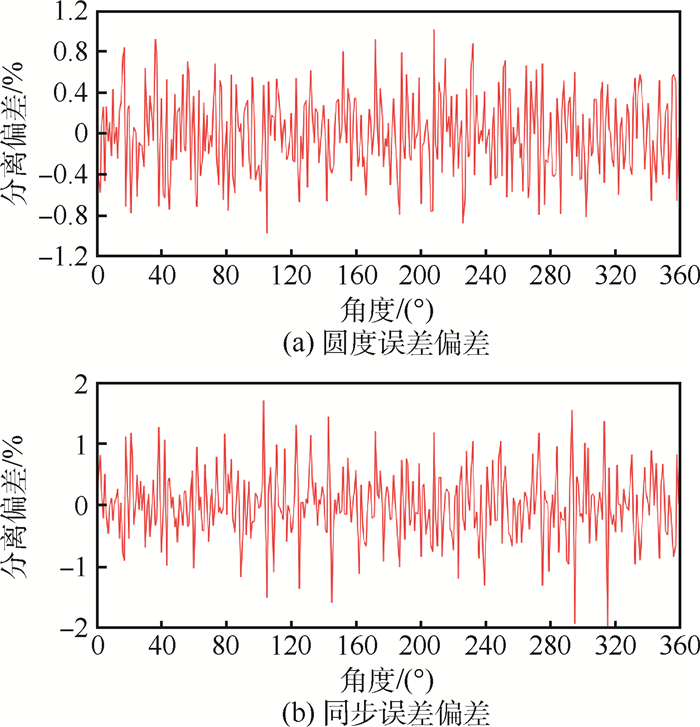

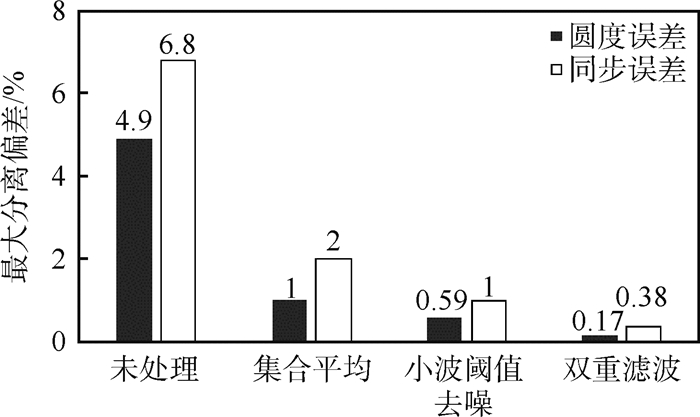

2.4 双重滤波方法

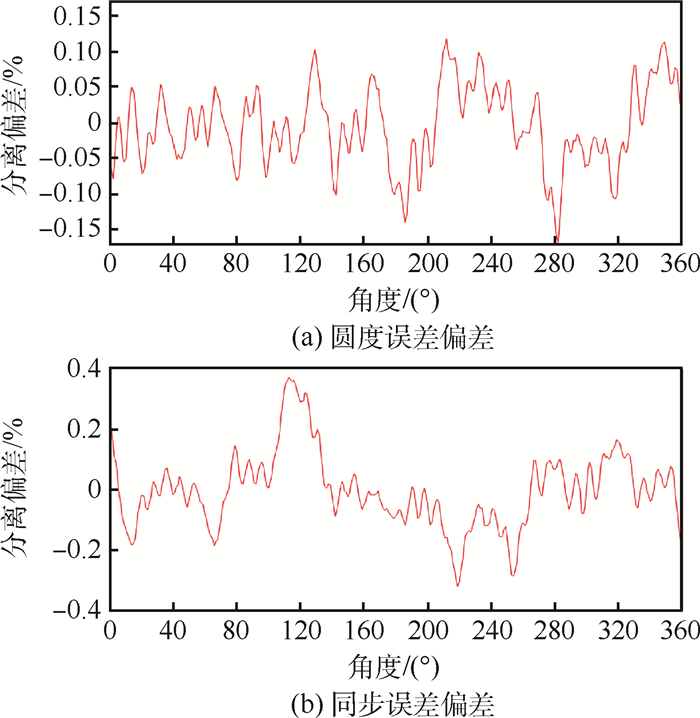

根据上述2种滤波的不足,本文提出对原始信号进行集合平均和小波阈值去噪处理,可以得到更好的去噪效果。保证设定参数不变,对含噪声仿真信号进行集合平均和小波阈值去噪并进行误差分离,分离结果如图 7所示。可以看出, 偏差变小且高频噪声被消除。圆度误差最大偏差约占峰峰值的0.17%,同步误差最大偏差约占峰峰值的0.38%。

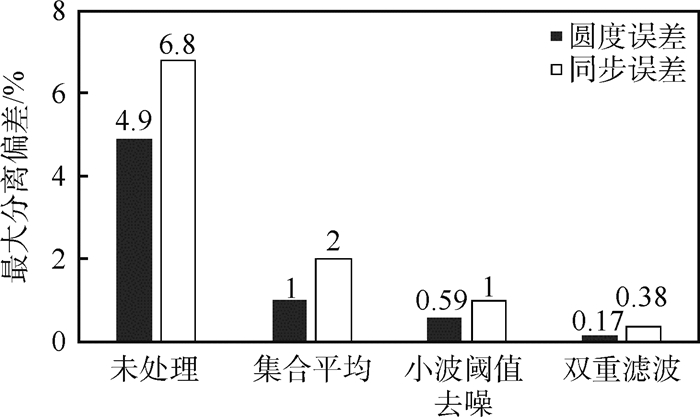

图 8比较了上述不同去噪方法的最大分离偏差。可以看出, 双重滤波方法结合了集合平均和小波阈值去噪的特点,分离偏差明显减小,起到较好的噪声去除效果。

2.5 异步误差中系统噪声去除方法

从除噪信号中分离得到同步误差、圆度误差和偏心误差,异步误差和系统噪声作为随机成分不参与误差分离计算,被留在原始信号中。在实际测试中,采集到的数据往往会有一两圈数据存在粗大误差,这会对异步误差的评价造成影响。根据加工误差的6σ原则,可以用异步误差的标准值σ的6倍对异步误差进行评价,以达到从异步误差中去除系统噪声的目的。

假设异步误差信号δ0(θ)和系统噪声信号δv(θ)均为高斯白噪声,且相互独立,可用式(22)表示:

(22) 在满足一定数据量的条件下,被测信号随机成分δ(θ)具有统计学规律,服从正态分布,则

(23) 求得被测信号随机成分标准差σ和系统噪声标准差σv,则实际的异步误差标准差σ0为

(24) 系统噪声信号δv(θ)可由δx(θ)、δy(θ)两支传感器的噪声信号表示,其中δx(θ)、δy(θ)分别表示噪声信号在x轴和y轴上的分量,表示为

(25) 则标准差为

(26) 由δx(θ)、δy(θ)求δv(θ)需要分别乘cos θ和sin θ,这会对标准差产生影响。经过仿真实验,在满足一定数据量的条件下,其影响是使均值不变,方差减半,则噪声信号标准差为

(27) 则真实异步误差标准差为

(28) 3. 实验验证

3.1 测试系统构成

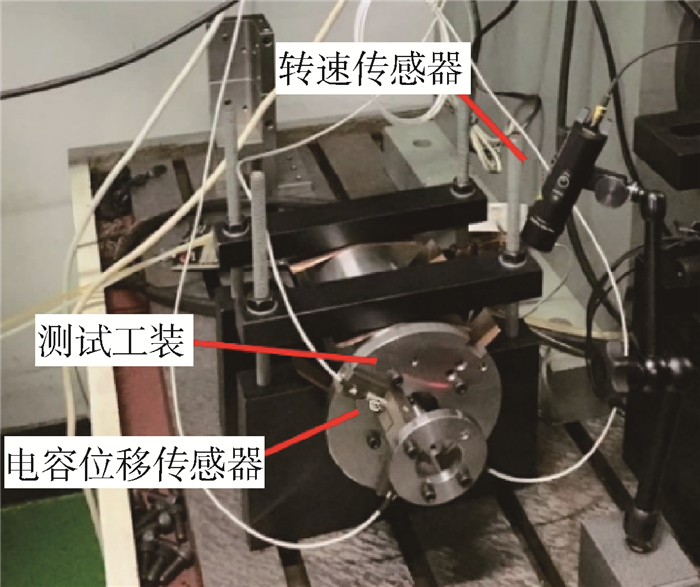

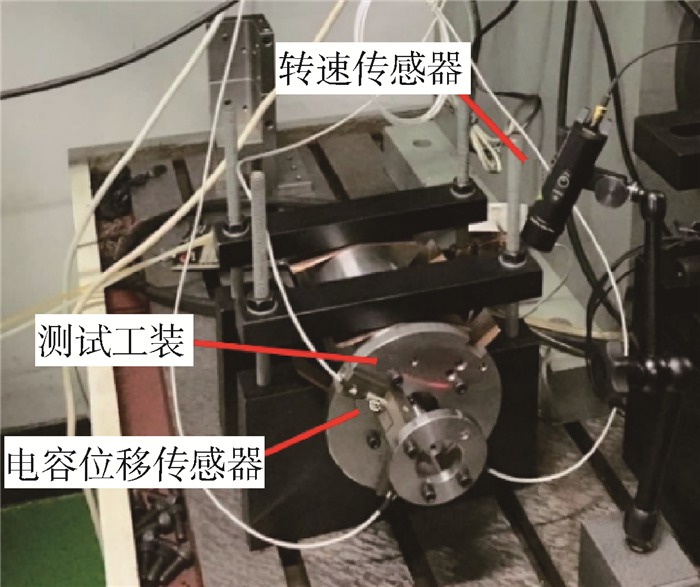

测试系统组成、测试工装分别如图 9和图 10所示。系统将传感器工装与主轴前端盖固定,相较于固定在平台上,该方法能减轻主轴振动对位移读数的影响。

在被测件同一被测截面上布置3支LION Precision的电容位移传感器(CDS),其主要性能参数如表 2所示。

表 2 CDS主要性能参数Table 2. Main performance parameters of CDS参数 数值 量程/μm 250 分辨率 3×10-5 带宽/kHz 15 线性度/% < 0.2 探芯直径/mm 2 选用NI同步数据采集卡PCI-6123,保证三路位移信号同步。设定每圈采样点N为720,根据转速设置采样频率,记录数据长度为1000圈。小波分解层数根据具体实际测试系统参数而定,本实验中,被测截面直径为12mm,电容式位移传感器探芯直径为2mm。由式(18)和式(19)可得,该条件下传感器能测得最大谐波阶数f为9阶,小波分解层数w为5。此外,为消除异步误差中的系统噪声,还需要测得相同工况下系统噪声的信号。

3.2 实验分析

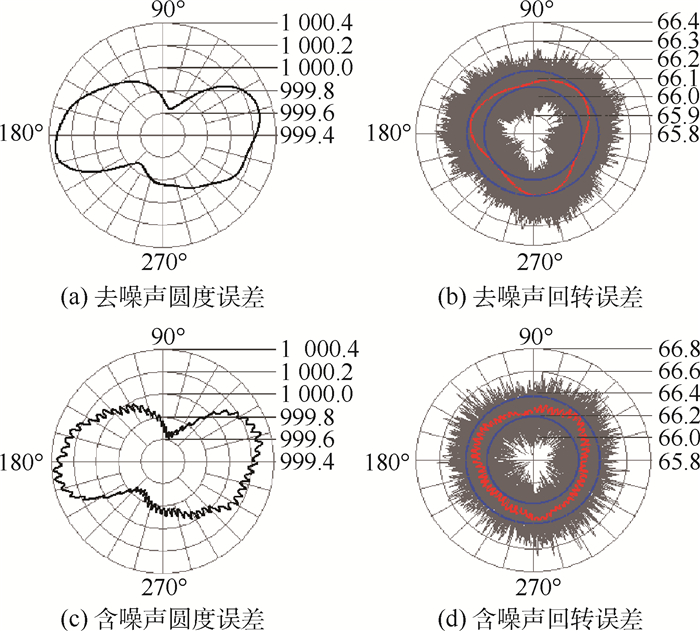

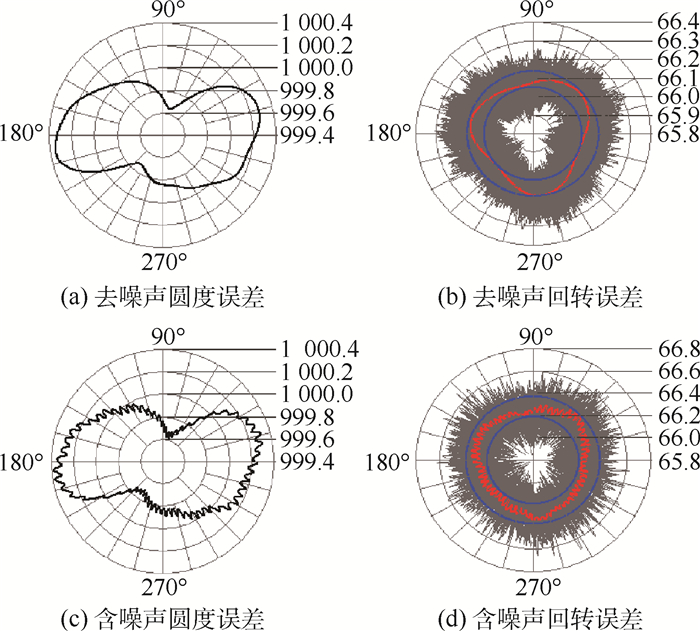

当转速为104r/min时,取采样频率为1.2×105Hz;当转速2×104r/min时,取采样频率为2.4×105Hz,以此类推。采集数据并分析电主轴1×104~4×104r/min转速下达到稳定时的回转误差和圆度误差,测试结果如表 3所示。可以看出,随着转速的升高,圆度误差基本不变。说明圆度分离结果可信。偏心误差、同步误差和异步误差随转速升高而增加,符合实际情况。转速1×104r/min时,去除噪声求得圆度误差和回转误差如图 11(a)、(b)所示;含噪声求得圆度误差和回转误差如图 11(c)、(d)所示。图 11(b)和图 11(d)中灰色为异步误差数值,蓝色为采样数值中同步误差的最小值和最大值,红色为同步误差信号。具体数值如表 4所示。可以看出,保留噪声会导致求得圆度误差和回转误差形状失真,且评价值偏大。

表 3 不同转速下回转误差分离结果Table 3. Results of separation of error motion at different rotational speeds转速/(104

r·min-1)圆度误差/

μm偏心误差/

μm同步误差/

μm异步误差/

μm1 0.707 1.937 0.087 0.230 2 0.707 2.045 0.106 0.856 3 0.704 2.263 0.184 0.891 4 0.704 2.701 0.189 1.544 注:表中异步误差按照6σ进行评价。 表 4 转速1×104r/min下噪声对误差分离结果的影响Table 4. Effect of noise on error separation results at rotational speed of 1×104r/min是否

去噪圆度误差/

μm偏心误差/

μm同步误差/

μm异步误差/

μm是 0.707 1.937 0.087 0.230 否 0.865 1.938 0.166 0.546 3.3 计算圈数对异步误差的影响

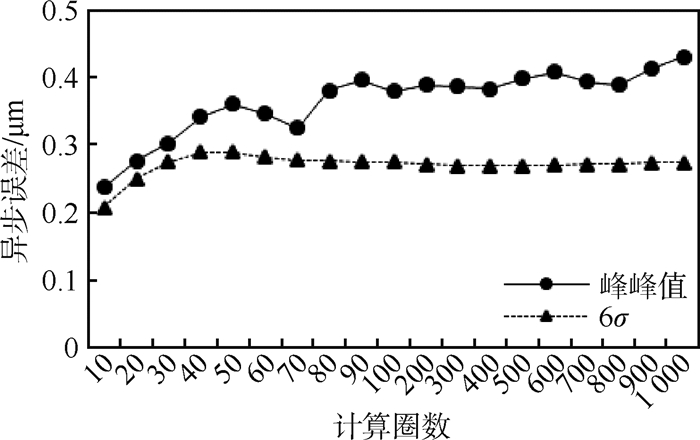

为研究计算圈数对异步误差的影响,提取采样圈数为10~1000圈的样本,采用峰峰值和6倍标准差(6σ)两种评价方式计算了不同圈数下的异步误差,结果如图 12所示。可以看出,随计算圈数增加,2种评价结果均逐渐趋于稳定,但峰峰值跳动略大,可以将计算圈数大于26圈时的6σ值作为异步误差的评价值。

4. 结论

本文针对回转误差测试中系统噪声分离技术进行了研究, 得出以下结论:

1) 为了消除测试信号中系统噪声对圆度误差和同步误差分离结果的影响,提出了对信号进行集合平均和小波阈值去噪的双重滤波方法,并给出了根据被测主轴直径和传感器探芯直径确定小波分解层数的计算公式。

2) 为了消除测试信号中系统噪声对异步误差的影响,通过在相同工况下采集测试系统噪声,利用高斯白噪声分布相互独立的特点,得出了消除系统噪声影响的公式。

3) 研究了计算圈数对异步误差测试结果的影响规律,建议采用标准差评价方式,且计算圈数以不小于26圈为宜。

-

表 1 仿真信号成分

Table 1. Simulated signal components

信号类型 周期成分 圆度误差 r(t)=1.3cos(ωt)-0.8sin(ωt)+0.16cos(2ωt)+

0.12sin(2ωt)+0.05cos(3ωt)-

0.07sin(3ωt)+0.05cos(4ωt)-0.1sin(4ωt)回转误差 v(t)=0.01cos(ωt)+0.05sin(ωt)-

0.06cos(2ωt)+0.02sin(2ωt)-

0.14cos(3ωt)+0.1sin(3ωt)+0.08cos(4ωt)表 2 CDS主要性能参数

Table 2. Main performance parameters of CDS

参数 数值 量程/μm 250 分辨率 3×10-5 带宽/kHz 15 线性度/% < 0.2 探芯直径/mm 2 表 3 不同转速下回转误差分离结果

Table 3. Results of separation of error motion at different rotational speeds

转速/(104

r·min-1)圆度误差/

μm偏心误差/

μm同步误差/

μm异步误差/

μm1 0.707 1.937 0.087 0.230 2 0.707 2.045 0.106 0.856 3 0.704 2.263 0.184 0.891 4 0.704 2.701 0.189 1.544 注:表中异步误差按照6σ进行评价。 表 4 转速1×104r/min下噪声对误差分离结果的影响

Table 4. Effect of noise on error separation results at rotational speed of 1×104r/min

是否

去噪圆度误差/

μm偏心误差/

μm同步误差/

μm异步误差/

μm是 0.707 1.937 0.087 0.230 否 0.865 1.938 0.166 0.546 -

[1] ANANDAN K P, OZDOGANLAR O B.A multi-orientation error separation technique for spindle metrology of miniature ultra-high-speed spindles[J].Precision Engineering, 2016, 43:119-131. [2] 伍良生, 杨勇, 周大帅.机床主轴径向回转误差的测试与研究[J].机械设计与制造, 2009(1):107-109.WU L S, YANG Y, ZHOU D S.Dynamic measurement technology of the spindle motion error of high speed spindle[J].Machinery Design & Manufacture, 2009(1):107-109(in Chinese). [3] 李自军, 洪迈生, 魏元雷, 等.精确的频域三点法直线误差分离技术[J].机械设计与研究, 2002, 18(3):54-55.LI Z J, HONG M S, WEI Y L, et al.Accurate frequency domain three-point method for straightness error separation[J].Machine Design and Research, 2002, 18(3):54-55(in Chinese). [4] FUJIMAKI K, SASE H, MITSUI K.Effects of sensor noise in digital signal processing of the three-point method[J].Measurement Science and Technology, 2008, 19(1):15201. [5] 李济顺, 洪迈生.提高圆度误差分离精度的措施[J].计量学报, 1999, 20(2):92-95.LI J S, HONG M S.Approaches to improve the accuracy of roundness error separation[J].Acta Metrologica Sinica, 1999, 20(2):92-95(in Chinese). [6] 苏恒, 洪迈生, 魏元雷, 等.机床主轴径向误差运动在线检测与信号处理[J].机械工程学报, 2002, 38(6):56-60.SU H, HONG M S, WEI Y L, et al.CNC machine spindle radial motion error on-line test and signal processing[J].Chinese Journal of Mechanical Engineering, 2002, 38(6):56-60(in Chinese). [7] 王世良.超精密车床主轴回转误差测试系统的研究[D].哈尔滨: 哈尔滨工业大学, 2016: 10-14.WANG S L.Research on measurement system of ultra precision in the spindle rotation error[D].Harbin: Harbin Institute of Technology, 2016: 10-14(in Chinese). [8] AOKI Y, OZONO S.On a new method of roundness measurement based on the three-point method[J].Journal of Japan Society of Precision Engineering, 1966, 32(12):27-32. [9] 韩正桐, 洪迈生, 李自军.三点法圆度误差分离及演化形式与精度分析[J].上海交通大学学报, 2002, 36(9):1225-1227.HAN Z T, HONG M S, LI Z J.Three-point method and its variation for roundness error separation and accuracy analysis[J].Journal of Shanghai Jiaotong University, 2002, 36(9):1225-1227(in Chinese). [10] 雷贤卿, 李言, 周彦伟, 等.3点法圆度误差分离技术的新算法[J].兵工学报, 2007, 28(1):73-77.LEI X Q, LI Y, ZHOU Y W, et al.A new matrix algorithm of three-point method roundness error separation technique[J].Acta Armamentarii, 2007, 28(1):73-77(in Chinese). [11] 曹青松, 俞爱兰.高精度转速测量新方法的研究[J].机床与液压, 2010, 38(17):38-40.CAO Q S, YU A L.A new method for high precision speed measurement[J].Machine Tool & Hydraulics, 2010, 38(17):38-40(in Chinese). [12] 陈钊, 杨现萍, 冯巧宁.等角度重采样在航空发动机振动分析中的应用[J].机械研究与应用, 2015, 28(1):71-73.CHEN Z, YANG X P, FENG Q N.Application of equal angle resampling method in aircraft engine vibration analysis[J].Mechanical Research & Application, 2015, 28(1):71-73(in Chinese). [13] 张怀, 王广君, 曾旭明, 等.基于FPGA的消噪同步叠加平均算法仿真分析及实现[J].测控技术, 2013, 32(12):13-16.ZHANG H, WANG G J, ZENG X M, et al.Simulation analysis and realization of the synchronization overlapping average algorithm for denoising based on FPGA[J].Measurement & Control Technology, 2013, 32(12):13-16(in Chinese). [14] 徐志钮.介损在线监测去噪方法的有效性[J].高电压技术, 2015, 41(3):909-917.XU Z N.Validity of noise reduction method in dielectric loss on-line monitoring[J].High Voltage Engineering, 2015, 41(3):909-917(in Chinese). [15] 王微.基于小波分析和统计理论的核磁共振信号消噪方法研究[D].长春: 长春大学, 2013: 24-30.WANG W.Research of the methods about MRS signal denosing based on wavelet analysis and statistical theory[D].Changchun: Jilin University, 2013: 24-30(in Chinese). [16] 郑钧, 侯锐锋.小波去噪中小波基的选择[J].沈阳大学学报, 2009, 21(2):108-110.ZHENG J, HOU R F.Selection of wavelet base in denoising of wavelet transform[J].Journal of Shenyang University, 2009, 21(2):108-110(in Chinese). [17] 朱艳芹, 杨先麟.几种基于小波阈值去噪的改进方法[J].电子测试, 2008(2):18-22.ZHU Y Q, YANG X L.Several new methods based on wavelet thresholding denoising[J].Electronic Test, 2008(2):18-22(in Chinese). 期刊类型引用(8)

1. 迟玉伦,李希铭,朱文博,余建华. 基于LSTM-GRU神经网络的机床主轴回转误差分离降噪研究. 计量学报. 2024(11): 1615-1625 .  百度学术

百度学术2. 樊祥洪,缑百勇,陈涛,何宇廷,崔荣洪,喻健. 柔性涡流阵列传感器孔边裂纹监测技术. 北京航空航天大学学报. 2023(03): 726-734 .  本站查看

本站查看3. 李晋斐,赵冬青,王栋民,蔡聪聪,贾晓雪,张乐添. 一种基于组合赋权法的小波去噪质量评价方法. 北京航空航天大学学报. 2023(03): 718-725 .  本站查看

本站查看4. 熊万里,曾旭,张翰乾,李媛媛,原帅,金志鑫. 全液体静压支承结构磨削系统的磨削成圆规律及圆度极限预测. 机械工程学报. 2023(21): 85-98 .  百度学术

百度学术5. 丁浩,王鹏武,刘保国,冯伟,申会鹏,曹乐. 磨削电主轴动态回转精度分析及实验. 机床与液压. 2022(21): 114-119 .  百度学术

百度学术6. 常洪伟,吴俊杰,魏佳斯,蔡潇雨,李洪宇. 三点法圆外径测量优化研究. 仪表技术与传感器. 2021(03): 106-111 .  百度学术

百度学术7. 熊万里,原帅,胡灿,汪剑,樊柳,雷群. 液体静压主轴的回转精度规律及其极限预测. 机械工程学报. 2021(13): 70-82 .  百度学术

百度学术8. 冯明,杜德渝,王新杰,周程瑜. 精密主轴回转误差和刚度测试技术研究. 机械工程学报. 2021(13): 18-25 .  百度学术

百度学术其他类型引用(1)

-

下载:

下载:

下载:

下载:

百度学术

百度学术