Face micro-deformation and its control method of rotating ring of hydrodynamic face seal under high speed, high pressure and wide temperature range

-

摘要:

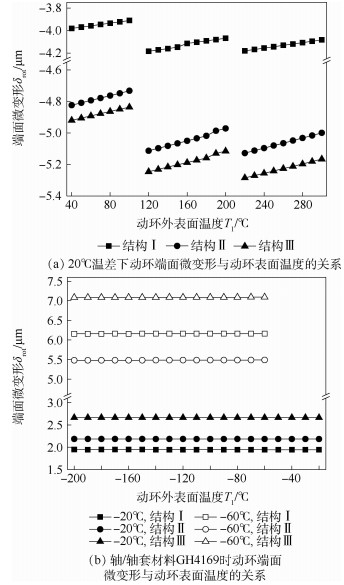

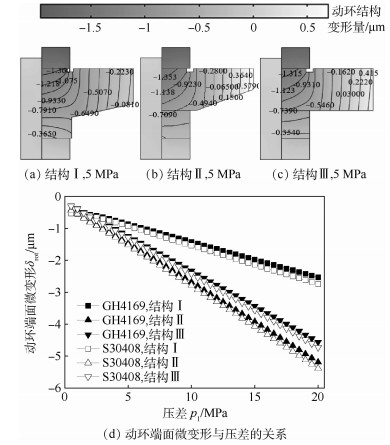

针对高速高压高温/低温工况下动压密封变形问题,以动压密封的典型结构为研究对象,考虑动环的支撑和约束,建立热固耦合分析模型,研究热载荷、力载荷和约束对动环端面微变形的影响,并提出动环端面微变形改善方法。结果表明:多载荷共同作用时,温差对动环端面微变形影响最大,其次是转速和压力;在2种情况下,动环端面微变形受温度值的影响很小,主要与温差有关;相比低温,动环端面微变形更易受高温的影响,单位温差的变形变化量为3~4倍;动环形心距旋转中心越远,动环端面微变形受转速影响越大,且呈抛物线关系;动环端面微变形与压差呈线性关系。对高速高压宽温域的动压密封,控制动环端面微变形,首先,应降低动环的温差;其次,若转速够高,应适当增加动环厚度,通过扩大形心变化区域能增加86%的动环端面微变形范围,若转速不够高,通过合理的结构设计约束动环内表面以控制动环翻转,最大能降低65.2%的动环端面微变形;最后,合理设计的轴向压紧力能进一步确保动环端面微变形维持在极小范围内。

Abstract:Aimed at the deformation of hydrodynamic face seal under high speed, high pressure and high/low temperature conditions, a thermal-solid coupling model of typical structure of hydrodynamic face seal is established, and the support and constraints of rotating ring are considered. The face micro-deformation caused by thermal loads, force and constraints are analyzed, and its control methods are proposed. The results show that, when multiple loads act together, temperature difference has the greatest influence on face micro-deformation, followed by the rotational speed and pressure. In two cases, the face micro-deformation of rotating ring is mainly affected by the temperature difference rather than the temperature. Face micro-deformation is more susceptible to high temperature, and the change of face micro-deformation per unit temperature difference is 3-4 times that of low temperature. The farther the centroid of rotating ring is from the rotating center, the greater the influence of the rotational speed on the face micro-deformation is, and it has a parabolic relationship. The face micro-deformation has a linear relationship with the pressure difference. For high-speed, high-pressure, and wide-temperature-range hydrodynamic face seals, controlling the face micro-deformation should first reduce the temperature difference between the inner and outer surfaces of the rotating ring. Under high-speed conditions, the thickness of rotating ring should be appropriately increased, and the deformation range can be increased by 86% by expanding the centroid change area. Under low-speed conditions, the inner surface of rotating ring is restrained by reasonable structure design, which can control the turning of rotating ring and reduce the face micro-deformation by 65.2% at most. The axial clamping force designed reasonably can further ensure that the face micro-deformation is kept in a minimum range.

-

表 1 动环结构参数及动环结构形式

Table 1. Structural parameters of rotating ring and structure form of rotating ring

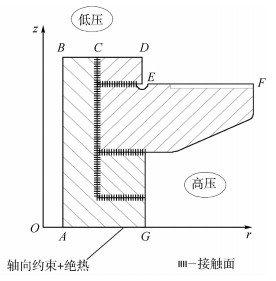

参数 数值 轴径d1/mm 50 定位环外径d2/mm 58 动环外径d3/mm 76 压紧环外径d4/mm 55 结构Ⅰ动环尾部外径d5/mm 57 结构Ⅰ动环厚度δ1/mm 10 结构Ⅱ、Ⅲ动环厚度δ2/mm 6 定位环厚度δ3/mm 4 结构Ⅰ背部倾斜角α1/(°) 15 结构Ⅱ背部倾斜角α2/(°) 25 表 2 载荷、约束与温度边界条件

Table 2. Load, constraint and temperature boundary conditions

边界 载荷与约束 温度 AB 零压力 T2 BC 零压力 T2 CD pcla + padd T2 DE 零压力 T2 EF 0.82p1 + ps FG p1 T1 GA 约束轴向(z向)位移 绝热 表 3 操作参数

Table 3. Operating parameters

参数 数值 外壁面温度T1/℃ -200~300 内壁面温度T2/℃ -200~300 介质压力p1/MPa 0~20 轴向压紧力pcla/MPa 25~100 转速ω/(r·min-1) 0~100 000 表 4 材料属性

Table 4. Material properties

物理性能 GH4169 S30408 弹性模量E/GPa 205 193 泊松比μ 0.3 0.3 导热系数

k/(W·(m·℃)-1)13.4 17.2 恒压热容

Cp/(J·(kg·℃)-1)435 500 线膨胀系数

αl/(10-6·℃-1)11.8 (20~100 ℃)

13.0 (20~200 ℃)

13.5 (20~300 ℃)16.0 (20~100 ℃)

16.8 (20~200 ℃)

17.5 (20~300 ℃)密度ρ/(kg·m-3) 8 240 7 930 表 5 验证性参数

Table 5. Confirmatory parameters

参数 数值 内面板半径Ri/mm 109 外面板半径Re/mm 153 外半径R0/mm 156 水力半径Rh/mm 122 转速ω/(r·min-1) 1 500 出口压力pi/MPa 0.55 入口压力po/MPa 15.5 密封圈的弹性模量E1/GPa 310 钢的弹性模量E2/GPa 200 密封圈导热系数k1/(W·(m·℃)-1) 22 钢的导热系数k2/(W·(m·℃)-1) 30 密封圈的线膨胀系数β1/(10-6 ℃-1) 2.5 钢的线膨胀系数β2/(10-6 ℃-1) 12 螺钉预紧力Fpre/N 8×5 000 -

[1] 张振强, 杨兵华, 赵洋, 等. 某型航空发动机主轴轴承试验故障分析及改进[J]. 轴承, 2017(11): 52-55.ZHANG Z Q, YANG B H, ZHAO Y, et al. Fault analysis and improvement on test for spindle bearings in an aero-engine[J]. Bearing, 2017(11): 52-55(in Chinese). [2] 谢伟松, 林鑫, 王伟韬, 等. 航空发动机弹性箔片气体动压轴承技术研究及性能评价综述[J]. 润滑与密封, 2018, 43(7): 136-147. doi: 10.3969/j.issn.0254-0150.2018.07.025XIE W S, LIN X, WANG W T, et al. Review of technique application and performance evaluation for aerodynamic elastic foil gas bearing in aero-engine[J]. Lubrication Engineering, 2018, 43(7): 136-147(in Chinese). doi: 10.3969/j.issn.0254-0150.2018.07.025 [3] 杨霞辉, 王少鹏, 侯宁涛. 液体推进系统高温高压动密封发展趋势分析[J]. 火箭推进, 2010, 36(4): 31-35. doi: 10.3969/j.issn.1672-9374.2010.04.006YANG X H, WANG S P, HOU N T. Trend of seals working under high temperatures and pressures for liquid propellant engines[J]. Journal of Rocket Propulsion, 2010, 36(4): 31-35(in Chinese). doi: 10.3969/j.issn.1672-9374.2010.04.006 [4] 孙电锋, 孙见君, 於秋萍, 等. 非接触式机械密封动力学研究进展[J]. 化工进展, 2019, 38(12): 5238-5246.SUN D F, SUN J J, YU Q P, et al. Progress of study on dynamics of non-contacting mechanical seals[J]. Chemical Industry and Engineering Progress, 2019, 38(12): 5238-5246(in Chinese). [5] 赵伟刚, 张树强, 陈杰, 等. 液氧泵用动静压混合式密封关键技术研究[J]. 润滑与密封, 2017, 42(1): 111-115. doi: 10.3969/j.issn.0254-0150.2017.01.019ZHAO W G, ZHANG S Q, CHEN J, et al. Key technologies of dynamic-hydrostatic hybrid seals used in liquid oxygen pump[J]. Lubrication Engineering, 2017, 42(1): 111-115(in Chinese). doi: 10.3969/j.issn.0254-0150.2017.01.019 [6] AIMONE R J, FORSTHOFFER W E, SALZMANN R M. Dry gas seal systems: Best practices for design and selection, which can help prevent failures[J]. Turbomachinery International, 2007, 48(1): 20-21. [7] KRIVSHICH N G, PAVLYUK S A, KOLESNIK S A, et al. Dry gas seal systems for equipment with slow shaft rotation[J]. Chemical and Petroleum Engineering, 2007, 43(11-12): 676-680. doi: 10.1007/s10556-007-0121-x [8] 李世聪, 钱才富, 李双喜, 等. 油气两相动压密封动态特性的热流固耦合研究[J]. 化工学报, 2020, 71(5): 2190-2201.LI S C, QIAN C F, LI S X, et al. Study of thermal-fluid-solid coupling on dynamic characteristics of oil-gas miscible backflow pumping seal[J]. Journal of Chemical Industry and Engineering, 2020, 71(5): 2190-2201(in Chinese). [9] TABATA H, SANO M. Study of high efficiency turbocompressor: Development of high-speed and high-pressure dry gas seal[J]. IHI Engineering Review, 2005, 38(1): 1-5. [10] KAVINPRASAD S, SHANKAR S, KARTHIC M. Experimental and CFD investigations of mechanical seals under dry/compressed air/liquid lubricating conditions[J]. Procedia Engineering, 2013, 64: 419-425. doi: 10.1016/j.proeng.2013.09.115 [11] SHAHIN I, GADALA M, ALQARADAWI M, et al. Three dimensional computational study for spiral dry gas seal with constant groove depth and different tapered grooves[J]. Procedia Engineering, 2013, 68: 205-212. doi: 10.1016/j.proeng.2013.12.169 [12] WILBUR S. Design and analysis of helium buffer face seal for high pressure liquid oxygen turbopump of main engine of space shuttle[J]. Missiles and Space Vehicles, 1992(4): 5-17(in Chinese). [13] 张国渊, 陈国忠, 赵伟刚, 等. 高速低温动静结合型机械密封结构优化及运转试验[J]. 航空动力学报, 2018, 33(5): 1093-1102.ZHANG G Y, CHEN G Z, ZHAO W G, et al. Optimization and test of parameters of the cryogenic hydrodynamic mechanical seal[J]. Journal of Aerospace Power, 2018, 33(5): 1093-1102(in Chinese). [14] THOMAS S, BRUNETIōRE N, TOURNERIE B. Thermo-elasto-hydrodynamic behavior of mechanical gas face seals operating at high pressure[J]. Journal of Tribology, 2007, 129(4): 841-850. doi: 10.1115/1.2768086 [15] THOMAS S, BRUNETIōRE N, TOURNERIE B. Numerical modeling of high pressure gas face seals[J]. Journal of Tribology, 2006, 128(2): 396-405. doi: 10.1115/1.2164471 [16] BAI S X, MA C H, PENG X D, et al. Thermo-elasto-hydrodynamic behavior of gas spiral groove face seals operating at high pressure and speed[J]. Journal of Tribology, 2015, 137(2): 1-11. [17] 胡琼, 陶凯, 孙见君, 等. 剖分式机械密封传热及耦合变形的数值研究[J]. 润滑与密封, 2018, 43(8): 24-31. doi: 10.3969/j.issn.0254-0150.2018.08.005HU Q, TAO K, SUN J J, et al. Numerical investigation on heat transfer and thermal-structural coupled deformation of split mechanical seals[J]. Lubrication Engineering, 2018, 43(8): 24-31(in Chinese). doi: 10.3969/j.issn.0254-0150.2018.08.005 [18] MAYER E. 机械密封[M]. 姚兆生, 译. 北京: 化学工业出版社, 1981: 46-49.MAYER E. Mechanical seal[M]. YAO Z S, translated. Beijing: Chemical Industry Press, 1981: 46-49(in Chinese). [19] 许静, 彭旭东, 白少先, 等. 高压干气密封扭转变形结构因素影响分析[J]. 摩擦学学报, 2014, 34(5): 543-552.XU J, PENG X D, BAI S X, et al. Analysis of structural factor effect on torsion deformation for a dry gas seal at high pressures[J]. Tribology, 2014, 34(5): 543-552(in Chinese). [20] DOUST T G. An experimental and theoretical study of pressure and thermal distortions in a mechanical seal[J]. ASLE Transactions, 1986, 29(2): 151-159. doi: 10.1080/05698198608981672 [21] SU H, RAHMANI R, RAHNEJAT H. Thermohydrodynamics of bidirectional groove dry gas seals with slip flow[J]. International Journal of Thermal Sciences, 2016, 110: 270-284. doi: 10.1016/j.ijthermalsci.2016.07.011 [22] BLASIAK S, ZAHORULKO A V. Aparametric and dynamic analysis of non-contacting gas face seals with modified surfaces[J]. Tribology International, 2016, 94: 126-137. doi: 10.1016/j.triboint.2015.08.014 [23] 彭旭东, 刘伟, 白少先, 等. 热弹变形对核主泵用流体静压型机械密封性能的影响[J]. 机械工程学报, 2010, 46(23): 146-153.PENG X D, LIU W, BAI S X, et al. Effects analysis of thermo-elastic deformation on the performance of hydrostatic mechanical seals in reactor coolant pumps[J]. Journal of Mechanical Engineering, 2010, 46(23): 146-153(in Chinese). [24] 丁雪兴, 陆俊杰, 刘勇, 等. 热耗散变形下干气密封系统轴向振动稳定性分析[J]. 振动工程学报, 2016, 29(1): 78-86.DING X X, LU J J, LIU Y, et al. Stability analysis on axial vibration of dry gas seal system under the thermo-elastic deformation considering the thermal dissipation[J]. Journal of Vibration Engineering, 2016, 29(1): 78-86(in Chinese). [25] 丁雪兴, 刘勇, 苏虹, 等. 热弹变形下螺旋槽干气密封泄漏量的计算与分析[J]. 兰州理工大学学报, 2014, 40(6): 75-79. doi: 10.3969/j.issn.1673-5196.2014.06.018DING X X, LIU Y, SU H, et al. Calculation and analysis of leakage from spiral groove dry gas seal subjected to thermo-elastic deformation[J]. Journal of Lanzhou University of Technology, 2014, 40(6): 75-79(in Chinese). doi: 10.3969/j.issn.1673-5196.2014.06.018 [26] 程香平, 刘小红, 张友亮, 等. 锥-孔组合型机械密封端面变形及密封性能分析[J]. 江西科学, 2016, 34(3): 357-363.CHENG X P, LIU X H, ZHANG Y L, et al. End face deformation and sealing performance analysis of cone-hole combination mechanical seal[J]. Jiangxi Science, 2016, 34(3): 357-363(in Chinese). [27] 陈汇龙, 李同, 任坤腾, 等. 端面变形对液体动压型机械密封液膜瞬态特性的影响[J]. 化工学报, 2017, 68(4): 1533-1541.CHEN H L, LI T, REN K T, et al. Influence of end face deformation on transient characteristics of fluid film in hydrodynamic mechanical seal[J]. Journal of Industry and Engineering, 2017, 68(4): 1533-1541(in Chinese). [28] 陈志, 高昀皞, 赵鹏, 等. 高压干气密封流场数值模拟[J]. 工程科学与技术, 2017, 49(2): 254-261.CHEN Z, GAO Y H, ZHAO P, et al. Numerical simulation of flow field for high pressure dry gas seal[J]. Advanced Engineering Sciences, 2017, 49(2): 254-261(in Chinese). [29] 李庆展, 郑娆, 李世聪, 等. 高速动压密封的气液两相性能对比分析和试验[J]. 哈尔滨工业大学学报, 2019, 51(7): 70-75.LI Q Z, ZHENG R, LI S C, et al. Comparative analysis and experiment on gas-phase and liquid-phase performance of high-speed hydrodynamic seal[J]. Journal of Harbin Institute of Technology, 2019, 51(7): 70-75(in Chinese). [30] 彭旭东, 冯向忠, 胡丹梅, 等. 非接触式气体润滑密封变形的数值分析[J]. 摩擦学学报, 2004(6): 536-540. doi: 10.3321/j.issn:1004-0595.2004.06.012PENG X D, FENG X Z, HU D M, et al. Numerical analysis of deformation of a non-contacting gas lubricated seal[J]. Tribology, 2004(6): 536-540(in Chinese). doi: 10.3321/j.issn:1004-0595.2004.06.012 [31] 王金红, 陈志, 刘凡, 等. 密封环支撑边界条件对机械密封端面变形的影响[J]. 化工学报, 2020, 71(4): 1744-1753.WANG J H, CHEN Z, LIU F, et al. Influence of support boundary conditions of a seal ring on deformation of mechanical seal end face[J]. Journal of Industry and Engnieering, 2020, 71(4): 1744-1753(in Chinese). [32] 廖传军, 黄伟峰, 索双富, 等. 流体静压型机械密封的半解析式流固耦合模型[J]. 机械工程学报, 2010, 46(20): 145-151.LIAO C J, HUANG W F, SUO S F, et al. Semi-analytical fluid-solid coupling model for hydrostatic mechanical seals[J]. Journal of Mechanical Engineering, 2010, 46(20): 145-151(in Chinese). [33] 何强, 王洪涛, 黄伟峰, 等. 静压型机械密封中螺钉预紧调节机制的研究[J]. 机械工程学报, 2020, 56(3): 137-143.HE Q, WANG H T, HUANG W F, et al. Regulation mechanism of screw preloading in hydrostatic mechanical face seals[J]. Journal of Mechanical Engineering, 2020, 56(3): 137-143(in Chinese). [34] 彭旭东, 康玉茹, 孟祥铠, 等. 核主泵用流体静压型机械密封性能的影响因素研究[J]. 机械工程学报, 2012, 48(17): 83-90.PENG X D, KANG Y R, MENG X K, et al. Study on factors affecting seal performance of a hydrostatic mechanical seal in reactor coolant pumps[J]. Journal of Mechanical Engineering, 2012, 48(17): 83-90(in Chinese). [35] 肖毅华, 张浩锋, 平学成. 无网格对称粒子法中两类热边界条件的处理[J]. 华东交通大学学报, 2014, 31(4): 65-70.XIAO Y H, ZHANG H F, PING X C. Treatment of two kinds of thermal boundary conditions in meshless symmetric particle method[J]. Journal of East China Jiaotong University, 2014, 31(4): 65-70(in Chinese). [36] MA C H, BAI S X, PENG X D. Thermo-hydrodynamic characteristics of spiral groove gas face seals operating at low pressure[J]. Tribology International, 2016, 95: 44-54. doi: 10.1016/j.triboint.2015.11.001 -

下载:

下载: