-

摘要:

临近空间超高速飞行器在飞行过程中受到外部干扰作用时会出现大迎角飞行姿态,此时需大角度偏转全动平尾进行配平,带来平尾大迎角下的气动弹性问题。采用计算流体力学/计算固体力学/计算热力学(CFD/CSD/CTD)耦合方法分析了一种超高速飞行器全动平尾的气动弹性特性,重点研究了大迎角下平尾的气动响应及结构变形特点。结果表明:各迎角时的气动力曲线均出现波动,随时间变化逐渐衰减至平衡位置。迎角越大,初始振幅越大,气动力系数减小的比例越大,但随时间衰减得越快。平尾存在弯曲/扭转耦合现象,结构变形导致表面压力分布发生变化,使得整体压力减小、升力系数降低,迎角越大现象越明显。平尾最大应力在迎角30°时达1.2 GPa,已达到所用镍合金材料的屈服强度极限。应在结构设计时在翼轴与平尾接触部位附近加强,或在控制方案设计时限制全动平尾的工作角度。结构发生轴向与法向变形,轴向变形主要由气动热引起,法向变形由气动力和气动热共同引起。

Abstract:During the flight of near space hypersonic vehicles, the external disturbances may result in high angle of attack conditions. And the off-design conditions may lead to a large deflection angle of the all-movable tail, which brings aeroelastic problem. Aimed at solving the aeroelastic problems, aeroelastic characteristics were analyzed by the CFD/CSD/CTD coupled method for the all-movable tail, and especially the aerodynamic response and structural deformation were focused on. The results show that aerodynamic response curves fluctuate and gradually decay to equilibrium position. The larger the attack angle is, the greater the initial amplitude is, the larger the proportion of aerodynamic coefficient decreases, and the amplitude decays faster. Bending/torsion coupling deformation occurs in the tail structure, and the structural deformation leads to the change of pressure distribution, the reduction of the whole pressure and the decrease of lift coefficient. The larger the attack angle is, the greater the decrease is. The maximum stress of the tail reaches 1.2 GPa at 30° angle of attack, which has reached yield strength limit of the nickel alloy material. It should be strengthened for the region where wing axis contacts with tail, or it should be limited for the operating angle in control law design. Axial deformation is mainly caused by aerodynamic thermal load, and normal deformation is caused by aerodynamic thermal load and aerodynamic force load.

-

Key words:

- hypersonic /

- all-movable tail /

- high angle of attack /

- aeroelastic /

- response characteristics

-

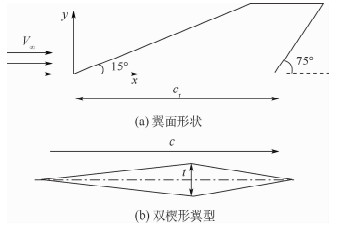

表 1 全动尾翼几何参数

Table 1. Geometric parameters of all-movable tail

参数 数值 翼根弦长/m 0.63 展长/m 0.22 相对厚度 0.04 面积/m2 0.15 表 2 钛合金材料参数

Table 2. Parameters of titanium alloy material

参数 数值 密度ρ/(kg·m-3) 4 400 弹性模量E/GPa 75~109 泊松比λ 0.34 热膨胀系数α/(10-6 K-1) 9.2~11.0 热导率k/(W·(m·K)-1) 6.8~11.8 比热C/(J·(kg·K)-1) 610~702 表 3 镍合金材料参数

Table 3. Parameters of nickel alloy material

参数 数值 ρ/(kg·m-3) 8 240 E/GPa 160~205 λ 0.30 α/(10-6 K-1) 11.8~18.7 k/(W·(m·K)-1) 13.4~30.4 C/(J·(kg·K)-1) 481~707 表 4 等效弹性常数

Table 4. Equivalent elastic constants

参数 数值 ρ/(kg·m-3) 924 Ex/MPa 850~1 353 Ey/MPa 605~963 Ez/MPa 1 984~3 157 α/(10-6 K-1) 13.3~18.6 k/(W·(m·K)-1) 14.2~32.7 C/(J·(kg·K)-1) 493~742 λ 0.3 表 5 不同迎角下气动力响应

Table 5. Aerodynamic response at different angles of attack

迎角/(°) CL减小量/% CD减小量/% 波动半衰期/s 10 1 1 0.97 20 3.6 4.7 0.73 30 4.1 4.9 0.60 40 5.1 6.6 0.48 -

[1] OPPENHEIMER M W, DOMAN D B, MCNAMARA J J, et al. Viscous effects for a hypersonic vehicle model[C]//AIAA Atmospheric Flight Mechanics Conference and Exhibit. Reston: AIAA, 2008: 374-387. [2] YENTSCH R J, GAITONDE D V, KIMMEL R. Performance of turbulence modeling in simulation of the HIFiRE-1 flight test[J]. Journal of Spacecraft and Rockets, 2014, 51(1): 117-127. doi: 10.2514/1.A32535 [3] WROBLE V. SR-72 could be obsolete[J]. Aviation Week & Space Technology, 2013, 175(42): 10. http://www.zhangqiaokeyan.com/academic-journal-foreign_other_thesis/0204110858977.html [4] LIGHTHILL M J. Oscillating airfoils at high Mach numbers[J]. Journal of Aeronautical Science, 1953, 20(6): 402-406. doi: 10.2514/8.2657 [5] ASHLEY H, ZARTARIAN G. Piston-theory: A new aerodynamic tool for the aeroelastician[J]. Journal of Aeronautical Science, 1956, 23(12): 209-222. [6] LAUTEN W T J, LEVEY G M, ARMSTRONG W O. Investigation of an all-movable control surface at a Mach number of 6.86 for possible flutter[J]. Technical Report Archive & Image Library, 1958, 14(5): 19-22. [7] GOETZ R C. Effects of leading-edge bluntness on flutter characteristics of some square-planform double-wedge airfoils at a Mach number of 15.4[M]. Champaign: National Aeronautics and Space Administration, 1962: 10-19. http://www.zhangqiaokeyan.com/ntis-science-report_other_thesis/020711171744.html [8] HEEG J, ZEILER T A, POTOTZKY A S, et al. Aerothermoelastic analysis of a NASP demostrator model[C]//Proceedings of the 34th Structures, Structural Dynamics and Materials Conference. Reston: AIAA, 2013: 1993-1366. [9] LIU D D, YAO Z X, SARHADDI D, et al. From piston theory to a unified hypersonic-supersonic lifting surface method[J]. Journal of Aircraft, 1997, 34(3): 304-312. doi: 10.2514/2.2199 [10] 陈劲松, 曹军. 超声速和高超声速翼型非定常气动力的一种近似计算方法[J]. 空气动力学学报, 1990, 8(3): 339-344. https://www.cnki.com.cn/Article/CJFDTOTAL-KQDX199003014.htmCHEN J S, CAO J. An approximate calculating method of supersonic/hypersonic unsteady aerodynamic forces of airfoils[J]. Acta Aerodynamica Sinica, 1990, 8(3): 339-344(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-KQDX199003014.htm [11] 杨炳渊, 宋伟力. 用当地流活塞理论计算大攻角翼面超音速颤振[J]. 振动与冲击, 1995, 14(2): 60-63. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ502.012.htmYANG B Y, SONG W L. Supersonic flutter calculation of a wing with attack angle by local flow piston theory[J]. Journal of Vibration and Shock, 1995, 14(2): 60-63(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ502.012.htm [12] MCNAMARA J J, FRIEDMANN P P. Flutter boundary identification for time-domain computational aeroelasticity[J]. AIAA Journal, 2007, 45(7): 1546-1555. doi: 10.2514/1.26706 [13] MCNAMARA J J, CROWELL A R, FRIEDMANN P P, et al. Approximate modeling of unsteady aerodynamics for hypersonic aeroelasticity[J]. Journal of Aircraft, 2010, 47(6): 1932-1945. doi: 10.2514/1.C000190 [14] MCNAMARA J J, FRIEDMANN P P. Aeroelastic and aerothermoelastic analysis in hypersonic flow: Past, present, and future[J]. AIAA Journal, 2011, 49(6): 1089-1122. doi: 10.2514/1.J050882 [15] 张伟伟, 叶正寅. 基于当地流活塞理论的气动弹性计算方法研究[J]. 力学学报, 2005, 37(5): 632-639. https://www.cnki.com.cn/Article/CJFDTOTAL-LXXB200505015.htmZHANG W W, YE Z Y. Numerical method of aeroelasticity based on local piston theory[J]. Acta Mechanica Sinica, 2005, 37(5): 632-639(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-LXXB200505015.htm [16] GUPTA K, VOELKER L S. CFD-based aeroelastic analysis of the X-43 hypersonic flight vehicle[C]//39th Aerospace Sciences Meeting & Exhibit. Reston: AIAA, 2001. [17] GUPTA K, BACH C. Computational fluid dynamics-based aeroservoelastic analysis with Hyper-X applications[J]. AIAA Journal, 2007, 45(7): 1459-1471. doi: 10.2514/1.21992 [18] GUPTA K K, VOELKER L S. Aeroelastic simulation of hypersonic flight vehicles[J]. AIAA Journal, 2012, 50(3): 717-723. doi: 10.2514/1.J051386 [19] ZENG K C, XIANG J W, LI D C. Aeroservoelastic modeling and analysis of a canard-configured air-breathing hypersonic vehicles[J]. Chinese Journal of Aeronautics, 2013, 26(4): 831-840. doi: 10.1016/j.cja.2013.06.001 [20] 史晓鸣, 梅睿, 苏轶龙, 等. 舵轴位置对全动舵面气动弹性稳定性影响[J]. 噪声与振动控制, 2016, 36(3): 81-84. https://www.cnki.com.cn/Article/CJFDTOTAL-ZSZK201603018.htmSHI X M, MEI R, SU Y L, et al. Influence of rudder shaft location on aeroelastic stablity of an all-moving rudder[J]. Noise and Vibration Control, 2016, 36(3): 81-84(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-ZSZK201603018.htm [21] 王文全, 张立翔. 计算流固耦合动力学及其应用[M]. 北京: 中国水利水电出版社, 2015: 2-12.WANG W Q, ZHANG L X. Computational fluid-structure interaction dynamics and applications[M]. Beijing: China Water & Power Press, 2015: 2-12(in Chinese). [22] 聂雪媛, 黄程德, 杨国伟. 基于CFD/CSD耦合的结构几何非线性静气动弹性数值方法研究[J]. 振动与冲击, 2016, 35(8): 48-53. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201608008.htmNIE X Y, HUANG C D, YANG G W. Numerical analysis for aeroelastic with structural geometrical nonlinearity using a CFD/CSD coupled method[J]. Journal of Vibration and Shock, 2016, 35(8): 48-53(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201608008.htm [23] 周迪, 陆志良, 郭同庆, 等. 基于CFD/CSD耦合的叶轮机叶片失速颤振计算[J]. 航空学报, 2015, 36(4): 1076-1085. https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201504005.htmZHOU D, LU Z L, GUO T Q, et al. Stall flutter computation of turbomachinery blade based on a CFD/CSD coupling method[J]. Acta Aeronautica et Astronautica Sinica, 2015, 36(4): 1076-1085(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201504005.htm [24] DUKOWICZ J K, KODIS J W. Accurate conservative remapping(rezoning) for arbitrary Lagrangian-Eulerian computations[J]. Journal on Scientific and Statistical Computing, 1987, 8(3): 305-321. doi: 10.1137/0908037 [25] BENSON D J, HALLQUIST J O. A single surface contact algorithm for the post-buckling analysis of shell structures[J]. Computer Methods in Applied Mechanics and Engineering, 1990, 78(2): 141-163. doi: 10.1016/0045-7825(90)90098-7 [26] JANSEN K, SHAKIB F, HUGHES T J R. Fast projection algorithm for unstructured meshes[J]. Computational Nonlinear Mechanics in Aerospace Engineering, 1992, 146(5): 175-204. [27] WIETING A R, HOLDEN M S. Experimental study of shock wave interference heating on a cylindrical leading edge at Mach 6 and 8[C]//Proceedings of the AIAA 22nd Thermophysics Conference. Reston: AIAA, 1987. -

下载:

下载: