Hot forming limit of TA15 titanium alloy based on M-K model

-

摘要:

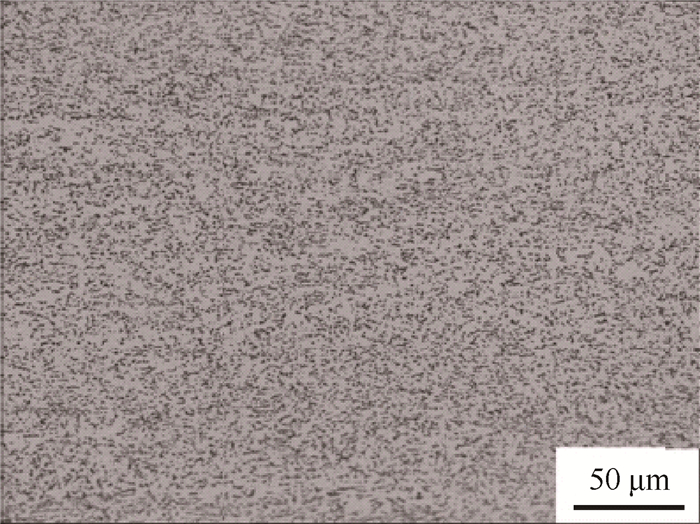

为了探究TA15钛合金高温环境下的成形极限,明确本构方程中参数对成形极限的影响规律,建立了考虑高温软化效应TA15钛合金高温环境下的本构关系,利用高温成形极限试验平台及M-K失稳理论对TA15钛合金板高温环境下的成形极限分别进行了试验测试及理论预测。理论预测结果表明当温度从800℃提升至880℃时,平面应变状态下的极限主应变由0.18提升至0.33。基于M-K失稳理论和建立的高温本构模型,分析了本构方程中的参数对成形极限的影响规律,结果表明提高加工硬化指数、速率敏感因子及减小软化因子,均可以提升应变强化率的大小,进一步延缓沟槽内应变状态趋于平面应变状态,从而提升理论成形极限曲线在应变空间中的位置。此外,理论计算结果表明速率敏感因子对成形极限曲线的左侧影响程度要大于其对右侧部分的影响,该现象主要归因于速率敏感因子对不同应变大小下的应变强化率的影响不同。

Abstract:In order to investigate the forming limit of TA15 titanium alloy at high temperature and clarify the influence of parameters in the constitutive equation on the forming limit, the constitutive relationship of TA15 titanium alloy in high temperature environment was established considering the high temperature softening phenomenon, and meanwhile, the forming limit of TA15 titanium alloy plate at high temperature was obtained by high temperature forming limit test platform and theoretical predicted through applying the M-K instability theory, respectively. The theoretical results indicate that the major strain under the plane strain state increases from 0.18 to 0.33 when the temperature increases from 800℃ to 880℃. Based on the M-K instability theory and the established high temperature constitutive model, the influence of the parameters in the constitutive equation on the forming limit is analyzed. The results show that, increasing the values of hardening index and the rate sensitivity factor, and decreasing the value of the softening factor can increase the strain hardening rate, and consequently the strain state in the groove region is delayed approaching the plane strain state. Therefore the position of the forming limit curve in strain space is improved. At the same time, the theoretical calculation results show that the influence of the strain rate sensitivity factor on the left side of the forming limit curve is greater than that on the right side, and it is attributed to the fact that the effect of the strain rate sensitivity factor on the strain hardening rate under different strain size is different.

-

表 1 TA15钛合金板化学成分

Table 1. Chemical compositions of TA15 titanium alloy plate

元素 质量百分比 Al 6.4 Mo 1.3 V 1.8 Zr 1.9 O 0.07 N 0.008 H 0.005 -

[1] 金和喜, 魏克湘, 李建明, 等.航空用钛合金研究进展[J].中国有色金属学报, 2015, 25(2):280-292.JIN H X, WEI K X, LI J M, et al.Research development of titanium alloy in aerospace industry[J].The Chinese Journal of Nonferrous Metals, 2015, 25(2): 280-292(in Chinese). [2] 李兴无, 沙爱学, 张旺峰, 等.TA15合金及其在飞机结构中的应用前景[J].钛工业进展, 2003, 20(4-5):90-94.LI X W, SHA A X, ZHANG W F, et al.TA15 titanium alloy and its applying prospects on airframe[J].Titanium Industry Process, 2003, 20(4-5):90-94(in Chinese). [3] 李成铭, 李萍, 赵蒙, 等.TA15钛合金高温压缩变形行为与组织研究[J].航空材料学报, 2013, 33(3):25-28.LI C M, LI P, ZHAO M, et al.Mechanical behavior and microstructure of TA15 titanium alloy during hot compressive deformation[J].Journal of Aeronautical Materials, 2013, 33(3):25-28(in Chinese). [4] 唐泽, 杨合, 孙志超, 等.TA15钛合金高温变形微观组织演变分析与数值模拟[J].中国有色金属学报, 2008, 18(4):722-727. doi: 10.3321/j.issn:1004-0609.2008.04.026TANG Z, YANG H, SUN Z C, et al.Microstructure evolution and numerical simulation of TA15 titanium alloy during hot compressive deformation[J].The Chinese Journal of Nonferrous Metals, 2008, 18(4):722-727(in Chinese). doi: 10.3321/j.issn:1004-0609.2008.04.026 [5] 沈昌武, 杨合, 孙志超, 等.基于BP神经网络的TA15钛合金本构关系建立[J].塑性工程学报, 2007, 14(4):101-104. doi: 10.3969/j.issn.1007-2012.2007.04.021SHEN C W, YANG H, SUN Z C, et al.Based on BP artificial neural network to building the constitutive relationship of TA15 alloy[J].Journal of Plasticity Engineering, 2007, 14(4):101-104(in Chinese). doi: 10.3969/j.issn.1007-2012.2007.04.021 [6] 李淼泉, 李晓丽, 龙丽, 等.TA15合金的热变形行为及加工图[J].稀有金属材料与工程, 2006, 35(9):1354-1357. doi: 10.3321/j.issn:1002-185X.2006.09.003LI M Q, LI X L, LONG L, et al.Deformation behavior and processing map of high temperature deformation of TA15 alloy[J].Rare Metal Materials and Engineering, 2006, 35(9):1354-1357(in Chinese). doi: 10.3321/j.issn:1002-185X.2006.09.003 [7] 孙志超, 杨合, 沈昌武.基于逐步回归法的TA15钛合金本构模型的建立[J].锻压技术, 2008, 33(2):110-115. doi: 10.3969/j.issn.1000-3940.2008.02.028SUN Z C, YANG H, SHEN C W.Establishment of TAl5 titanium alloy constitutive model based on stepwise regression method[J].Foring & Stamping Technology, 2008, 33(2):110-115(in Chinese). doi: 10.3969/j.issn.1000-3940.2008.02.028 [8] MARCINIAK Z, KAZIMIERZ K.Limit strains in the process of stretch-forming sheet metals[J].International Journal of Mechanical Sciences, 1967, 9(9):609-612. doi: 10.1016/0020-7403(67)90066-5 [9] 马博林, 刘俊雄, 王文平, 等.钛合金高温FLD试验系统[J].锻压技术, 2015, 40(10):76-81.MA B L, LIU J X, WANG W P, et al.Hot FLD test system for titanium alloy[J].Forging & Stamping Technology, 2015, 40(10):76-81(in Chinese). [10] 王承鑫.钛合金及Ti2AlNb金属间化合物板材热成形极限图[D].哈尔滨: 哈尔滨工业大学, 2014.WANG C X.Hot forming limit diagram for titanium alloy and Ti2AlNb intermetallics sheets[D].Harbin: Harbin Institute of Technology, 2014(in Chinese). [11] 申发兰.TA15钛合金高温变形规律研究[D].南京: 南京航空航天大学, 2013.SHEN F L.Study on hot deformation rule of TA15 titanium alloy[D].Nanjing: Nanjing University of Aeronautics and Astronautics, 2013(in Chinese). [12] MA B L, WU X D, LI X J, et al.Investigation on the hot formability of TA15 titanium alloy sheet[J].Materials & Design, 2016, 94:9-16 [13] YANG L, WANG B Y, LIU G, et al.Behavior and modeling of flow softening and ductile damage evolution in hot forming of TA15 alloy sheets[J].Materials & Design, 2015, 85:135-148. [14] 杨雷.TA15钛合金板材高温塑性损伤本构建模与成形极限研究[D].北京: 北京科技大学, 2016.YANG L.Study on ductile damage constitutive model and forming limit of TA15 titanium alloy sheet at elevated temperatures[D].Beijing: University of Science and Technology Beijing, 2016(in Chinese). [15] SUN Z C, YANG H, TANG Z.Microstructural evolution model of TA15 titanium alloy based on BP neural network method and application in isothermal deformation[J].Computational Materials Science, 2010, 50(2):308-318. doi: 10.1016/j.commatsci.2010.08.020 -

下载:

下载: