-

摘要:

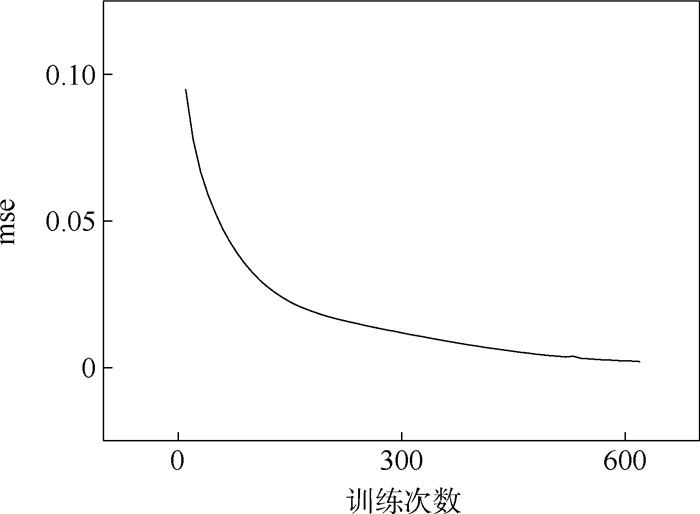

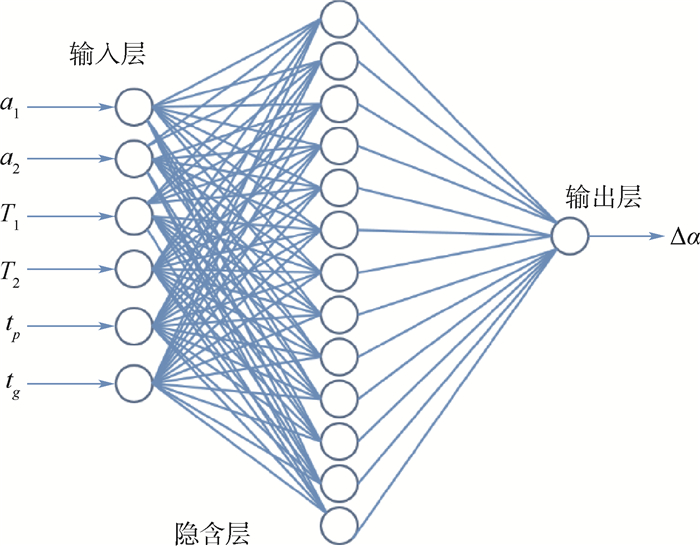

复合材料热压罐成型过程中的固化度差值是复合材料固化度均匀性的主要表征参数之一。基于3层BP神经网络,以复合材料双平台固化工艺曲线的加热速率、保温时间和保温温度为输入参数,建立了成型过程任一时刻最大固化度差值的快速估算模型。仿真复合材料热压罐成型过程,得到最大固化度差值作为试验样本数据,对BP神经网络进行训练,训练结束后对该模型的准确性进行验证。结果表明:该BP神经网络估算模型准确性和效率较高,为复合材料热压罐成型最大固化度差值的估算提供了一种快速有效的新方法。

Abstract:The difference in degree of cure in the forming process of composite autoclave is one of the main characterization parameters of degree of cure uniformity of composite. Based on thethree-layer BP neural network, this paper established a rapid estimation model of maximum difference of curing degree at any time in the forming process with heating rate, holding time and holding temperature as input parameters. Maximum difference in degree of cure was obtained by simulating the forming process of composite autoclave as test sample data to train the BP neural network, and the accuracy of the model was verified after the training. The results show that the accuracy and efficiency of this BP neural network model are high, which provides a fast and effective new method for estimating the difference of the maximum curing degree of composite autoclave.

-

Key words:

- composite /

- neural network /

- estimation /

- curing process /

- autoclave /

- residual stress

-

表 1 复合材料AS4/3501-6热力学及固化动力学模型参数

Table 1. Thermodynamics and cure kinetics model parameters for AS4/3501-6 composites

参数 数值 ρ/(kg·m-3) 1 578 Cp/(J·(kg·K)-1) 862 kT/(W·(m·K)-1) 0.413 5 kL/(W·(m·K)-1) 12.83 Hr/(J·kg-1) 198.6×103 A1/min-1 2.102×109 A2/min-1 -2.014×109 A3/min-1 1.960×105 ΔE1/(J·mol-1) 8.07×104 ΔE2/(J·mol-1) 7.78×104 ΔE3/(J·mol-1) 5.66×104 注:ρ为复合材料的密度; Cp为比热; kT和kL分别为复合材料的横向和纵向导热系数; Hr为最终反应热; Ai(i=1, 2, 3)为频率因子; ΔEi(i=1, 2, 3)为活化能。 表 2 工艺参数取值范围

Table 2. Range of process parameters

参数 取值范围 a1/(℃·min-1) [1,5] a2/(℃·min-1) [1,5] T1/℃ [115,155] T2/℃ [175,215] tp/min [0, 100] tg/min [0, 150] 表 3 固化数据

Table 3. Curing data

a1/(℃·min-1) a2/(℃·min-1) T1/℃ T2/℃ tp/min tg/min Δα 3 3 120 180 120 60 0.008 23 3 3 121 180 120 60 0.008 23 3 3 119 180 120 60 0.008 36 4 3 120 179 120 60 0.008 04 2 3 120 179 120 60 0.007 96 2 4 120 179 120 60 0.008 50 2 2 120 179 120 60 0.006 78 2 2 120 179 123 60 0.006 78 1 1 116 176 102 72 0.003 48 1 1 116 175 93 78 0.003 42 1 1 116 176 93 78 0.003 42 1 2 116 175 93 78 0.005 89 1 1 116 175 90 78 0.003 42 1 1 116 175 96 78 0.003 41 1 1 116 175 96 80 0.003 39 1 1 115 177 66 100 0.003 26 1 1 121 175 78 100 0.002 92 1 1 121 177 78 100 0.002 92 1 1 130 175 78 100 0.002 33 1 1 130 176 78 100 0.002 34 表 4 Δα的估算

Table 4. Estimation of Δα

a1/(℃·min-1) a2/(℃·min-1) T1/℃ T2/℃ tp/min tg/min Δα的试验值Δαs Δα的估算值Δαg 误差值Δ=Δαs-Δαg 误差率Δ/Δs 3 3 120 181 120 60 0.008 56 0.008 09 0.000 47 0.054 2 2 120 179 123 60 0.006 78 0.006 53 0.000 25 0.036 1 1 119 178 120 60 0.003 82 0.003 89 -0.000 07 -0.018 1 1 117 117 114 64 0.003 69 0.003 66 0.000 03 0.008 1 1 115 175 90 88 0.003 38 0.003 50 -0.000 12 -0.035 -

[1] DOLKUN D, ZHU W D, XU Q, et al. Optimization of cure profile for thick composite parts based on finite element analysis and genetic algorithm[J]. Journal of Composite Materials, 2018, 52(28): 1-5. [2] 顾轶卓, 李敏, 李艳霞, 等. 飞行器结构用复合材料制造技术与工艺理论进展[J]. 航空学报, 2015, 36(8): 2773-2797.GU Y Z, LI M, LI Y X, et al. Progress on manufacturing technology and process theory of aircraft composite[J]. Acta Aeronautica et Astronautica Sinica, 2015, 36(8): 2773-2797(in Chinese). [3] 王永贵, 梁宪珠, 曹正华, 等. 热压罐工艺成型先进复合材料构件的温度场研究综述[J]. 玻璃钢/复合材料, 2009(3): 81-85. doi: 10.3969/j.issn.1003-0999.2009.03.021WANG Y G, LIANG X Z, CAO Z H, et al. Review of the temperature field research of autoclave moulding for advanced composite components[J]. Fiber Reinforced Plastics/Composites, 2009(3): 81-85(in Chinese). doi: 10.3969/j.issn.1003-0999.2009.03.021 [4] 李彩林. 复合材料热压罐固化设计的数值模拟[J]. 玻璃钢/复合材料, 2014(11): 26-29.LI C L. Numerical simulation for autoclave curing design of composite materials[J]. Fiber Reinforced Plastics/Composites, 2014(11): 26-29(in Chinese). [5] 向炳东, 李敏, 李艳霞, 等. 筒状复合材料制件热压罐成型温度模拟及影响因素分析[J]. 航空学报, 2017, 38(11): 298-307.XIANG B D, LI M, LI Y X, et al. Numerical simulation and parameter analysis of temperature distribution of autoclave cured composite cylindrical structure[J]. Acta Aeronautica et Astronautica Sinica, 2017, 38(11): 298-307(in Chinese). [6] LOOS A C, SPRINGER G S. Curing of epoxy matrix composites[J]. Journal of Composite Materials, 1983, 17(2): 135-169. doi: 10.1177/002199838301700204 [7] BOGETTI T A, GILLESPIE J W. Two-dimensional cure simulation of thick thermosetting composites[J]. Journal of Composite Materials, 1991, 25(3): 239-273. doi: 10.1177/002199839102500302 [8] JOHNSTON A A. An integrated model of the development of process-induced deformation in autoclave processing of composite structures[D]. Ann Arbor: The University of British Columbia (Canada), 1998. [9] HOA S V. Design and manufacturing of composites[C]//Proceedings of the Second Joint Hamada Concordia University Montreal, 1998, 16(1): 2-16. [10] 焦李成. 神经网络系统理论[M]. 西安: 西安电子科技大学出版社, 1990.JIAO L C. Theory of neural network system[M]. Xi'an: Xidian University Press, 1990(in Chinese). [11] 吴简彤, 王建华. 神经网络技术及其应用[M]. 哈尔滨: 哈尔滨工程大学出版社, 1998.WU J T, WANG J H. Neural network technology and its application[M]. Harbin: Harbin Engineering University Press, 1998(in Chinese). [12] 张德丰, 丁伟雄, 雷晓平. MATLAB程序设计与综合应用[M]. 北京: 清华大学出版社, 2012: 1-3.ZHANG D F, DING W X, LEI X P. MATLAB programming and comprehensive application[M]. Beijing: Tsinghua University Press, 2012: 1-3(in Chinese). [13] BLEST D C, DUFFY B R, MCKEE S, et al. Curing simulation of thermoset composites[J]. Composites Part A: Applied Science and Manufacturing, 1999, 30(11): 1289-1309. doi: 10.1016/S1359-835X(99)00032-9 [14] CHEUNG A, YU Y, POCHIRAJU K. Three-dimensional finite element simulation of curing of polymer composites[J]. Finite Elements in Analysis and Design, 2004, 40(8): 895-912. doi: 10.1016/S0168-874X(03)00119-7 [15] KIM Y K, WHITE S R. Viscoelastic analysis of processing-induced residual stress in thick composite laminates[J]. Mechanics of Composite Materials and Structures, 1997, 4(4): 361-387. doi: 10.1080/10759419708945889 [16] 高腾龙. 热固性树脂基复合材料固化变形模拟及控制方法研究[D]. 西安: 西北工业大学, 2018.GAO T L. Simulation and control methods of curing deformation of thermosetting resin matrix composites[D]. Xi'an: Northwestern Polytechnical University, 2018(in Chinese). [17] 林仕高, 欧元贤. BP神经网络学习参数优化研究[J]. 微计算信息, 2010, 26(6): 199-200.LIN S G, OU Y X. Research of the optimization of the learning parameters in BP neural network[J]. Microcomputer Information, 2010, 26(6): 199-200(in Chinese). [18] HECHT-NIELSEN R. Theory of the backpropagation neural network[J]. Neural Networks, 1988, 1(S1): 445. [19] 蒋佳欣, 王博, 王猛, 等. 基于BIM技术和BP神经网络的成都理工大学图书馆天然采光研究[J]. 土木建筑工程信息技术, 2020, 12(1): 30-38.JIANG J X, WANG B, WANG M, et al. Study on natural lighting design for CDUT library based on BIM and BP neural network[J]. Journal of Information Technology in Civil Engineering and Architecture, 2020, 12(1): 30-38(in Chinese). [20] 薛掌安, 邓海亮. BP神经网络在复合材料研究中的应用[J]. 材料导报, 2009, 23(14): 250-253.XUE Z A, DENG H L. Application of BP neural networks in the composites research[J]. Materials Reports, 2009, 23(14): 250-253(in Chinese). [21] 柳小桐. BP神经网络输入层数据归一化研究[J]. 机械工程与自动化, 2010(3): 122-123.LIU X T. Study on data normalization in BP neural network[J]. Mechanical Engineering & Automation, 2010(3): 122-123(in Chinese). [22] HECHT-NIELSEN R. Kolmogorov's mapping neural network existence theorem[C]//Proceedings of the International Conference on Neural Networks, 1987, 3: 11-13. -

下载:

下载: