Research on Improved damage index for evaluating bolt looseness of flange structures

-

摘要:

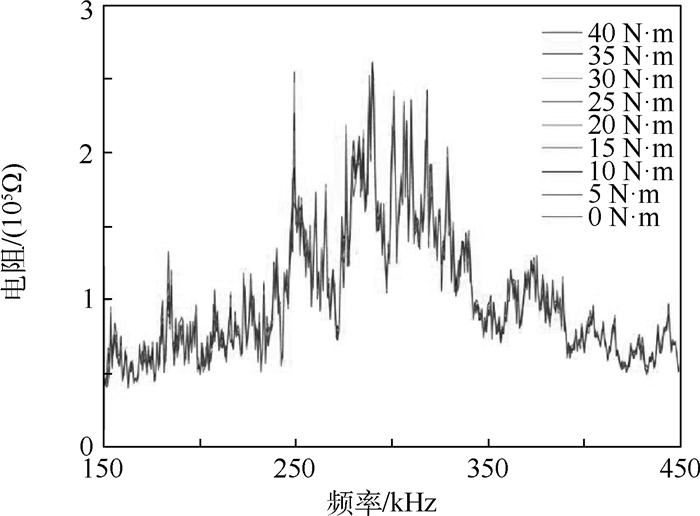

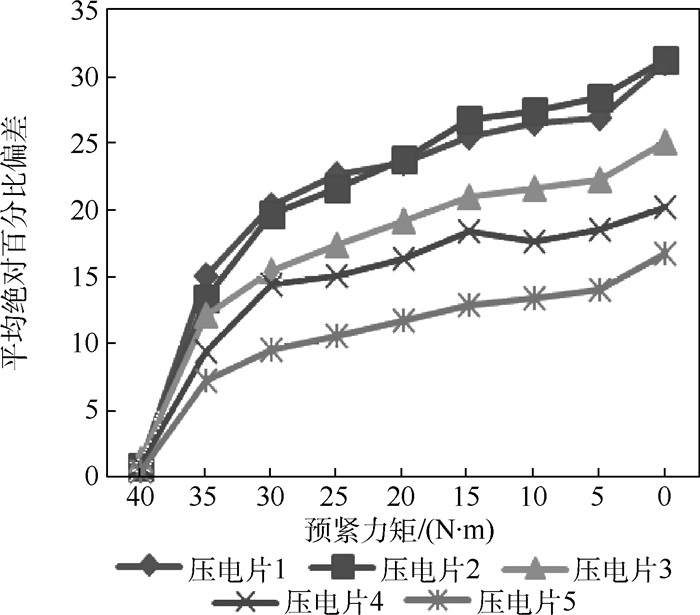

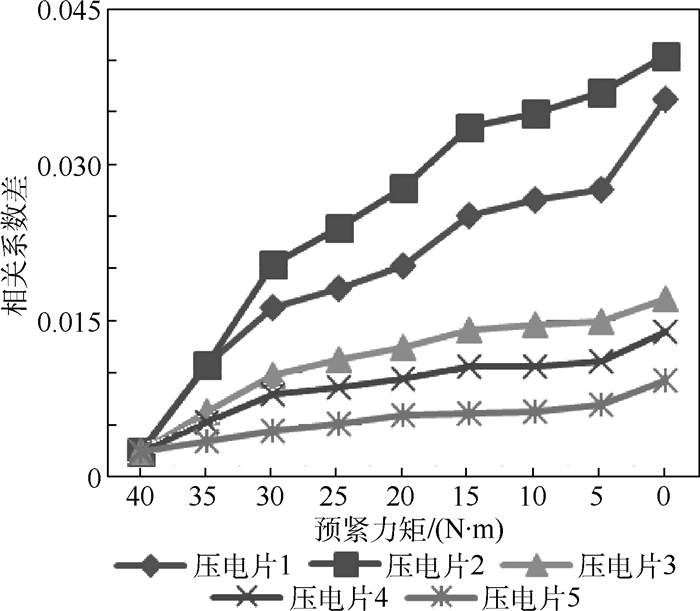

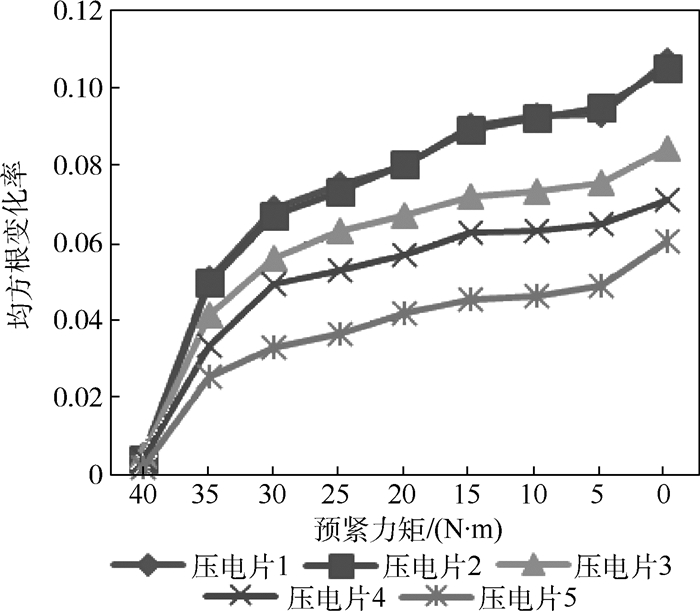

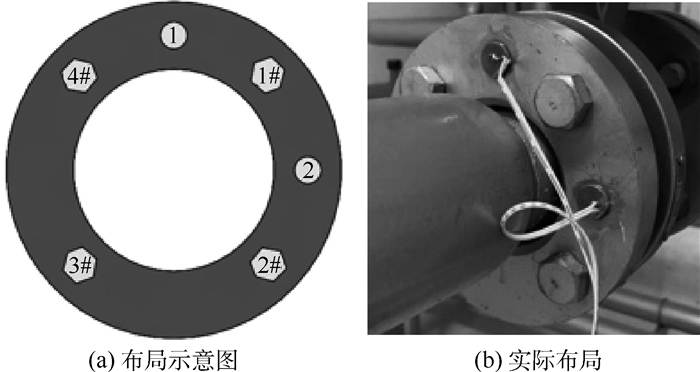

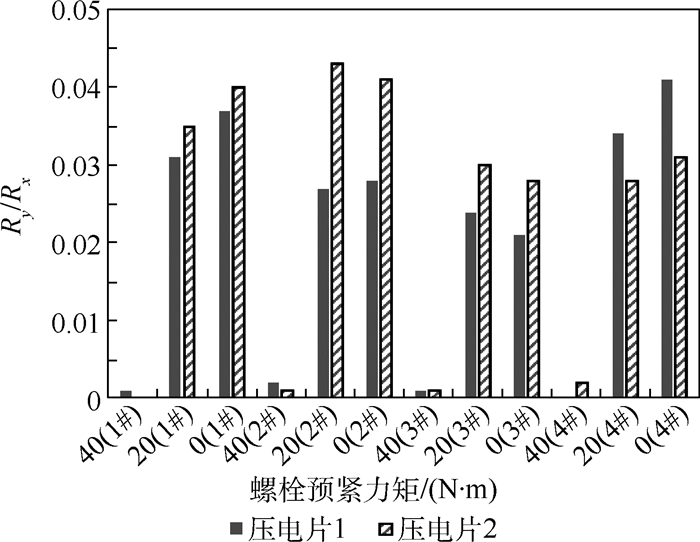

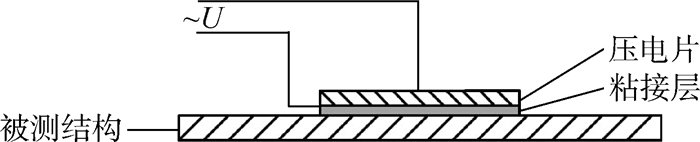

基于压电阻抗法的采用统计学参数作为损伤指标评估螺栓松动的方法有着广泛的应用,然而采用该方法的试验对象多数为实验室条件下的板等结构,并非真实结构。因此,针对真实的法兰结构,这些损伤指标是否适用、是否需要改进仍需进一步研究。通过实验,得出不同损伤指标与法兰结构螺栓松动之间的规律:螺栓松动的程度越大位置越近,均方根偏差(RMSD)、平均绝对百分比偏差(MAPD)、相关系数差(CCD)的值越大,而指标

R y /R x 因无显著规律不适合作为评估法兰结构螺栓松动的损伤指标。通过对比结果发现:结构差异对前3个损伤指标均有不同程度的影响,改进后的损伤指标均方根变化率(RMSCR)只与法兰结构螺栓松动的位置和程度有关,受结构差异影响小。因此,RMSCR具有重要实践意义:当任一压电片损坏时只需更换为同型号的压电片即可,无需更新损伤指标库。通过实验验证了上述结果的正确性与基于RMSCR的法兰结构螺栓松动检测方法的适用性。-

关键词:

- 螺栓松动检测 /

- 法兰结构 /

- 压电阻抗法 /

- 损伤指标 /

- 均方根变化率(RMSCR)

Abstract:The method based on the piezoelectric impedance method using statistical parameters as the damage index to evaluate loose bolt has a wide range of applications. However, most of the test objects adopting this method are structures such as plates under laboratory conditions, which are not real structures. Therefore, for real flange structures, whether these damage indexes are still applicable and whether these damage indexes need to be improved need further study. The rules between different damage indexes and loose bolt of flange structure are obtained through experiments:the larger the degree of bolt looseness is and the closer the position is, the larger the values of the Root Mean Square Deviation (RMSD), the Mean Absolute Percent Deviation (MAPD), and the Correlation Coefficient Difference (CCD) are, and

R y /R x is not suitable to be used as a damage index for evaluating the loose bolt of flange structures because it has not a significant rule. The comparison of results shows that the structural difference affects the first three damage indicators to different degrees, and the improved damage index Root Mean Square of Change Rate (RMSCR) is only related to the position and degree of the loose bolt of flange structures, which is barely affected by the structural difference. Hence, the RMSCR has a crucial practical significance:when any piezoelectric sheet is damaged, it only needs to be replaced with a piezoelectric sheet of the same type without updating the damage index library. Finally, verification experiments verify the correctness of the above results and the applicability of the detection method for loose bolt of flange structure based on RMSCR. -

表 1 损伤指标RMSD

Table 1. Damage index RMSD

压电片编号 螺栓预紧力矩/(N·m) 40 35 30 25 20 15 10 5 0 1 0.003 0.052 0.066 0.071 0.076 0.085 0.088 0.090 0.104 2 0.002 0.050 0.073 0.080 0.086 0.096 0.098 0.101 0.106 3 0.003 0.044 0.060 0.066 0.071 0.076 0.078 0.079 0.085 4 0.003 0.032 0.044 0.047 0.050 0.054 0.054 0.056 0.064 5 0.001 0.023 0.031 0.036 0.041 0.042 0.044 0.047 0.059 表 2 损伤指标MAPD

Table 2. Damage index MAPD

压电片编号 螺栓预紧力矩/(N·m) 40 35 30 25 20 15 10 5 0 1 1.05 15.02 20.38 22.61 23.57 25.51 26.56 26.95 30.99 2 0.81 13.48 19.76 21.61 23.82 26.78 27.44 28.46 31.32 3 1.35 12.17 15.44 17.43 19.23 21.07 21.63 22.34 25.08 4 0.91 9.44 14.41 15.15 16.33 18.40 17.69 18.57 20.19 5 0.45 7.23 9.59 10.61 11.79 12.93 13.47 14.06 16.71 表 3 损伤指标CCD

Table 3. Damage index CCD

压电片编号 螺栓预紧力矩/(N·m) 40 35 30 25 20 15 10 5 0 1 0.003 0.011 0.016 0.018 0.020 0.025 0.027 0.028 0.036 2 0.003 0.011 0.020 0.024 0.028 0.034 0.035 0.037 0.040 3 0.003 0.006 0.010 0.011 0.013 0.014 0.015 0.015 0.017 4 0.003 0.005 0.008 0.009 0.010 0.011 0.011 0.011 0.014 5 0.003 0.004 0.004 0.005 0.006 0.006 0.006 0.007 0.009 表 4 损伤指标Ry/Rx

Table 4. Damage index Ry/Rx

压电片编号 螺栓预紧力矩/(N·m) 40 35 30 25 20 15 10 5 0 1 0.001 0.002 0.004 0.009 0.008 0.008 0.008 0.005 0.010 2 0.000 0.002 0.001 0.003 0.006 0.006 0.009 0.004 0.004 3 0.000 0.005 0.001 0.000 0.001 0.003 0.004 0.001 0.004 4 0.000 0.001 0.005 0.005 0.004 0.004 0.005 0.005 0.002 5 0.000 0.000 0.001 0.002 0.003 0.002 0.001 0.000 0.007 表 5 损伤指标RMSCR

Table 5. Damage index RMSCR

压电片编号 螺栓预紧力矩/(N·m) 40 35 30 25 20 15 10 5 0 1 0.005 0.051 0.069 0.075 0.080 0.090 0.093 0.093 0.107 2 0.004 0.050 0.067 0.073 0.080 0.089 0.092 0.095 0.105 3 0.005 0.041 0.056 0.063 0.067 0.072 0.073 0.076 0.084 4 0.004 0.034 0.049 0.053 0.057 0.063 0.063 0.065 0.071 5 0.002 0.026 0.033 0.036 0.042 0.045 0.046 0.049 0.061 表 6 验证实验中的损伤指标RMSD

Table 6. Damage index RMSD in verification experiment

压电片编号 螺栓预紧力矩/(N·m) 40(1#) 20(1#) 0(1#) 40(2#) 20(2#) 0(2#) 40(3#) 20(3#) 0(3#) 40(4#) 20(4#) 0(4#) 1 0.001 0.063 0.081 0.001 0.037 0.046 0 0.035 0.046 0.001 0.064 0.083 2 0.002 0.053 0.069 0.002 0.055 0.067 0.001 0.027 0.038 0.001 0.026 0.039 表 7 验证实验中的损伤指标MAPD

Table 7. Damage index MAPD in verification experiment

压电片编号 螺栓预紧力矩/(N·m) 40(1#) 20(1#) 0(1#) 40(2#) 20(2#) 0(2#) 40(3#) 20(3#) 0(3#) 40(4#) 20(4#) 0(4#) 1 0.573 10.11 15.32 0.678 6.730 9.019 0.640 7.012 9.181 0.550 10.07 14.89 2 0.434 8.630 13.61 0.672 8.441 13.49 0.511 5.981 7.873 0.512 5.871 7.903 表 8 验证实验中的损伤指标CCD

Table 8. Damage index CCD in verification experiment

压电力编号 螺栓预紧力矩/(N·m) 40(1#) 20(1#) 0(1#) 40(2#) 20(2#) 0(2#) 40(3#) 20(3#) 0(3#) 40(4#) 20(4#) 0(4#) 1 0.002 0.089 0.110 0.002 0.041 0.062 0.001 0.044 0.063 0.002 0.086 0.107 2 0.002 0.063 0.093 0.001 0.067 0.096 0.001 0.031 0.043 0.002 0.034 0.045 表 9 验证实验中的损伤指标Ry/Rx

Table 9. Damage index Ry/Rx in verification experiment

压电片编号 螺栓预紧力矩/(N·m) 40(1#) 20(1#) 0(1#) 40(2#) 20(2#) 0(2#) 40(3#) 20(3#) 0(3#) 40(4#) 20(4#) 0(4#) 1 0.001 0.031 0.037 0.002 0.027 0.028 0.001 0.024 0.021 0.000 0.034 0.041 2 0.000 0.035 0.040 0.001 0.043 0.041 0.001 0.030 0.028 0.002 0.028 0.031 表 10 验证实验中的损伤指标RMSCR

Table 10. Damage index RMSCR in verification experiment

压电片编号 螺栓预紧力矩/(N·m) 40(1#) 20(1#) 0(1#) 40(2#) 20(2#) 0(2#) 40(3#) 20(3#) 0(3#) 40(4#) 20(4#) 0(4#) 1 0.023 0.427 0.489 0.021 0.302 0.344 0.018 0.297 0.351 0.015 0.420 0.487 2 0.021 0.430 0.495 0.024 0.427 0.489 0.020 0.289 0.346 0.015 0.291 0.350 -

[1] 杨光瑜.基于PZT阻抗分析的结构健康监测技术研究[D].长沙: 国防科学技术大学, 2002: 48.YANG G Y.Research on structural health monitoring technology based on PZT impedance analysis[D].Changsha: National University of Defense Technology, 2002: 48(in Chinese). [2] 王丹生, 朱宏平, 鲁晶晶, 等.基于压电导纳的钢框架螺栓松动检测试验研究[J].振动与冲击, 2007, 26(10):157-160. doi: 10.3969/j.issn.1000-3835.2007.10.034WANG D S, ZHU H P, LU J J, et al.Experimental study on detection loosened bolts of a steel frame based on piezoelectric admittance[J].Journal of Vibration and Shock, 2007, 26(10):157-160(in Chinese). doi: 10.3969/j.issn.1000-3835.2007.10.034 [3] 任凯, 张子涵, 杜飞, 等.基于阻抗法的多螺栓连接预紧扭矩检测试验研究[J].动力学与控制学报, 2018, 16(5):467-472. http://www.cnki.com.cn/Article/CJFDTotal-DLXK201805013.htmREN K, ZHANG Z H, DU F, et al.Experimental study on pre-tightening torque detection of multi-bolt connection based on impedance method[J].Journal of Dynamics and Control, 2018, 16(5):467-472(in Chinese). http://www.cnki.com.cn/Article/CJFDTotal-DLXK201805013.htm [4] 石耀坤.压电阻抗法在结构健康监测中应用研究与系统实现[D].荆州: 长江大学, 2019: 15-16.SHI Y K.Application research and system implementation of piezoelectric impedance method in structural health monitoring[D].Jingzhou: Yangtze University, 2019: 15-16(in Chinese). [5] 胡显燕.基于压电阻抗技术的板结构损伤识别研究[D].武汉: 华中科技大学, 2018: 23-24.HU X Y.Research on damage identification of plate structure based on piezoelectric impedance technique[D].Wuhan: Huazhong University of Science and Technology, 2018: 23-24(in Chinese). [6] 唐超.基于PZT阻抗法的钢结构桥梁高强螺栓损伤监测试验研究[D].长沙: 长沙理工大学, 2017: 26-27.TANG C.Experimental research on damage detection of high strength bolt of steel bridge based on PZT impedance method[D].Changsha: Changsha University of Science and Technolegy, 2017: 26-27(in Chinese). [7] 张兢, 徐霞, 张志文.基于压电陶瓷的结构损伤检测技术[J].压电与声光, 2006, 28(3):350-356. doi: 10.3969/j.issn.1004-2474.2006.03.033ZHANG J, XU X, ZHANG Z W.Structural damage detection technology based on piezoelectric ceramics[J].Piezoelectrics and Acoustoptics, 2006, 28(3):350-356(in Chinese). doi: 10.3969/j.issn.1004-2474.2006.03.033 [8] 林枫.基于压电阻抗的GFRP板螺栓连接损伤监测[D].武汉: 华中科技大学, 2017: 43.LIN F.Damage monitoring of bolted connections to GFRP plate based on the piezoelectric impedance[D].Wuhan: Huazhong University of Science and Technology, 2017: 43(in Chinese). [9] 叶亮.基于压电阻抗方法的结构健康监测与损伤识别研究[D].北京: 北京化工大学, 2013: 66-72.YE L.Structural health monitoring and damage localization based on EMI technology[D].Beijing: Beijing University of Chemical Technology, 2013: 66-72(in Chinese). [10] 邵俊华, 王涛, 汪正傲, 等.基于压电阻抗频率变化的螺栓松动检测技术[J].中国机械工程, 2019, 30(12):1395-1399. doi: 10.3969/j.issn.1004-132X.2019.12.002SHAO J H, WANG T, WANG Z A, et al.Bolt looseness detection using piezoelectric impedance frequency shift method[J].China Mechanical Engineering, 2019, 30(12):1395-1399(in Chinese). doi: 10.3969/j.issn.1004-132X.2019.12.002 [11] 张鑫.基于EMI的结构损伤检测技术研究[D].西安: 第二炮兵工程大学, 2015: 29-53.ZHANG X.Research on detection of structural damage based on EMI[D].Xi'an: The Second Artillery Engineering University, 2015: 29-53(in Chinese). [12] ZHANG Y X, ZHANG X, CHEN J Z, et al.Electro-mechanical impedance based position identification of bolt loosening using LibSVM[J].Intelligent Automation and Soft Computing, 2018, 24(1):81-88. doi: 10.1080/10798587.2016.1267245 [13] MIN J Y, PARK S, YUN C B, et al.Impedance-based structural health monitoring incorporating neural network technique for identification of damage type and severity[J].Engineering Structures, 2012, 39:210-220. doi: 10.1016/j.engstruct.2012.01.012 [14] PAVELKO V.Electromechanical impedance for SHM of aircraft bolted joints[C]//Proceedings of the Nondestructive Characterization for Composits Materials, Aerospace Engineering, Civil Infrastructure, and Homeland Security, 2013: 1-14. [15] AN Y, SOHN H.Integrated impedance and guided wave based damage detection[J].Mechanical Systems and Signal Processing, 2012, 28:50-62. doi: 10.1016/j.ymssp.2011.11.016 [16] 刘增华, 于洪涛, 蔡小明, 等.用于结构健康监测的无线智能机电阻抗传感器[J].仪表技术与传感器, 2013(8):11-14. doi: 10.3969/j.issn.1002-1841.2013.08.004LIU Z H, YU H T, CAI X M, et al.Electro-mechanical impedance wireless smart sensor for structural health monitoring[J].Instrument Technique and Sensor, 2013(8):11-14(in Chinese). doi: 10.3969/j.issn.1002-1841.2013.08.004 -

下载:

下载: