Tilted orbital milling method for hole-making of CFRP/titanium alloy laminated structures

-

摘要:

陀螺铣孔方法在普通螺旋铣孔的基础上,通过将铣刀倾斜一定的角度,使其在自转的同时围绕孔中心轴线做圆锥摆动式公转,以减少轴向力、提高制孔质量。利用陀螺铣孔方法对碳纤维增强复合材料(CFRP)/钛合金叠层构件进行制孔,分析了陀螺铣孔方法下制孔入口和出口阶段的材料去除速率、刀具侧刃和底刃的切削比例、底刃速度零点等。与普通螺旋铣孔相比,陀螺铣孔方法不会引起制孔入口和出口阶段材料去除速率的突变、其侧刃和底刃切削比例变大、底刃速度零点不进行切削。通过试验研究了制孔轴向力、切削温度的变化情况,发现陀螺铣孔方法可显著减小轴向力和切削温度。利用扫描电镜(SEM)对孔壁的表面质量进行了观测,发现陀螺铣孔方法可以消除CFRP孔入口部位的分层现象,且CFRP和钛合金材料的过渡部位也未产生明显的损伤。研究结果表明,陀螺铣孔方法有助于提高CFRP/钛合金叠层构件的制孔质量,具有潜在的工业应用价值。

-

关键词:

- 叠层构件 /

- 碳纤维增强复合材料(CFRP) /

- 钛合金 /

- 螺旋铣孔 /

- 陀螺铣孔

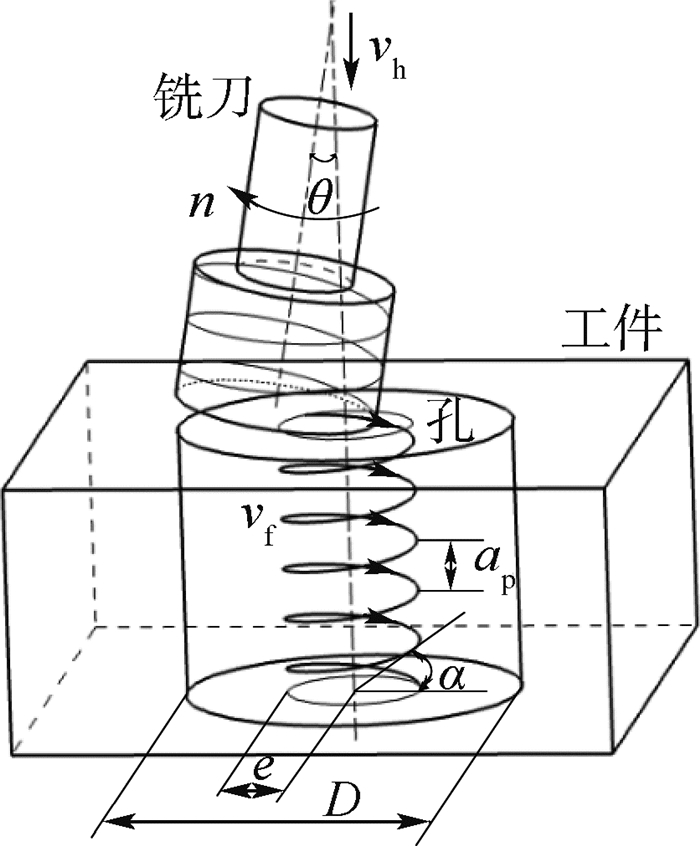

Abstract:In a titled orbital milling process, the cutting tool is set as tilted against the axis of the hole with a small angle, which makes the revolving motion of cutting tool in conventional helical milling process be changed to a conical pendulum motion. It reduces the axial drilling forces and improves the hole-making quality. In this paper, the tilted orbital milling method is adopted to make a hole for the Carbon Fiber Reinforced Polymer (CFRP)/titanium alloy laminated structures. The material removal rates in the region of entrance and exit of hole, the ratios of the material removed by peripheral cutting edge and frontal cutting edge, and the velocity zero point in the frontal edge are analyzed. Compared with the conventional helical milling process, there is no sharply change of the material removal rate in the entrance and exit of hole, its peripheral cutting edge milling ratio is increased, and the the velocity zero point in the frontal edge is not cut. The axial cutting forces and cutting temperatures are analyzed through experiments. The results show that the axial cutting force and temperature decrease significantly in the tilted orbital milling process. The morphology of the holes is checked through Scanning Electron Microscope (SEM), and the results show that the delamination of CFRP in the region of entrance is eliminated and there is no obvious defect in the boundary region of CFRP and titanium alloy. The results of this research show that the tilted orbital milling method is helpful to improve the hole-making quality of CFRP/titanium alloy laminated structures and has a potential application in the industry.

-

-

[1] 朱春燕, 蒋红宇, 张烘洲.飞机装配铣削制孔和钻孔技术对比分析[J].南京航空航天大学学报, 2012, 44(S1):37-41. http://d.old.wanfangdata.com.cn/Periodical/njhkht2012z1009ZHU C Y, JIANG H Y, ZHANG H Z.Comparing analysis of milling and drilling holes for aircraft assembly[J].Journal of Nanjing University of Aeronautics & Astronautics, 2012, 44(S1):37-41(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/njhkht2012z1009 [2] HOCHENG H, TSAO C C.Effects of special drill bits on drilling-induced delamination of composite materials[J].International Journal of Machine Tools and Manufacture, 2006, 46(12-13):1403-1416. doi: 10.1016/j.ijmachtools.2005.10.004 [3] TSAO C C.Effect of deviation on delamination by saw drill[J].International Journal of Machine Tools and Manufacture, 2007, 47(7-8):1132-1138. doi: 10.1016/j.ijmachtools.2006.09.016 [4] TSAO C C, HOCHENG H.Effect of eccentricity of twist drill and candle stick drill on delamination in drilling composite materials[J].International Journal of Machine Tools & Manufacture, 2005, 45(2):125-130. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=b806537229e3359b3419d1d210081454 [5] FANGMANN S, MEYER I, BRINKSMEIER E.Extended theory for orbital drilling(helical drill-milling) [J].Materialwissenschaft und Werkstofftechnik, 2011, 42(6):506-518. doi: 10.1002/mawe.201100699 [6] DENKENA B, BOEHNKE D, DEGE J H.Helical milling of CFRP-titanium layer compounds[J].CIRP Journal of Manufacturing Science and Technology, 2008, 1(2):64-69. doi: 10.1016-j.cirpj.2008.09.009/ [7] BRINKSMEIER E, FANGMANN S, MEYER I.Orbital drilling kinematics [J].Production Engineering, 2008, 2(3):277-283. doi: 10.1007/s11740-008-0111-7 [8] BRINKSMEIER E, FANGMANN S.Orbital drilling of high tolerance boreholes[C]//International Conference on Applied Production Technology(APT'07).Bremen: BIAS-Verlag, 2007: 75-84. [9] DENKENA B, DE LEON L, DEGE J H.Kinematics and undeformed chip geometry in helical milling[J].Materialwissenschaft und Werkstofftechnik, 2008, 39(9):610-615. doi: 10.1002/mawe.200800343 [10] 陆翠.CFRP/Ti-6Al-4V叠层结构螺旋铣孔过程工艺优化研究[D].天津: 天津大学, 2012. http://cdmd.cnki.com.cn/Article/CDMD-10056-1013039804.htmLU C.The optimization research on helical milling of CFRP/Ti-6Al-4V stacks[D].Tianjin: Tianjin University, 2012(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10056-1013039804.htm [11] 邵振宇, 姜兴刚, 张德远, 等.CFRP旋转超声辅助钻削的缺陷抑制机理及实验研究[J].北京航空航天大学学报, 2019, 45(8):1613-1621. doi: 10.13700/j.bh.1001-5965.2018.0713SHAO Z Y, JIANG X G, ZHANG D Y, et al.Defect suppression mechanism and experimental study on rotary ultrasonic-assisted drilling of CFRP[J].Journal of Beijing University of Aeronautics and Astronautics, 2019, 45(8):1613-1621(in Chinese). doi: 10.13700/j.bh.1001-5965.2018.0713 [12] 李哲, 张德远, 姜兴刚.钛合金旋转超声辅助钻削的出口毛刺[J].北京航空航天大学学报, 2017, 43(7):1380-1386. doi: 10.13700/j.bh.1001-5965.2016.0556LI Z, ZHANG D Y, JIANG X G.Exit burr in rotary ultrasonic-assisted drilling of titanium alloys[J].Journal of Beijing University of Aeronautics and Astronautics, 2017, 43(7):1380-1386(in Chinese). doi: 10.13700/j.bh.1001-5965.2016.0556 [13] TANAKA H, OHTA K, TAKIZAWA R, et al.Experimental study on tilted planetary motion drilling for CFRP[J].Procedia CIRP, 2012, 1:443-448. doi: 10.1016/j.procir.2012.04.079 [14] WANG Q, WU Y B, ITOU T, et al.Proposal of a tilted helical milling technique for high quality hole drilling of CFRP:Kinetic analysis of hole formation and material removal[J].The International Journal of Advanced Manufacturing Technology, 2018, 94(9-12):4221-4235. doi: 10.1007/s00170-017-1106-3 [15] WU Y B, WANG Q, NOMURA M.Proposal of tilt helical milling method for hole creation of carbon fiber reinforced plastic(CFRP)[J].Advanced Materials Research, 2016, 1136:190-195. doi: 10.4028/www.scientific.net/AMR.1136.190 [16] WANG Q, WU Y B, LI Y, et al.Proposal of a tilted helical milling technique for high-quality hole drilling of CFRP:Analysis of hole surface finish[J].The International Journal of Advanced Manufacturing Technology, 2019, 101(1-4):1041-1049. doi: 10.1007/s00170-018-2995-5 [17] 方向恩.CFRP/钛合金叠层材料陀螺铣孔新方法制孔质量研究[D].南昌: 南昌航空大学, 2019. http://kns.cnki.net/KCMS/detail/detail.aspx?dbcode=CMFD&filename=1019654572.nhFANG X E.Research on the hole-making quality of CFRP/Ti alloy laminated materials during a new method of gyro milling process[D].Nanchang: Nanchang Hangkong University, 2019(in Chinese). http://kns.cnki.net/KCMS/detail/detail.aspx?dbcode=CMFD&filename=1019654572.nh -

下载:

下载: